This project was part of an Industrial Design Capstone (Senior) Project through Jefferson University, East Falls Campus in Philadelphia, Pennsylvania. Progress is ongoing.

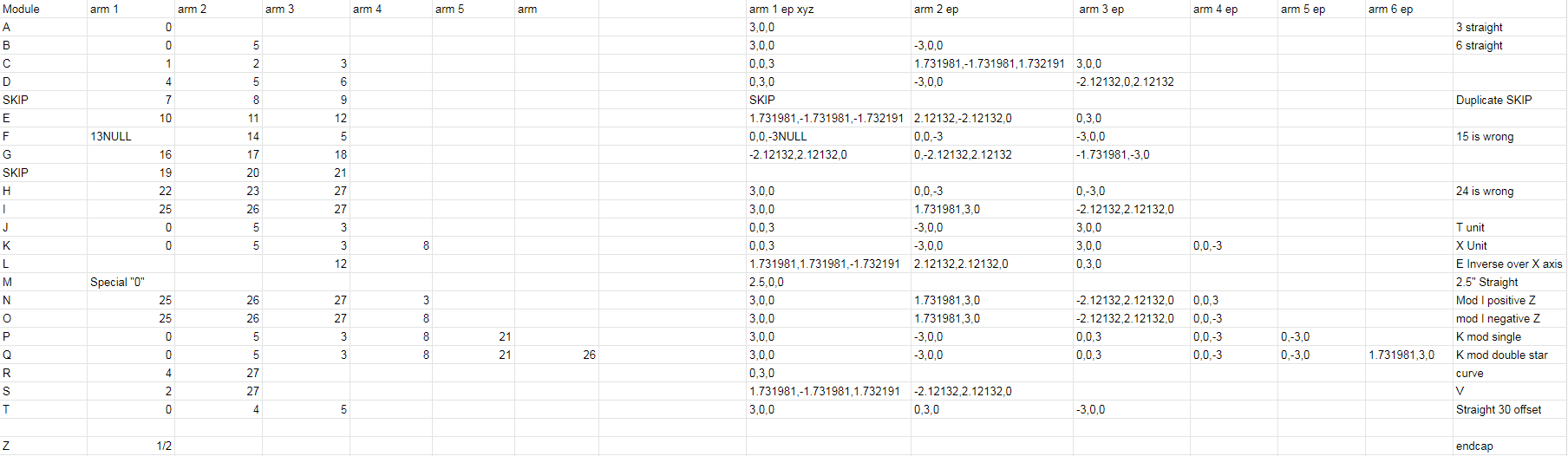

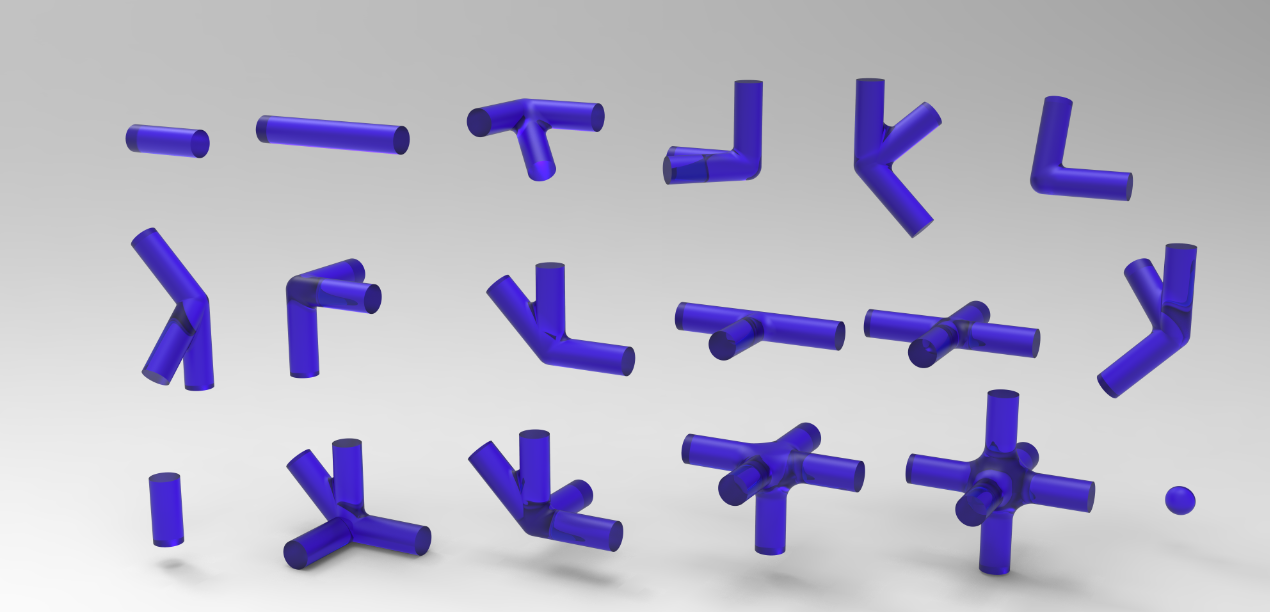

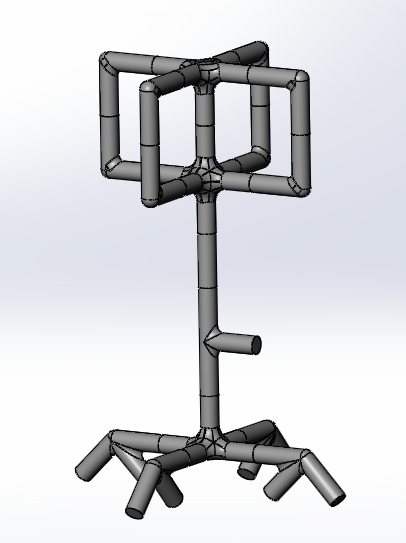

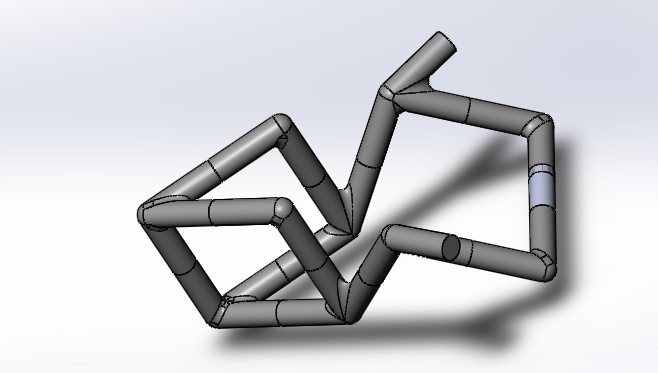

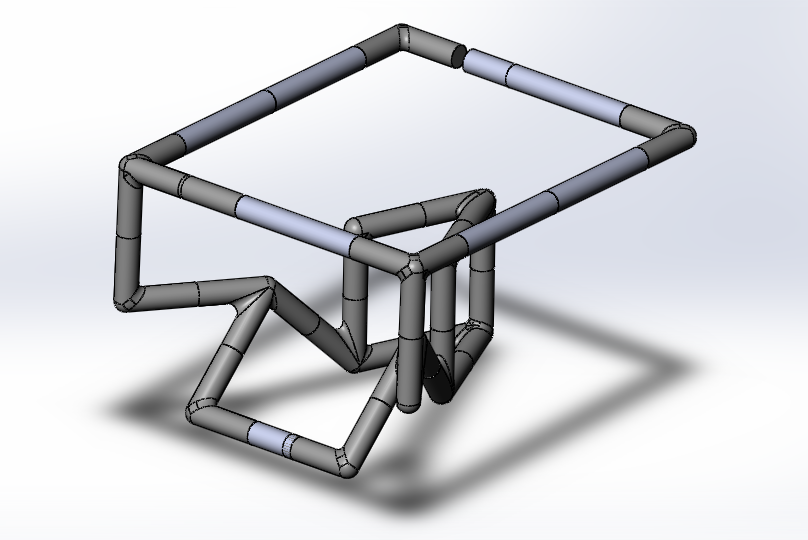

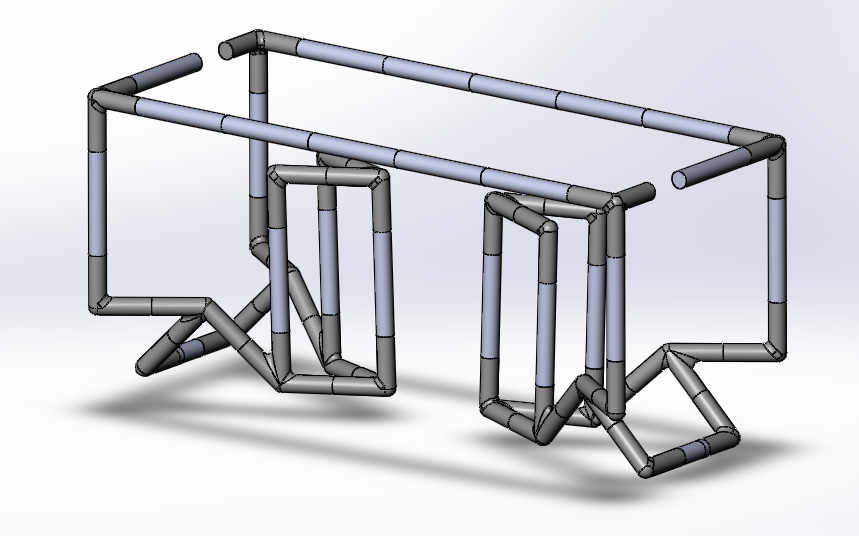

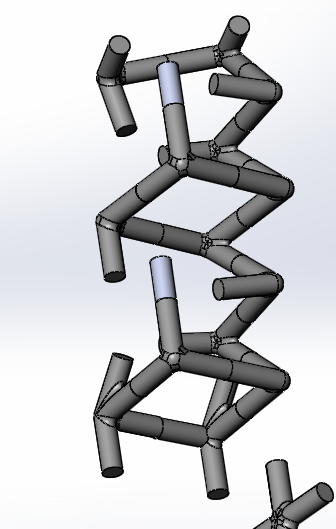

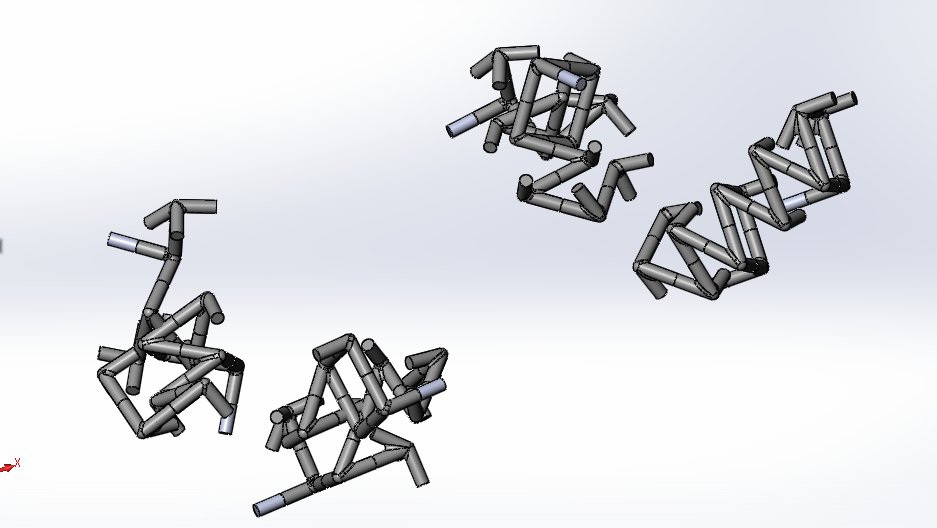

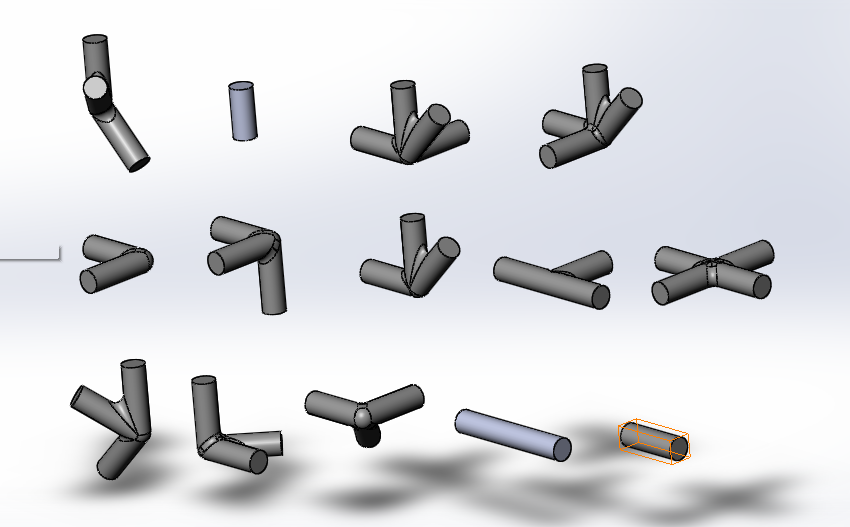

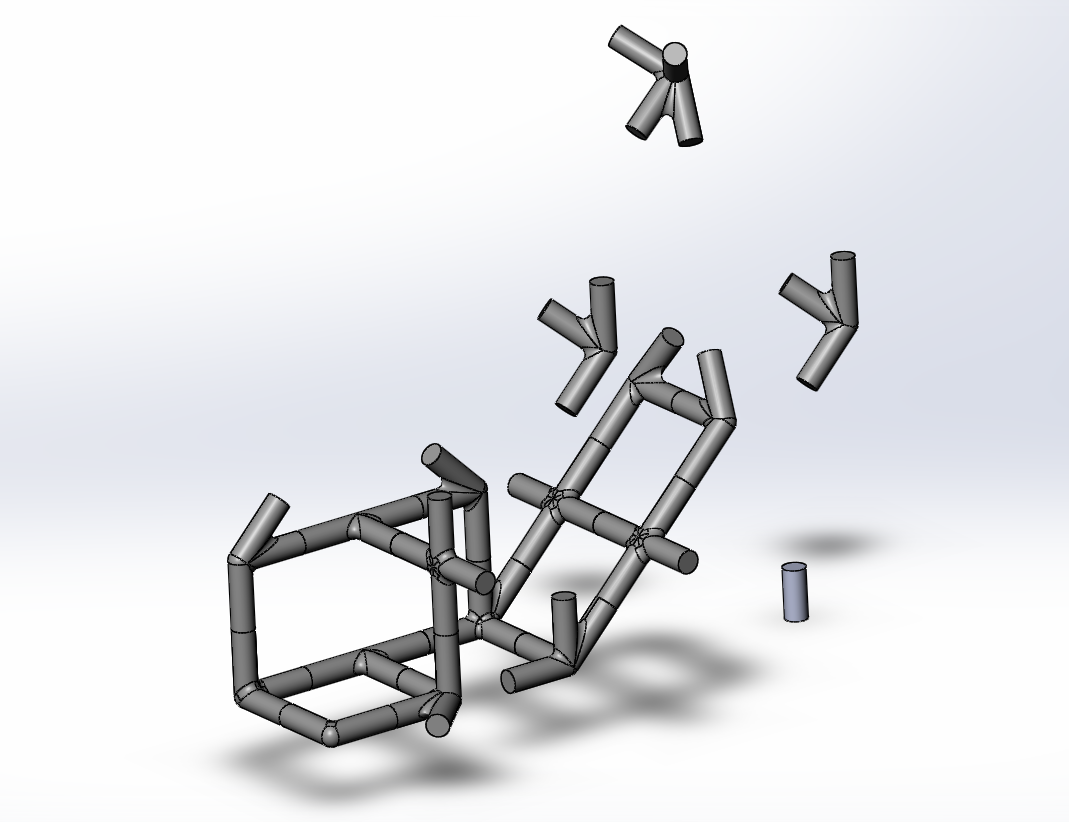

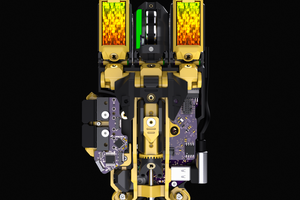

Generated using Grasshopper and Rhino 3D:

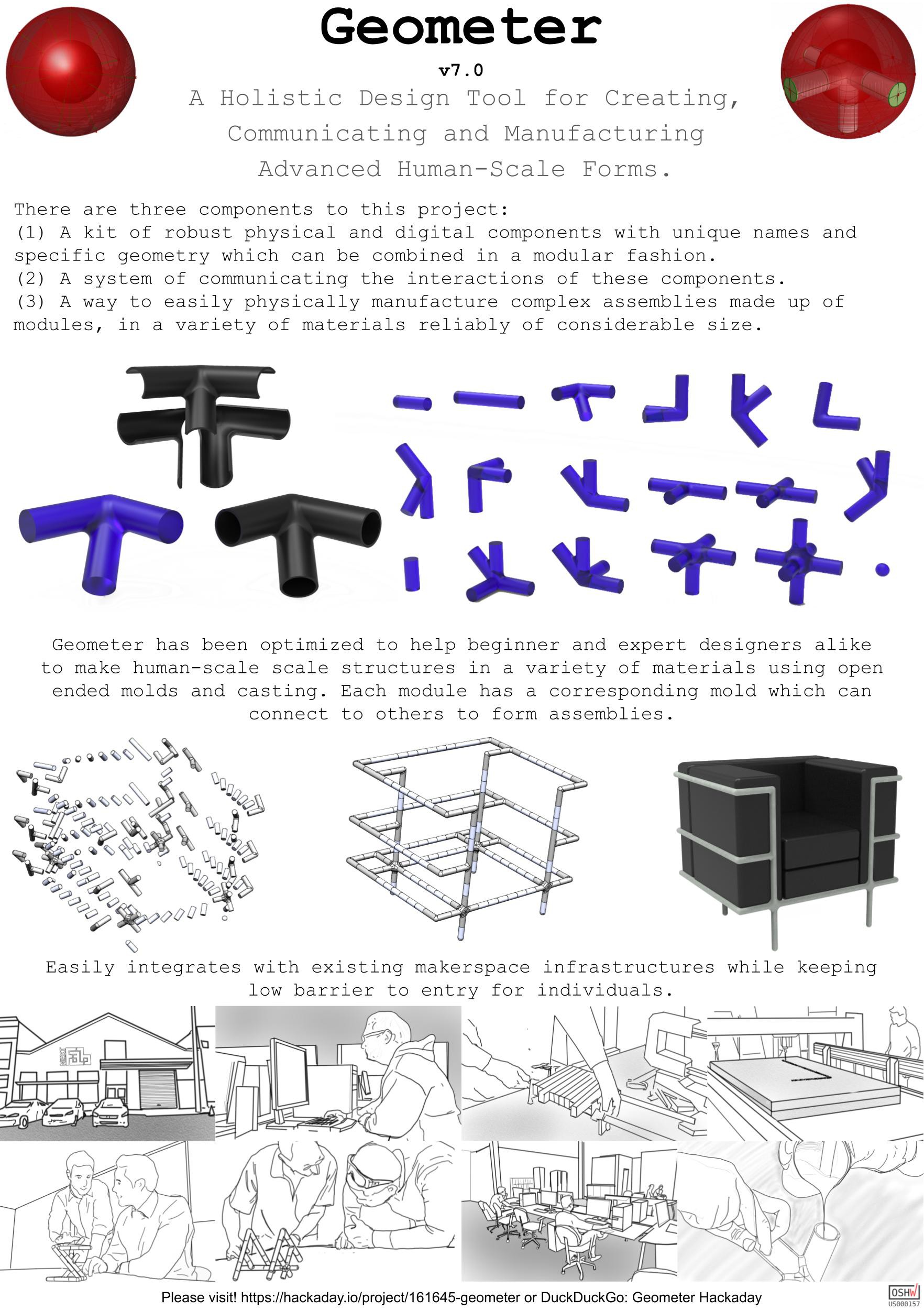

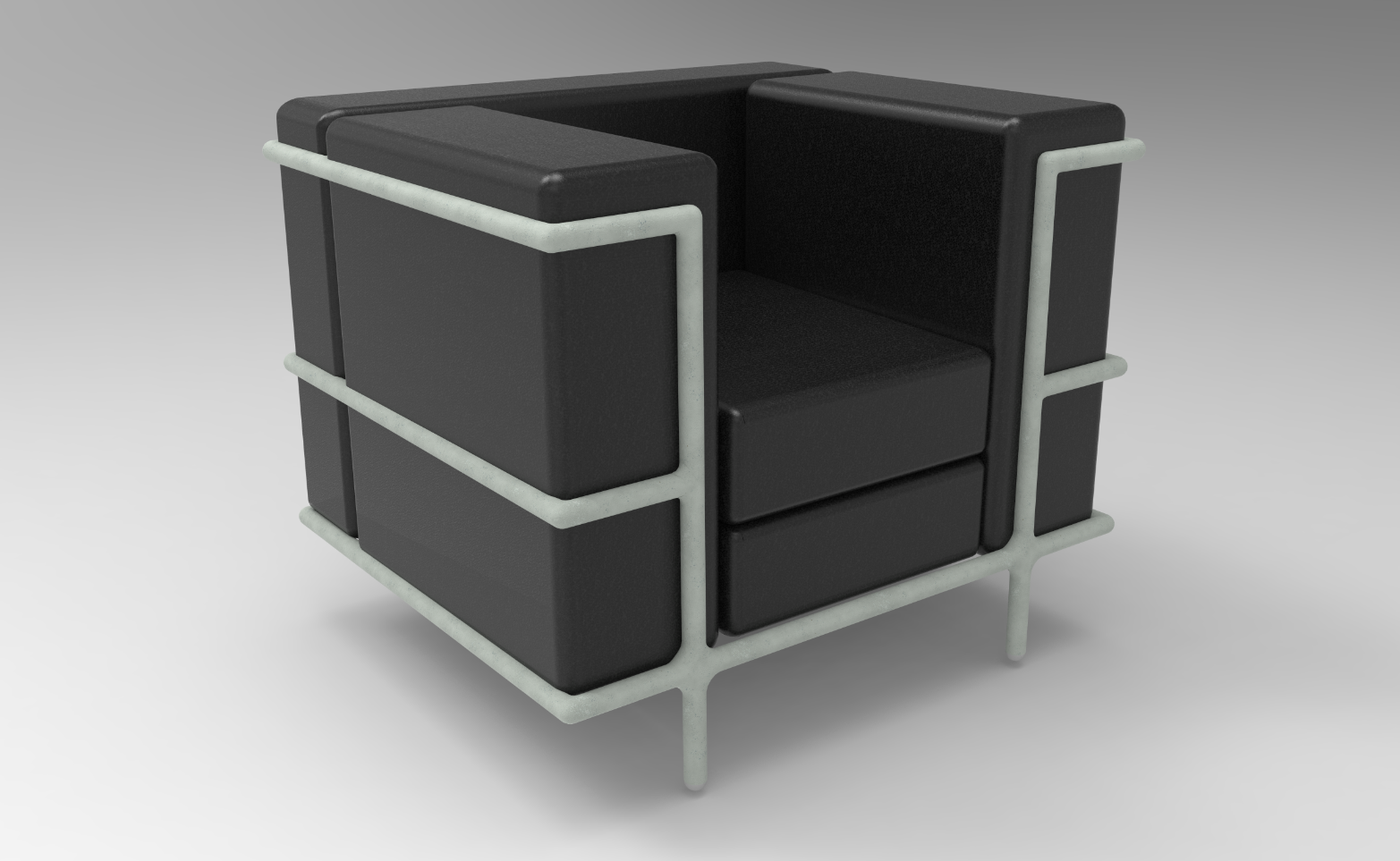

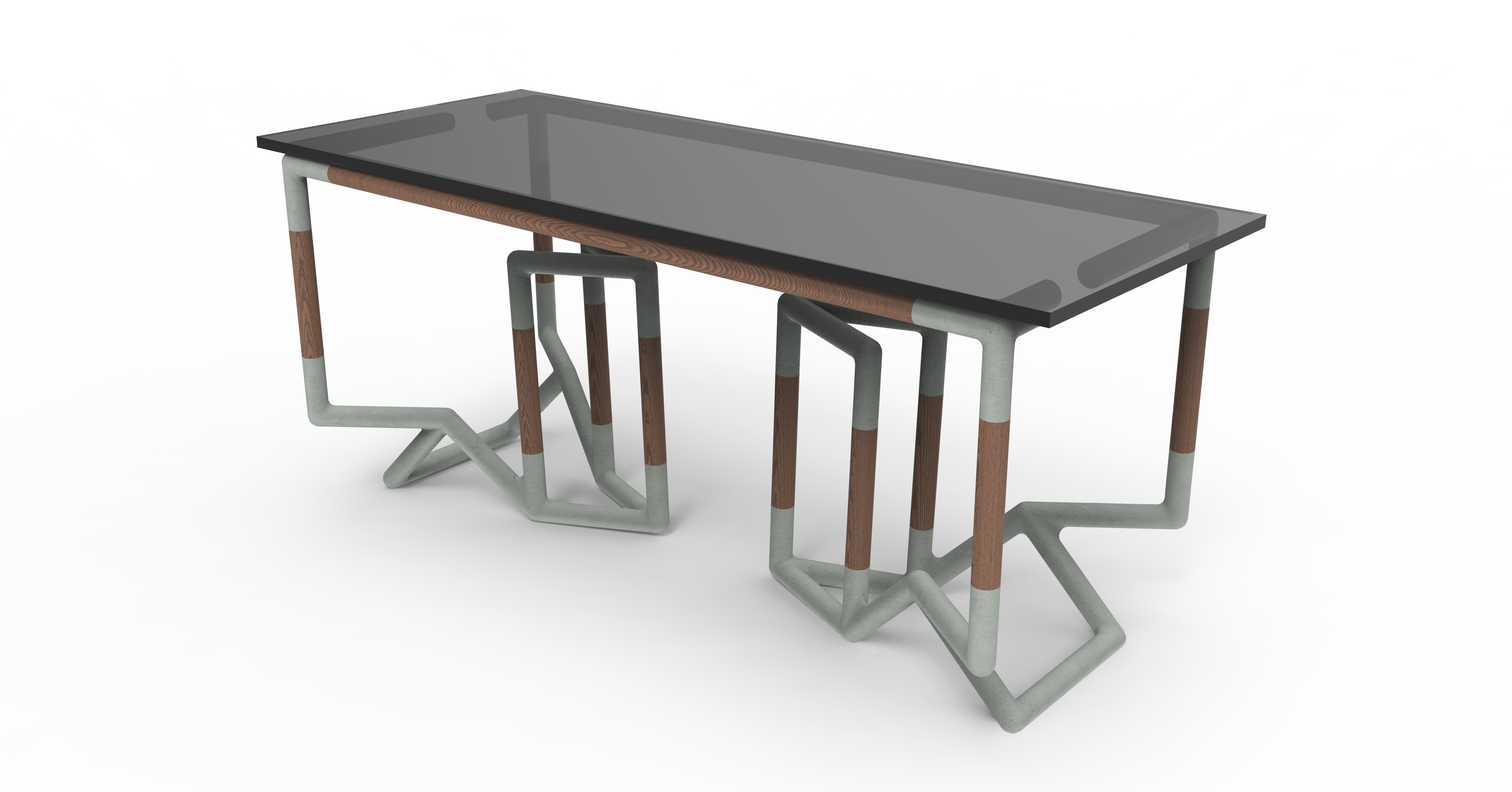

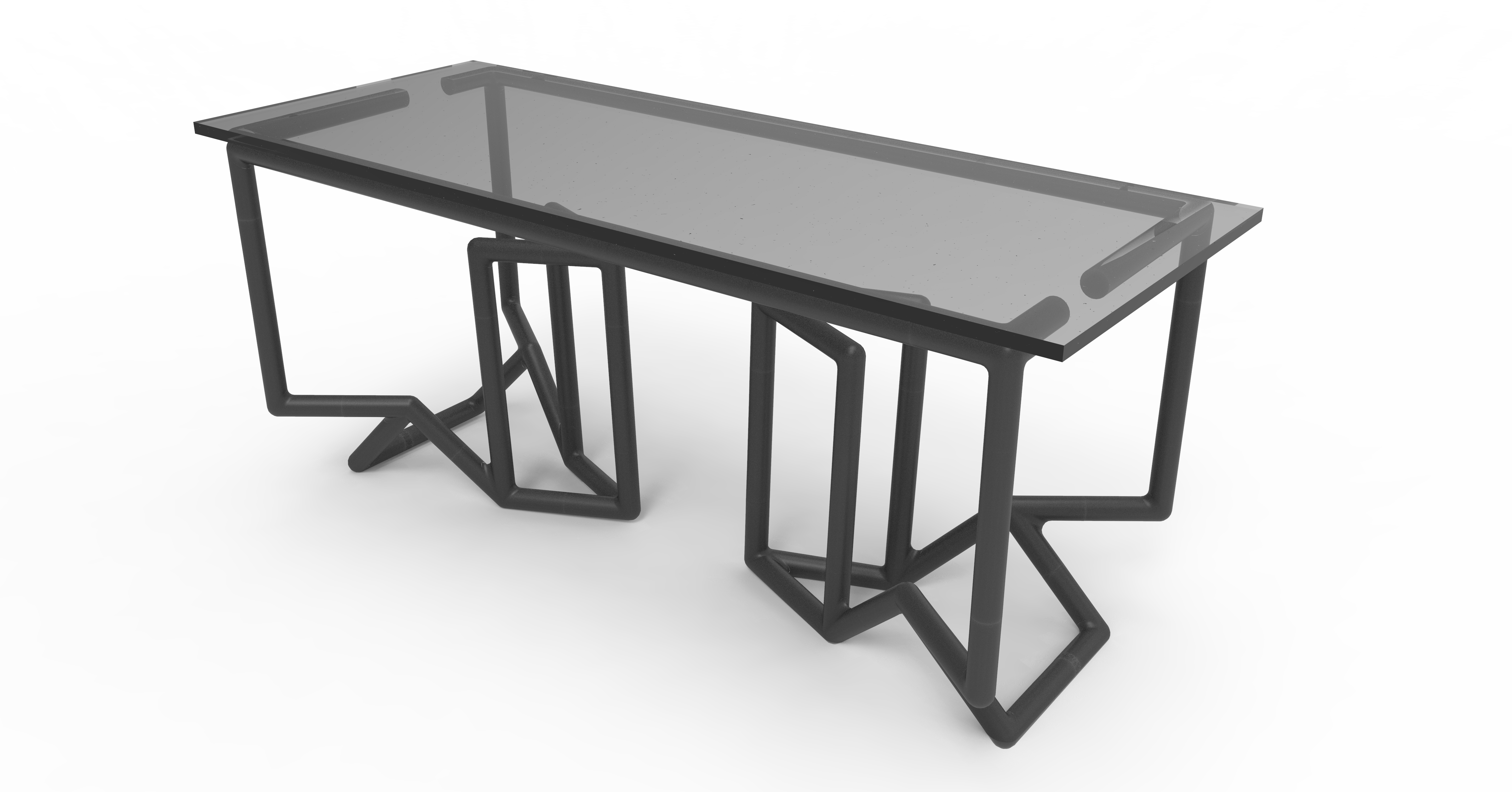

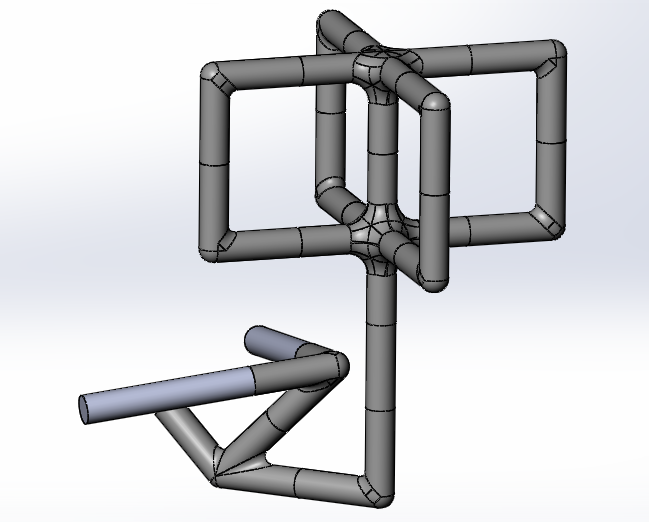

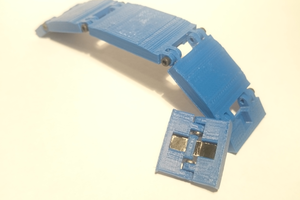

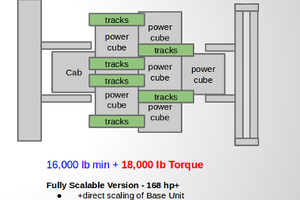

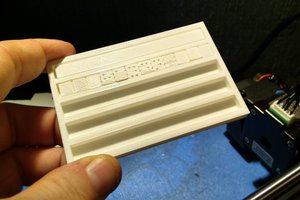

Using open ended molds based on these reference modules, complex assemblies can be easily communicated, understood and manufactured.

Licensed under CERN OHL v.1.2 or later http://ohwr.org/cernohl

Geometer by David Troetschel is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Geometer by David Troetschel is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Permissions beyond the scope of this license may be available at dtroetschel@hotmail.com.

Open Source Hardware Association Certification https://certification.oshwa.org/us000157.html

As of 8/2020 an effort to combine Geometer and Wasp has been started, in essence this was the missing component of our capstone project! Even with only three modules and no rules this is very powerful, check it out!

David Troetschel

David Troetschel

novirium

novirium

marcin

marcin

haydn jones

haydn jones

benw

benw