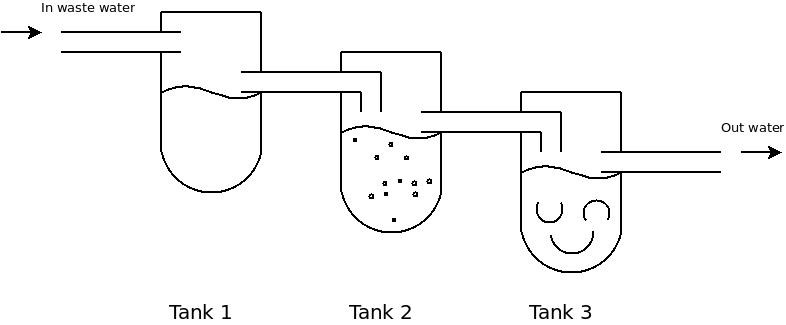

There are multiple approaches for sewage treatment. In general multiple stages of water treatment exist. Usual principle is that on every stage we have our waste cleaner compared to previous step. In simplest installations wastewater treatment consist of three water tanks. Where I live three tanks system is the most popular wastewater treatment concept. Controller that is built as part of this project directly fits to such a system but it also can be adopted to other wastewater systems. Project doesn't provide details on how to build sewage treatment plant but focuses on controller only.

Controller is an entity that allows to:

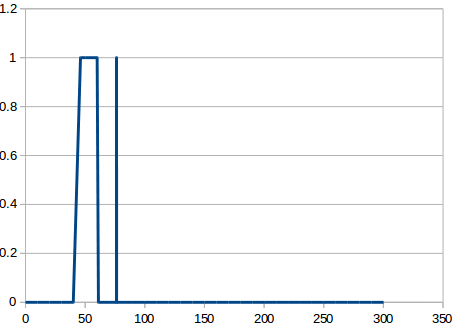

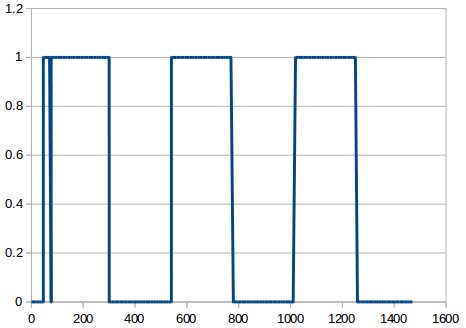

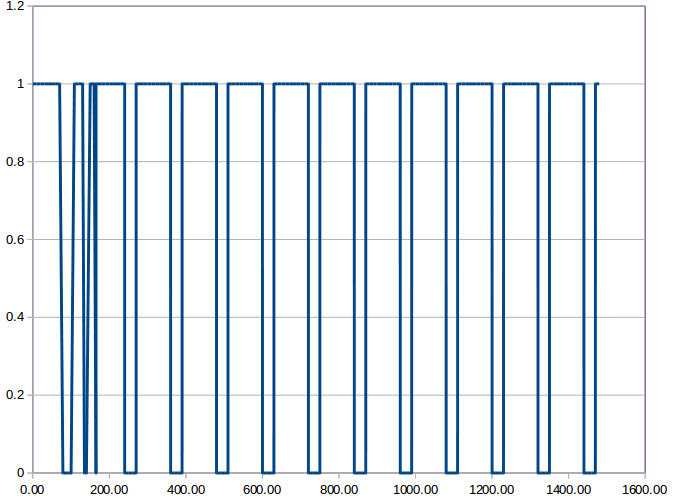

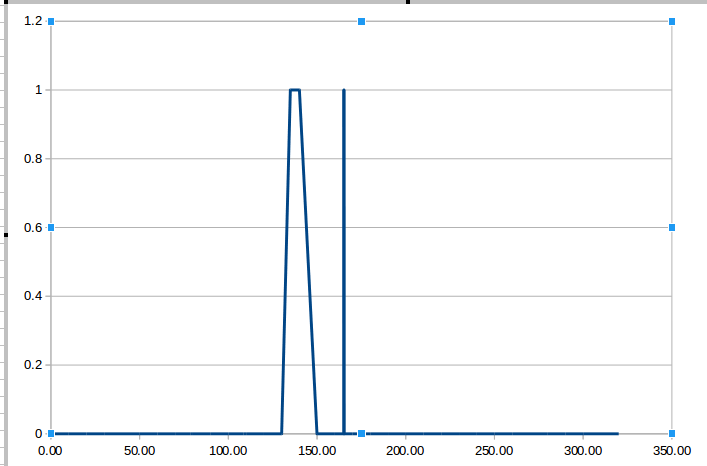

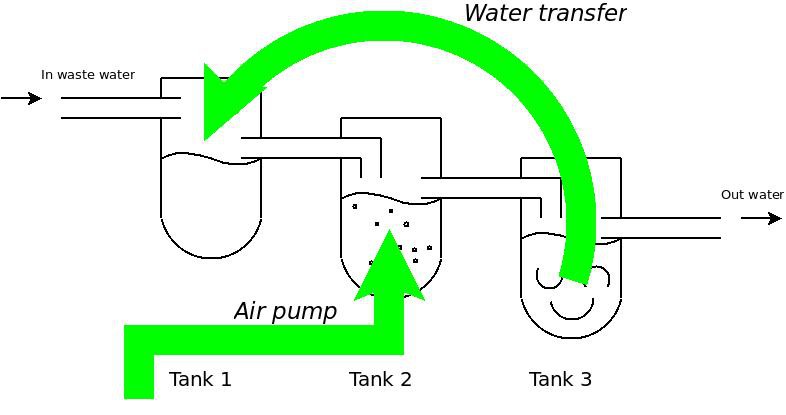

- Reduce power consumption for wastewater treatment process by powering on and off the air pump

- Reduce size of wastewater treatment plant by creating circulation flows between water tanks

- Simplify maintenance procedures as in long term there is only one tank that require waste water drain

- Remind to execute maintenance procedures for sewage treatment plant

- Monitor execution elements of sewage treatment elements

Project consist of two parts:

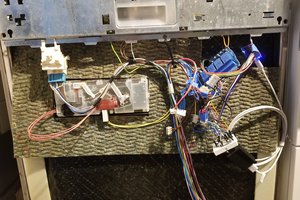

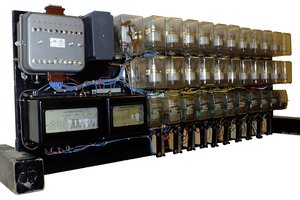

- Reverse engineering of commercial off the shelf controller

- Building controller from scratch

For anyone that is interested in wastewater treatment process I provided brief explanation in one of my first logs. I encourage you to expand all logs in this project. In case of any question please feel to ask in comment section.

leszek-wojcik

leszek-wojcik

Marcel Ochsendorf

Marcel Ochsendorf

David H. Bronke

David H. Bronke

Josh Starnes

Josh Starnes

Artem Kashkanov

Artem Kashkanov