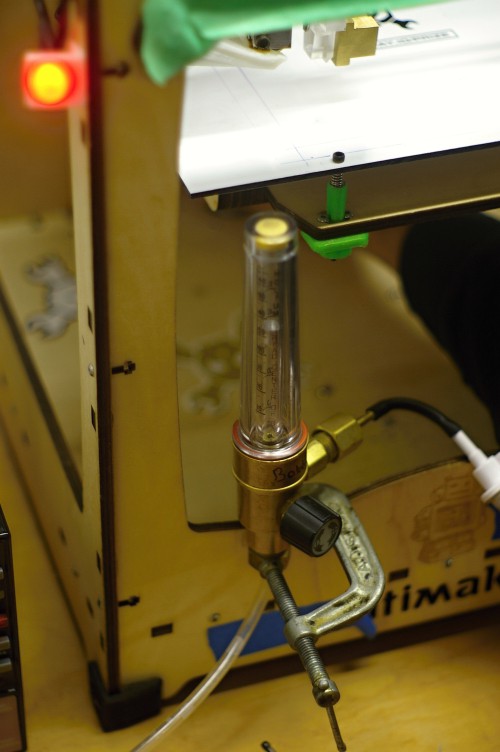

Sorry for the long radio silence, we've been quite busy with the hacklab.to move! We have been making progress on the Retro Populator, including some work towards part rotation, and some improvements in our pick-n-place percentage (number of parts correctly placed versus failed). One key step in the latter has been the addition of a vacuum regulation device, basically, a flow meter with integrated valve, pictured here:

It's plumbed between the hot-air rework intake (our vacuum source) and the pick-n-place needle. It allows us to very finely control the vacuum suction, which is important for making sure that both picks and places happen easily. The hot-air station does have some regulation, but since we improved all the plumbing, we've discovered that even the lowest setting on that machine is too much suction to make places work reliably. This new valve has greatly improved reliability and repeatability, and it's likely that we'll be including some version of this device with kits, because it makes it much less important what your source of vacuum is. Simply adjust valve while manually testing picks and places with the needle, until things work (setting also depends a little on what parts you want - though we've found that moderate settings are great for everything from 0603 resistors right up to SOT23s, no further adjustments required!). Then note the flow rate reading, so that you know for future runs or if you ever swap equipment around.

Eric Boyd

Eric Boyd

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.