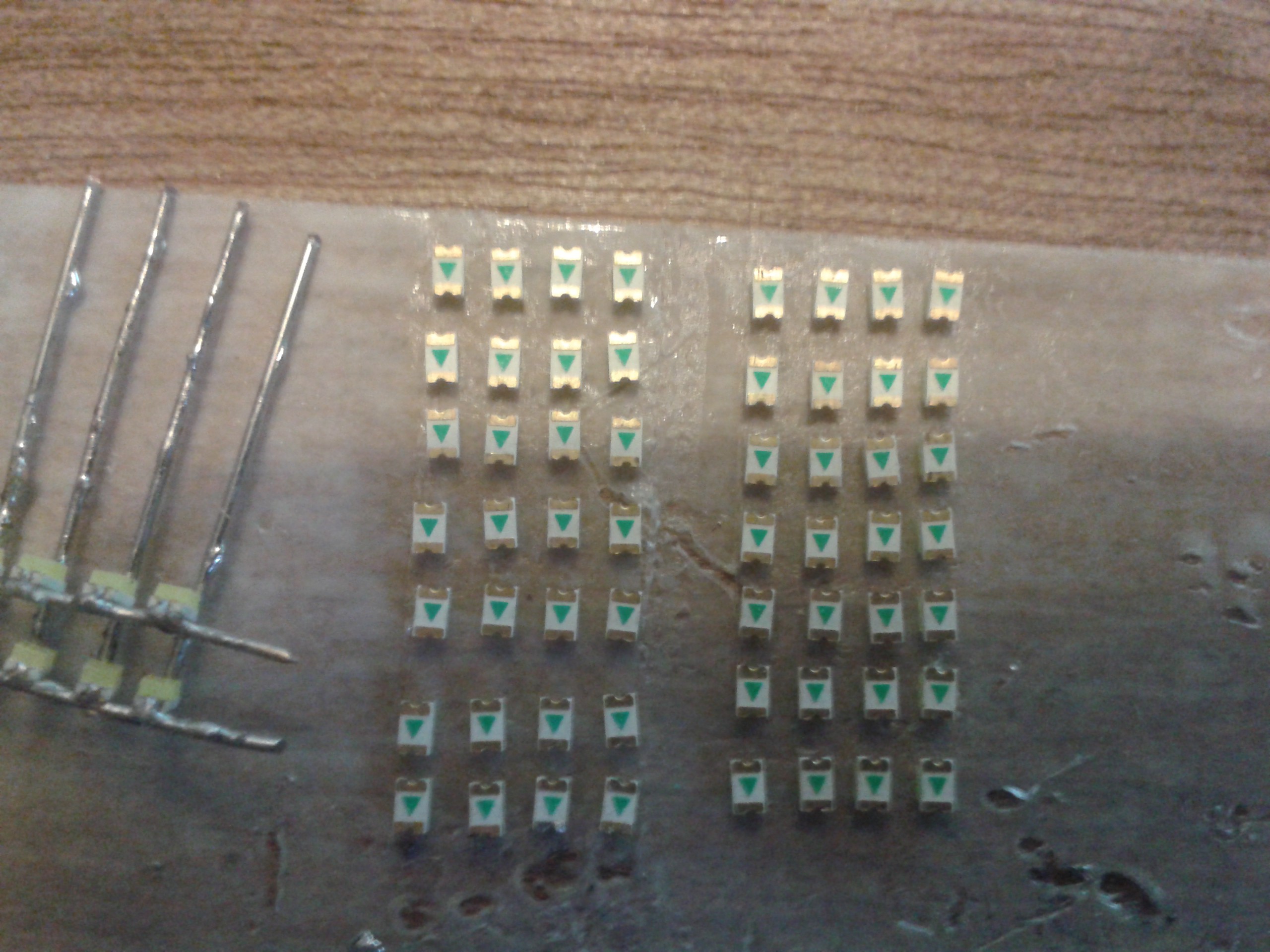

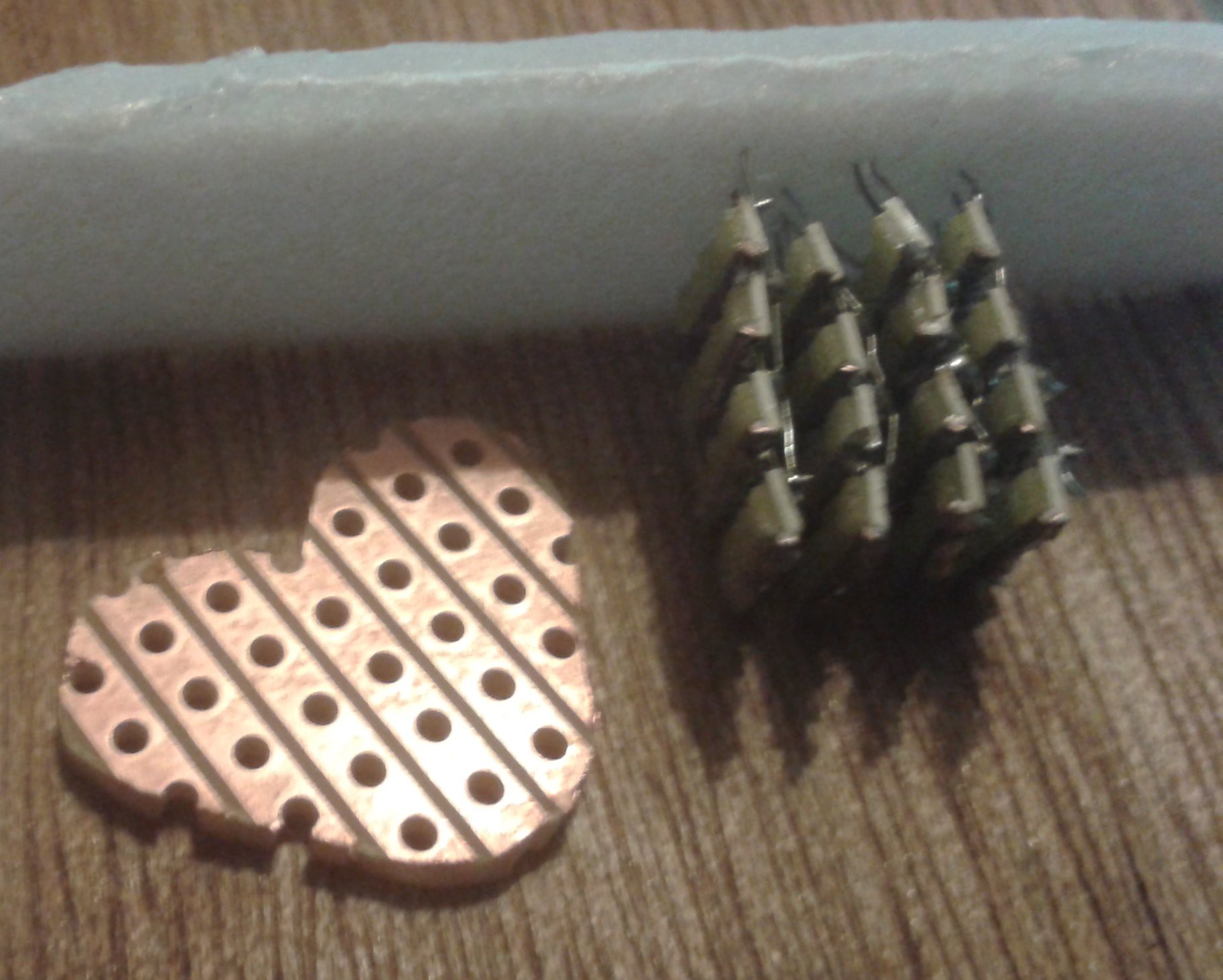

0805 White SMD LEDs, 70 of. What could I possibly make with these?

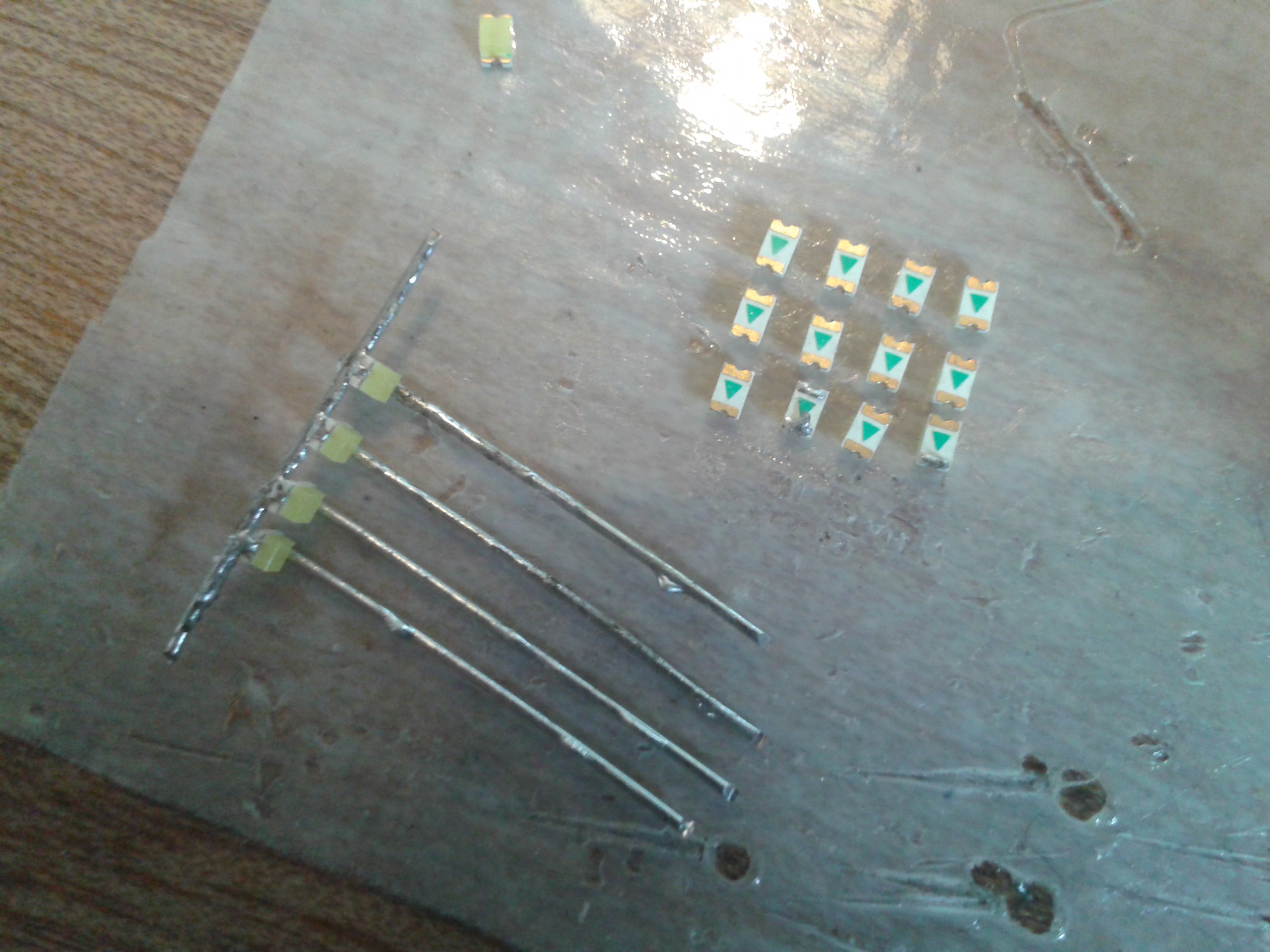

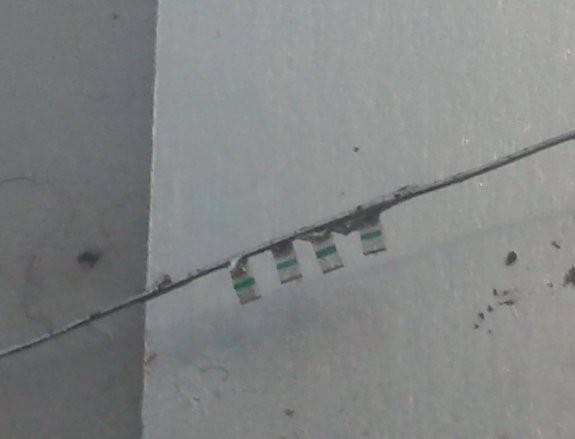

I tried many ways of holding these ridiculous little devices. In the end I discovered a sticky surface is by far the best. Preferably a large sticky surface because they are legendary for pinging out of tweezers and skittering across a desk to become dust-bunny breakfast.

One bounce on this stuff and they stop dead, if they ever launch. So far I've handled 64 of the little bleeders numerous times and not lost one.

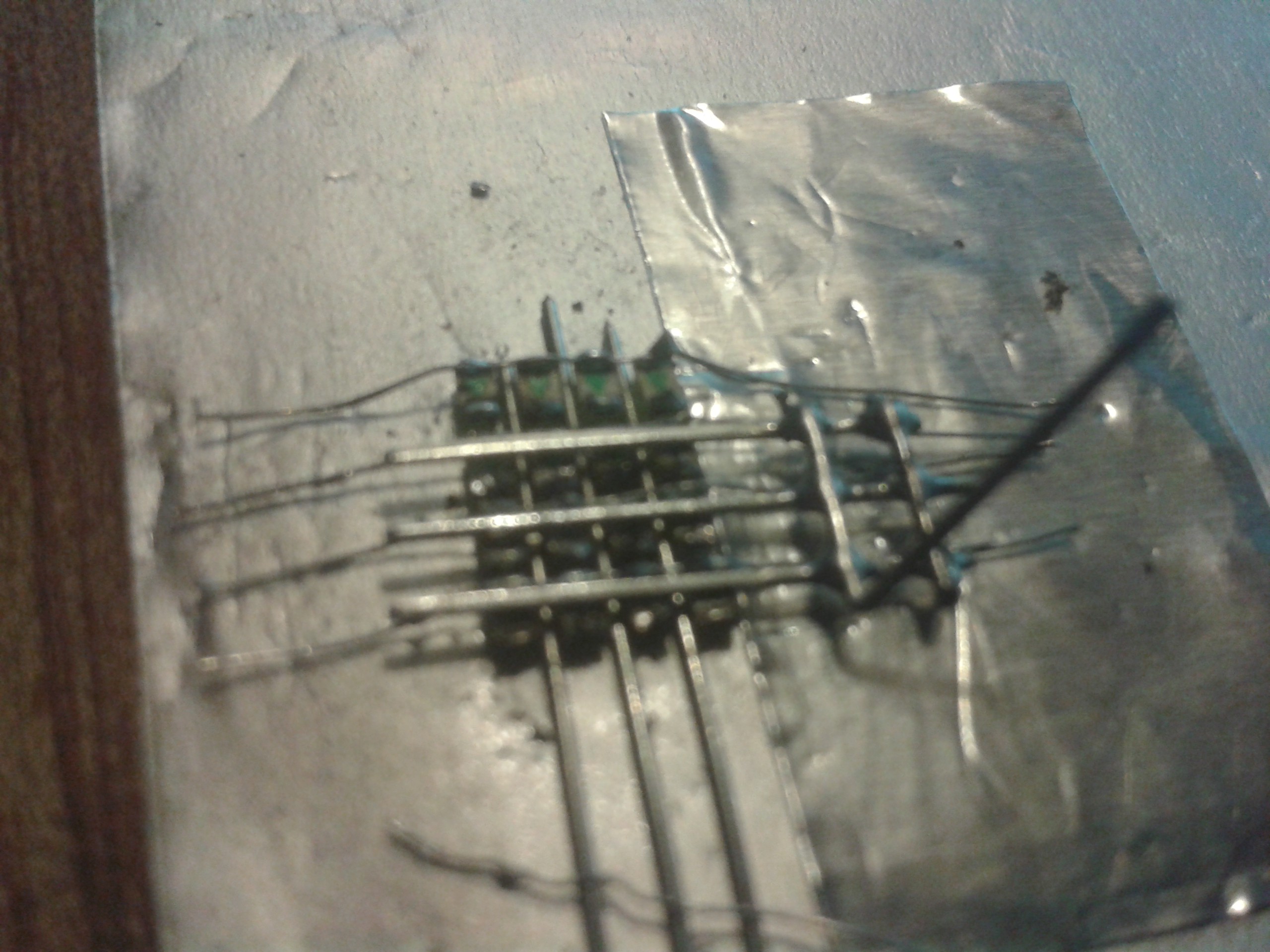

Step One, Sticky Tape. More on this later.

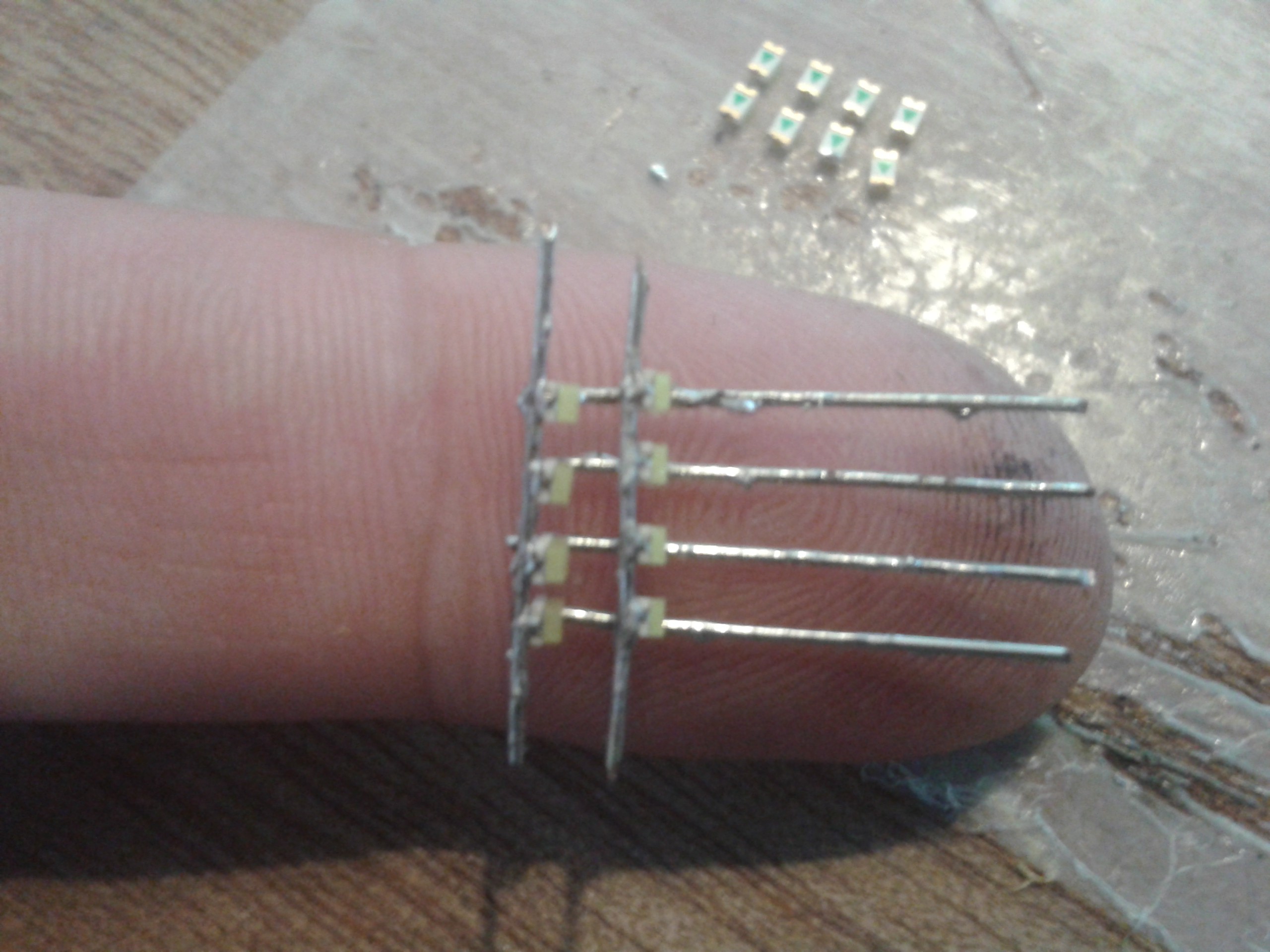

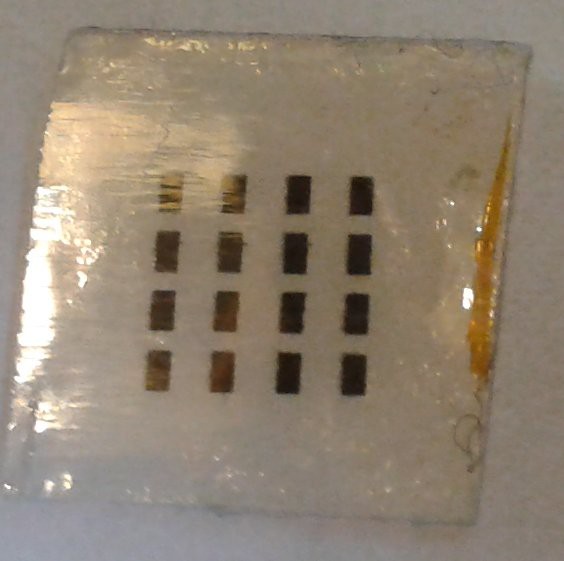

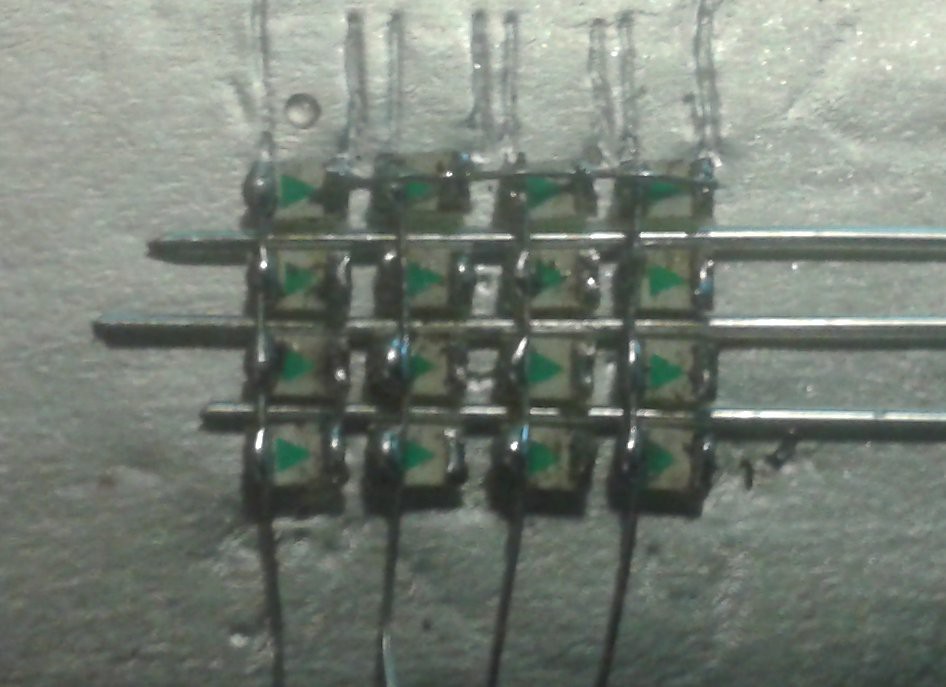

This is hard work, one row and I'm already sweating.

The others fall off when you touch the wire anywhere, so they have to be held together on two points while soldering one. Luckily, this is a diode array and is already a grid, I can use that.

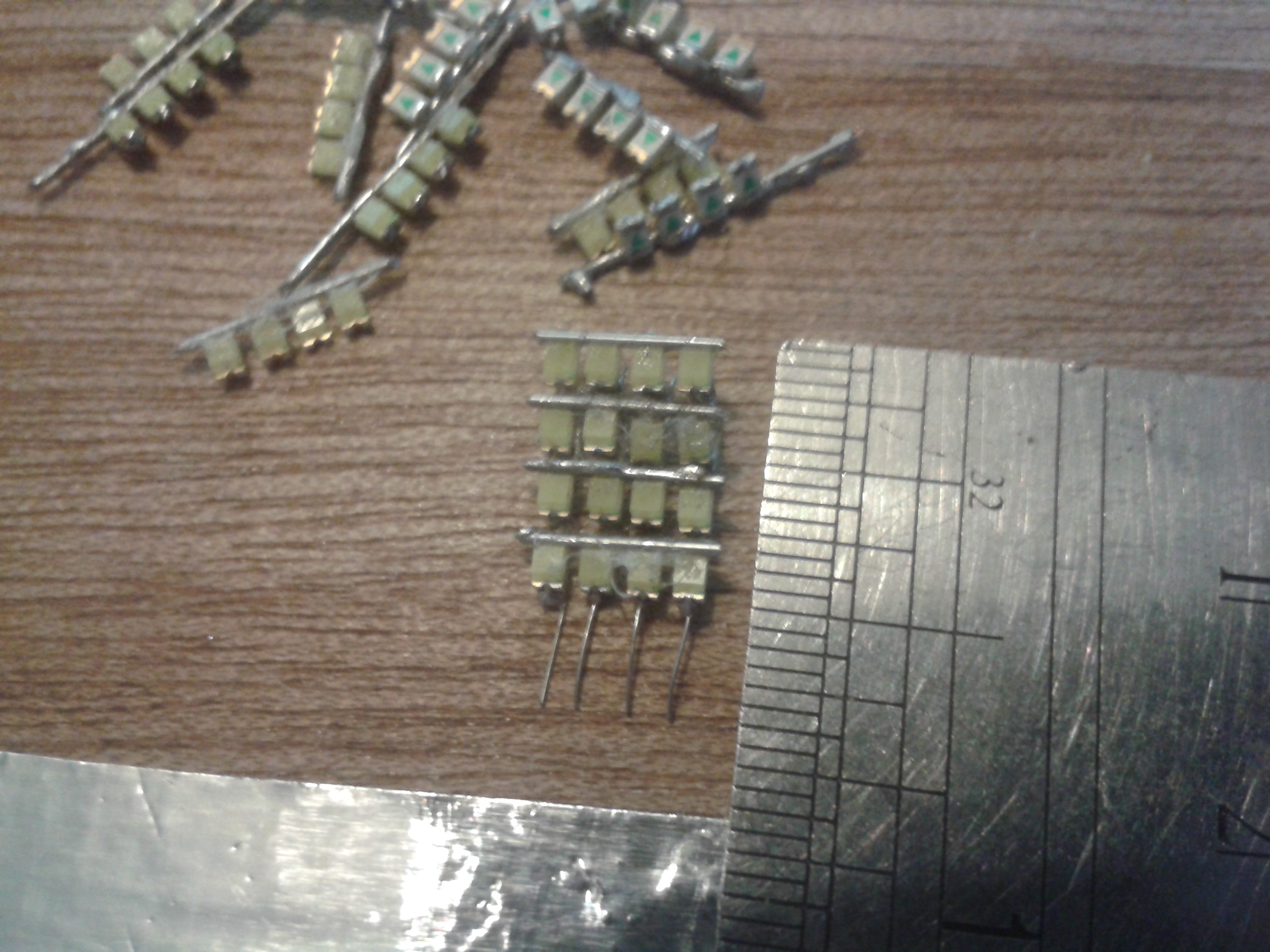

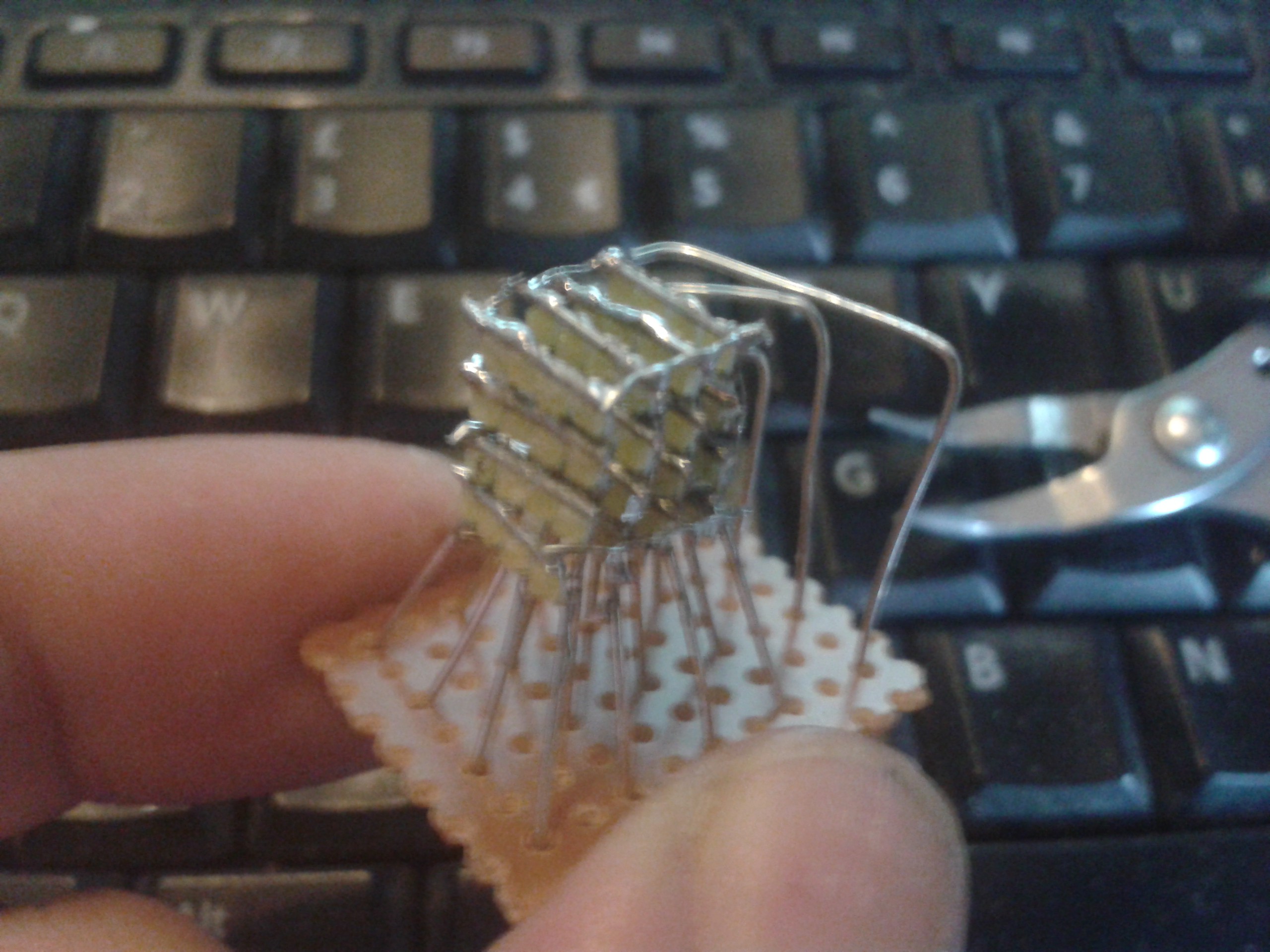

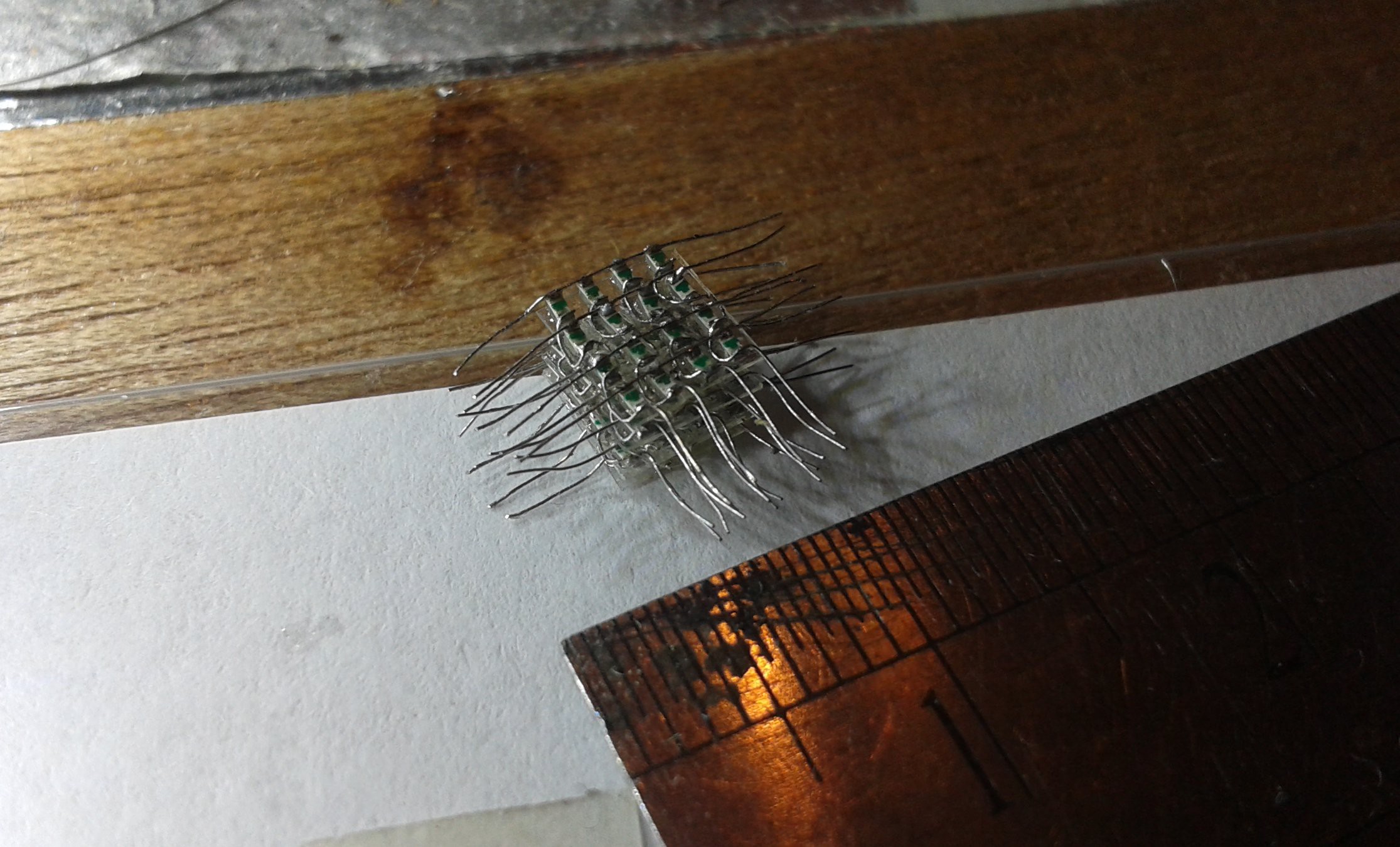

Holding four of them proved to be a bit of a problem, so I attempted to rewire the cube with the layers flat instead.

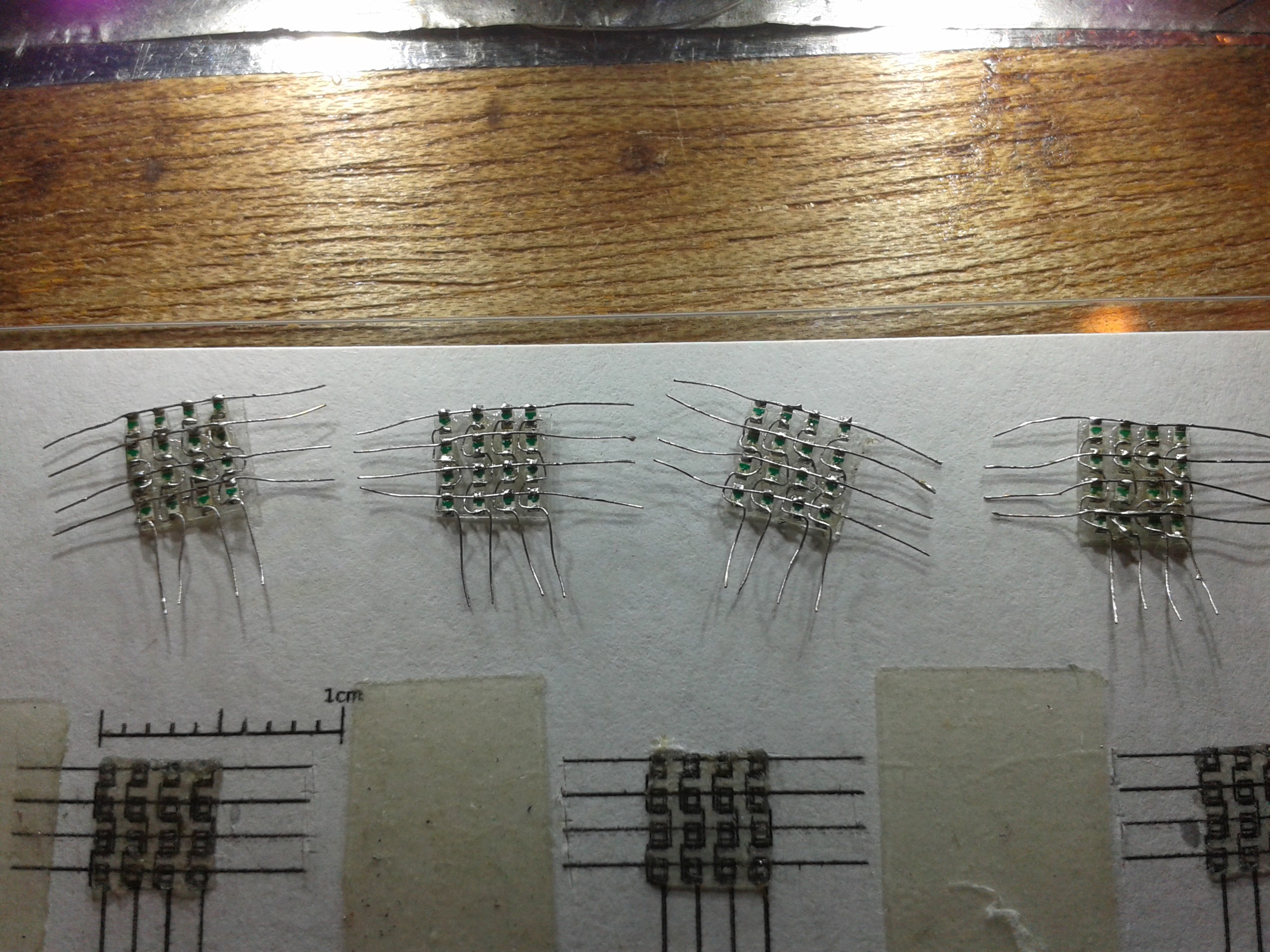

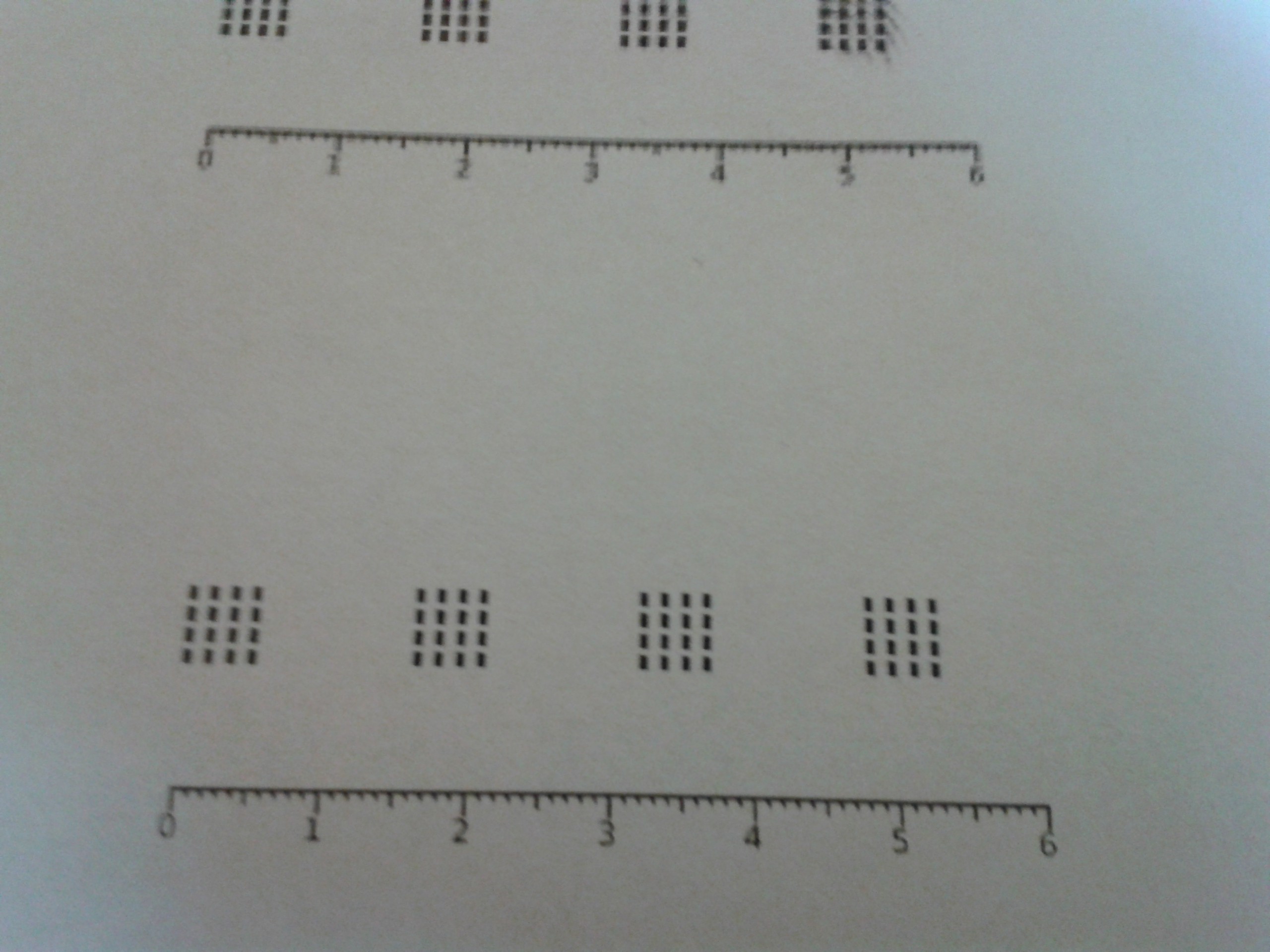

I spent ages lining these up, bit of a waste of time as it turned out.

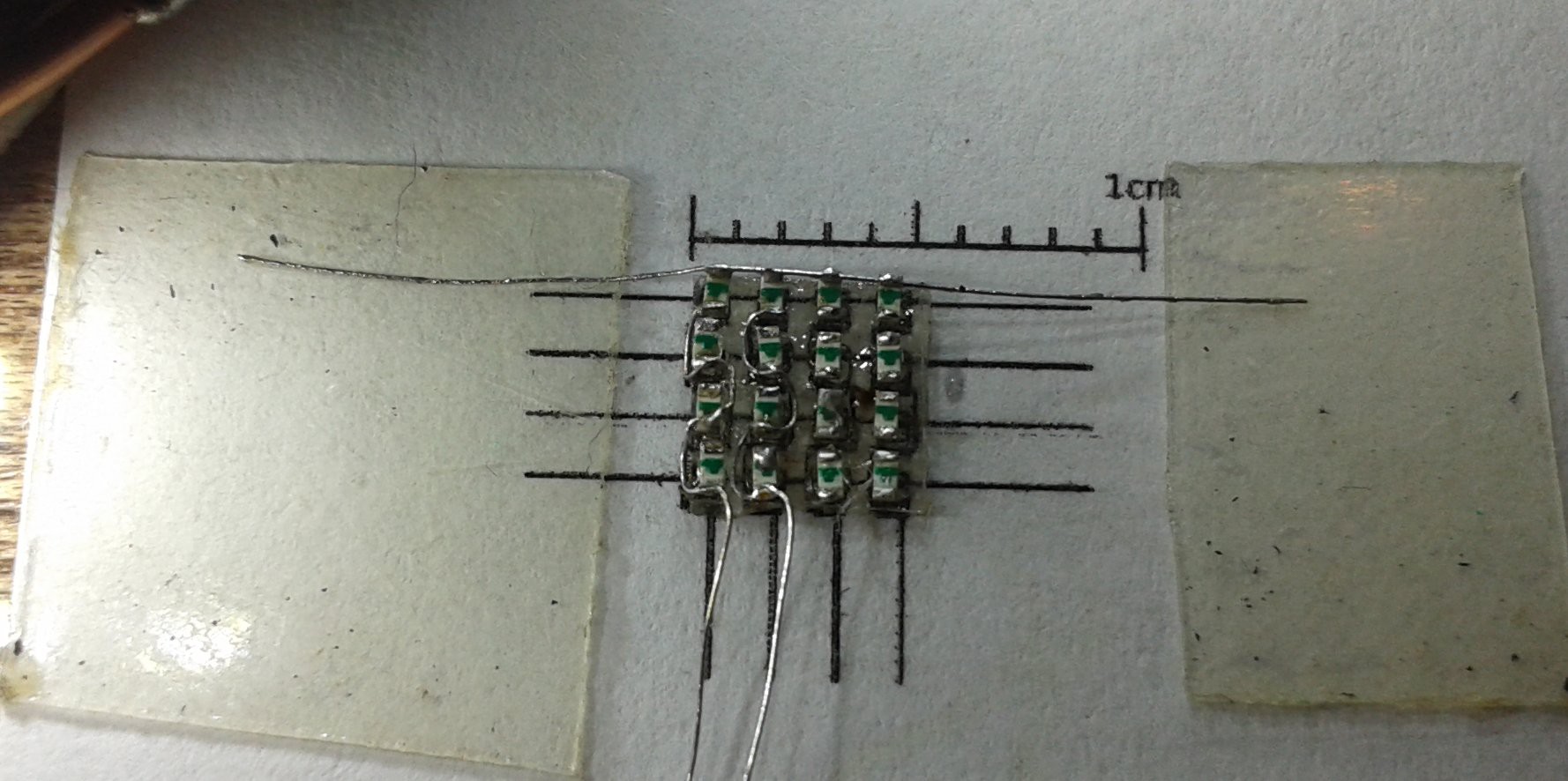

Step 2, Repetition. Thats the key to working with small devices.

Every one takes concentration, so minimising that is key.

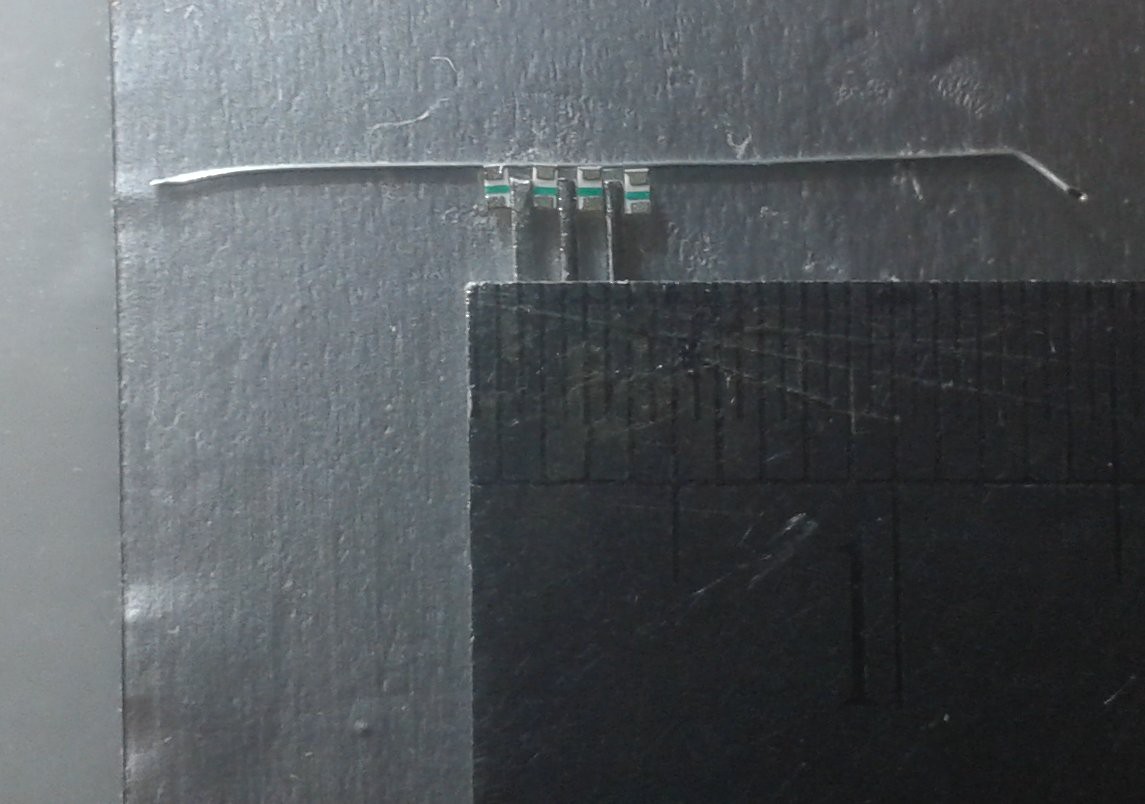

They only have to be laid out roughly, and the tip of the soldering iron rolls the wire into place, lining them all up neatly horizontally. A little prod with the tip of a scalpel and they sit nice against the wire if you tin them first.

128 pads isnt so bad stuck to sticky tape after all, even if they are less than a mm across.

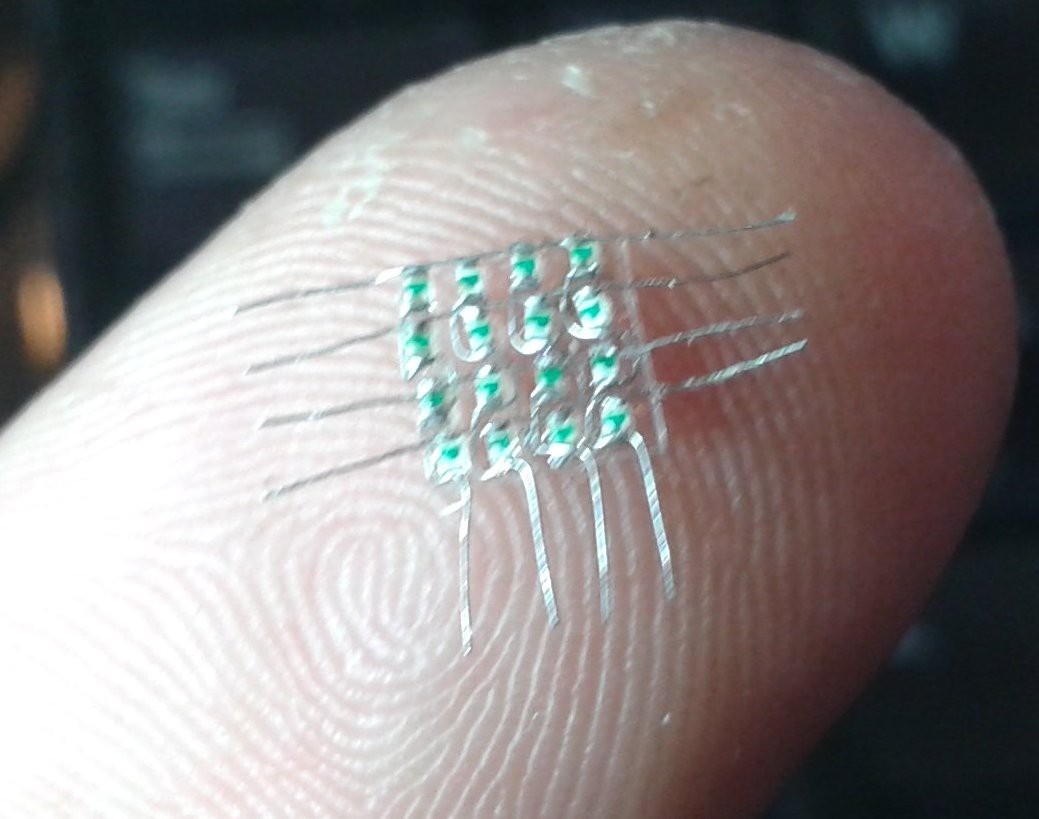

So small they are getting hard to photograph reliably to scale.

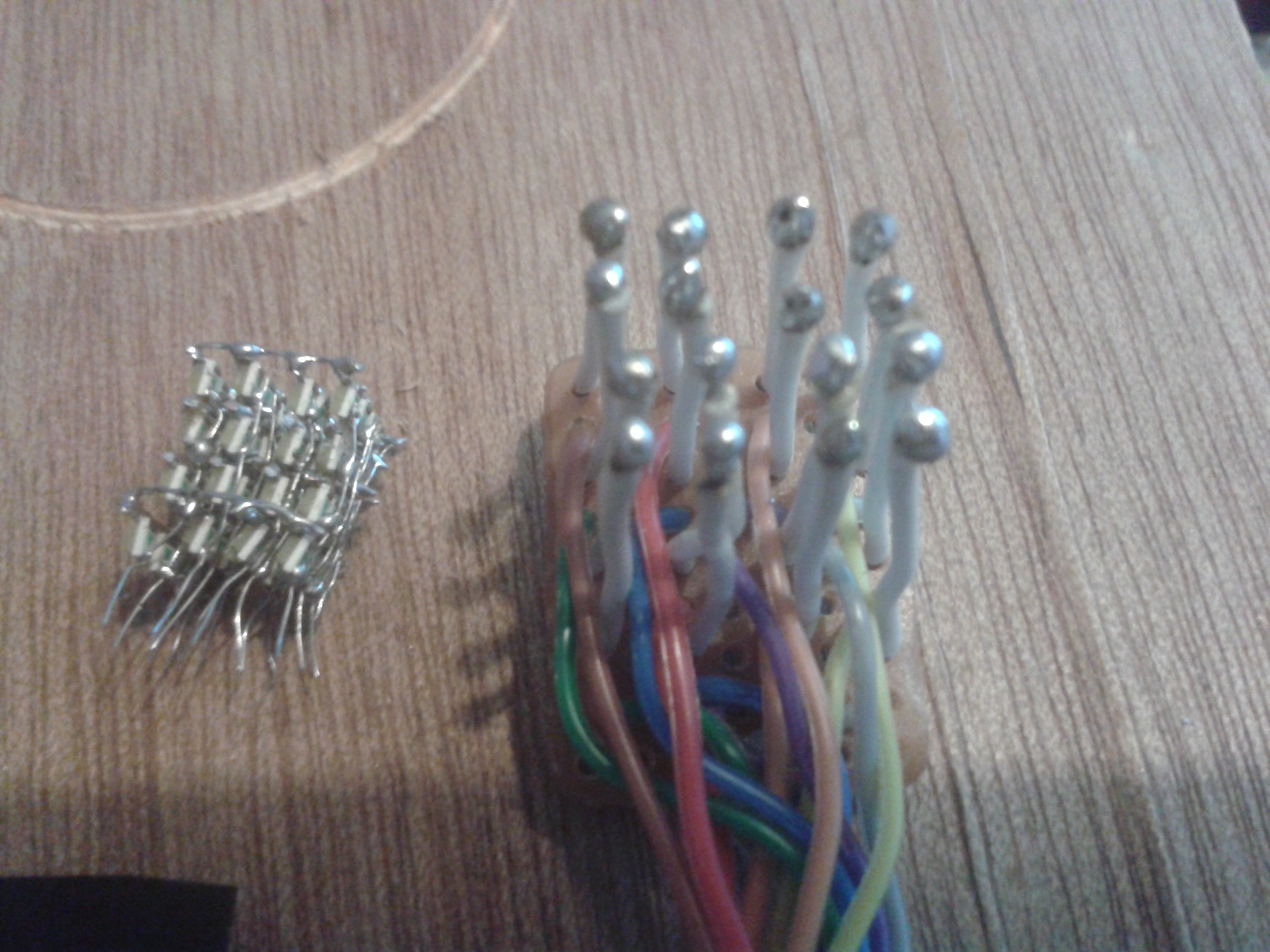

I deliberately left the bearers as tails so I could use them to mount the completed layers. They are the column wires, I'll need something to connect to eventually as well.

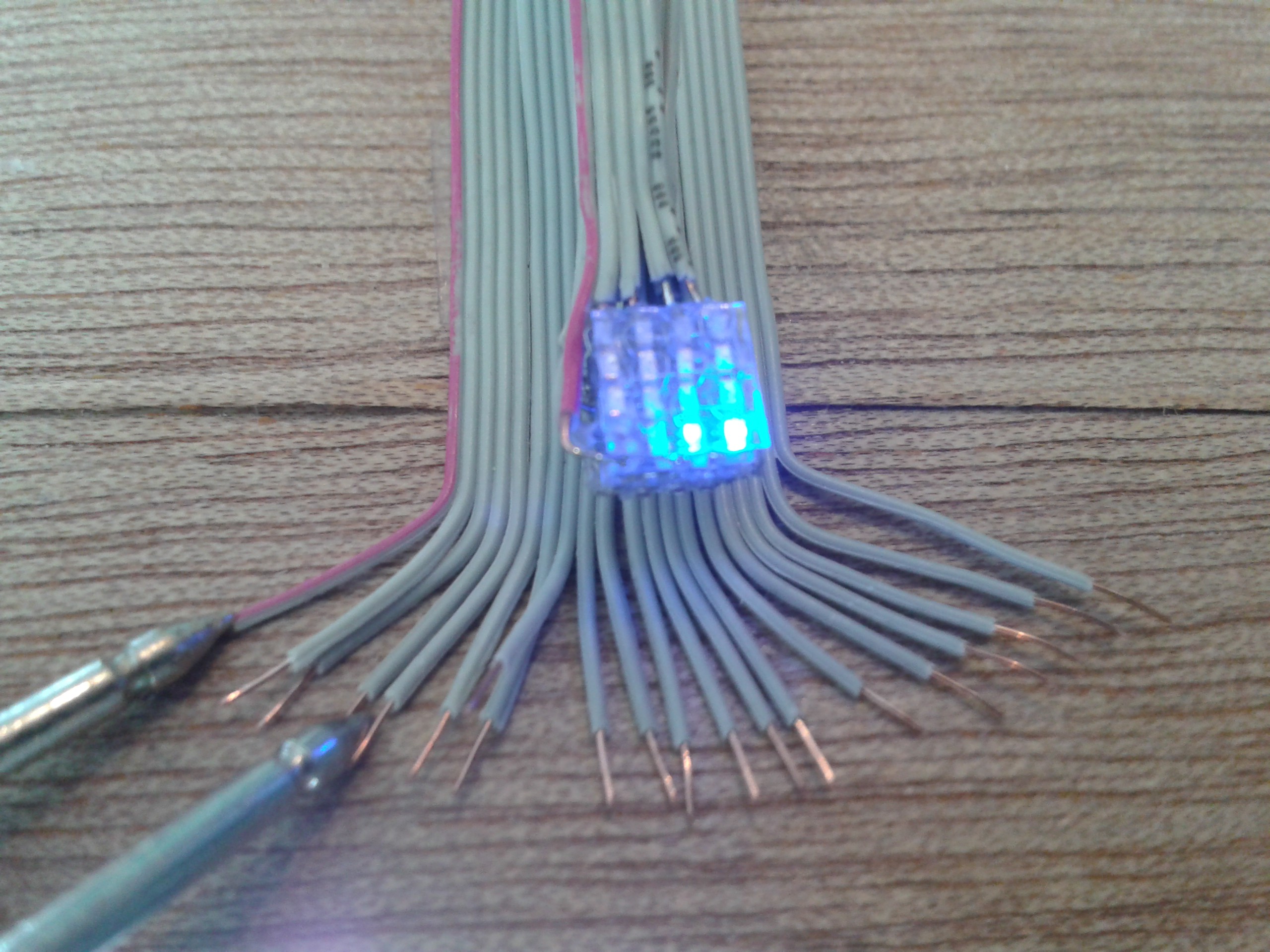

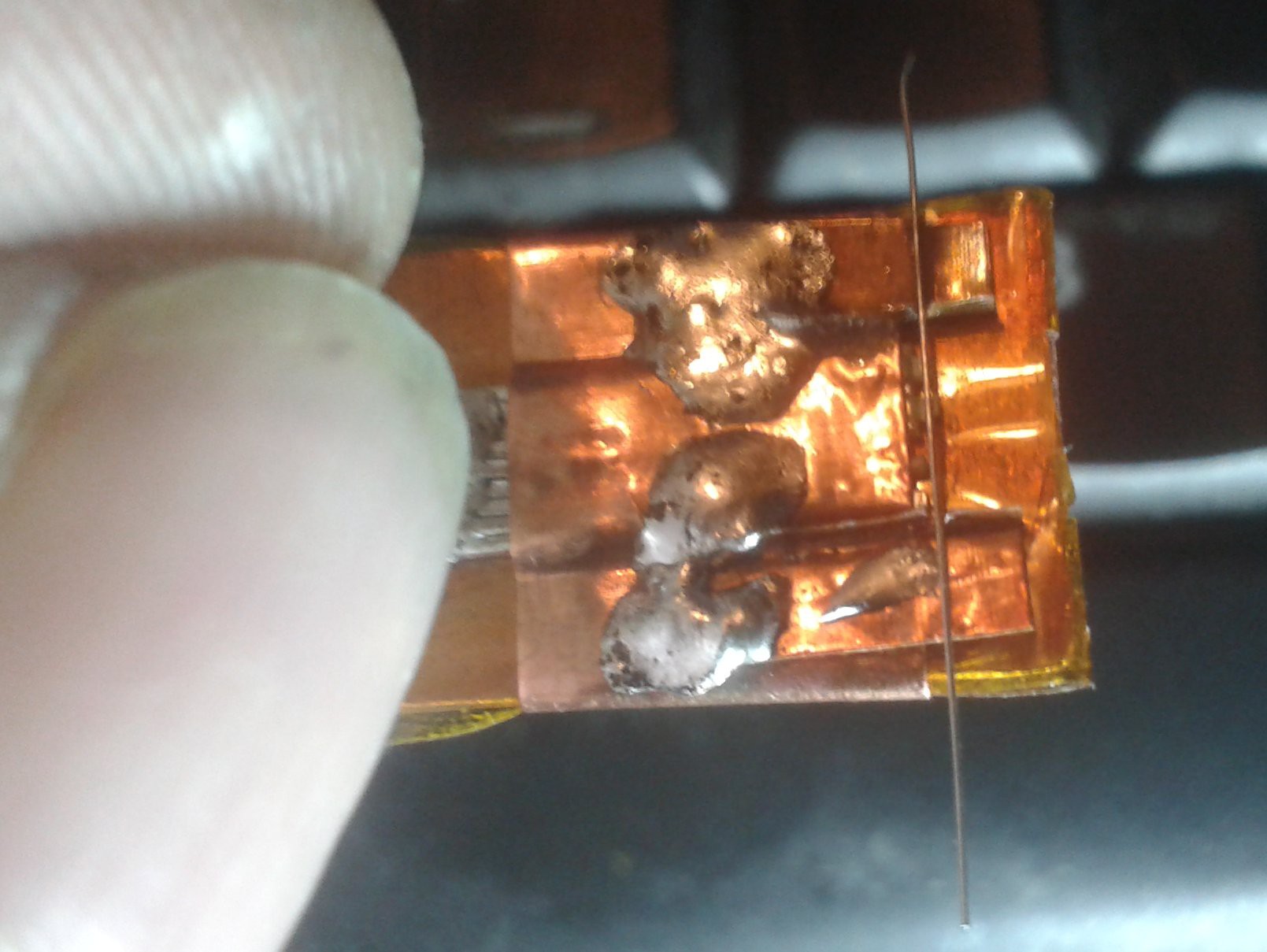

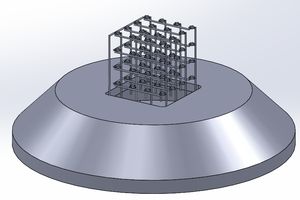

126 pieces in a 13x10x10mm cube, soldered freehand using a fine-tipped 15w iron. Despite testing each LED, row and grid so far to make sure there were no shorts I had grave doubts it would work 100%.

So far so good, all the LEDs light up when addressed by a layer and a column as they should.

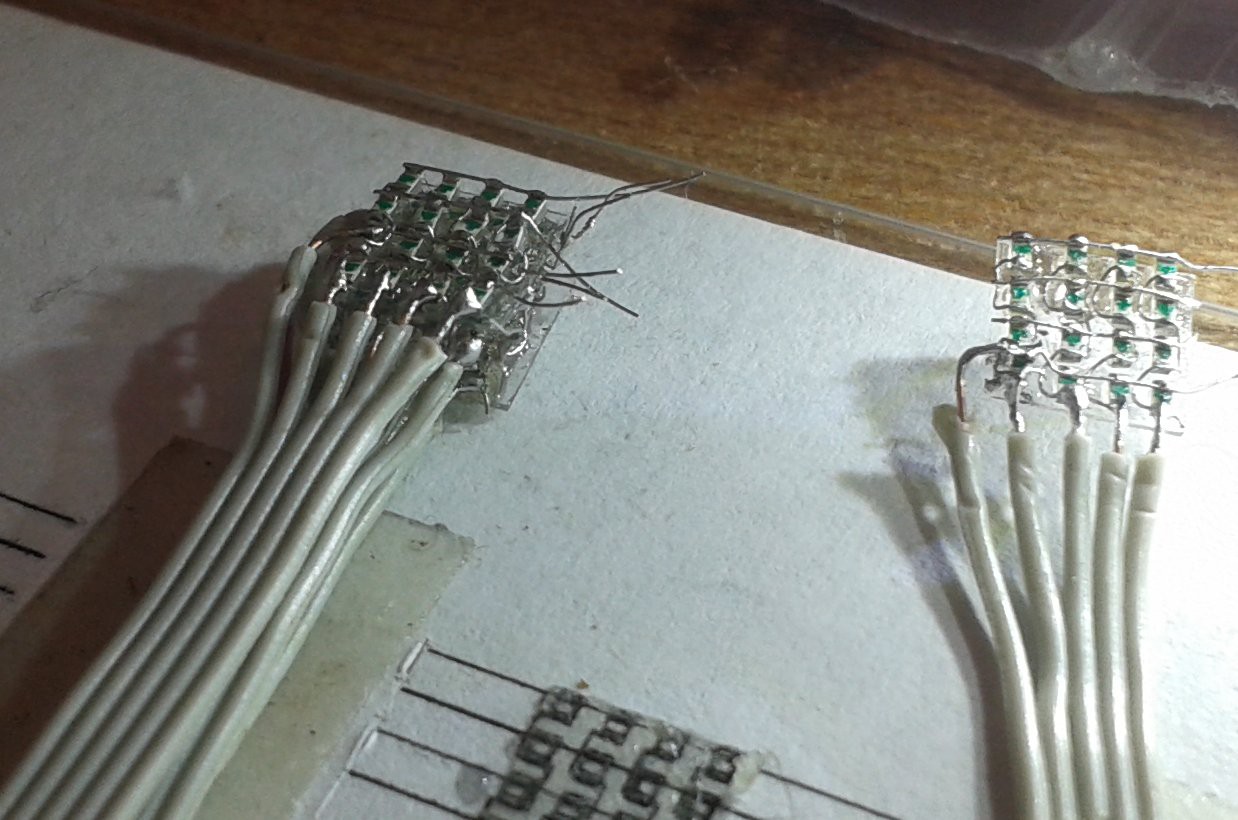

Now to wire it to a processor.. I hadnt thought about this much, (Oh, magnet wire...) until it came to strip and tin 20 bits of it and solder them to the tails. I did one. I did another. I touched the second one putting the third one on and it fell off, so I cussed and gave up. Some things are just too hard.

More than one way of skinning a cat

Putting 16 balls of solder on top of zipwire without burning the insulation was challenging enough without the device tails in the way. I gave up trying to get row three on when I inevitably spilled one next to the one I was trying to bury the bearer in.

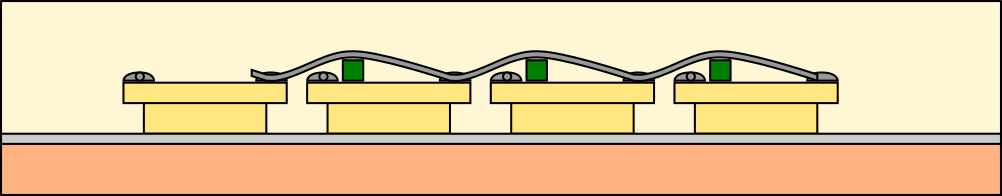

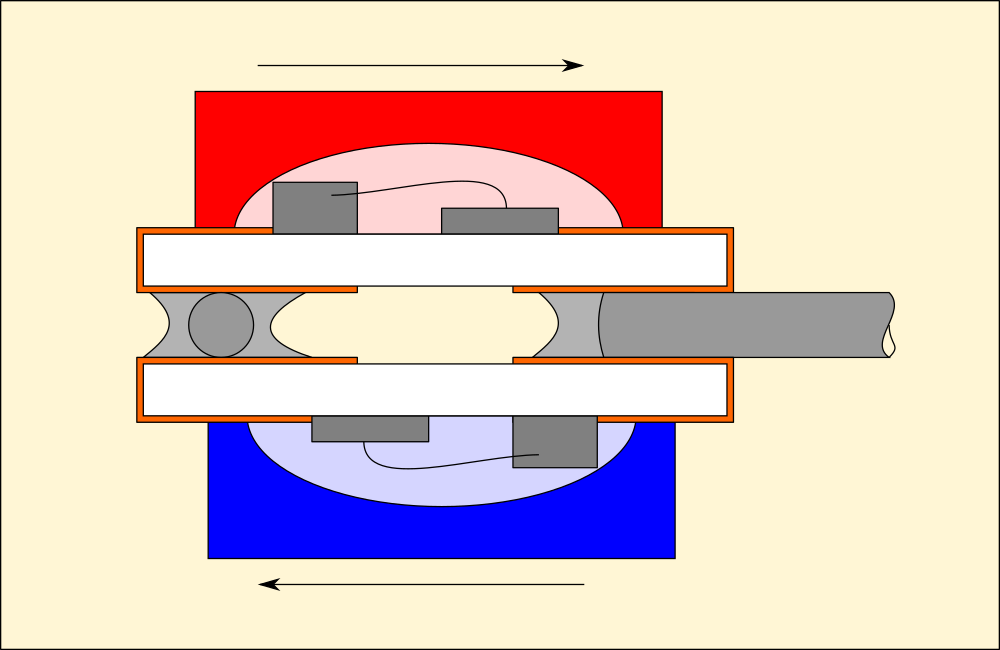

Step 3, Conduction soldering.

In the end I cut them off, and replaced them with long thick wires threaded through the board. Soldering them into place at the board also heats the far end, connecting them to the LED at the same time. I tinned the ends first with a small blob of solder, mounted the cube on two corners and threaded them through first to hold it, and the rest were conduction soldered to the LEDs.

Remember not to hold the other end with bare fingers, the heat will travel as a wave up it and reach the far end, burning you on the way. Man I love copper... ;-)

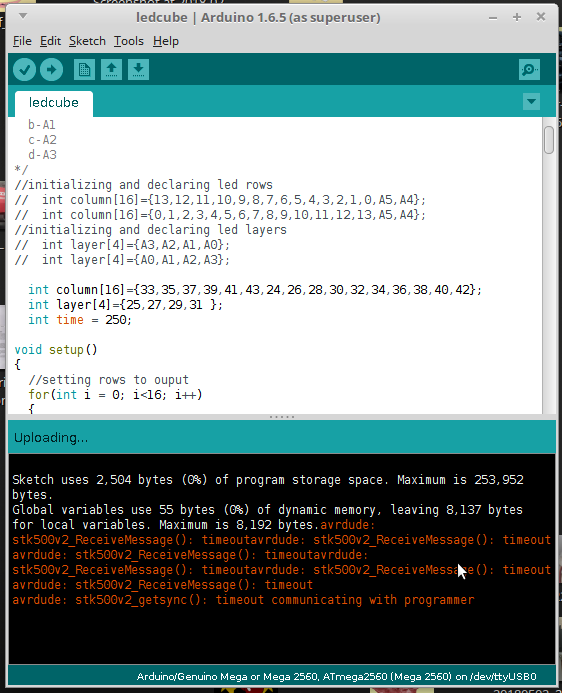

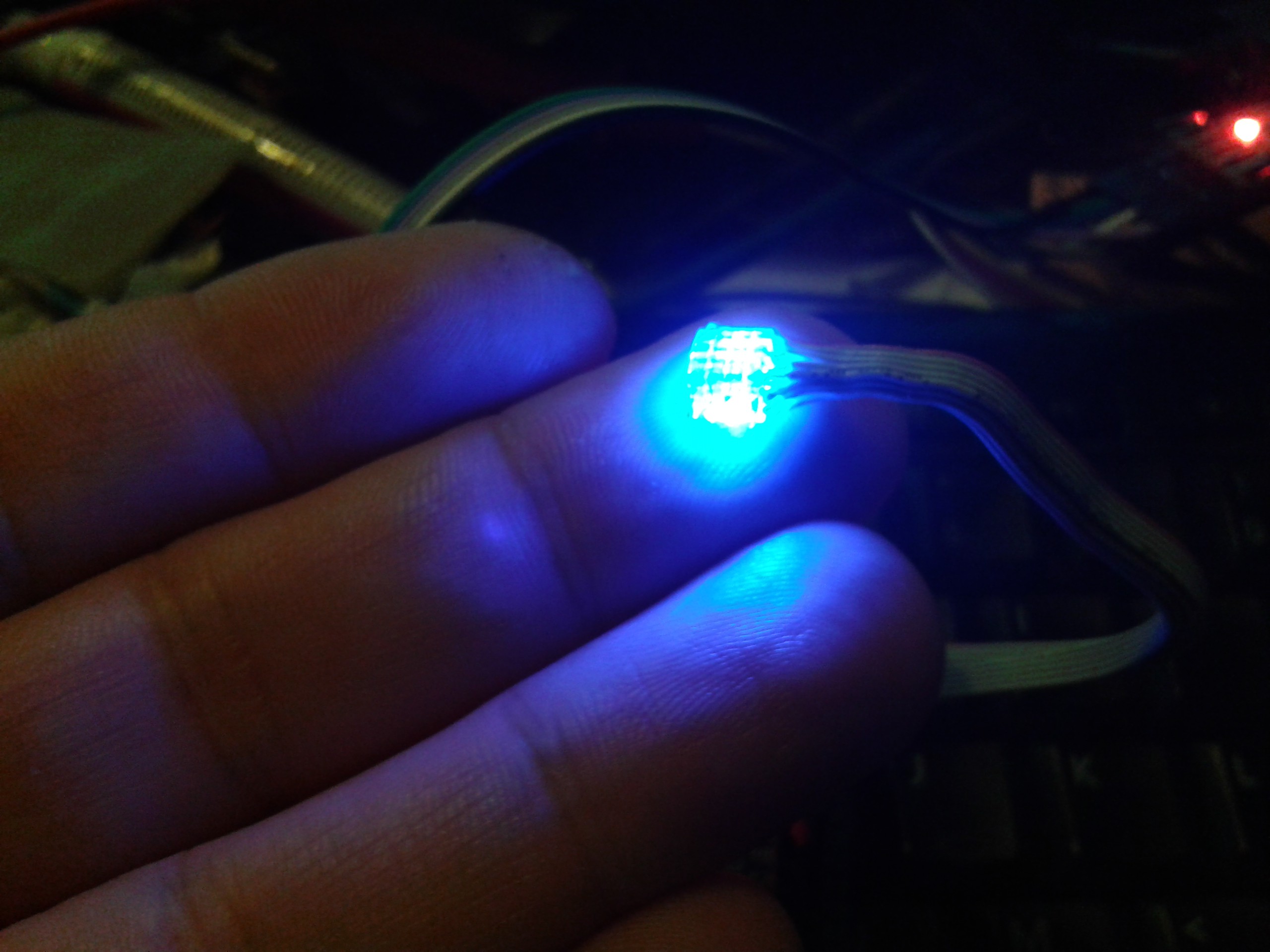

After adding a resistor network underneath for the four Anode connections at the layers, I hooked it up to a MCU and bingo!

The world's smallest deadbugged LED Cube, 13x10x10mm excluding mounts and electronics.

See the logs for details on how to make that even smaller and neater.

* New Feature * Outtakes

Sunday Morning Soldering Like A Bat

Morning.Star

Morning.Star

Neither was the soldering iron. I tried several different wires on this in an attempt to do two things. One, I dont have a TCO, thats a plain 15W Antex with a needle bit. Way too hot and too big, the tip is...

Neither was the soldering iron. I tried several different wires on this in an attempt to do two things. One, I dont have a TCO, thats a plain 15W Antex with a needle bit. Way too hot and too big, the tip is...

Kevin Arne

Kevin Arne

Jarrett

Jarrett

Sarah Petkus

Sarah Petkus

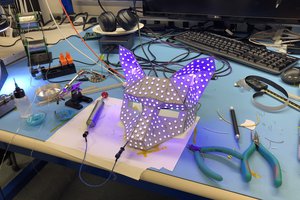

@Pete Prodoehl The other end of the spectrum from your cube.. :)