I'll try to update this asap with a progress timelapse as it turns out taking a 1 picture per second timelapse in 1080p over a period of 2 days takes over 40gb.

Jadoo's All in one

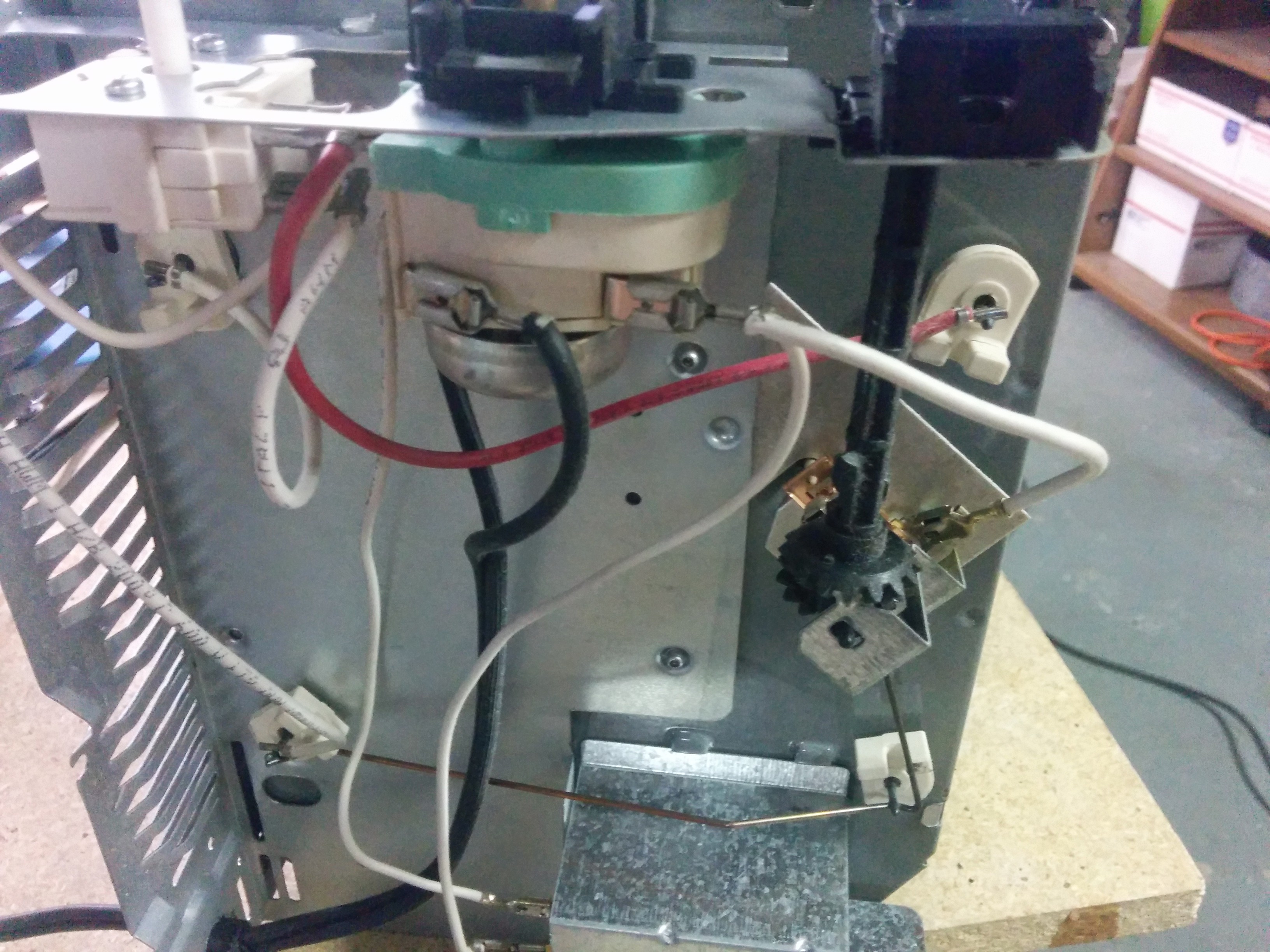

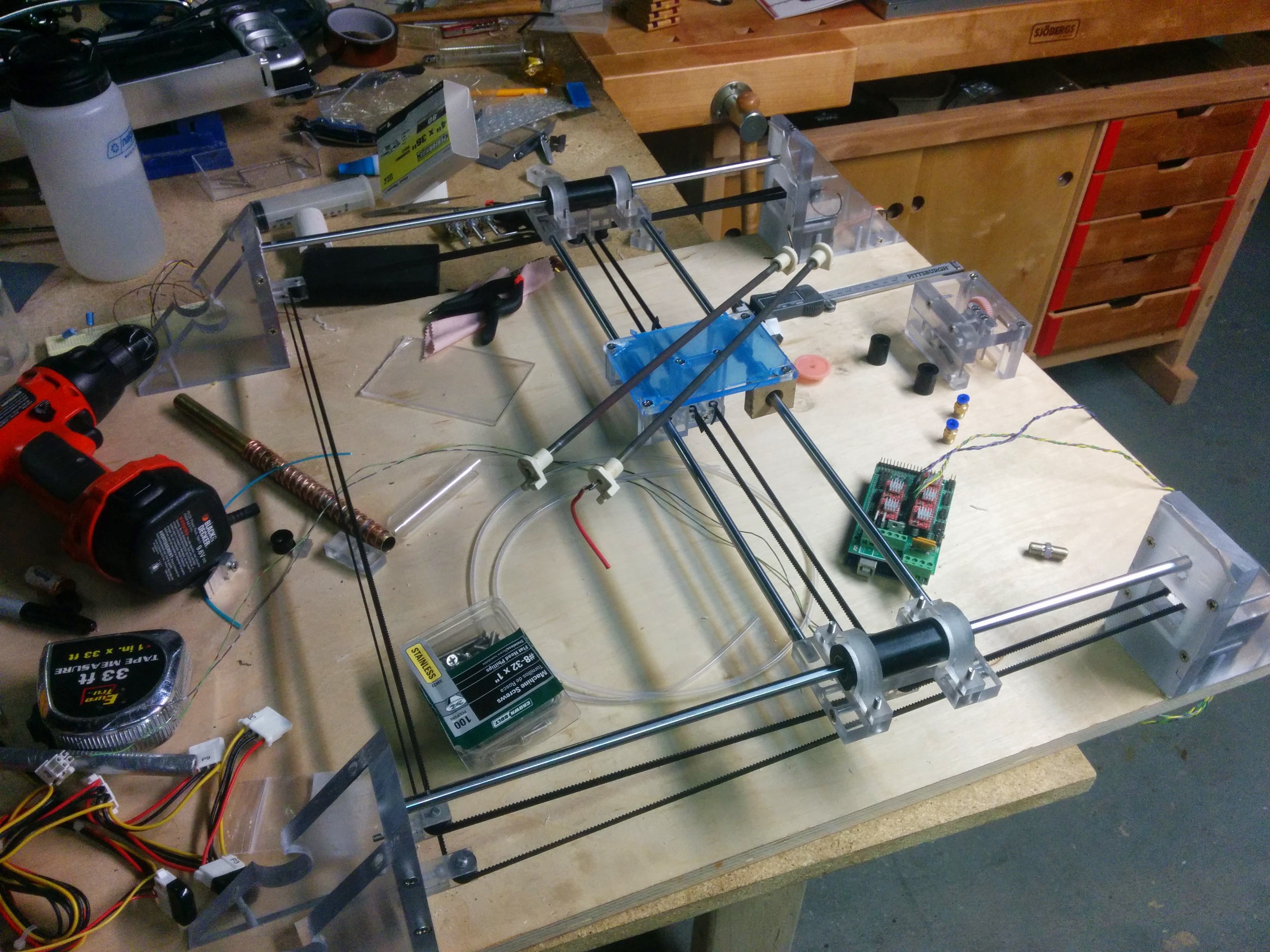

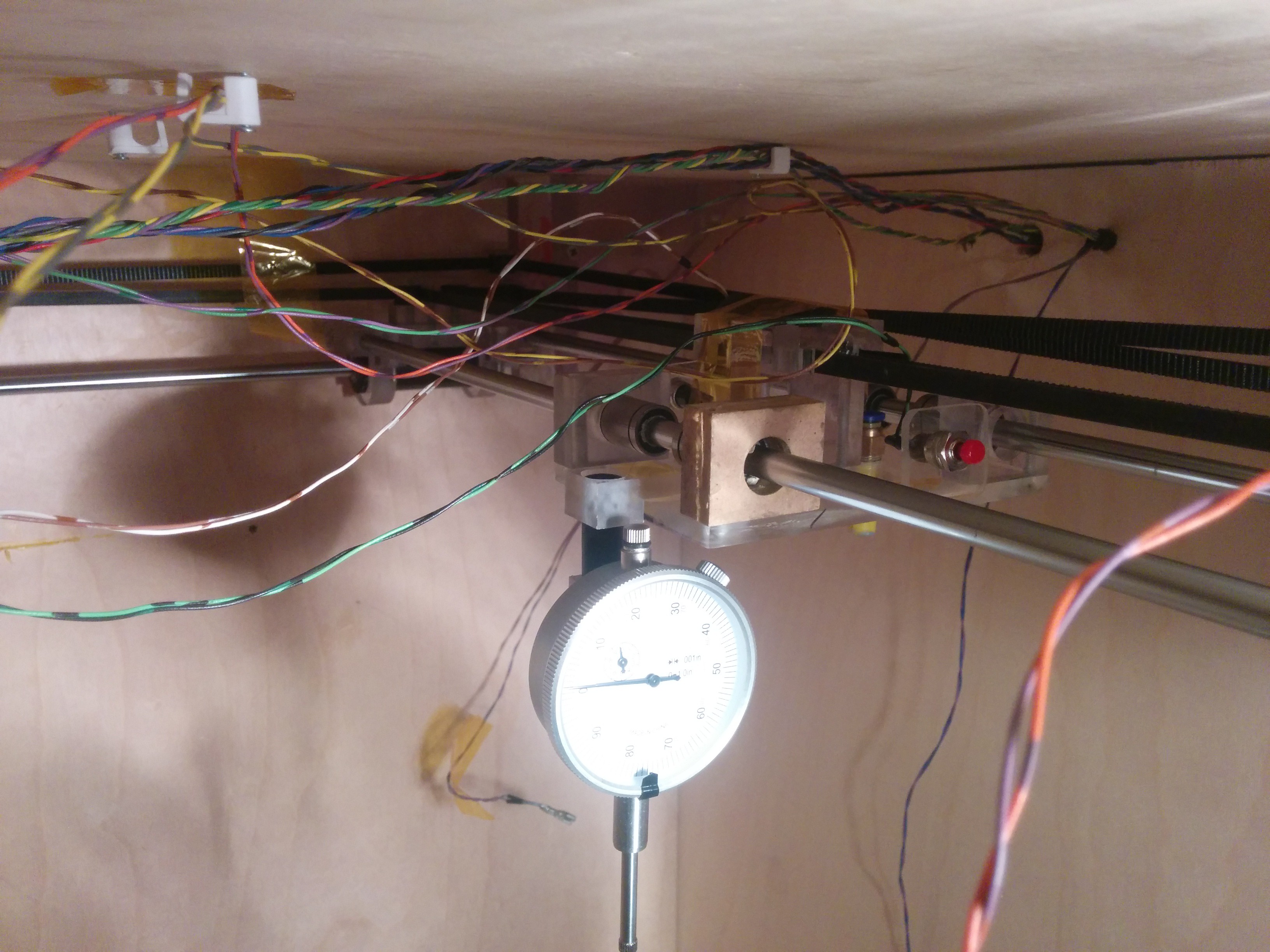

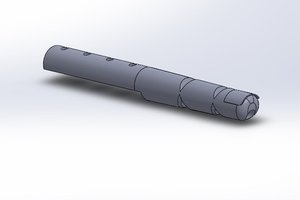

An all in one DIY lab in a box 3d printer, laser cutter

Heated Chamber and Exhaust removing enclosure.

Eric (Jadoo)

Eric (Jadoo)

Tomas Starek

Tomas Starek

Sebastian Lenartowicz

Sebastian Lenartowicz

Alan Chambers

Alan Chambers

Elliot

Elliot

Hi

Nice to meet you after viewing your profile i am Jacinda, from (jakarta) indonesia,

i have a project discussion with you please email me on: (jacinda.seiler@yahoo.com)