I bought a £29.99 glass table just for the glass although it had 4 of these metal adaptors glued in place. It was the correct size for the table project and it was tempered and bevelled glass (thought it'd be worth the risk). After a bit of research on the internet, I realised I had to apply enough heat to the adaptor to melt the glue used to attach the adaptor without risking too much heat to the glass.

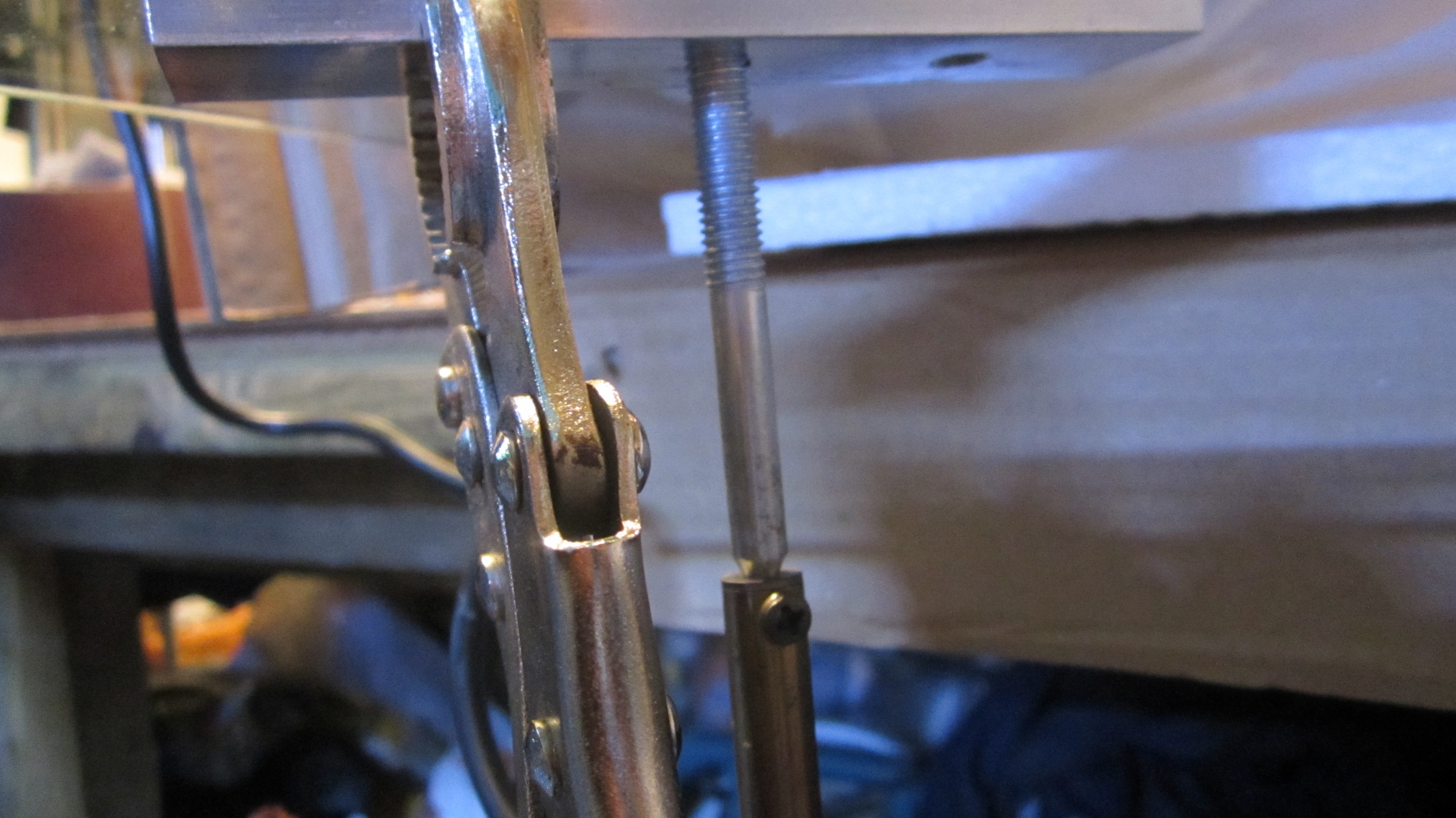

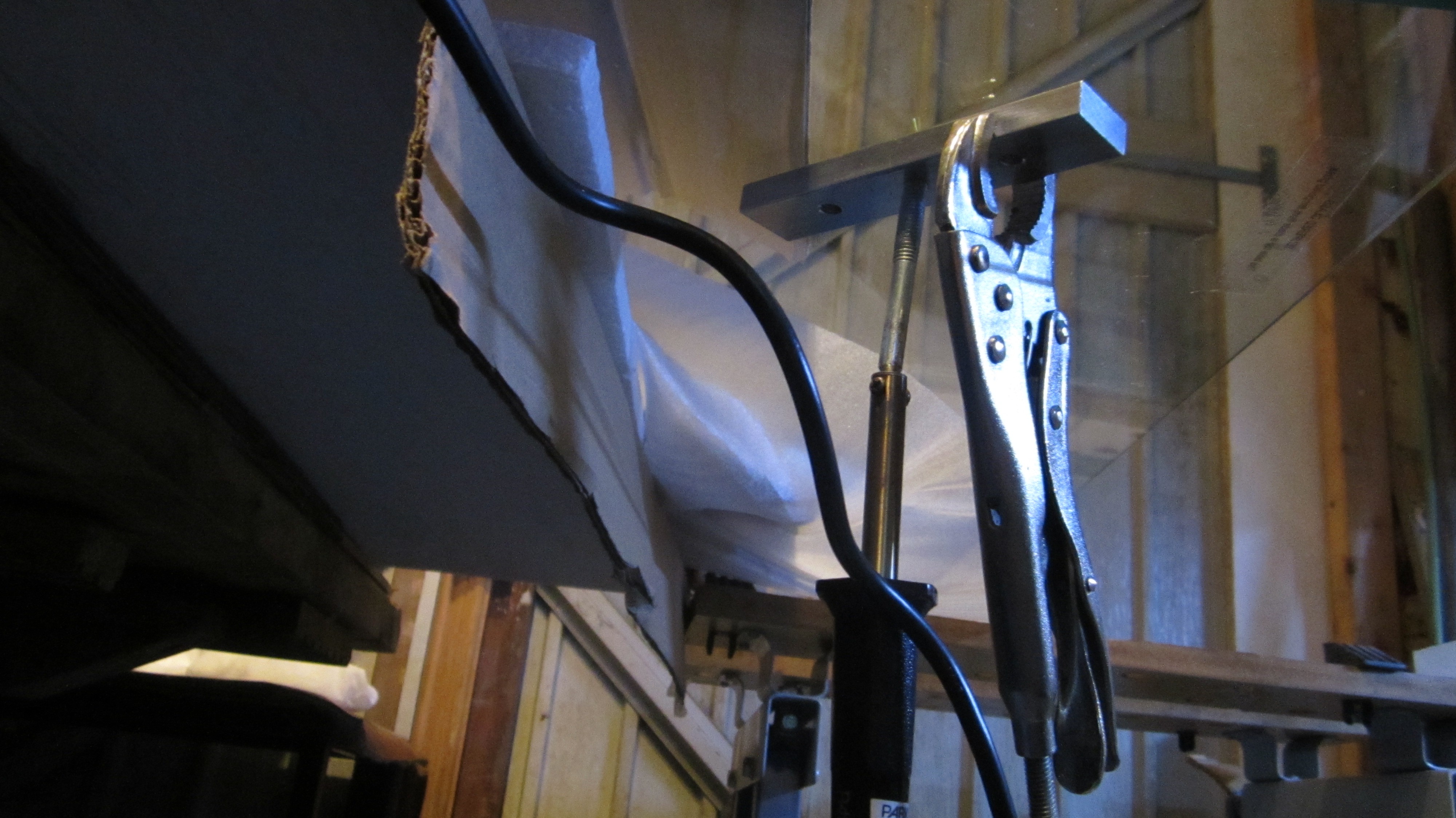

I used a soldering iron and ground down a steel bolt so it would replace the tip and could be also screwed into the metal adaptors and rest there while heating up. While it was heating I clamped some mole grips to the metal and applied a constant downward pressure to it until the glue got to its its melting / softening point (500 degrees?)and it comes away. So no heating of the glass and just enough heat to get it off.

Worked great and we now have a clean piece of bevelled tempered glass for the project.

While it was heating I clamped some mole grips to the metal and applied a constant downward pressure to it.

It took about 40 mins before any signs of softening.

The bubbles began appearing on the edge and spread across the adaptor.

Just drops off when soft enough without any damage to the glass, just another three to go!

Steve Wells

Steve Wells

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

By the way, this is really informative and useful information. To know more hacks related to the glass industry, visit https://www.glassstructureslimited.com/glass-staircases/ where you also can find professional specialists to make glass staircases for yourself!

Are you sure? yes | no