The campaign is over. You can pre-order here:

https://www.indiegogo.com/projects/wiphone-a-phone-for-hackers-and-makers#/

Or join the mailing list to follow along:

Description

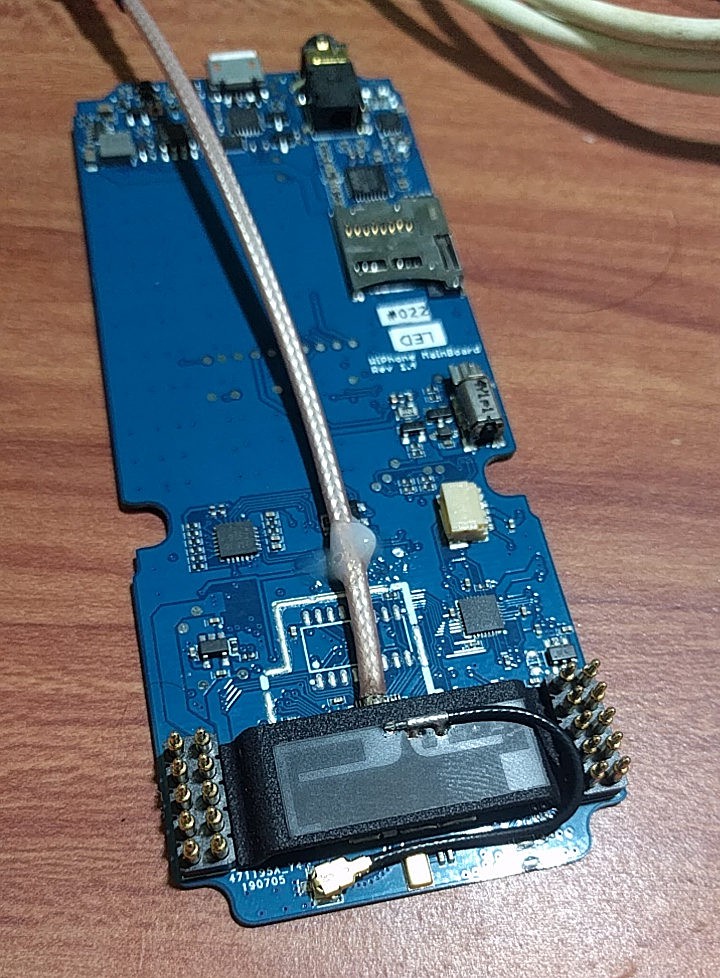

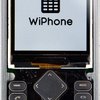

The WiPhone project is an open source phone capable of making free calls through the internet. It makes calls over WiFi, without the need for a cellular radio.

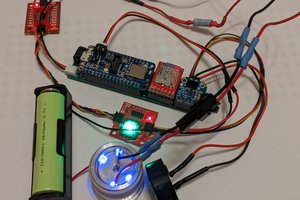

It's also an open source, self-contained Arduino development platform. It comes in a nice package, with a battery, power supply, and on/off circuitry, unlike most other dev boards. Once your project is done, instead of an eyesore of tangled wires, it's discreet and visually appealing.

The phone is intended to be hackable, modular, cheap, and open, while remaining usable by everyday people.

Motivation

Modern smartphones are more and more a tool we don't own, we're only allowed to carry around. One that serves the interests of those who allow you to buy it in return for the tentacles that get inserted into your life. You don't own it, it owns you. It tracks you, serves you ads, and sucks away your time with mindless dopamine hits. We want a phone that's firmly in our control, optimized for the convenience of the owner, not various corporate boards, ad and tracking networks and government organizations.

We want a phone that reverses that, and puts us back in control. Maybe even fights back a little. Full control of the firmware to allow us to repurpose the phone into whatever application we want. Hardware with accessible I/O and an easy disassembly process.

Benefits

- Completely free calling, as long as you can set up an account and install a SIP/VoIP app on the devices you need to call.

- International calls are same as local ones. No restrictions based on borders or calling plans.

- Don’t need to deal with another country’s SIM cards or radio compatibility when traveling.

- Keep the same address all over the world.

- Set up your kid with a phone that lets them contact you without the distractions of a smartphone.

- Give a pre-configured phone to an elderly relation set up with just the numbers they need.

- Keep a spare in a bag in case your primary phone gets broken or lost. Don’t need to maintain a service plan for the backup.

- Avoid being tracked by cell tower triangulation or IMSI catching (Stingray).

- Load your own firmware to implement different calling protocols or completely different use-cases. The firmware is unlocked and freely modifiable.

- Commercial phone interchange services are available if you need to call someone on a regular phone. Typical plans cost about $25/year (US or Europe providers).

Planned Features

- polished enough normal (non-hackers) are happy to use it as an everyday phone

- open source

- can call other WiPhones using the internet

- can call smartphones or computers (using an app installed on the device being called)

- wireless firmware updates

- Arduino compatible software

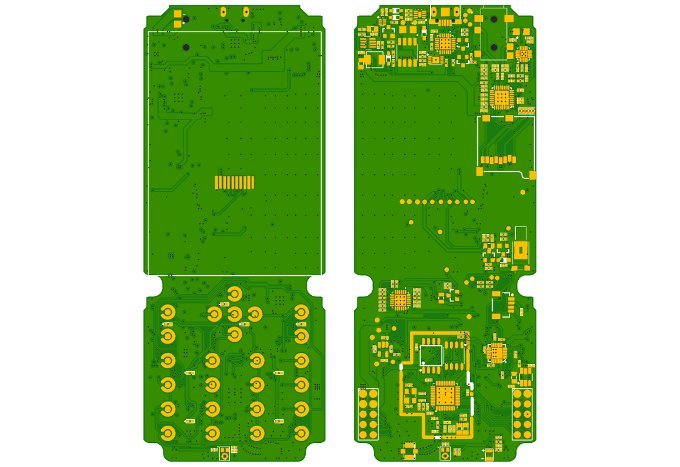

- Espressif ESP32 processor

- roughly 120 x 65 x 12mm

- 320 x 240 (2.4“) LCD screen

- spare I/O broken out to user-accessible header

stupid

stupid

Arya

Arya

minifig404

minifig404

timonsku

timonsku

The Big One

The Big One

Which SIP-stack/library does WiPhone use?