Based on this board, I made several training projects. I'll post them a little later, as soon as I figure out how.

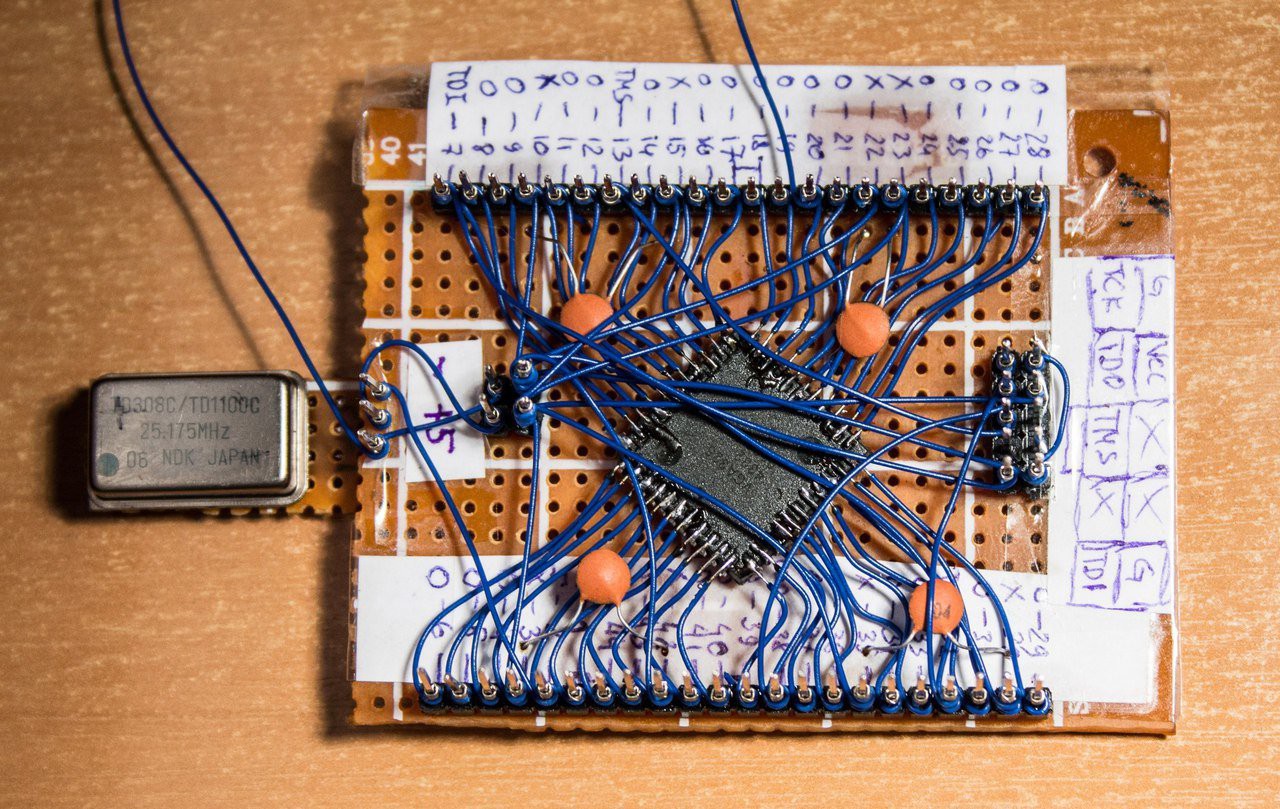

The FPGA evaluation board - Frankenstein

In old PCB's i found a low-capacity FPGA(CPLD) - EPM7064. I decided to make a small evaluation board.

Alex

Alex

ASHUMHRPROJECTS

ASHUMHRPROJECTS

Dave's Dev Lab

Dave's Dev Lab

Lukasz

Lukasz

Christoph

Christoph

Frankenstein is pretty close to me. I am glad that you raise this issue in your article. I can tell you that last week I needed to do an essay on the subject of Frankenstein and what I did, I turned to the guys for help https://blablawriting.com/essay-examples/frankenstein It's good that there are some really good quality essay examples for all kinds of topics.