This project need a box to contain the electronic boards, I'm a IT guy and I have not experience on mecanical drawings, designing mecanical parts and 3d print. Hopefully my Univeristy allow me to have some professional products with an "educator" license. So using this method I decided to use Fusion 360. Back at school we studied a but of AutoCAD so working with parametric design is lot easier for me than other methods.

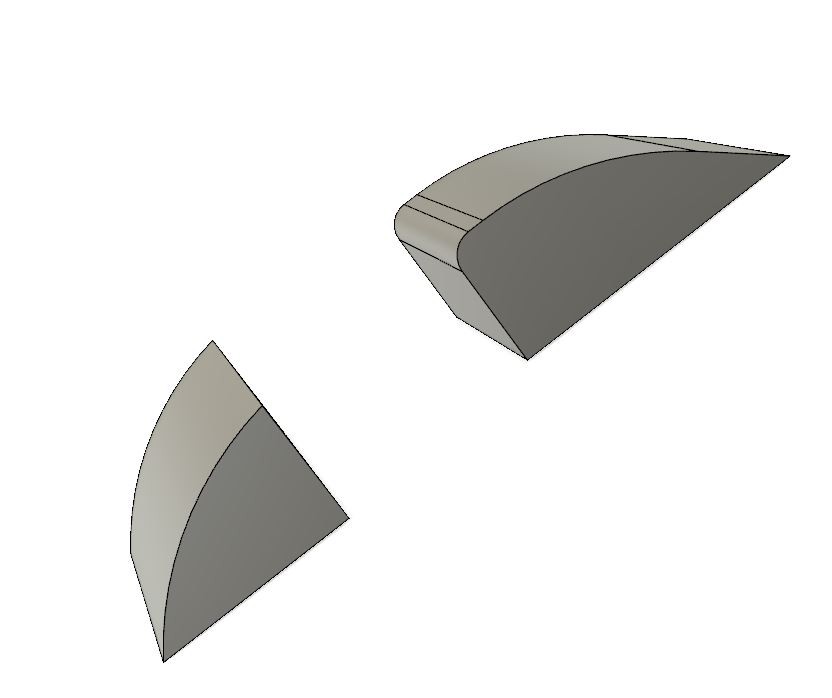

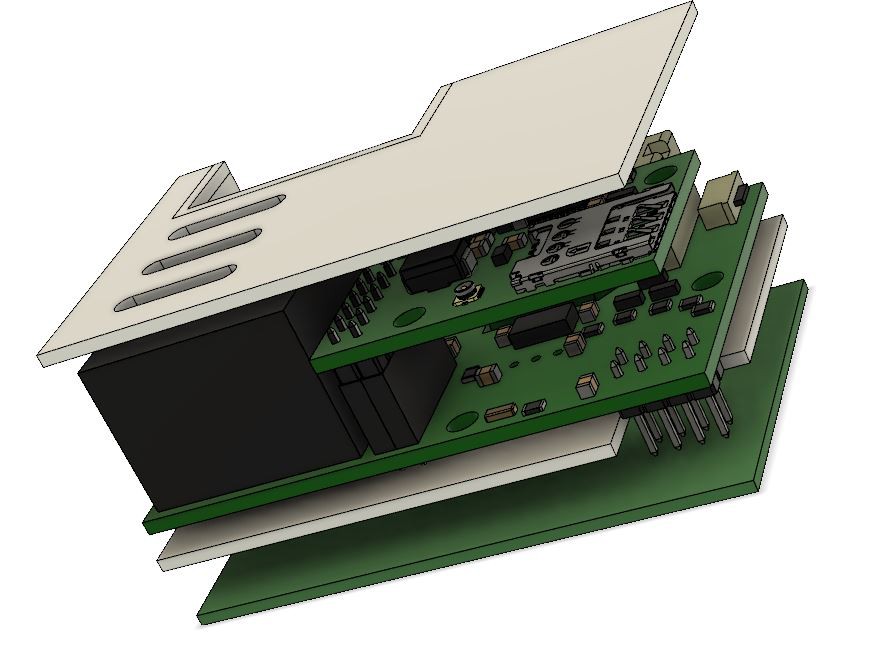

For test I have started to design the clips to hold the board in place, nothing fancy just two pieces one with a smooth border to guide the board in position:

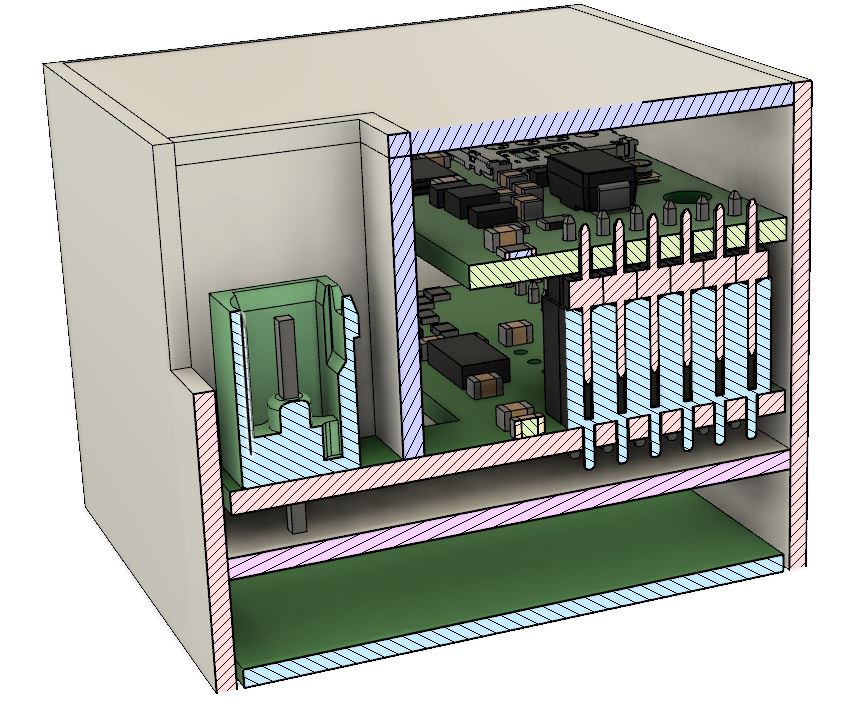

The smaller board is the GSM module, the second one is the Baseboard. Both have been imported iinto fusion from the SETP file. (exported by Circuit Maker)

The third one is the fornt board but as you can see, the front board is not populated becouse I'm still designign that one. I want to be shure that the others works before starting the development of the ARM board.

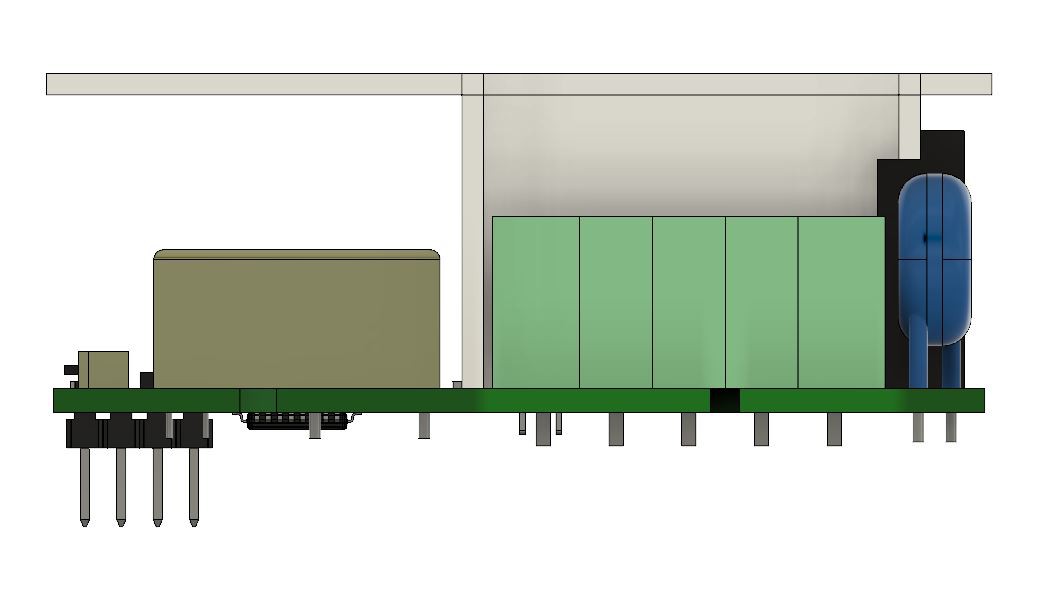

This is the lateral view of the box, I have hidden all the unnecesssary stuff. In this way you can see how the back lid lock the board in position.

Another

The next picture shows all the layers stacked together.

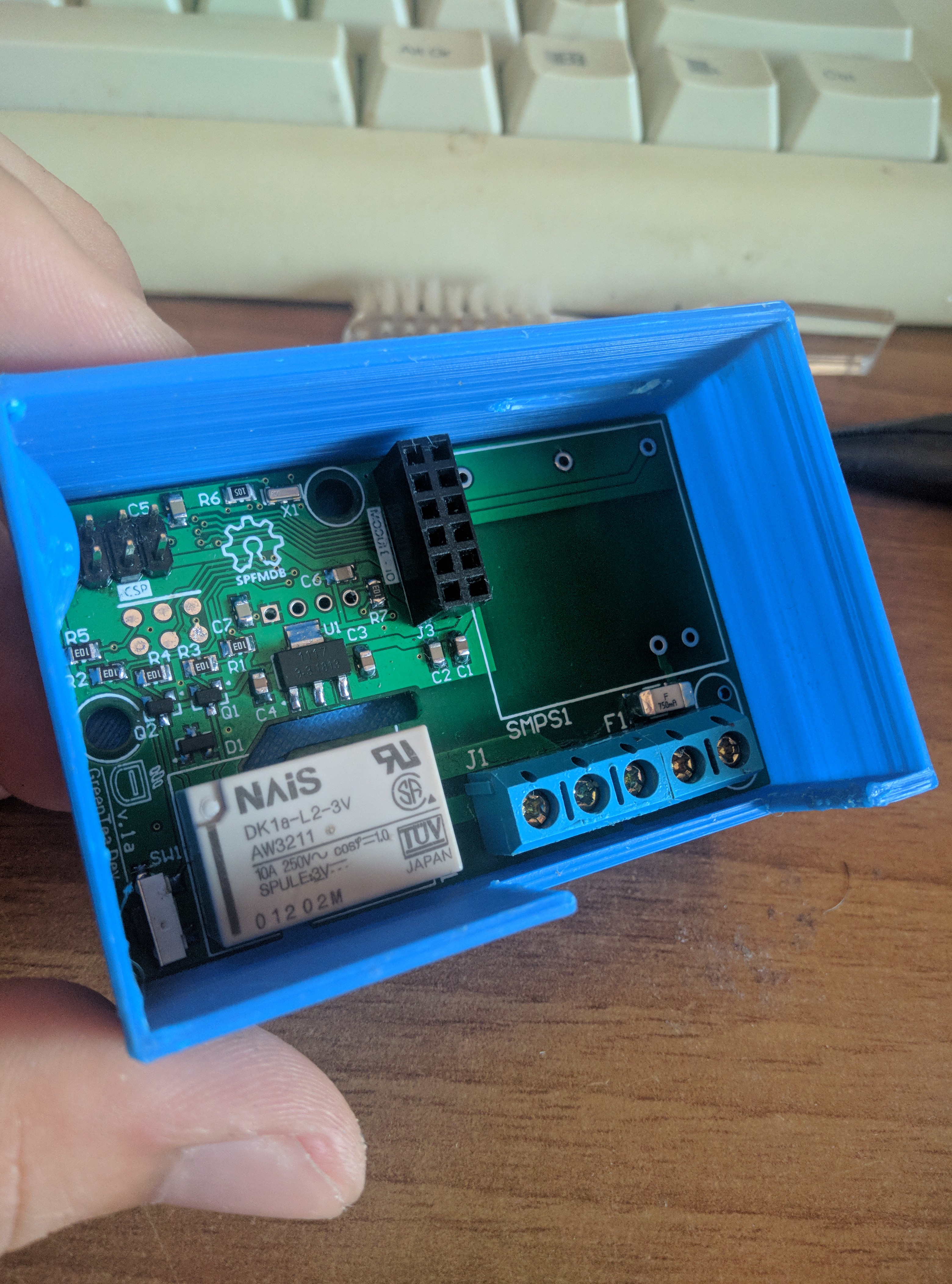

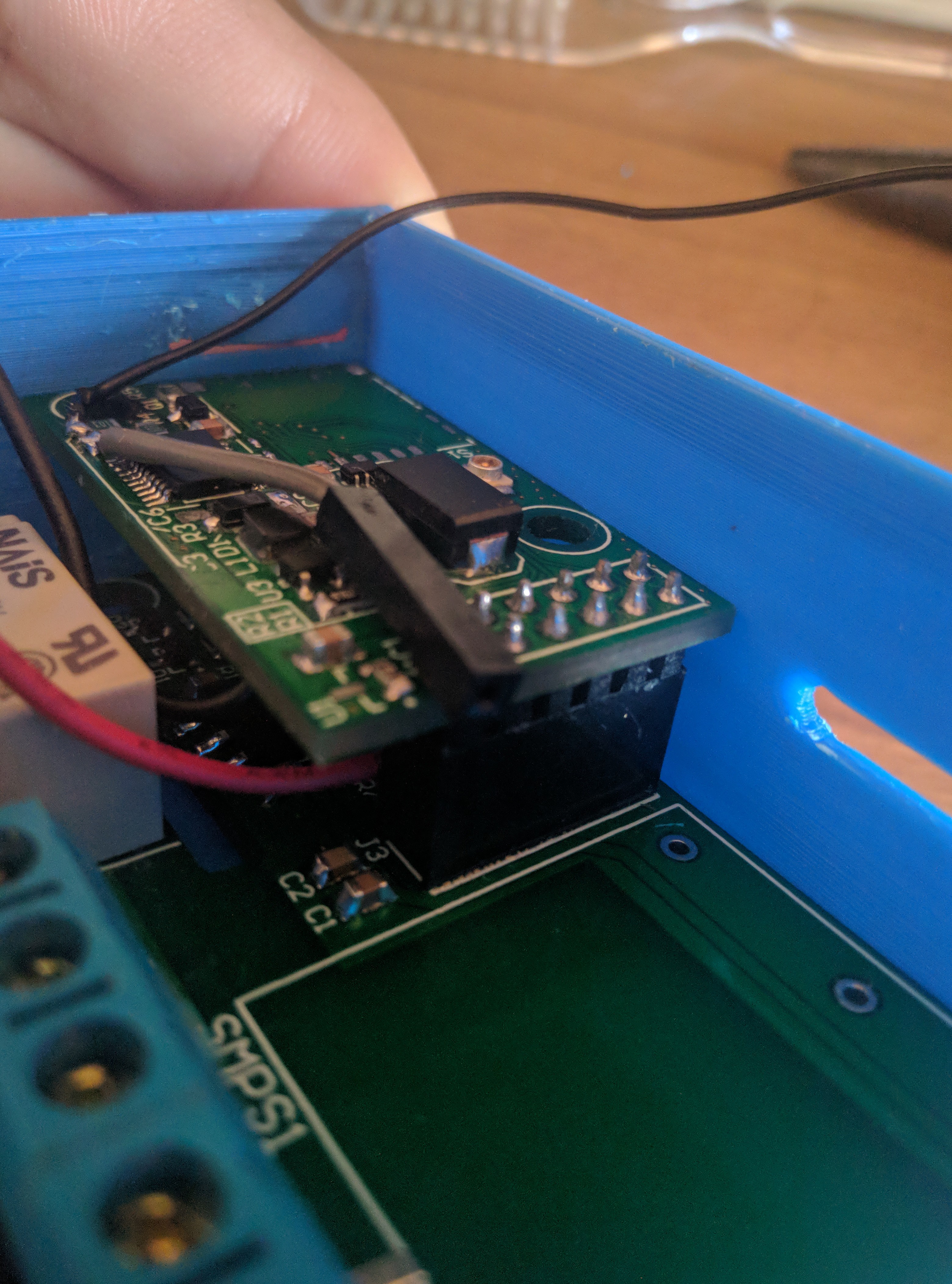

Unfortunatly things don't go always as planned; Even if I have added 1mm spacing the print is a bit smaller. The boards don't fit in without pushing it in with lots of force. The print also have lot's of warping.

Unfotunatly my friend don't have experience with ABS so we are tring and failing.

Another error is the design is the hole for the SIM tray. Unfortunatly the module can't be installed. So I will have to move the SIM groove to the back lid.

Another error is the design is the hole for the SIM tray. Unfortunatly the module can't be installed. So I will have to move the SIM groove to the back lid.

On the main page you can find the render of this box!

Nicolò

Nicolò

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.