Did you know fish can suffocate underwater? When dissolved oxygen in the water drops below a certain level (a condition called hypoxia), they become stressed and in extreme cases - die. While a number of studies have looked at coastal water quality changes (e.g., hypoxia), we still don't really know how the drivers of hypoxia and benthic processes are linked. So the LoBSTAS's goal is to learn about hypoxia in relation to pictures and videos of the benthic environment.

How is the seafloor changing? What are the currents like? Any 'storms'? How are the plants and animals doing down there? Are they thriving or surviving? Is human activity and waste damaging the coastal environment?

"But don't we already have professional equipment that do these stuff?" Well yes, but they're very expensive. That's why a key goal is to make this project as CHEAP and EASY to build as possible, so that people with limited finances or tech experience can study the seafloor too.

*If you're curious, LoBSTAS stands for Low-cost Benthic Sensing Trap-Attached System. It's a mouthful, I know!

Ellie T

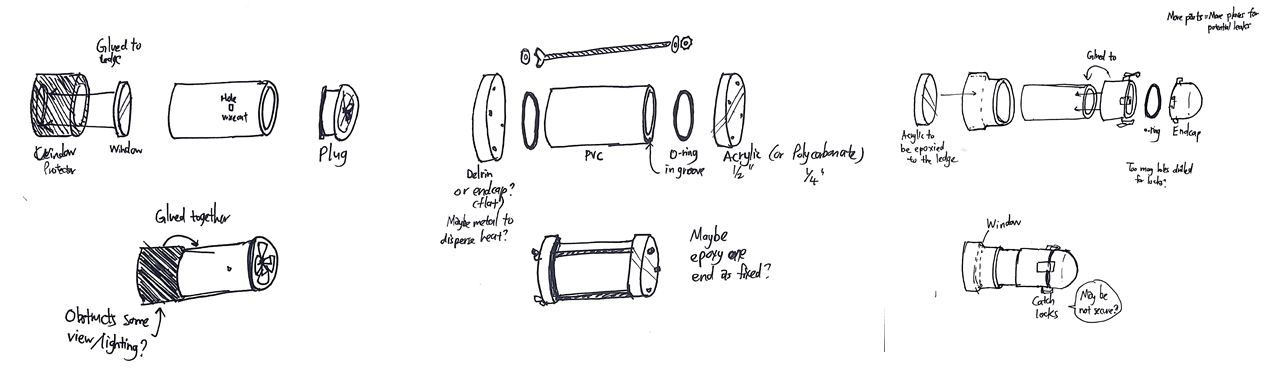

Ellie T (The middle and right design were inspired by MBARI's

(The middle and right design were inspired by MBARI's

Kayser-Sosa

Kayser-Sosa

jdelbe

jdelbe

mark gunderson

mark gunderson

Mime Industries

Mime Industries

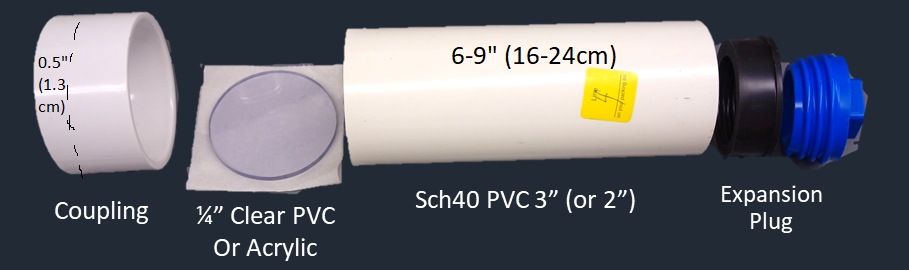

Nice project, have been looking for options for a waterproof outdoor webcam.

Something that might work: https://www.shoppopdisplays.com/11045/2-d-x-375-thick-round-acrylic-display-block.html?st-t=adwords&vt-k=&vt-pti=254874467990&gclid=CjwKCAjwh9_bBRA_EiwApObaOK14a86N0dFBcRXkVfa6BS1tF3AyMgIAUaeT77dsf41ELV6EsVs8kRoCBx4QAvD_BwE

shipping cost might make it less attractive ...

I may try a local plastics shop, but I'm guessing it'd also be a costly custom cut.

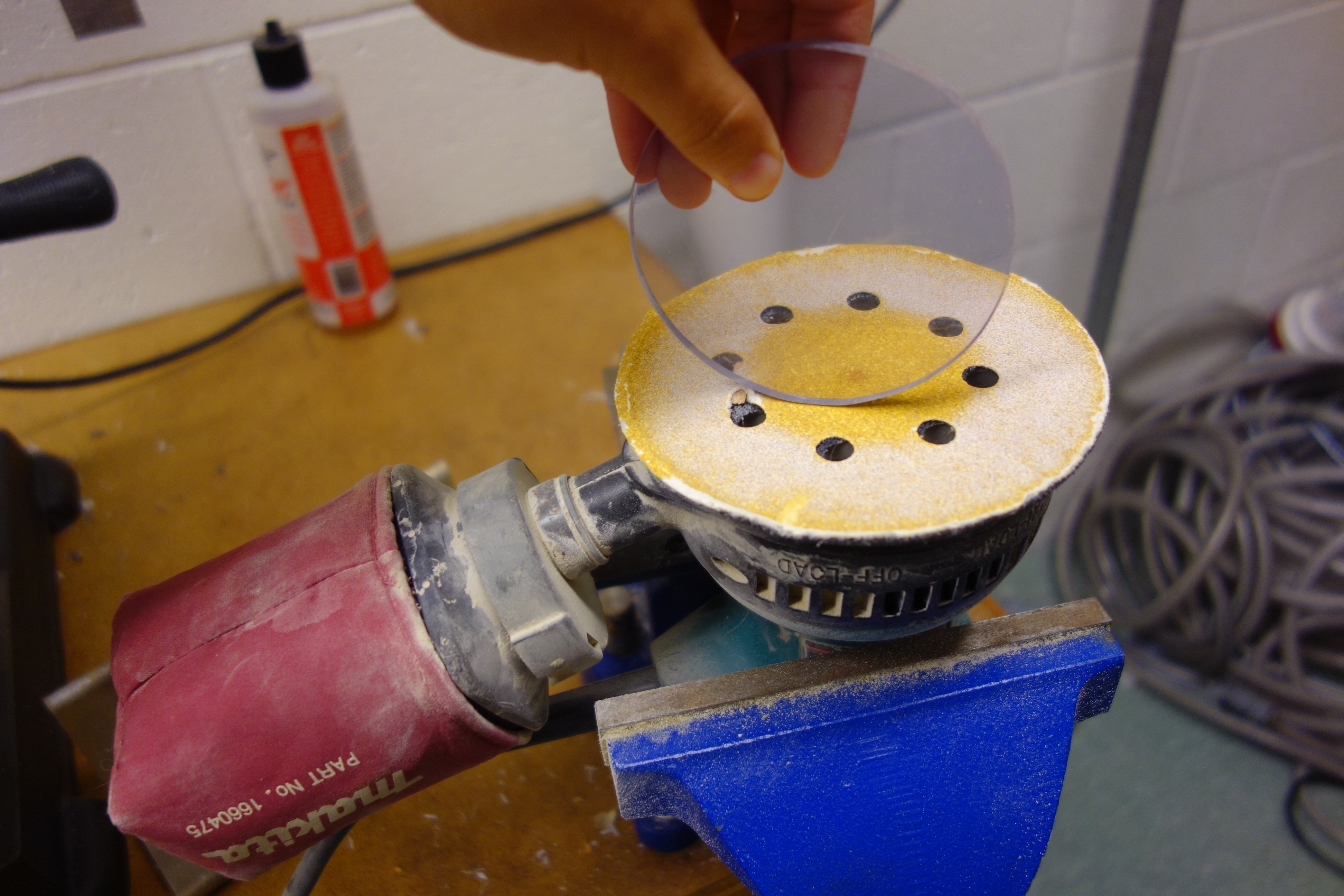

Or a hole saw without the pilot drill bit: https://www.youtube.com/watch?v=VE3CWW6ZYZU