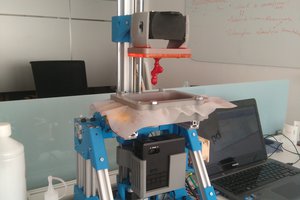

One of our focal points for the development of Hector 9000 is, to make it as easy as possible to replicate the machine. Thus we

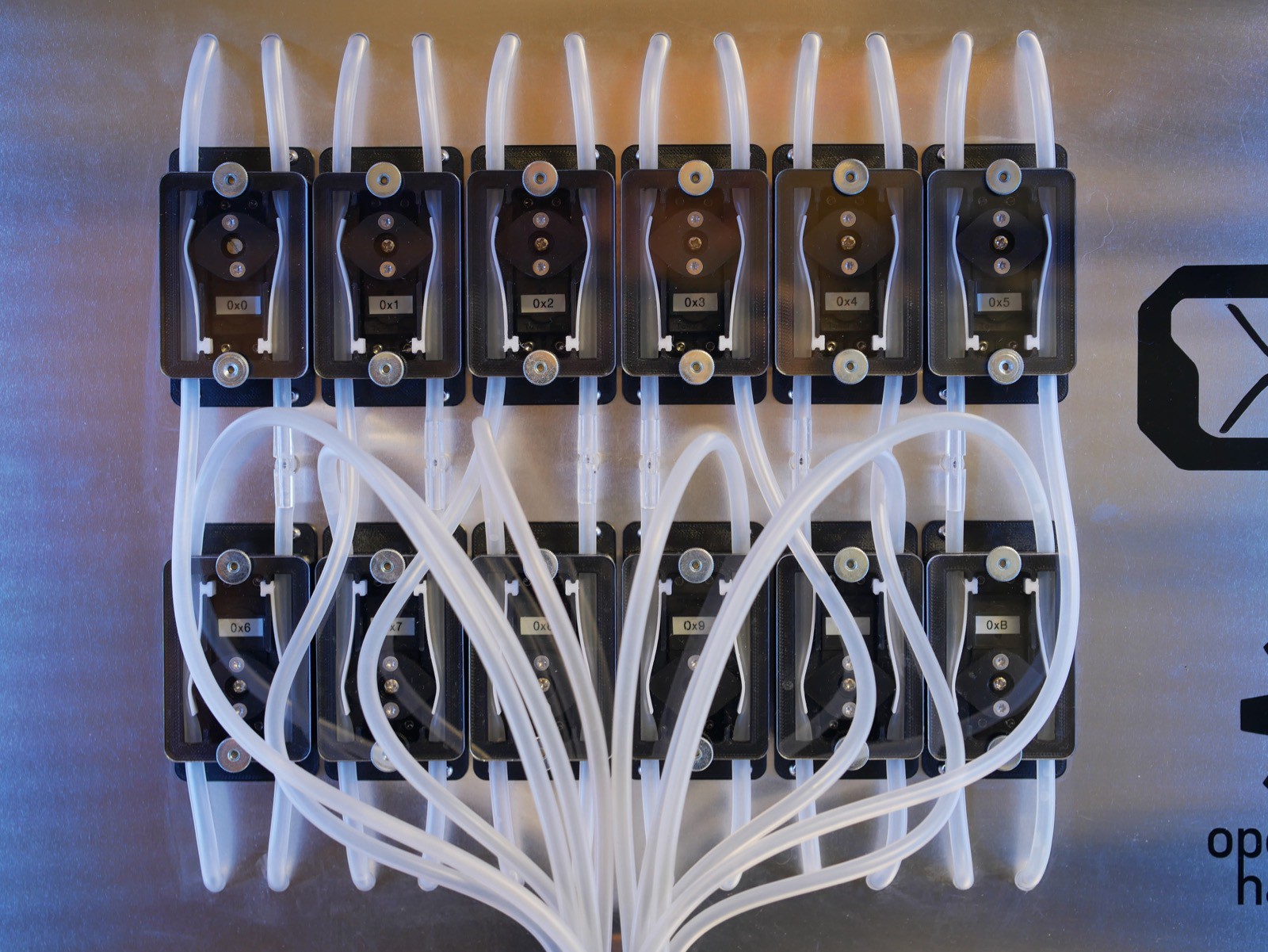

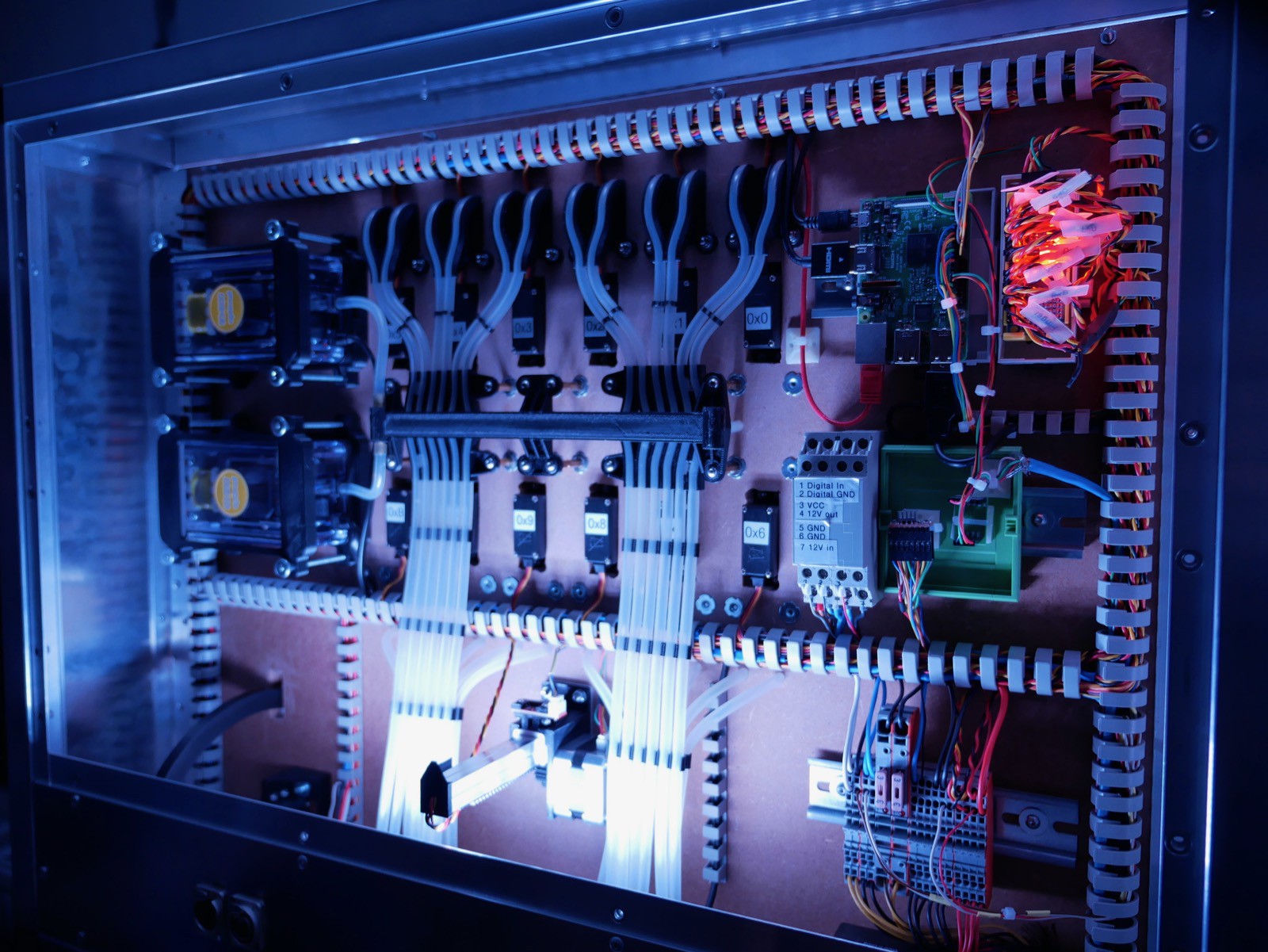

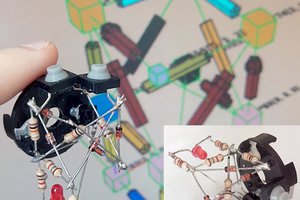

- used of the shelf & easy to source electronic components

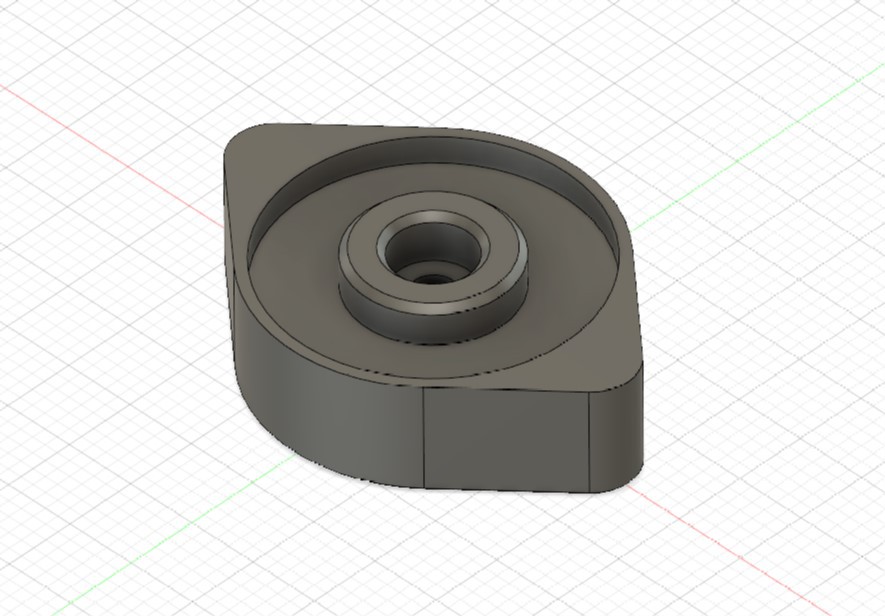

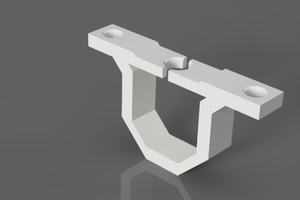

- made the mechanical hardware parts mainly by FDM printing (without support)

- host the software on GitHub

- try to make a good documentation

We also made most of the functional parts independent from the structural parts to give a high degree of freedom for an individual case/cabinet design.

During the work on Hector 9000 we had a lot of ideas for additional features and improvements. Here are some of them:

- Ice dispensing unit

- Cocktail Umbrella dispensing unit

- Dispenser for sugar

- GUI based on Qt

- Statistic functions (Best Drink of the Day, ...)

- AI to create new Coctail recipes

Cadmium

Cadmium

Frank Herrmann

Frank Herrmann

Jaime García

Jaime García

Brien Allison

Brien Allison

Anderson Antunes

Anderson Antunes

Hallo.

Welches Relais Modul wurde für die Ansteuerung der Pumpe verwendet?

Grüße Michi