Electronic jewelry is difficult to make, especially when it's supposed to be worn on your head. Things like earrings, hair clips, studs, and even glasses are difficult because of the size and power requirements. There is one accessory that doesn't have such strict requirements: it can be large and relatively heavy, it doesn't touch your skin, and it can fit a rechargeable battery: it's the hair clasp, also known as barrette.

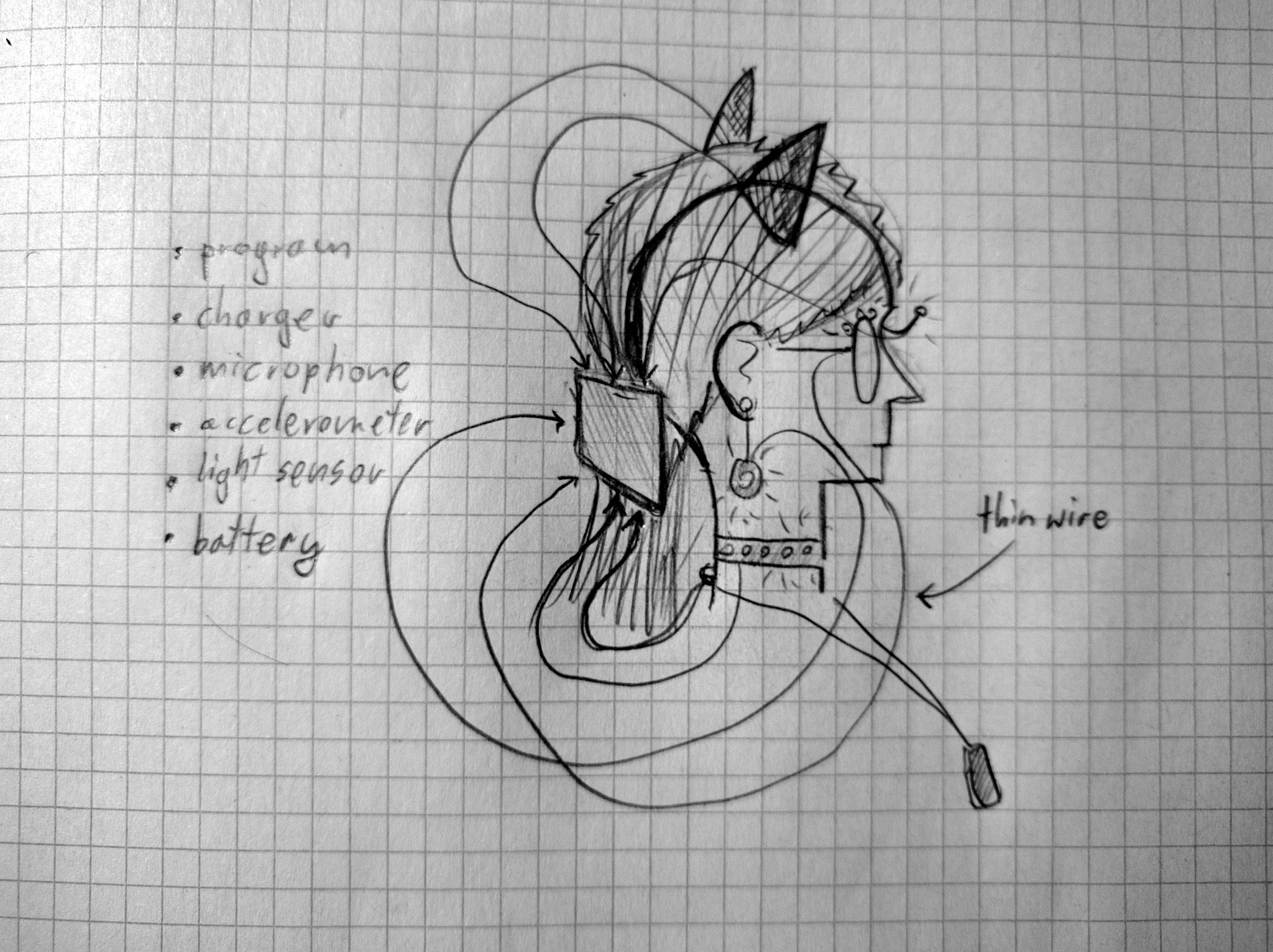

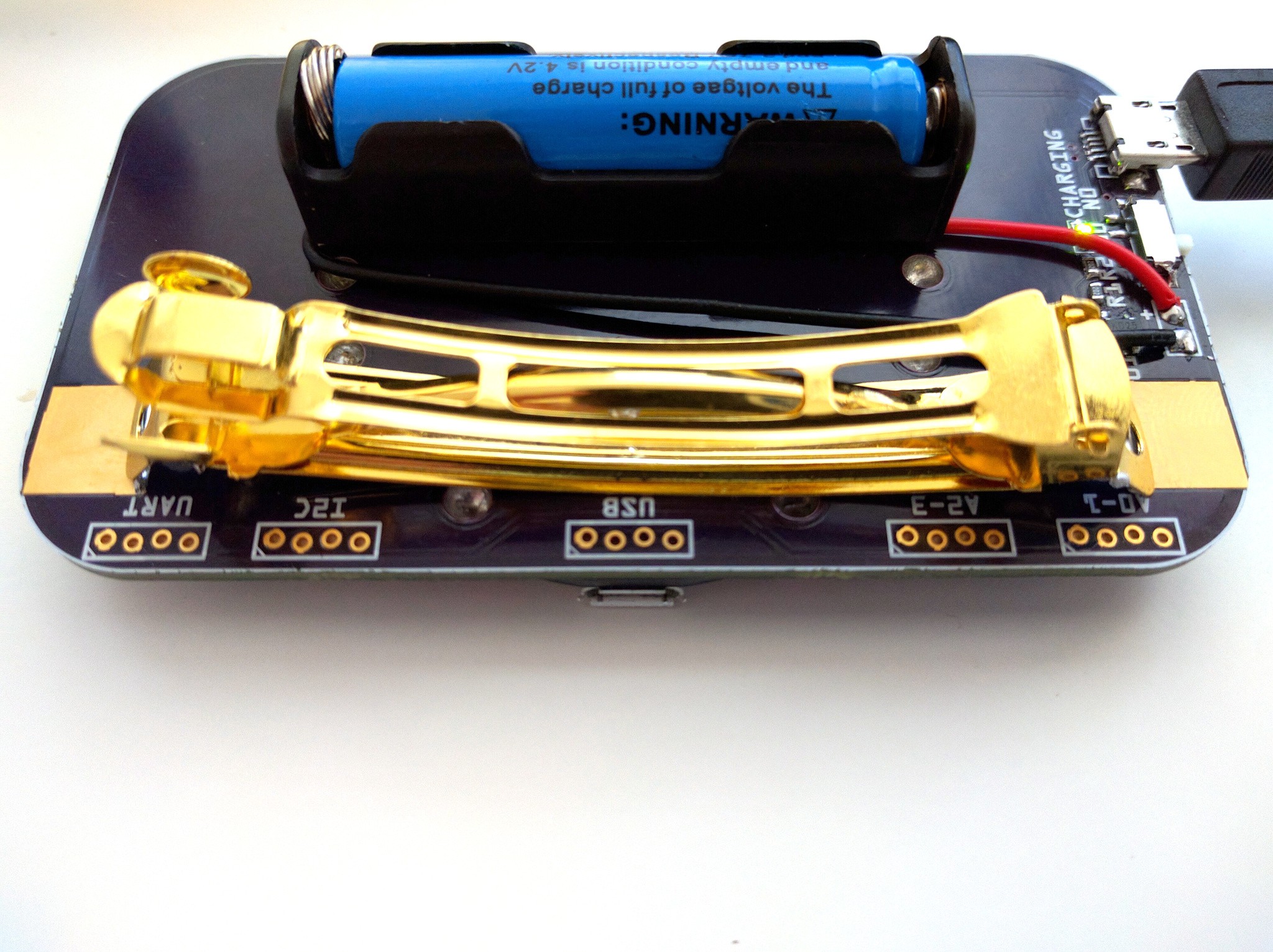

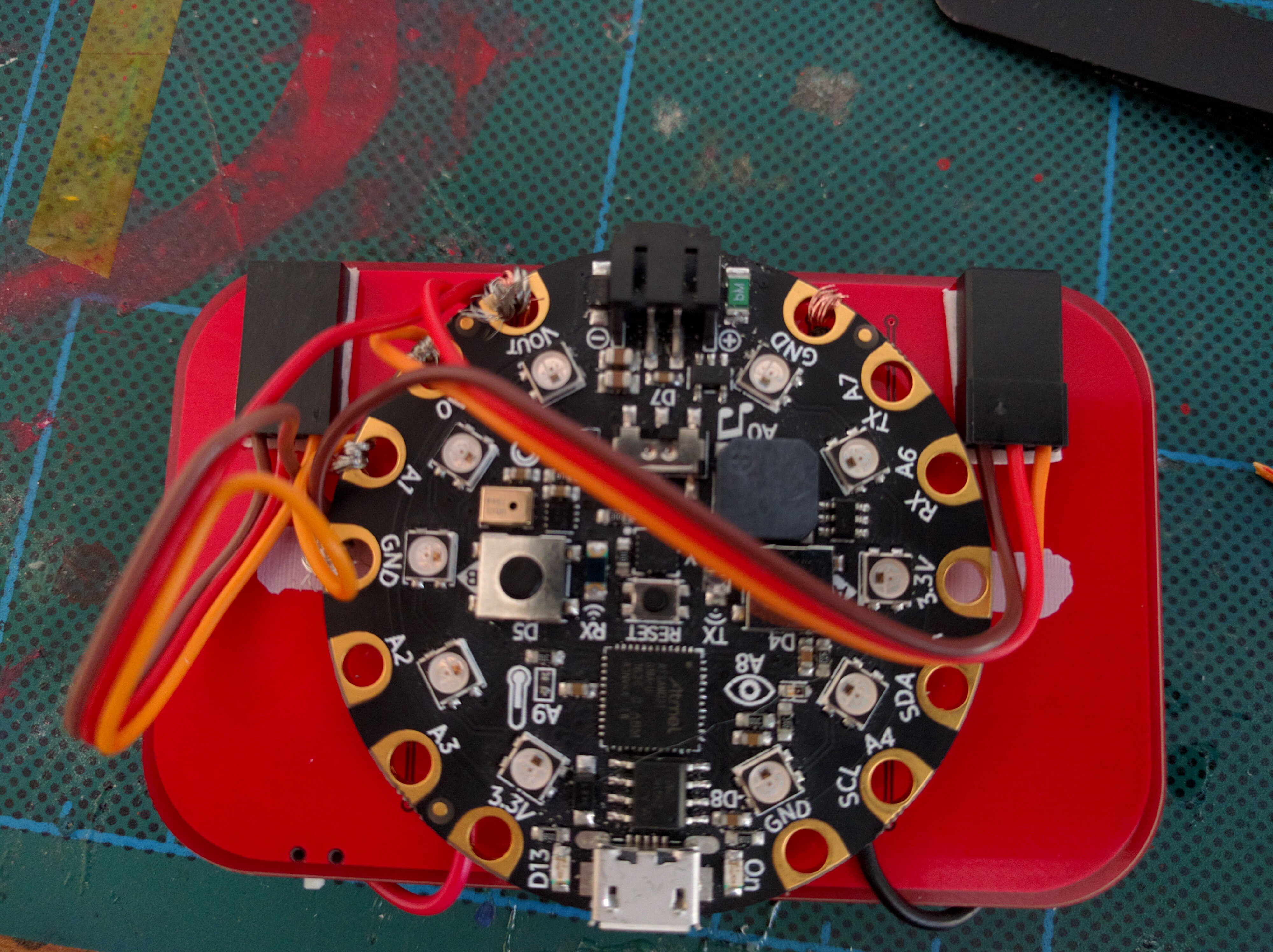

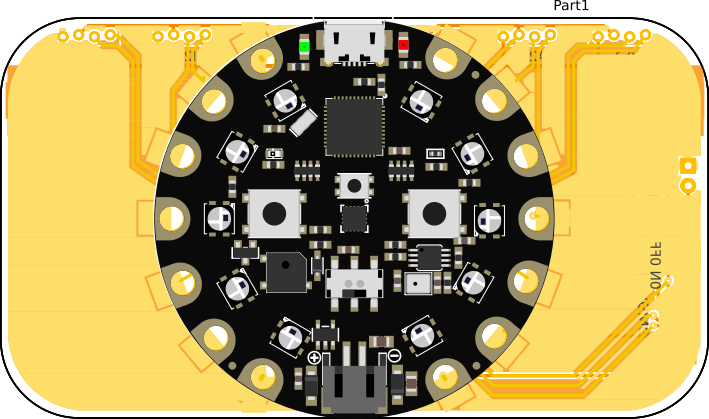

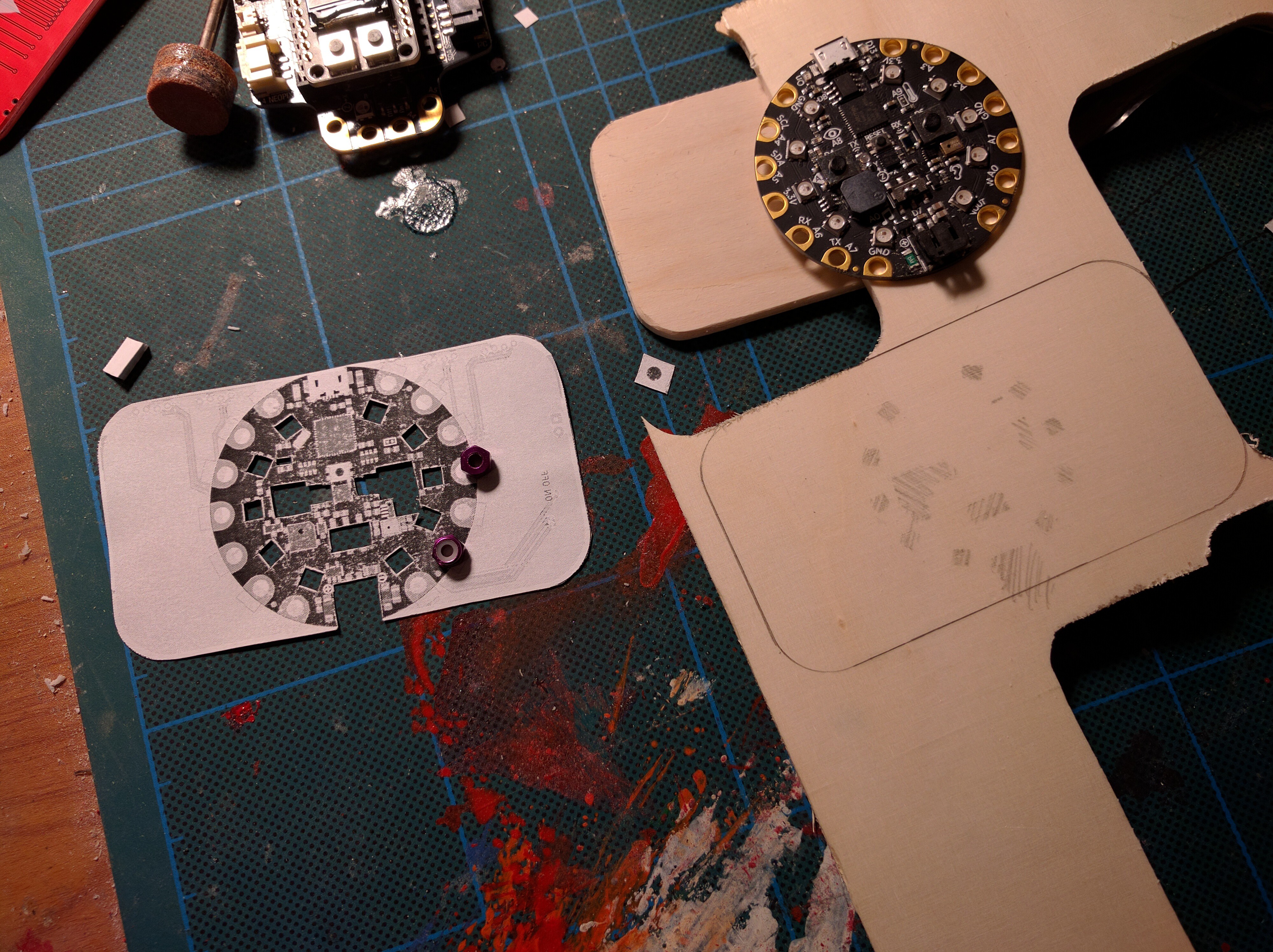

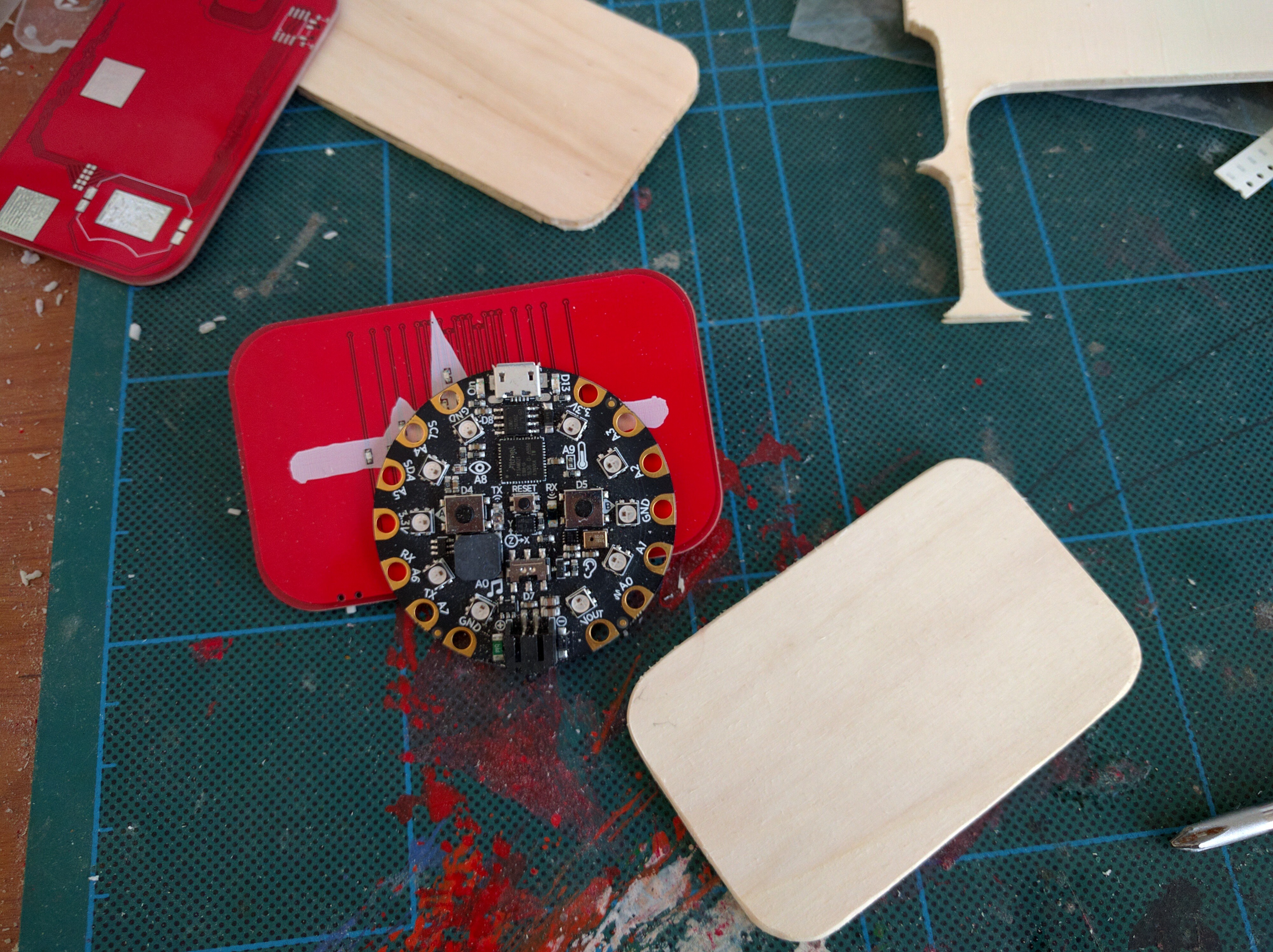

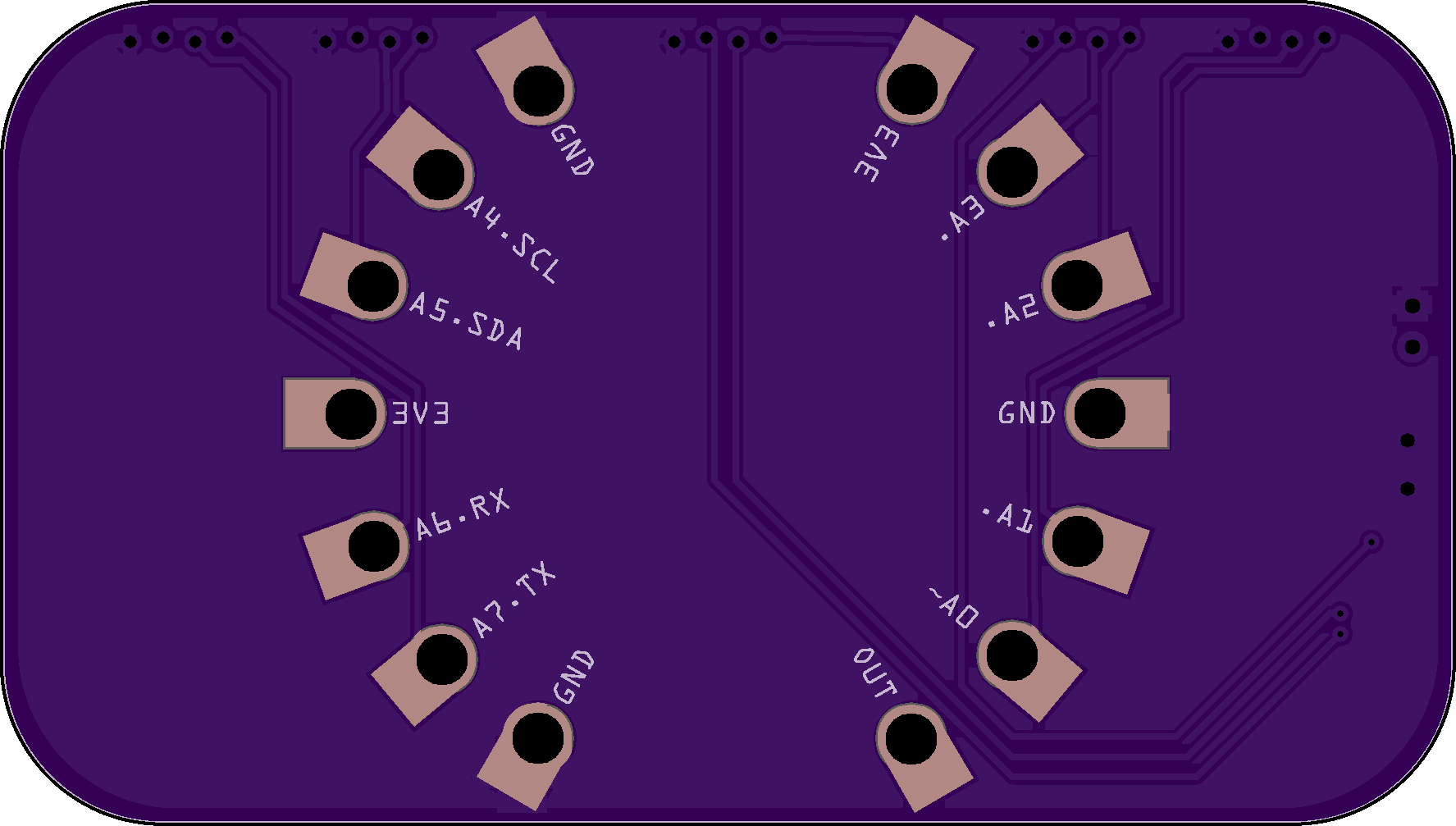

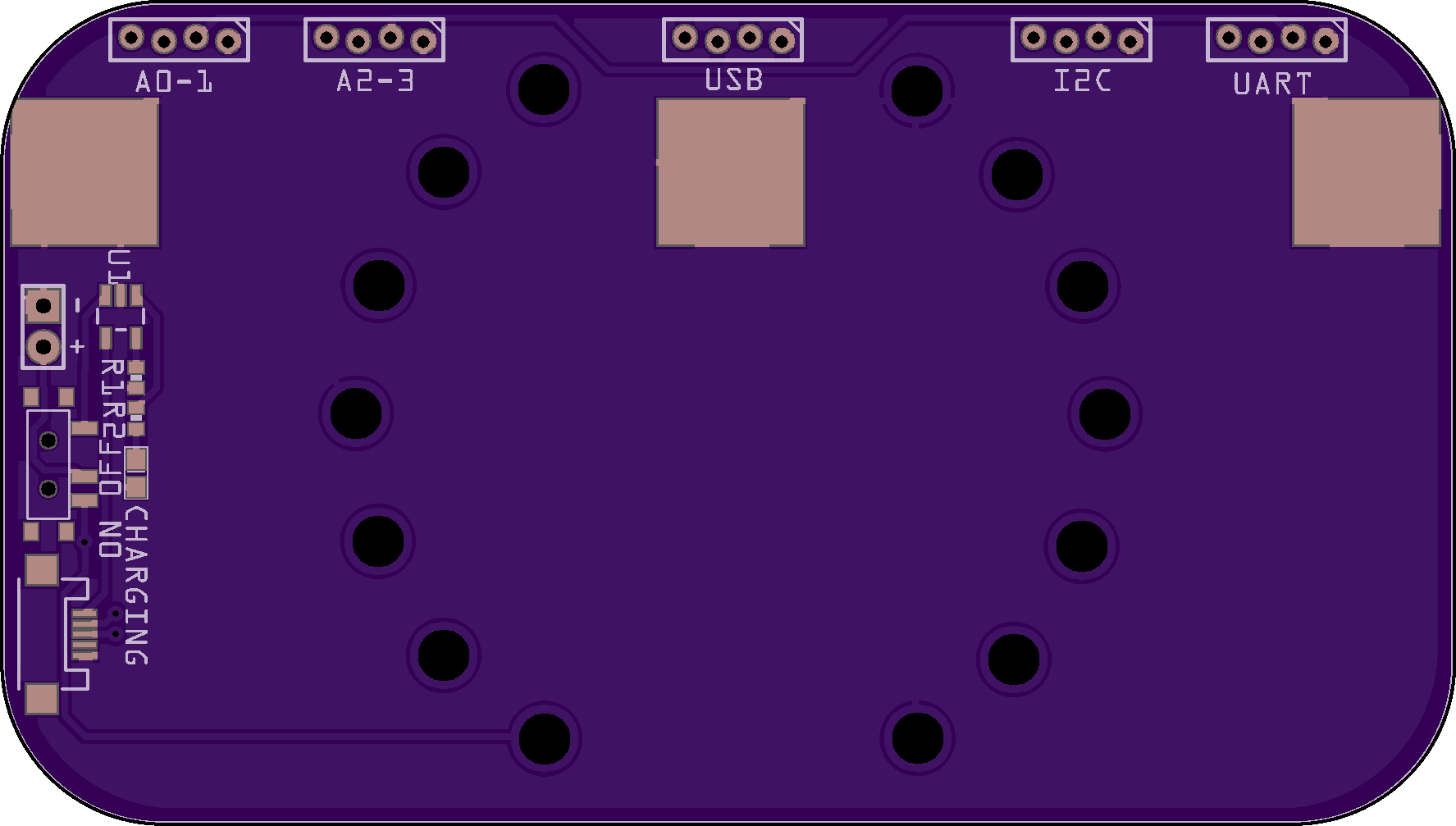

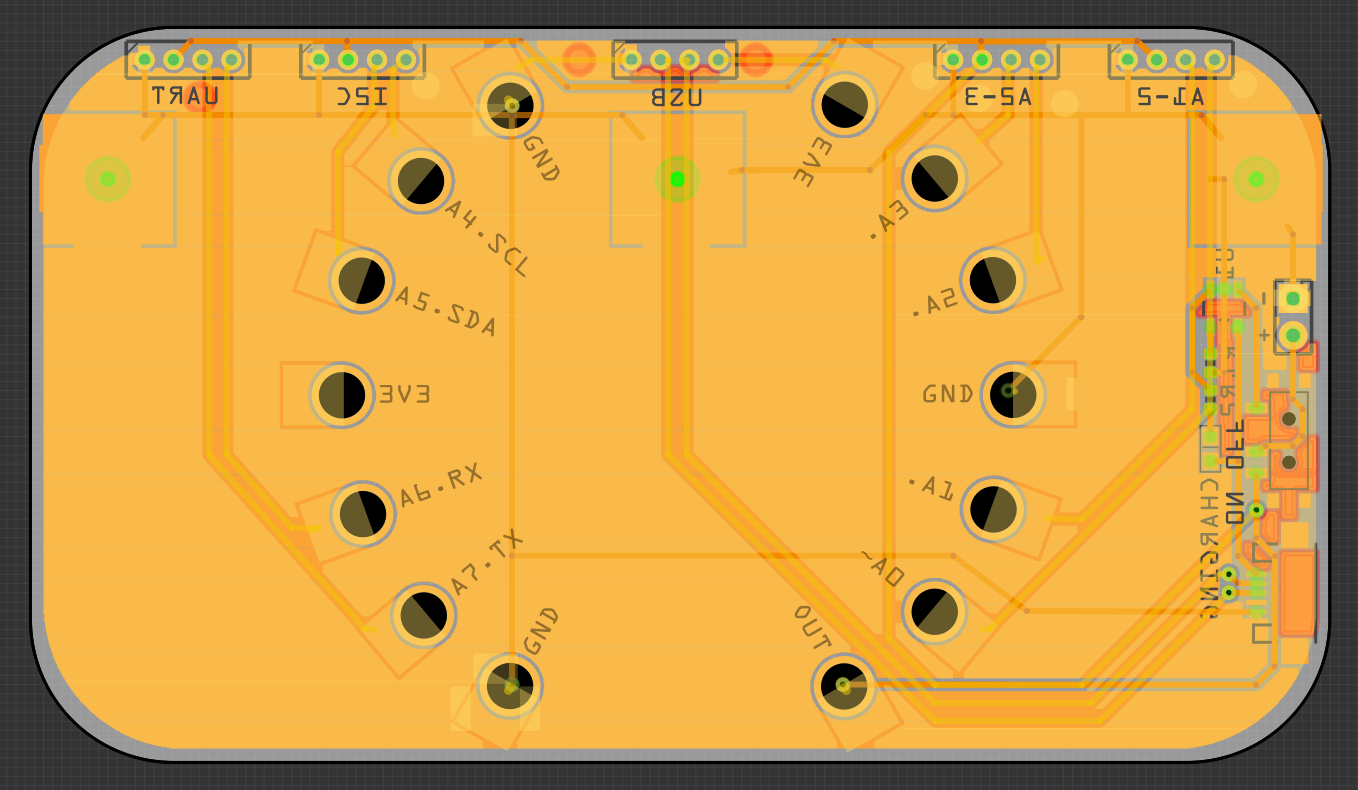

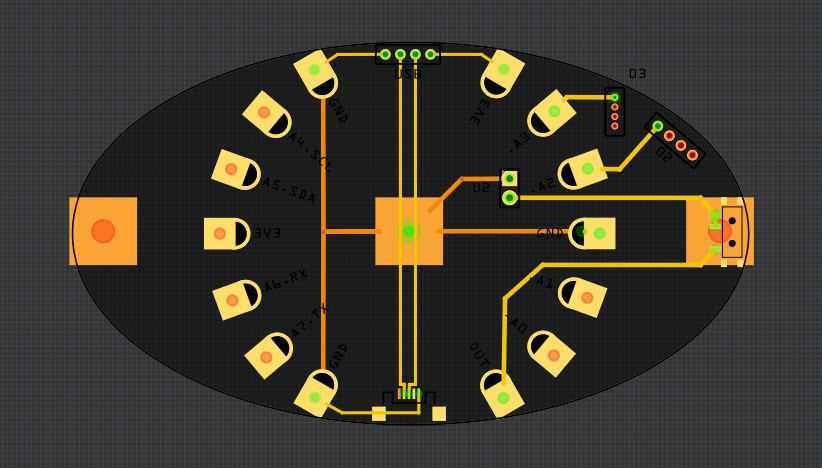

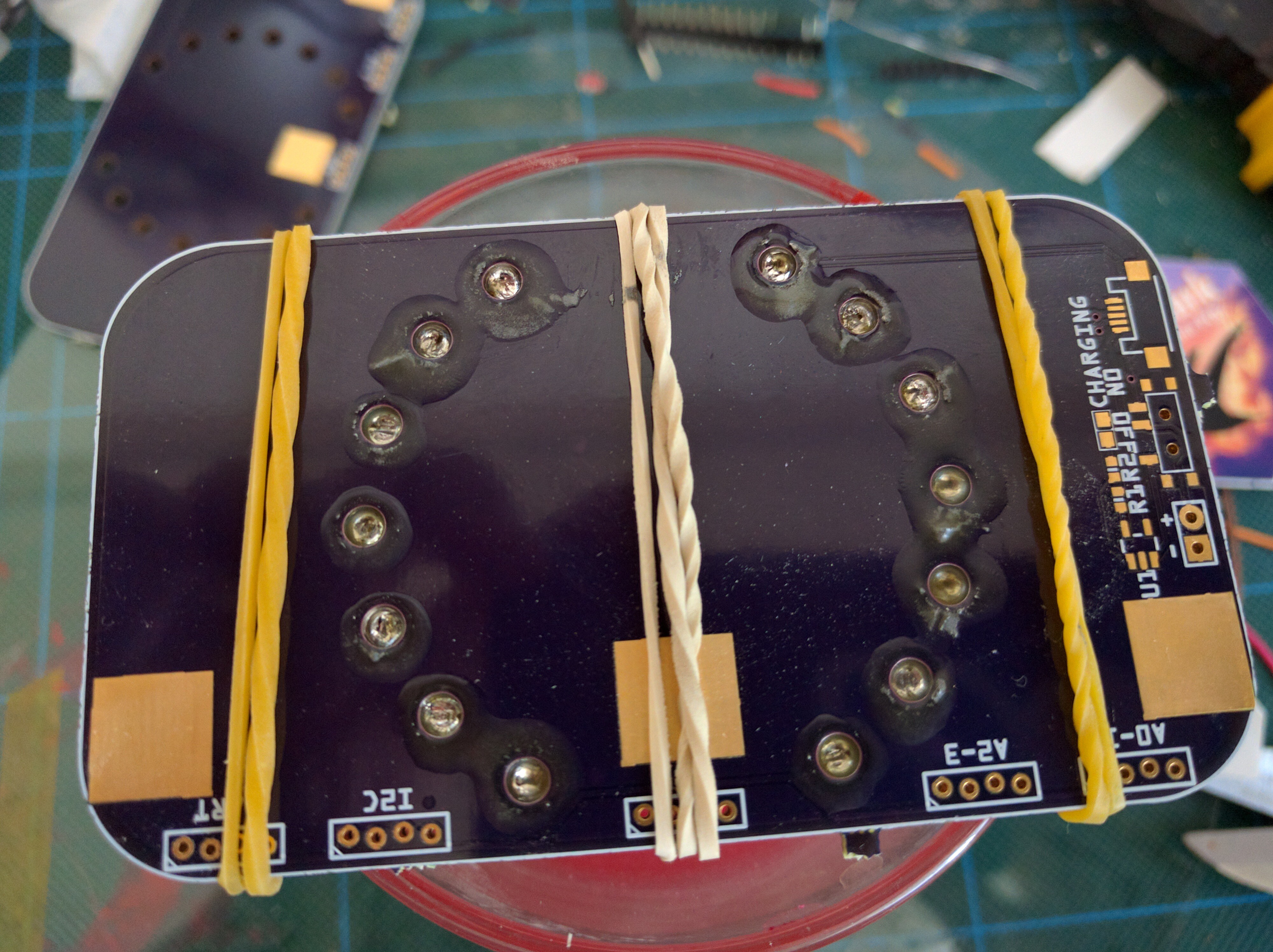

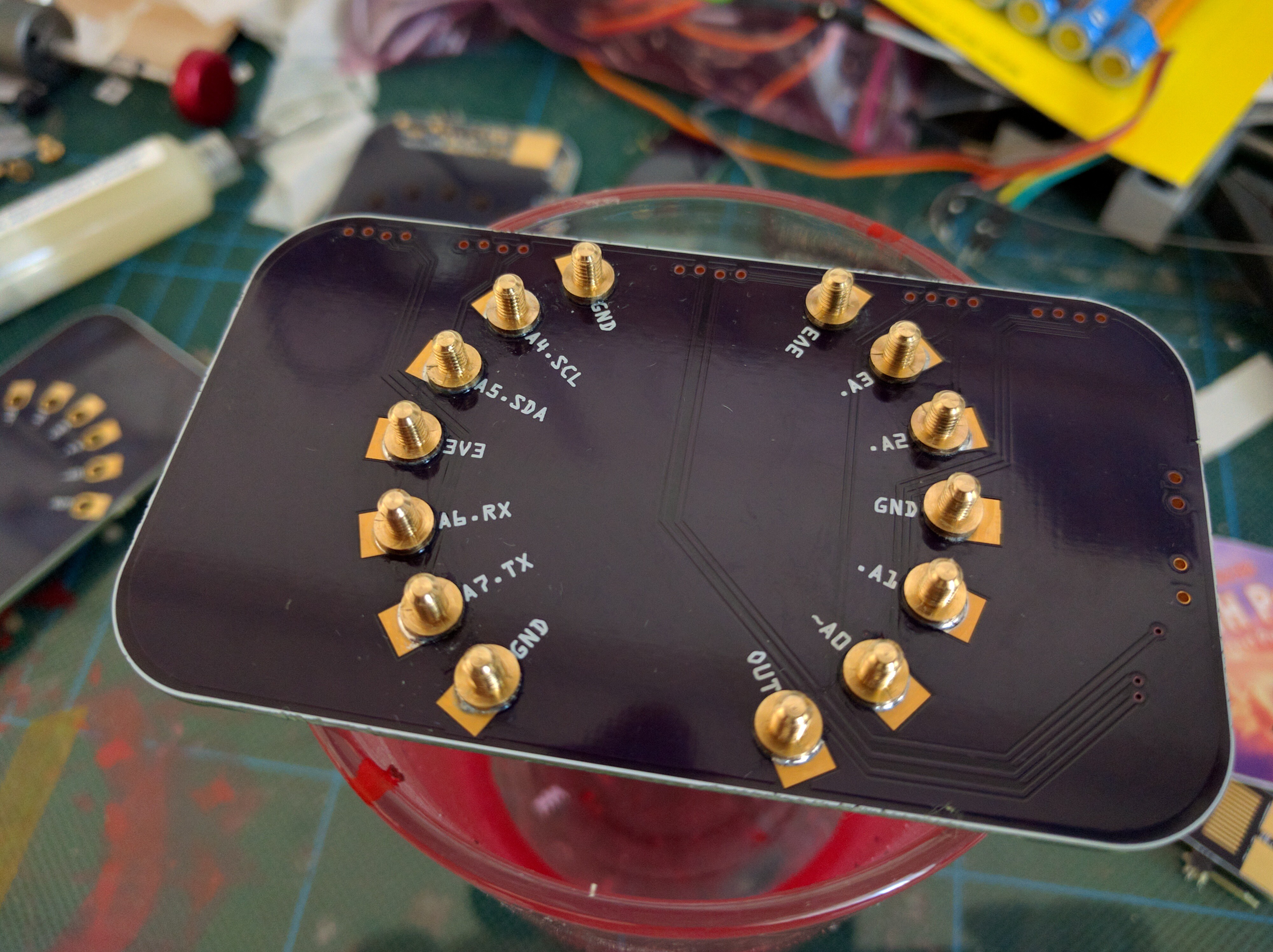

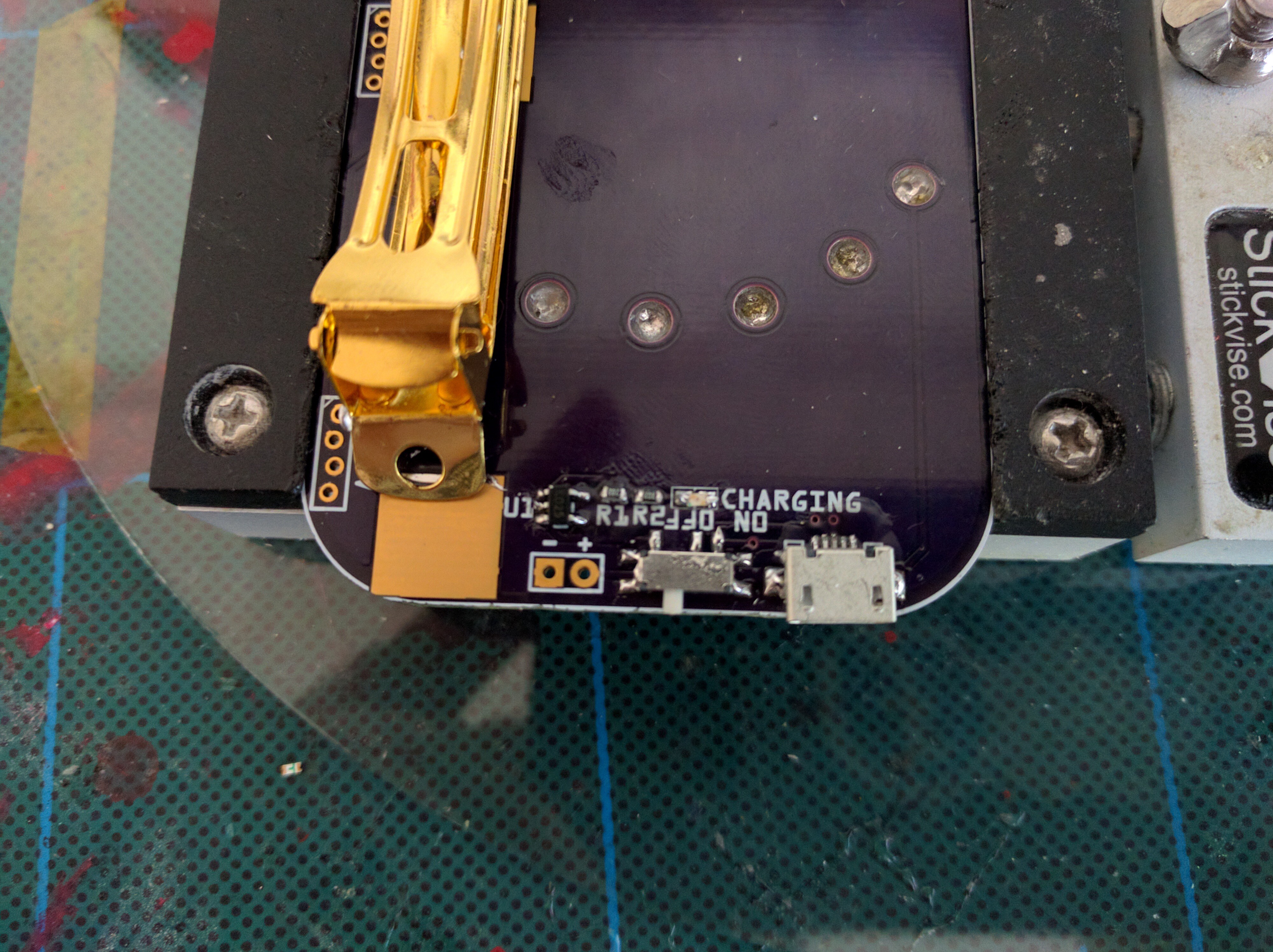

The idea here is to use a barrette as a sort of a hub providing power and control to other accessories on your head. It will contain a microcontroller programmable with CircuitPython, an accelerometer, a light sensor and a microphone — so that you can make things react to movement and sound — and a dozen small sockets, into which you can plug thin wires leading to the actual accessories. You can even have LED eye lashes or #Mechatronic Ears with this!

deʃhipu

deʃhipu

RRichmond

RRichmond

Jean Simonet

Jean Simonet

Xasin

Xasin

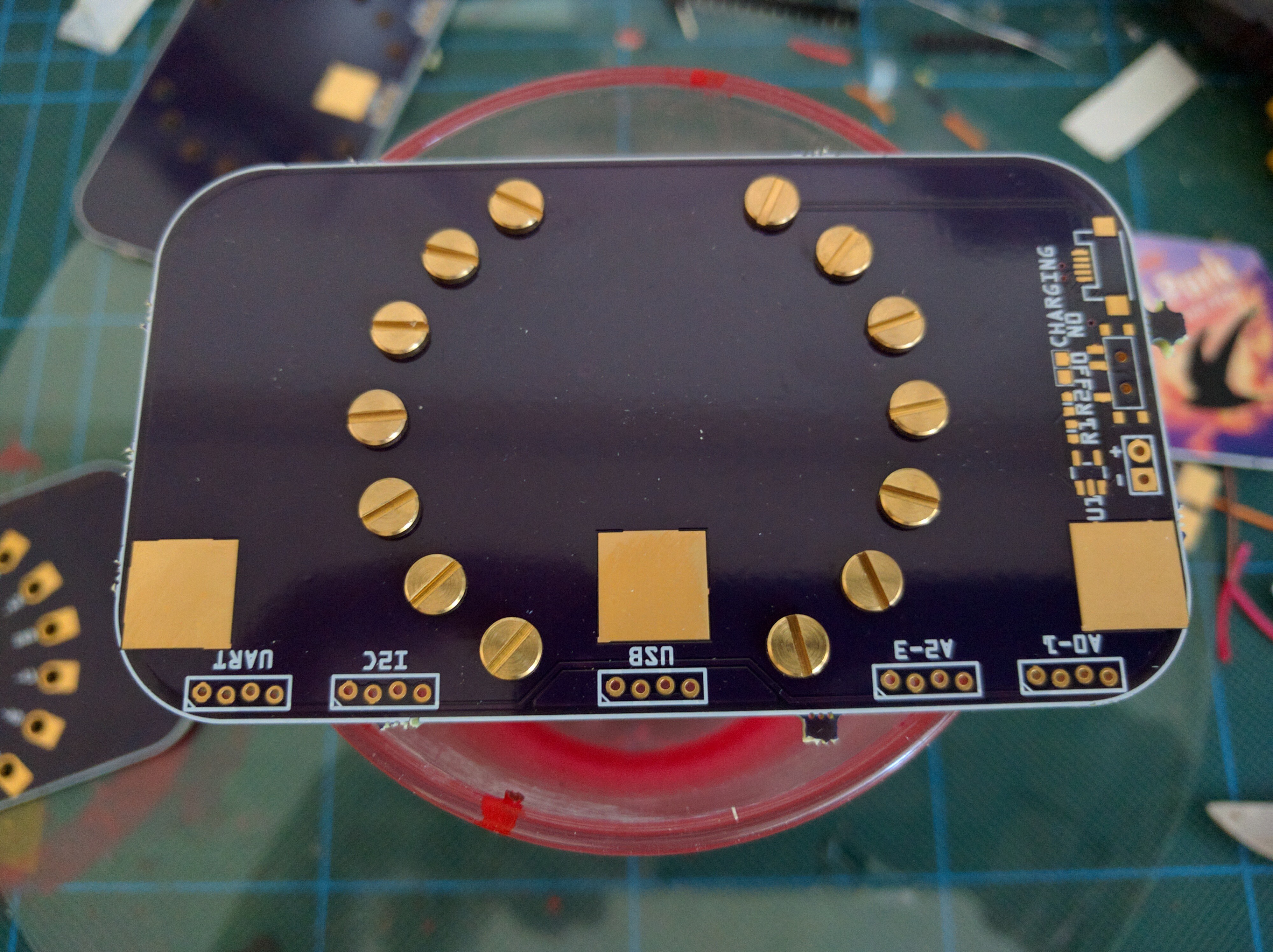

Those soldered down bolts are amazing touch, and then purple anno bolts?!? That's extra style for days. Nice work.