For the pcb I choosed to a company that in the last period is papering the web of advertising!

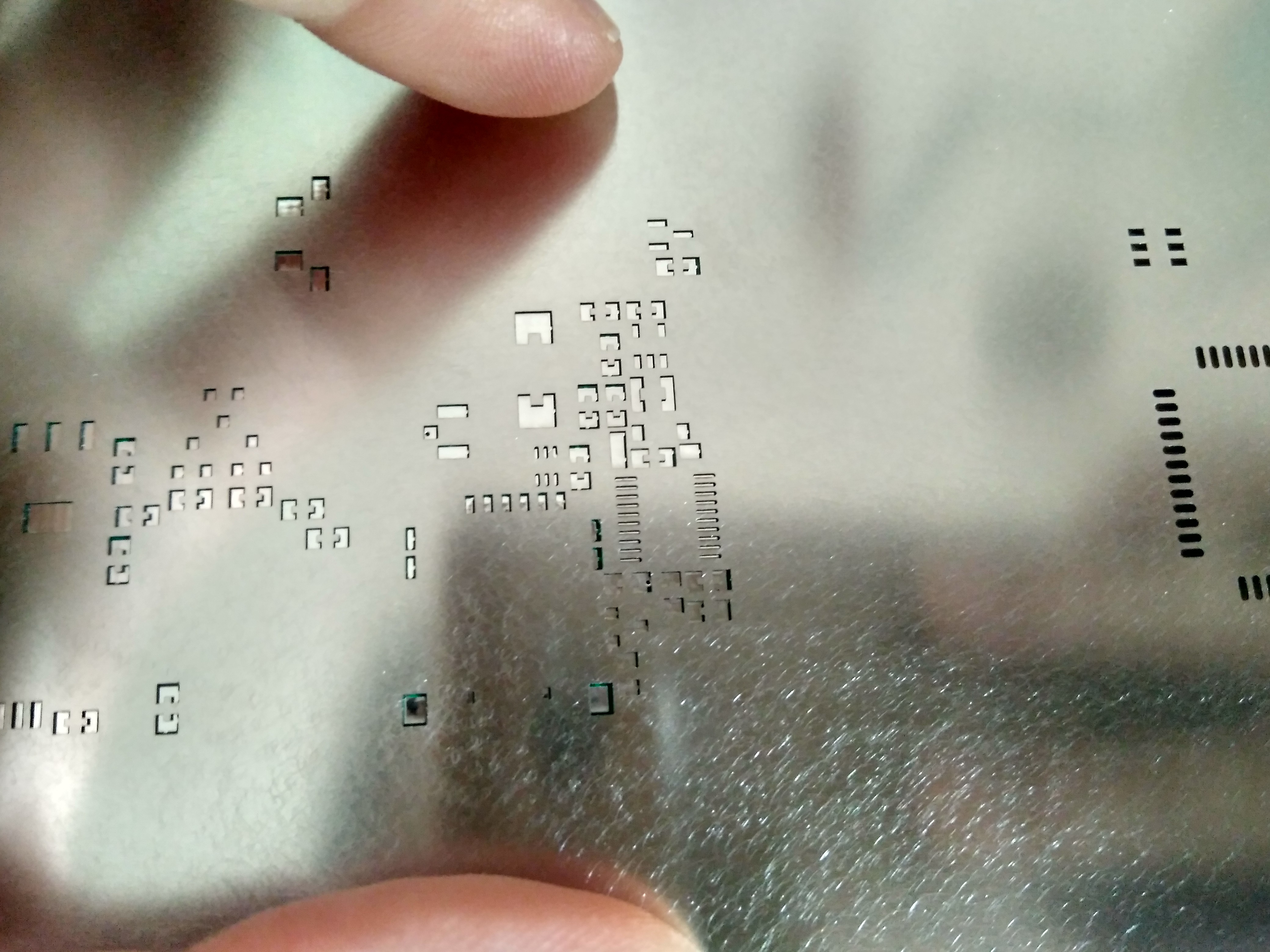

The catchy price allowed me to make the panels, I had never made them. I used the excellent videos of EEVBLOG to learn. As a stencil would have helped me, I decided to order that too.

I'm certainly not an expert, the quality seems good, the only flaw I found is the thickness / quality of the solder mask. I noticed that it is easily scratched exposing the copper layer.

Even the silkscreen looks like quality and despite the very small font the result was excellent. (Only the "i" and "l" are too thin) This is a limit case: different components in a decidedly reduced space!

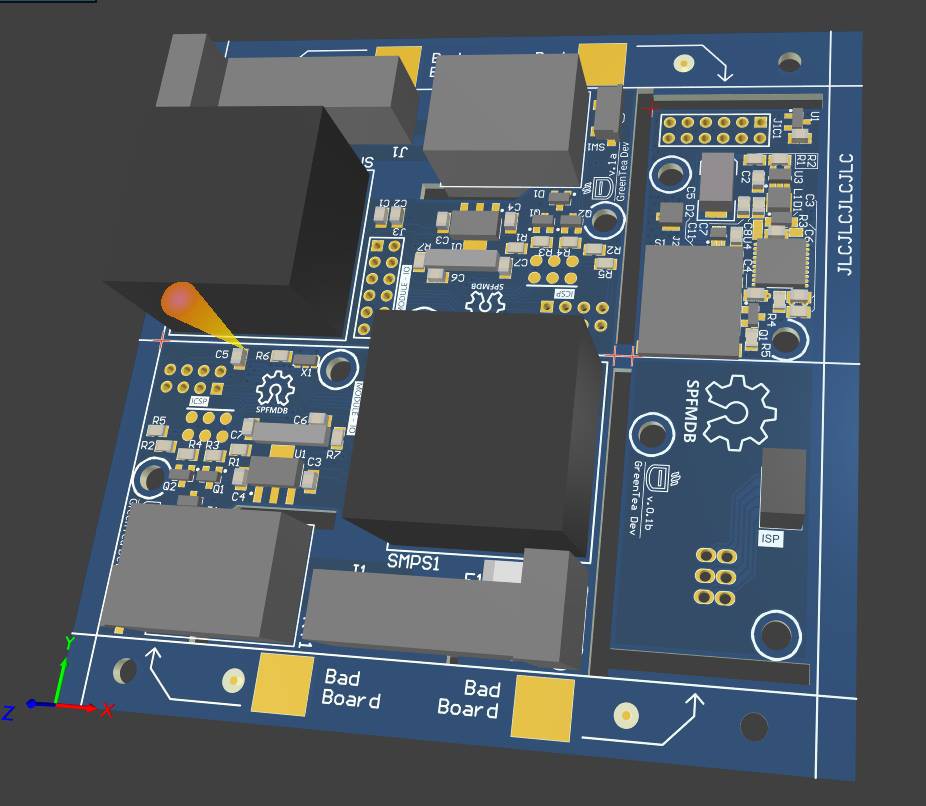

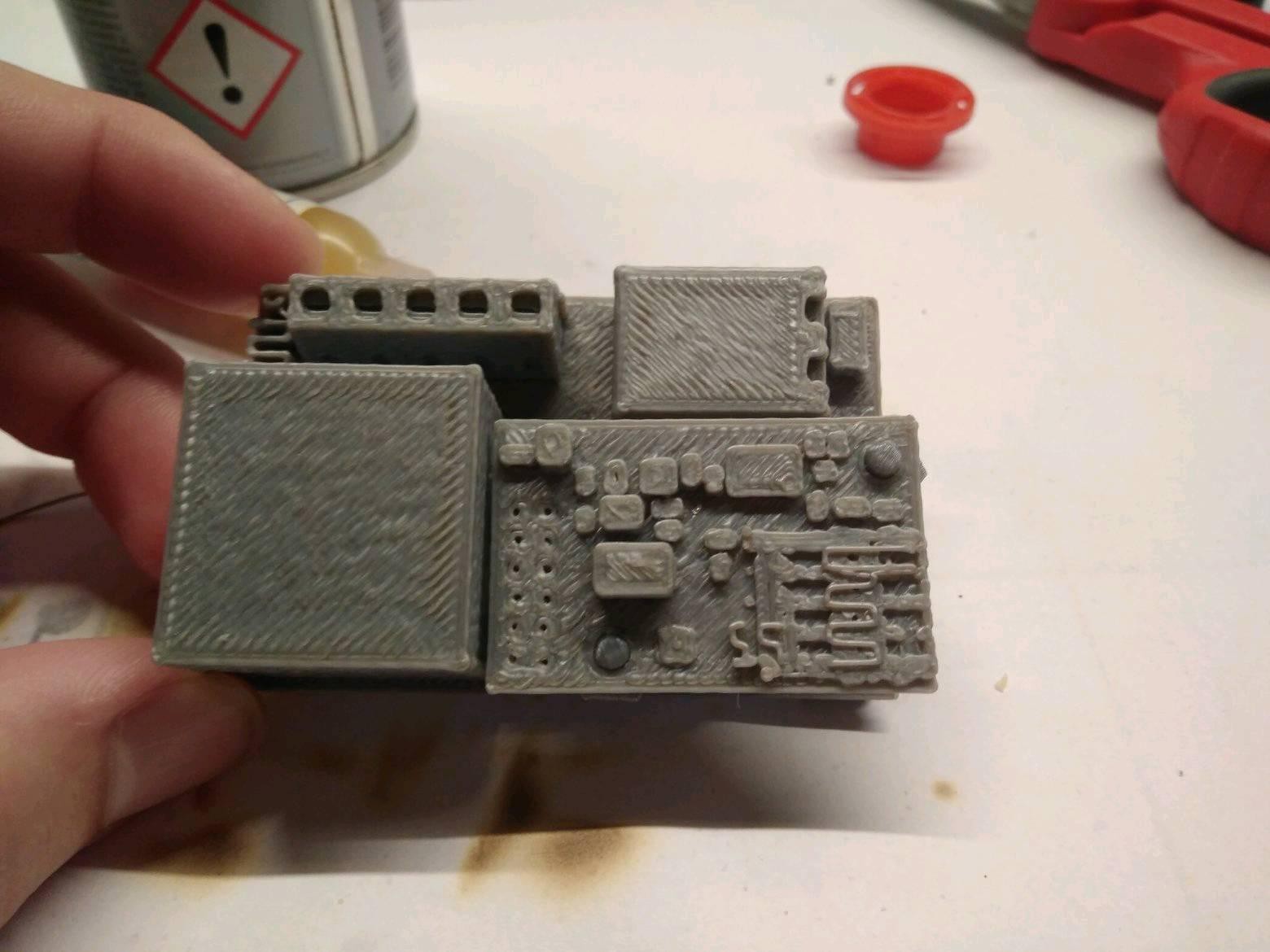

What to do while I was waiting the pcbs? Thanks to the STEP export function of Circuit Maker I was able to 3D print the pcbs and thest the physical dimensions of the boards. (I don't own a 3d printer so I had to ask a favour to a friend)

Fiew weeks later also the components that I had ordered arrived:

And the assembly and testing process started of the first prototype board.

Nicolò

Nicolò

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.