We are finalizing set five, we are going with a chord length based fillet operation.

As this is finished we will be converting to OBJ for use in VR.

We are installing Mindesk https://www.food4rhino.com/app/mindesk-vr to hopefully enable easier design workflows.

I am starting to compile the spreadsheet with proper naming conventions for each module, once that and all files are in usable formats they will be uploaded. Molds will follow shortly, they take a little more planning and intentional input when it come to three and four legged modules.

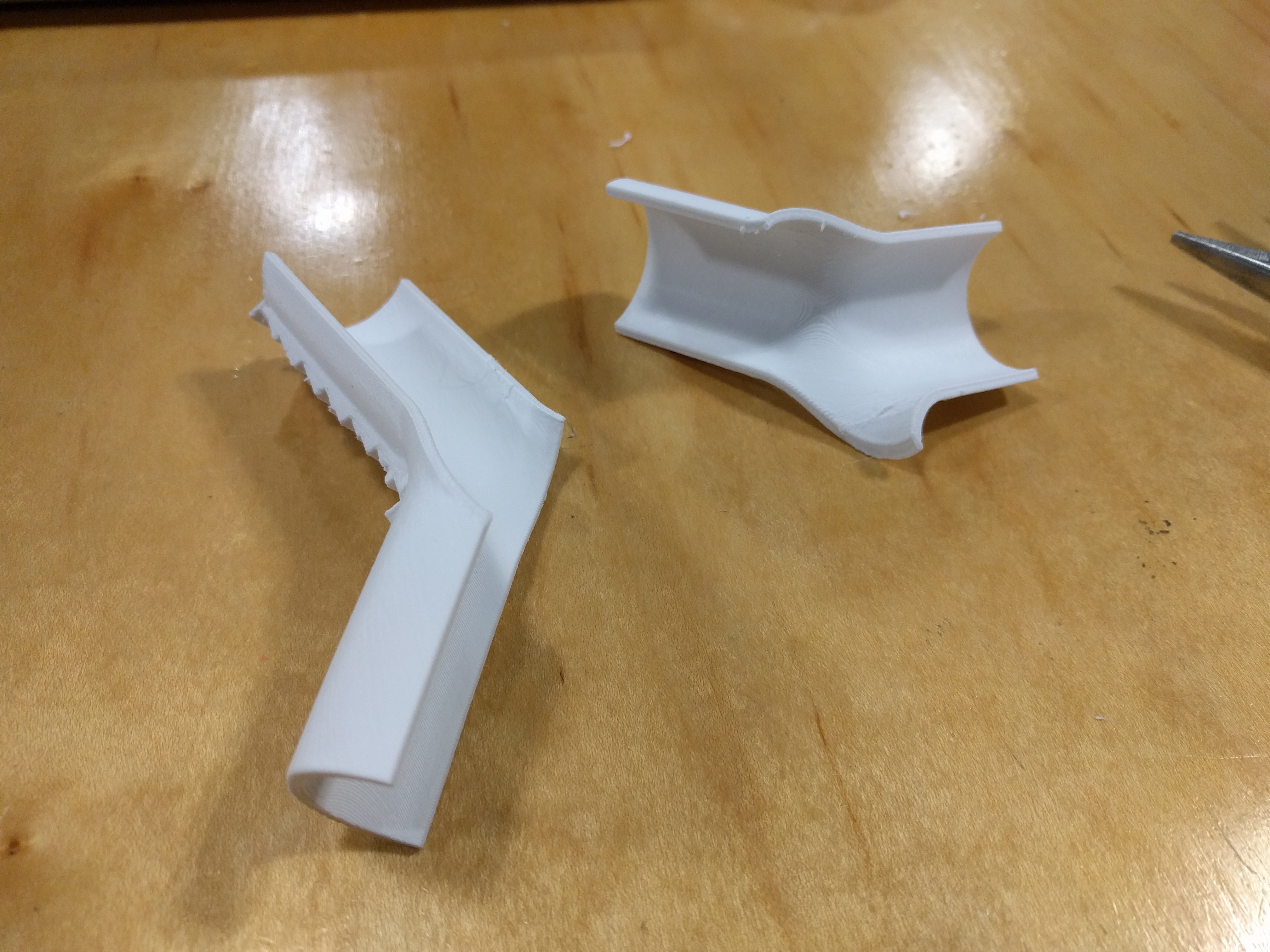

Module A mold and end caps for use with Instron Machine.

Two parts of one of our most complex modules, it needs to be four parts to guarantee removal after casting of an assembly. This was done quickly on a Dremel 3D printer by DIVE Design.

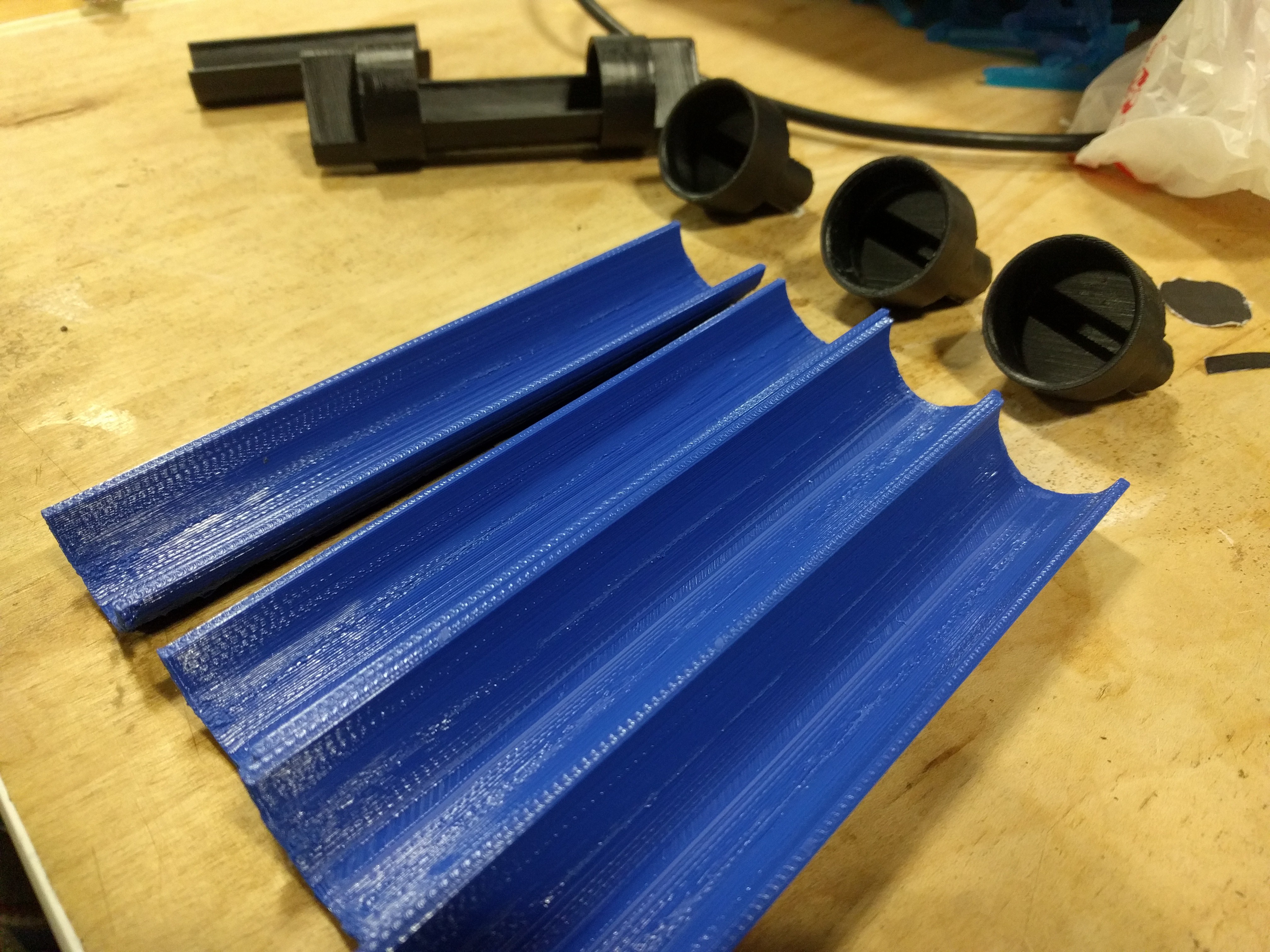

Module B and A in the background with adapters for Instron Machine.

Rubber bands are used here to test fit, but if we were to assemble more than one module together we would be unable to remove them easily. so we are investigating using something like velcro or silicone cinch straps.

We are also considering using worm drive metal bands.

Our efforts to try and find a more dense version of our substrate (Hemp Hurd) have come to fruition. Our original material on the left has much larger particles, which should theoretically give more strength... if it wasn't a problem having more to do with delamination of the mycelium. Either way, we have something now about twice as dense (to be measured.) Our hope is that it will prove stronger. If this happens to be the case we will try to reproduce results using a food processor or related, the main concern is that you don't want to potentially contaminate everything with mycelium spores.

We will be conducting testing on the above Instron machine, looking principally for tension and compression ratings. Unfortunately the jaws of the machine only open to ~.25" where our nominal thickness is 1" for modules. Thus, an adapter is needed and will affect our test results if not considered. As time allows we will do comparative studies of other materials using the same molds, this will hopefully help us tune our theoretical model with better understood materials.

The bulk of our Hackaday page is slowly getting updated as we have expanded our ambitions for this project and clarified other goals, hopefully the new descriptions will be more straight forward. Please let us know any feedback related to our technical communications.

David Troetschel

David Troetschel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.