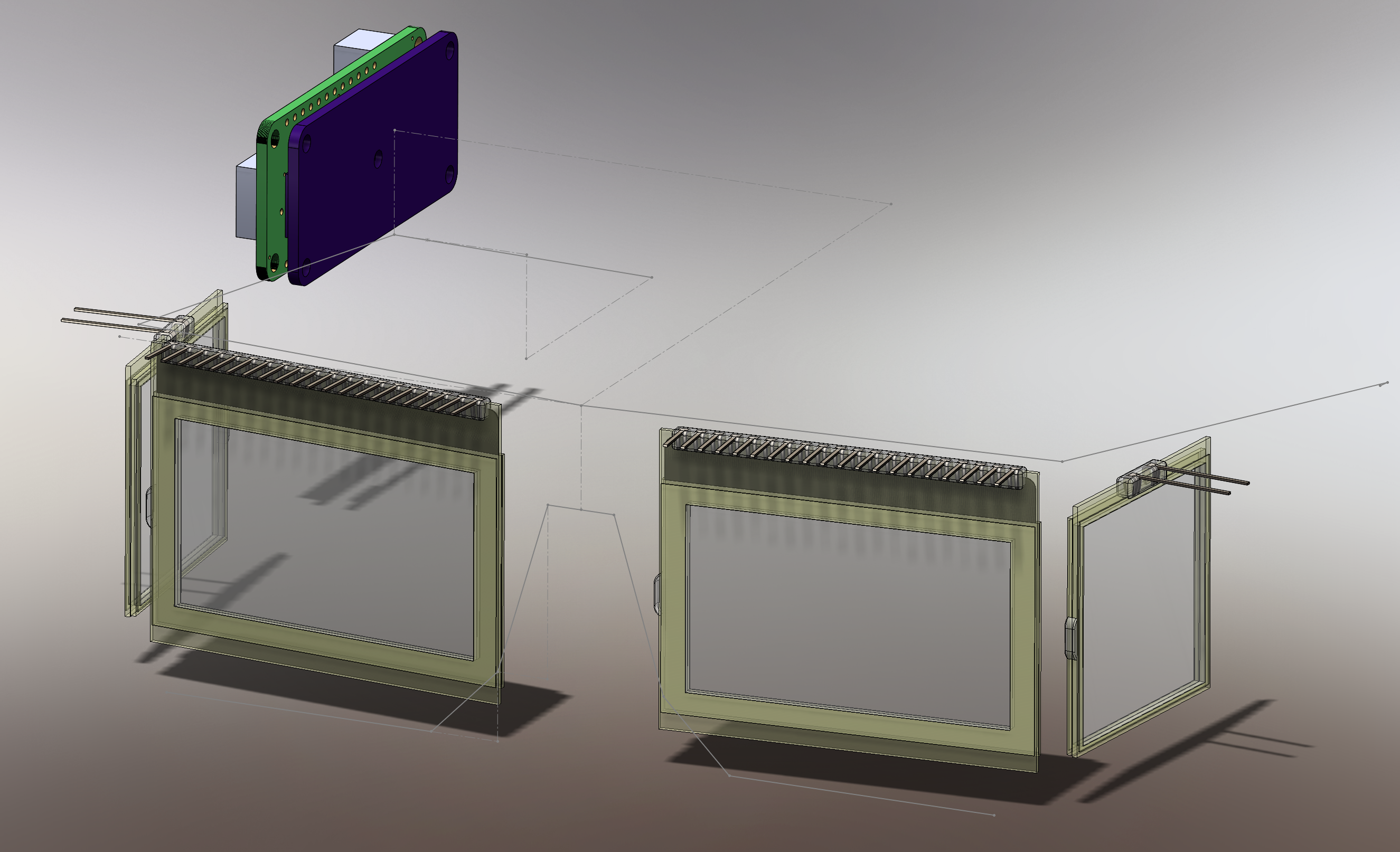

With the breadboard operational, the next step is to develop a wearable prototype. Our plan is to 3D-print a frame with a shape similar to traditional glasses which will hold all of the components while being (reasonably) comfortable to wear. The LCD displays and shutters will fit into grooves in the frame which will capture them on 3 sides. The front LCD displays will each be mounted to a small PCB which will then attach to the frame with 2 screws, securing those displays in place. The side LCD shutters will be retained by a small bracket. A carrier PCB for the Feather PCB will be mounted above the right ear, and the battery will be mounted above the left ear.

Before modeling the frame, it was necessary to develop CAD models of the major components. The LCD display and LCD shutter models were built using the datasheets (where possible) and plenty of measurements of the actual components. The board outline for the Feather was exported from Eagle, and blocks representing keepout zones for the larger board components were added from measurements.

A 3D guide sketch for the glasses was developed based on measurements of my face and of a pair of cheap sunglasses which were a giveaway at last year’s Maker Faire. This is only a starting point, as it will probably take a few iterations to make the shape and size feel comfortable. The major components were arranged on the guide sketch so that modeling of the frame could begin.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.