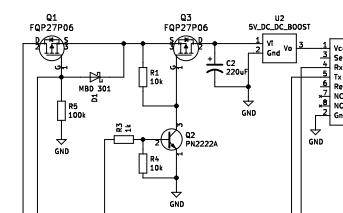

Building the power conditioning module for the particulate sensor is the subject of this log. The components in this module include all of the MOSFETS, transistors, diode, and the DC-DC boost converter. An overview of the modules was described in Modular Design Concept

The purpose of this module:

- Provide 5V power to the particulate sensor, for both USB and Battery power

- Provide a 3.3V compatible digital signal that will allow the MicroPython code running on the ESP32 the ability to turn off the DC-DC converter. Turning off the DC-DC converter eliminates the power consumption and noise of the particulate sensor

The components are shown below. The full schematic is here: schematic.

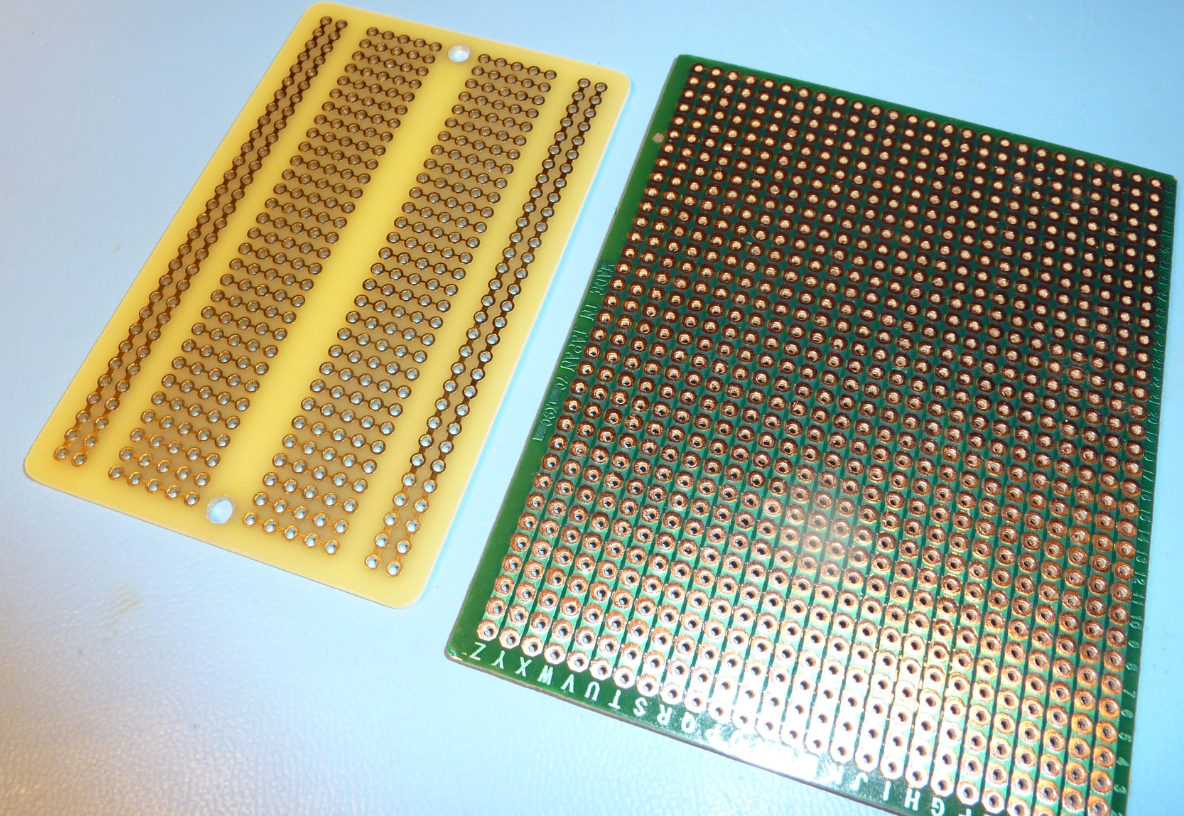

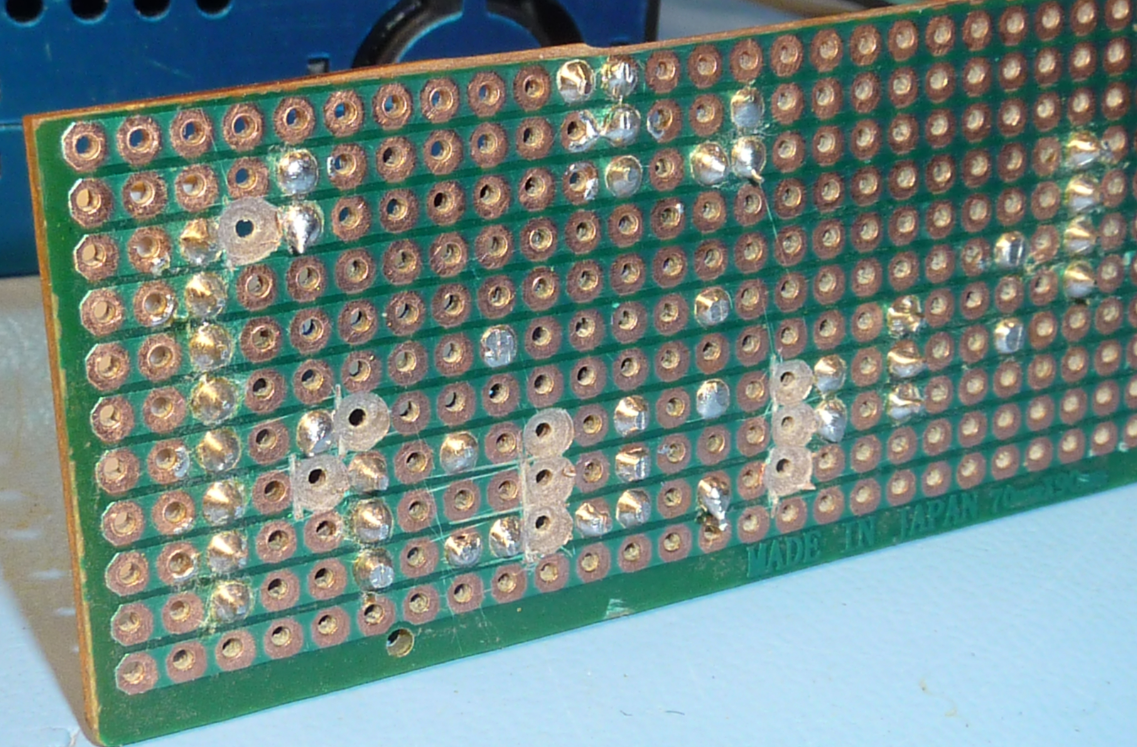

A soldered protoboard will be used for construction. For protoboard, I either use Adafruit Perma-Proto (left in photo below) or a generic stripboard (right in photo), cut to a custom size.

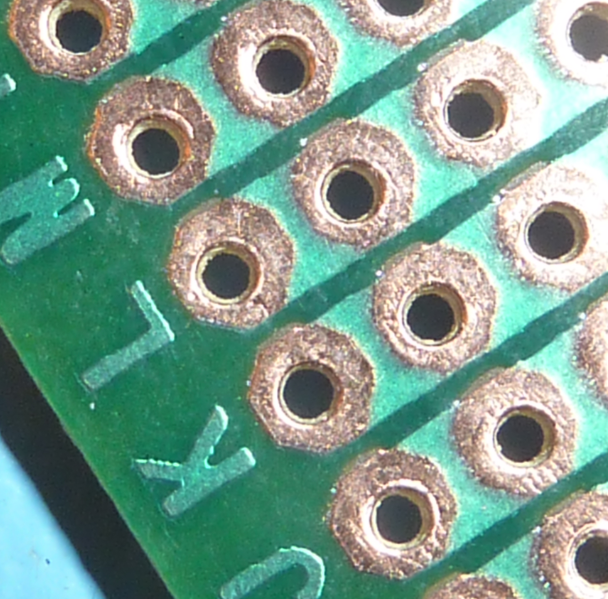

The Adafruit product is high quality - the through holes are accurately drilled and plated. The stripboad is somewhat lower quality - no though hole plating and inconsistent drilling which can lead to track lifting if there is any rework. The photo below shows some of the off-center drill holes on the stripboard.

However, compared to a Perma-Proto board a stripboard module can be designed with a denser component layout, leading to a smaller module. In the end, the need for a small module size led to the selection of stripboard.

Related stripboard idea: There is high quality stripboard that is available, but it comes a significant price premium. I think it might be possible to design a stripboard in KiCad and then have it built by a custom PCB manufacturer. I am seeing low-cost PCB manufacturers offering 3 PCBs (10cm x 10cm) for USD $10 + shipping. These PCBs would have plated through holes and solder resist between the holes, and hopefully accurate hole placement. I might explore this avenue and document the results in a Hackaday project.

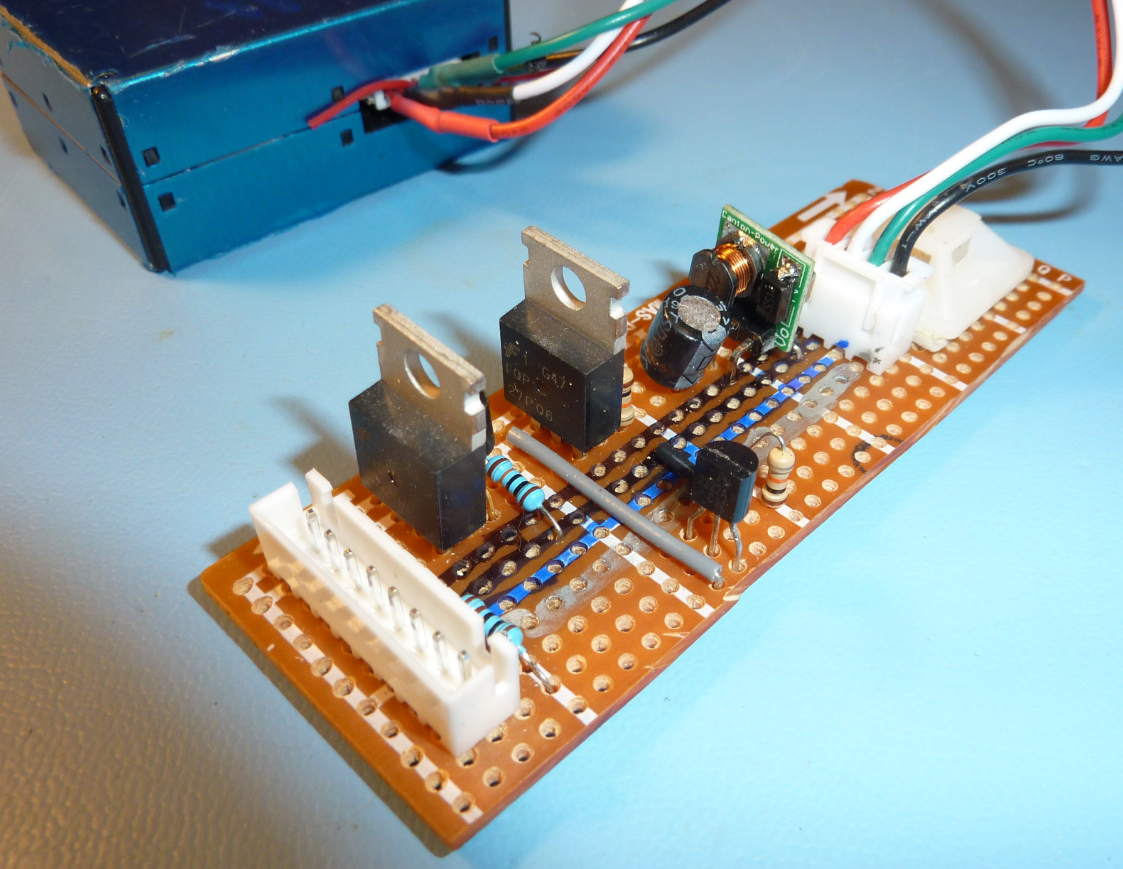

The completed power conditioning module is shown below. I am using polarized JST connectors for connection to the particulate sensor and cpu module.

Mike Teachman

Mike Teachman

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.