It's very inefficient to 3D print every joint connector for the snap together sets.

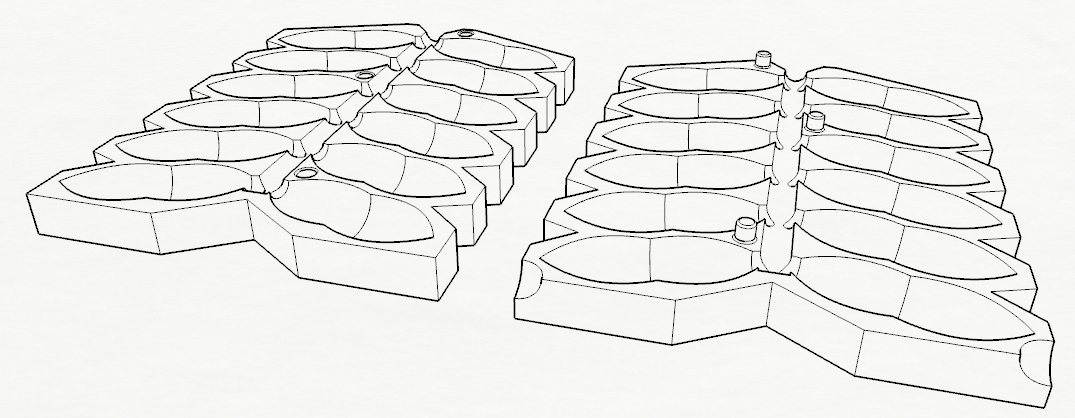

Since this type of medium seems like it will be so popular, I made a mold.

With this you can connect twelve modules together with a single casting. I think that expanding on this and making a tree which has enough connectors for an entire "set" will make sense. The end user can cut them apart to save a little labor and organizational nightmare.

If we decide to really scale up production an alternative design will probably make sense. This mold only looks complex to save some some material on the printer.

Once a casting is made the master can be used to make more molds exponentially.

Making molds for the actual snap together modules will be a little more annoying.

Right now I am thinking a block mold with a five piece insert assembly for each end point... Definitely not the simplest of setups. It would likely require the precision machining of small metal components. At that point we'll be so close to automation that I might as well go the extra step and make a machine with jigs and everything.

David Troetschel

David Troetschel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.