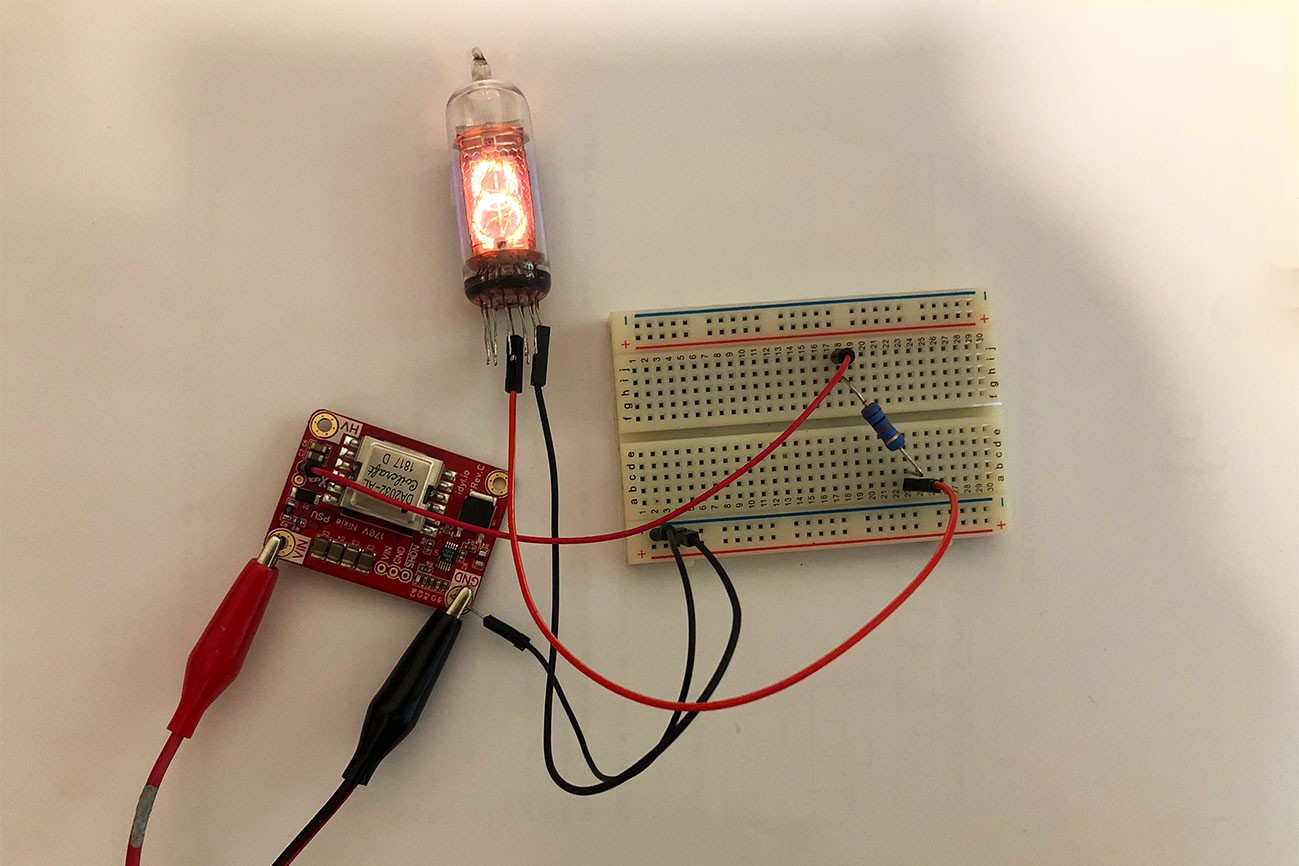

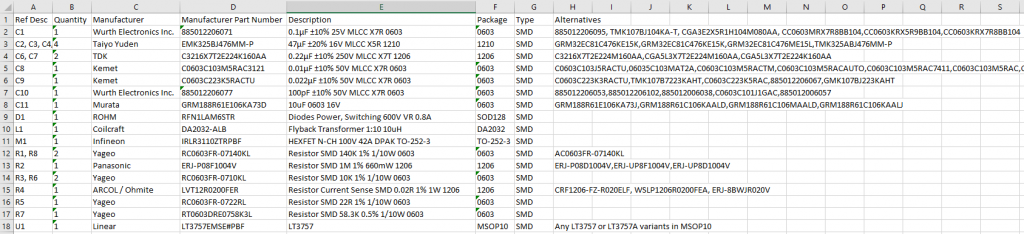

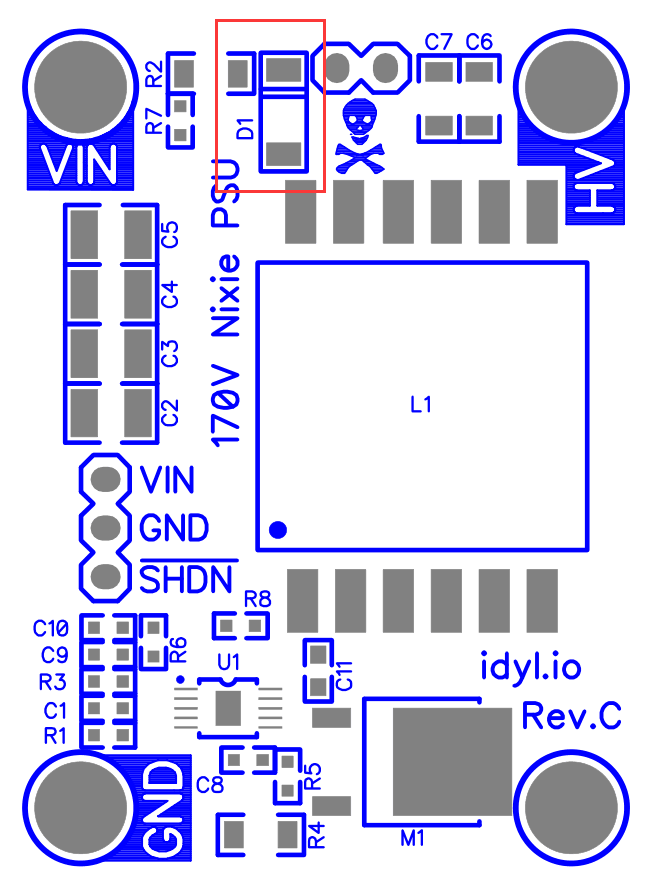

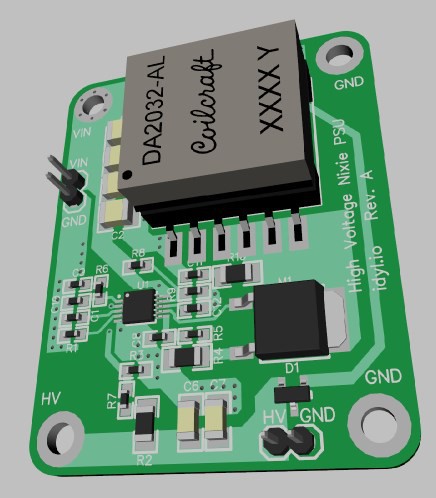

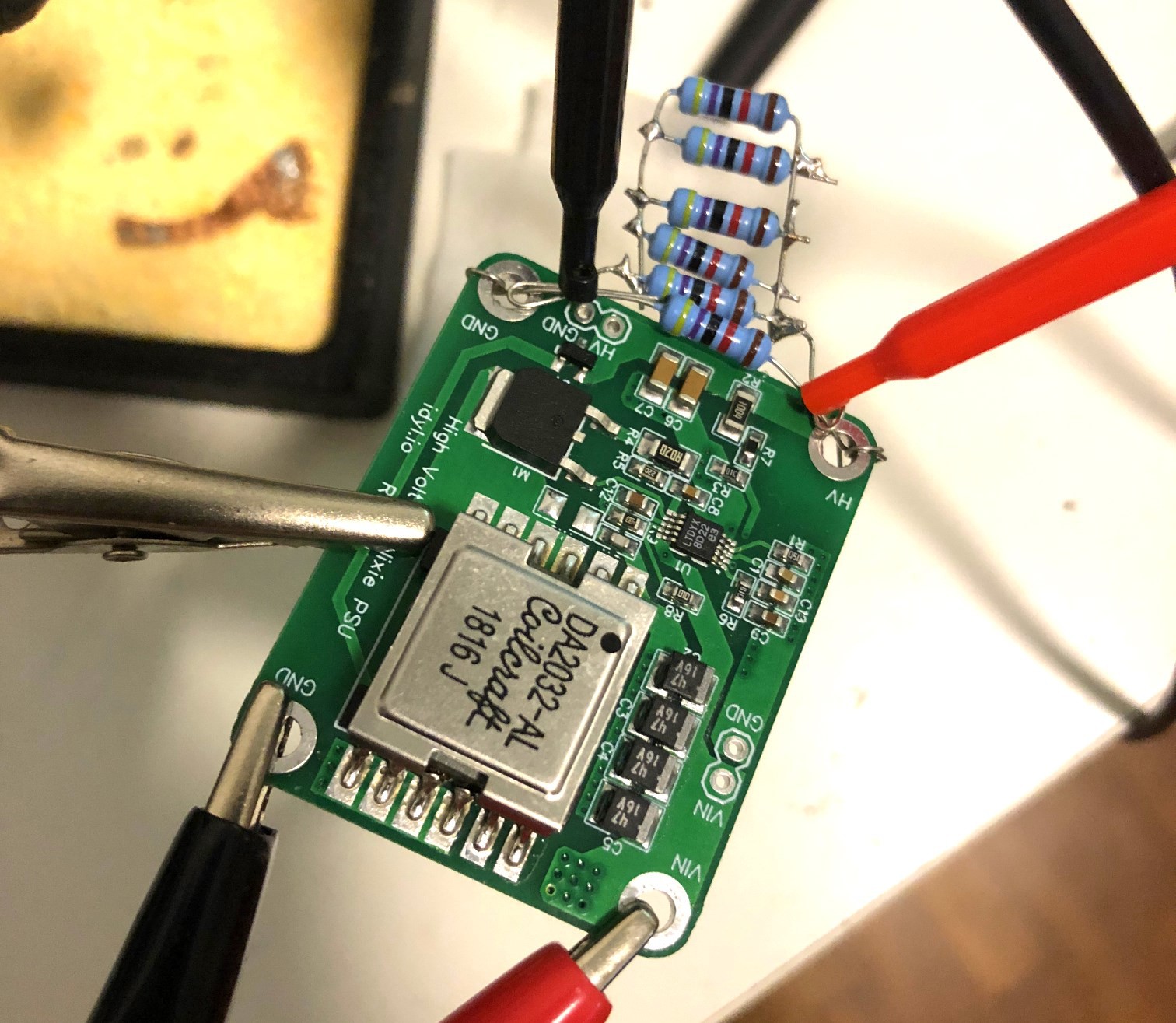

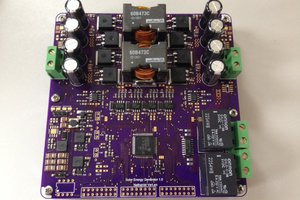

These pages describe in great details how I built a reliable and efficient high voltage nixie power supply -showcased above-; from the idea to selling it!

Be sure to read project logs!

- Part 1: Idea

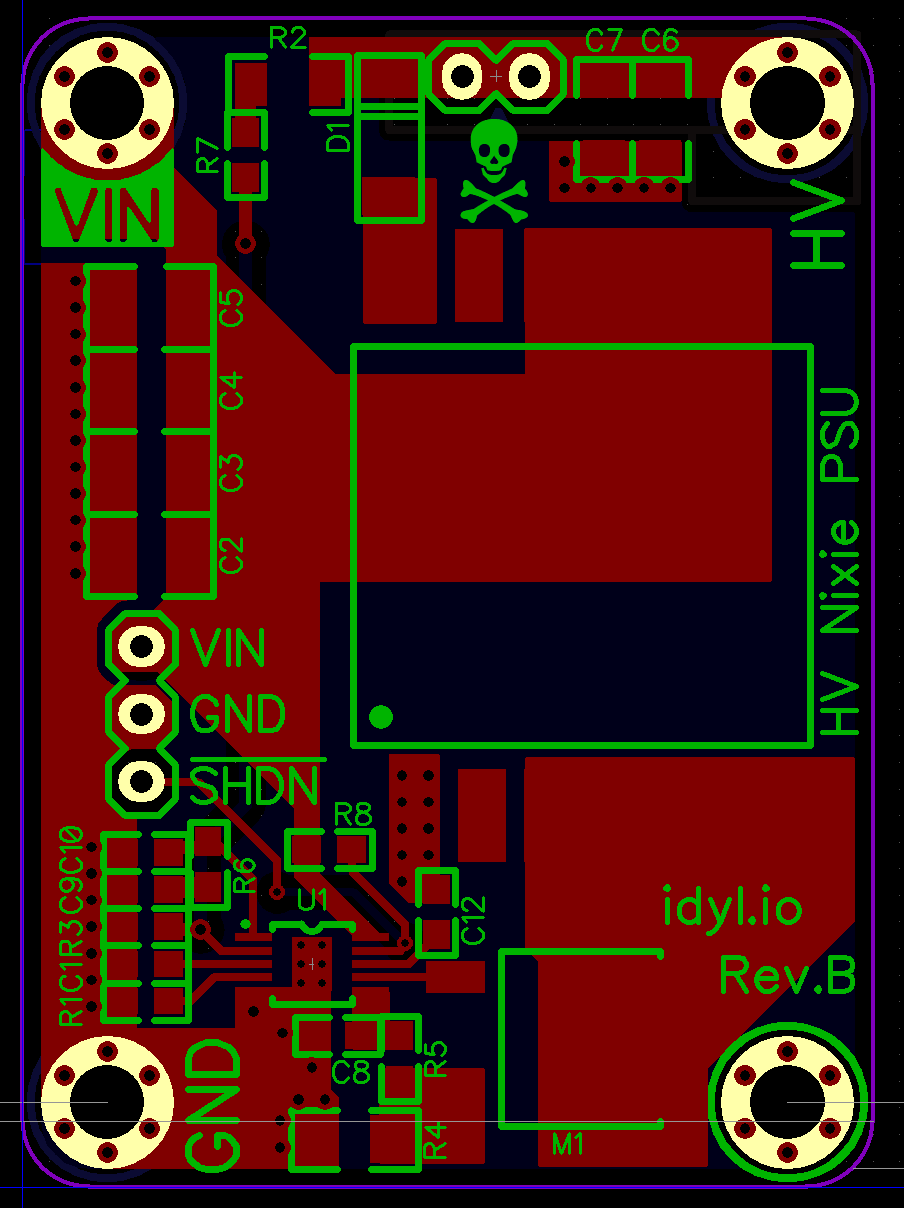

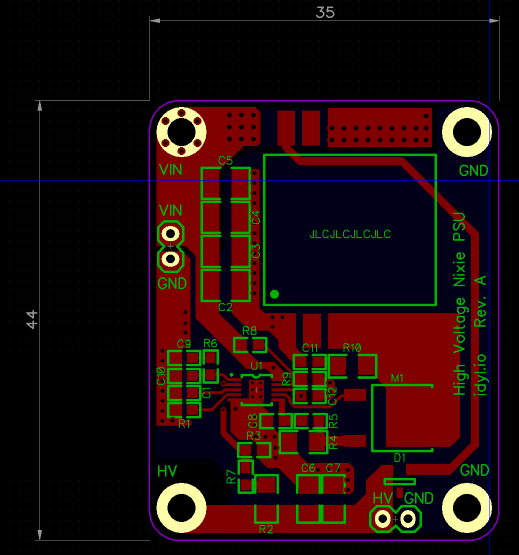

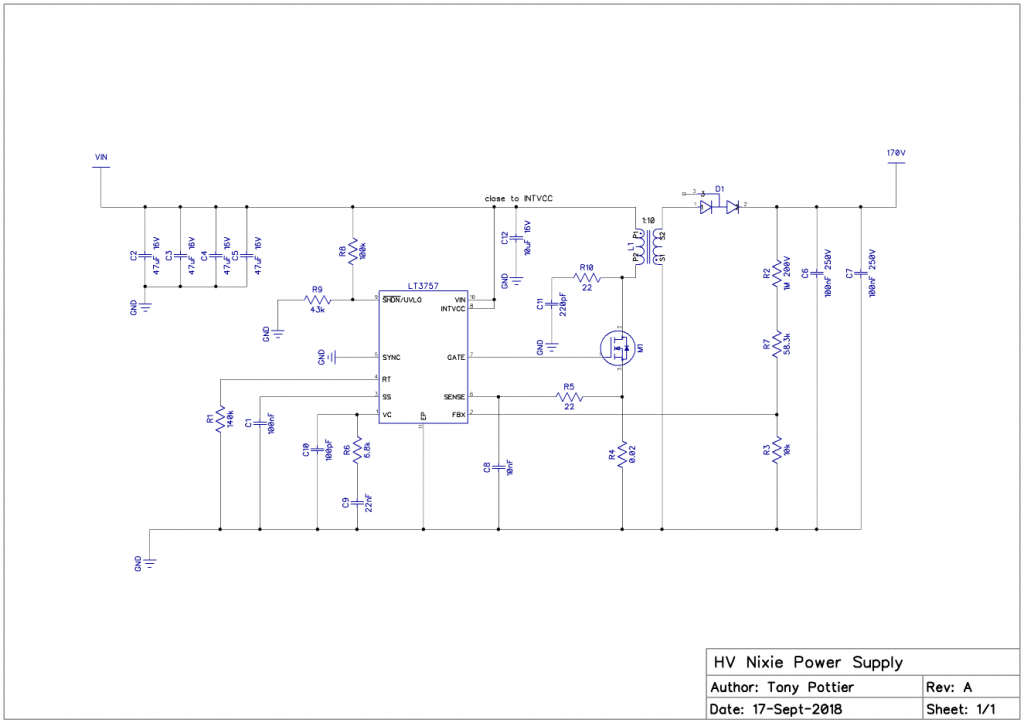

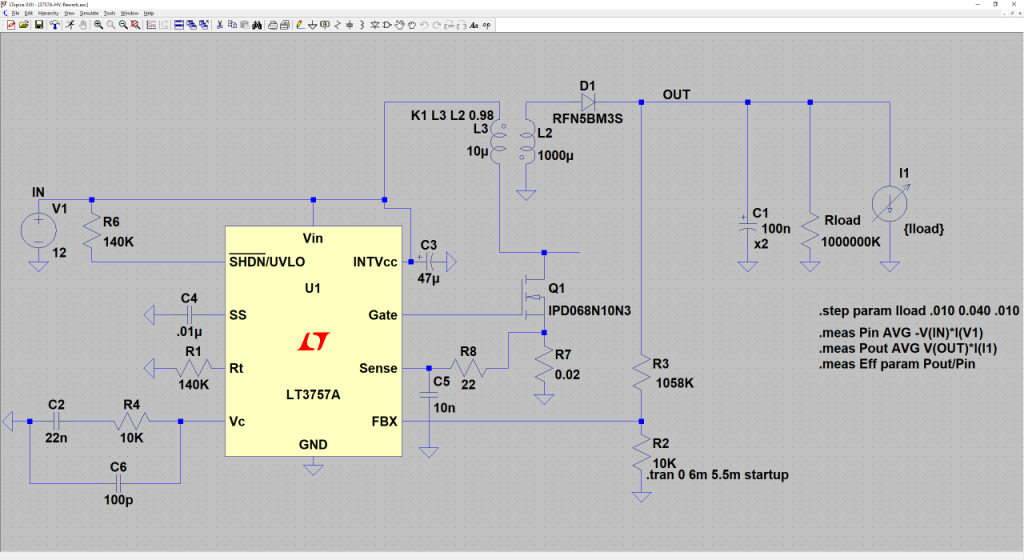

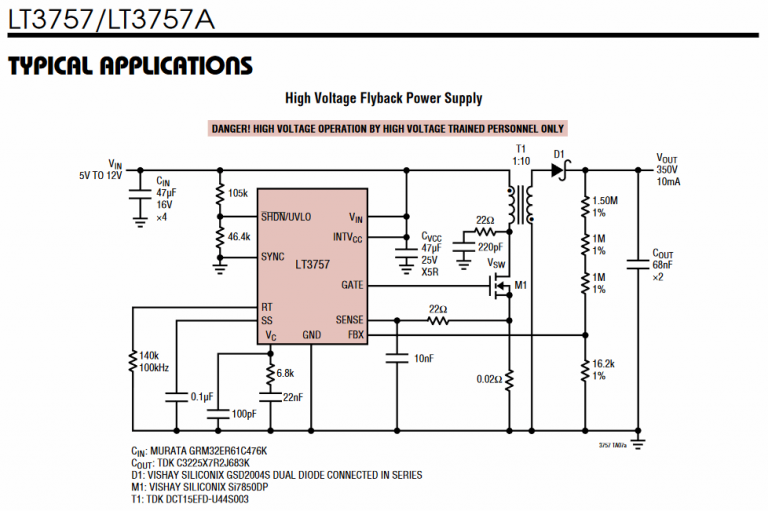

- Part 2: Design & Simulation

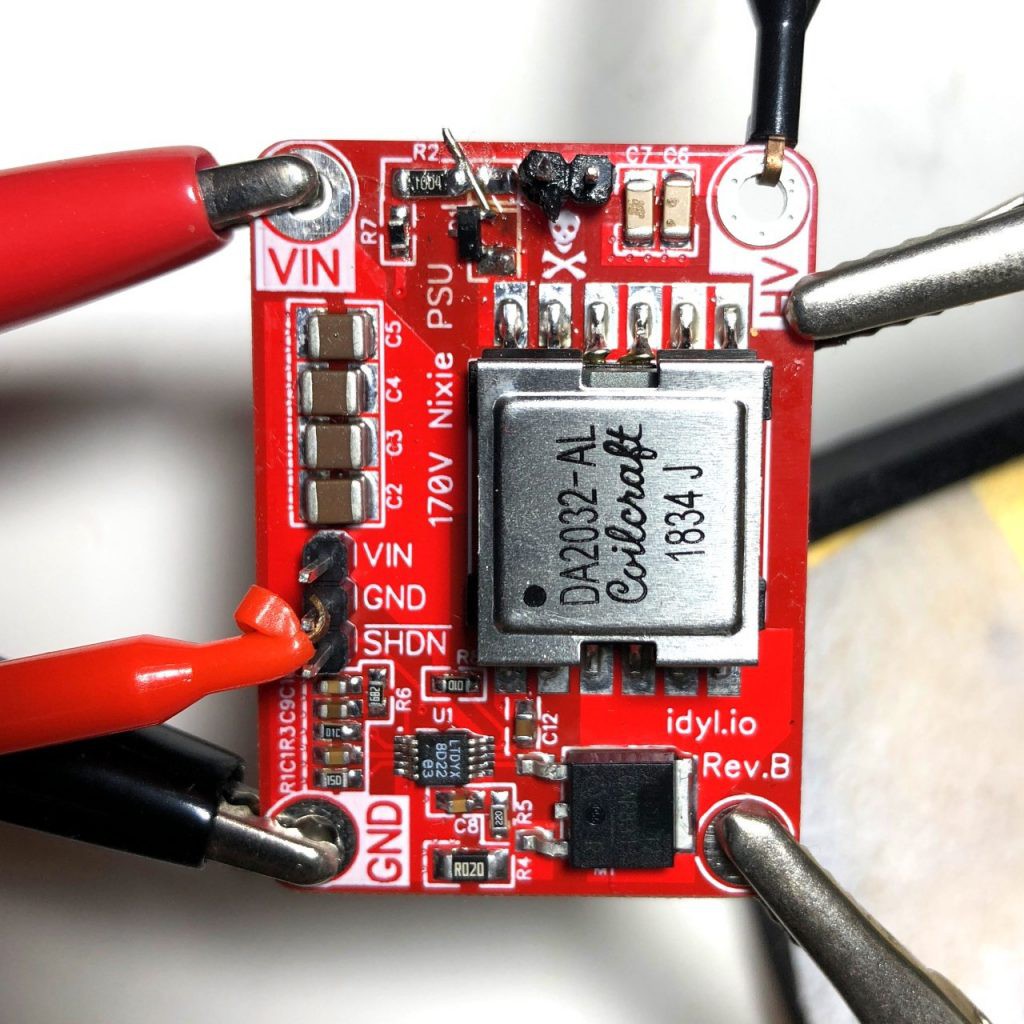

- Part 3: Making a prototype

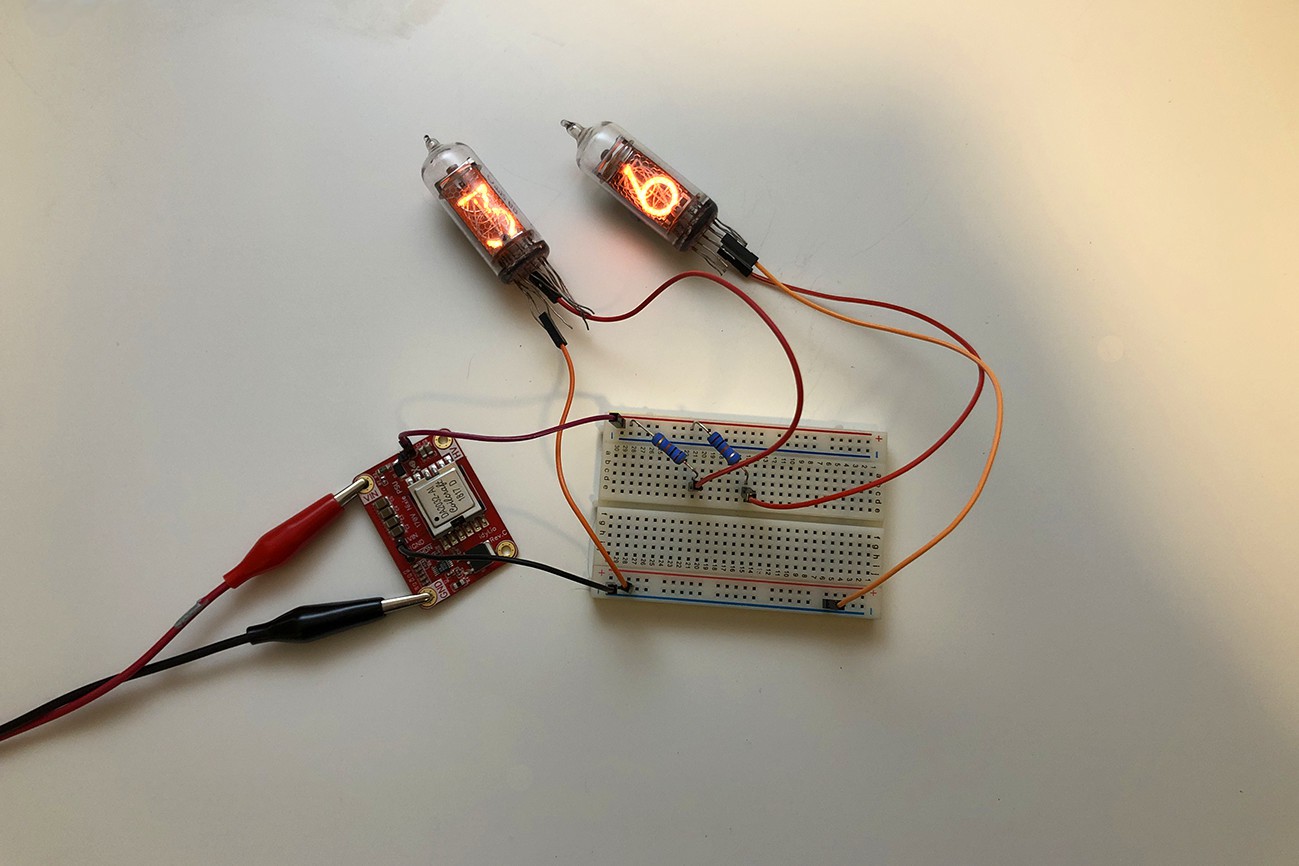

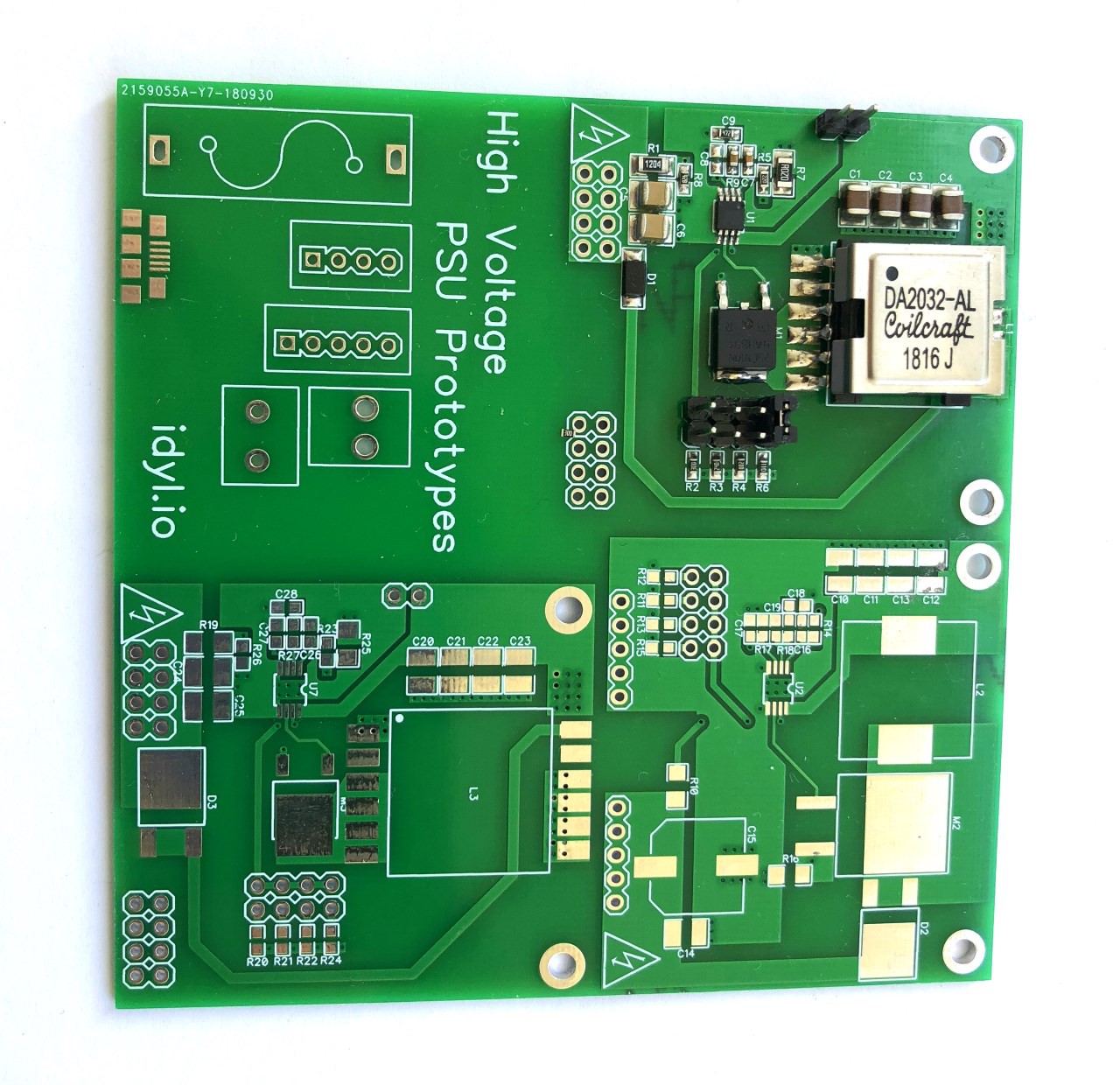

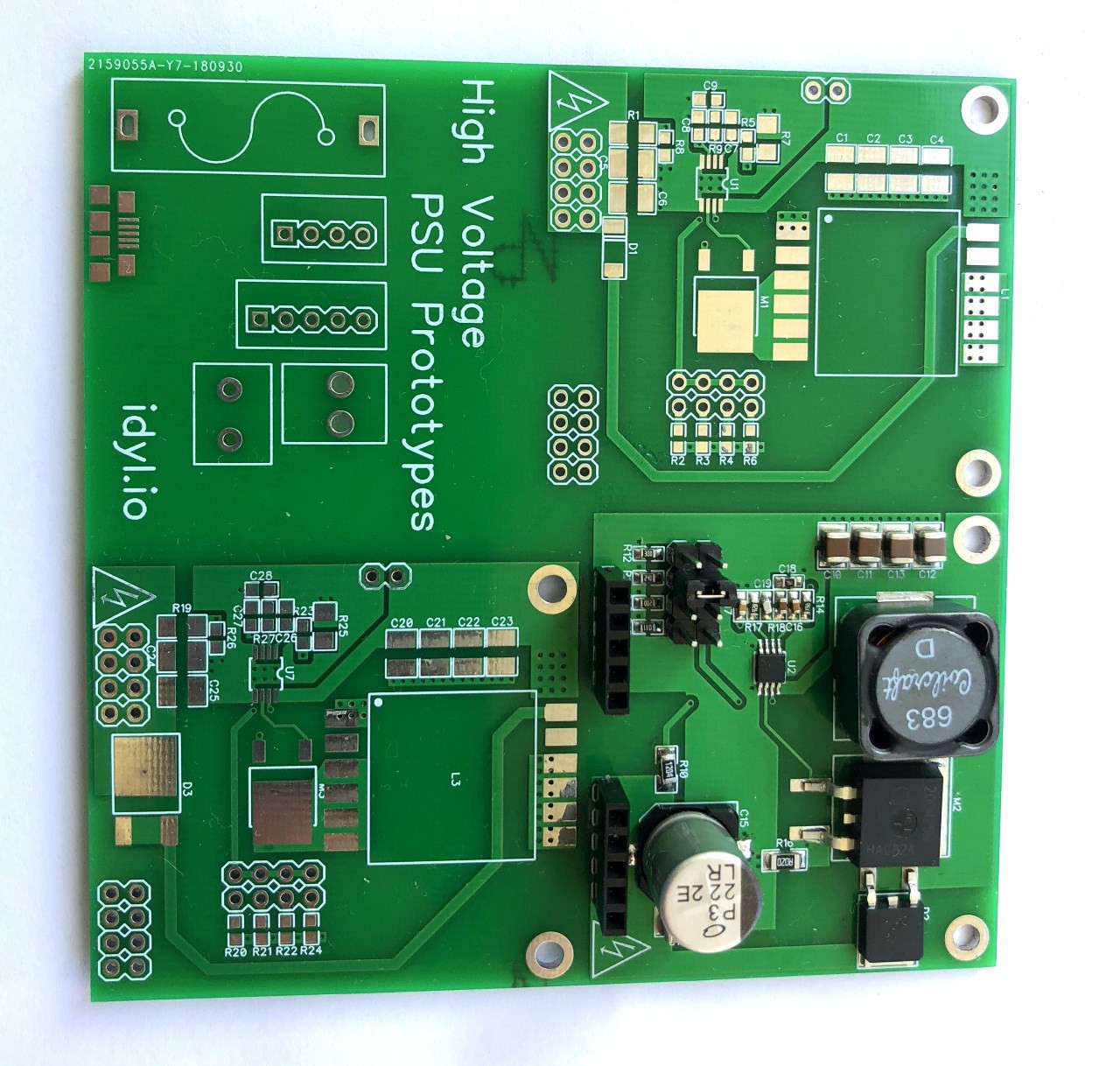

- Part 4: More prototypes!

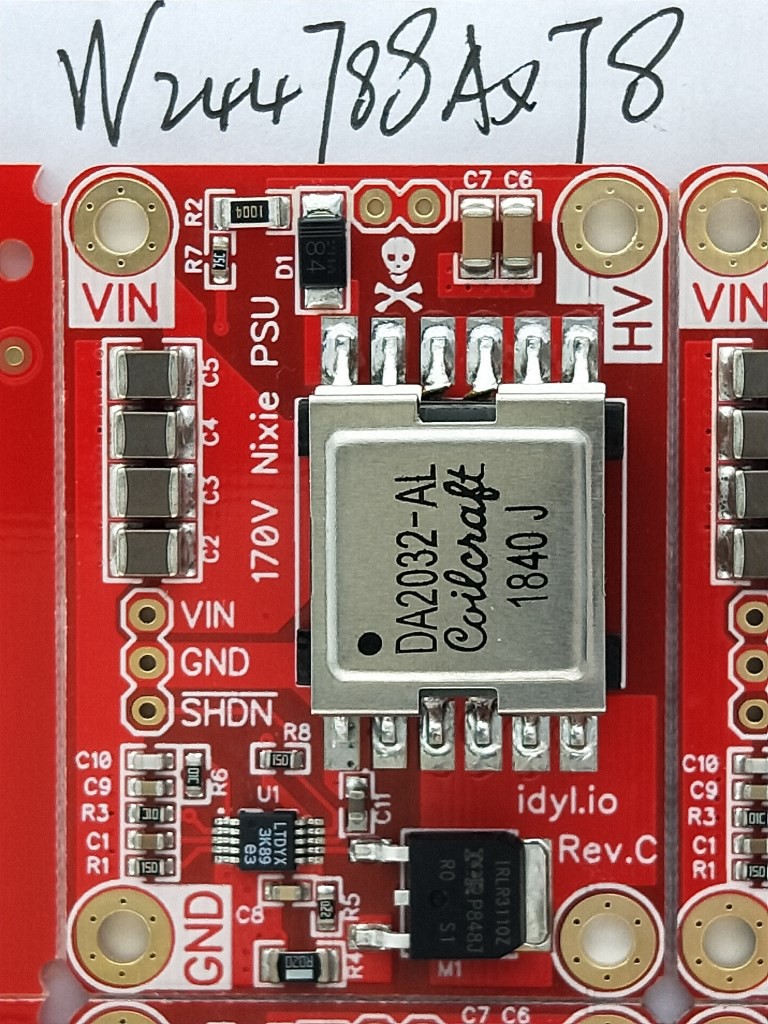

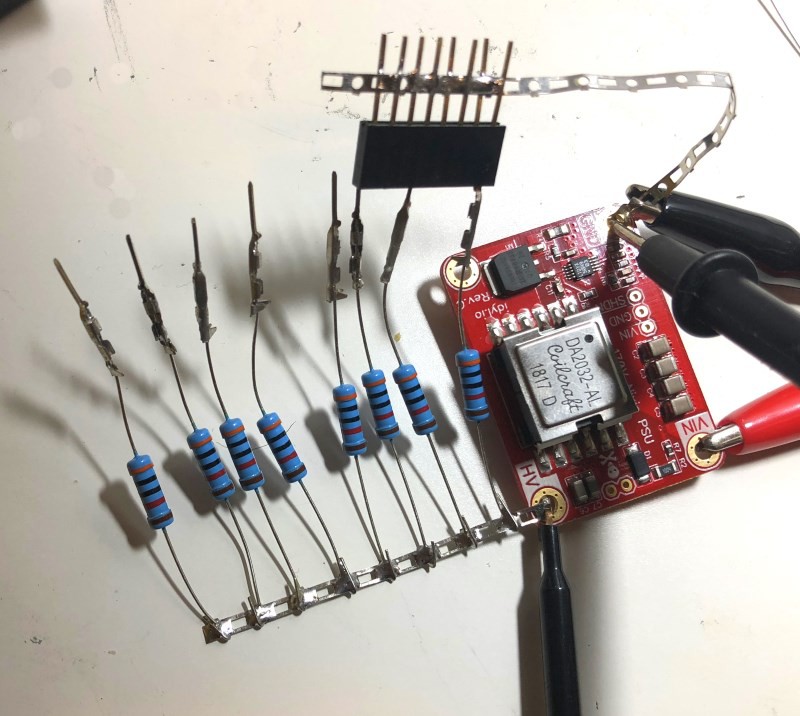

- Part 5: Sending for Assembly

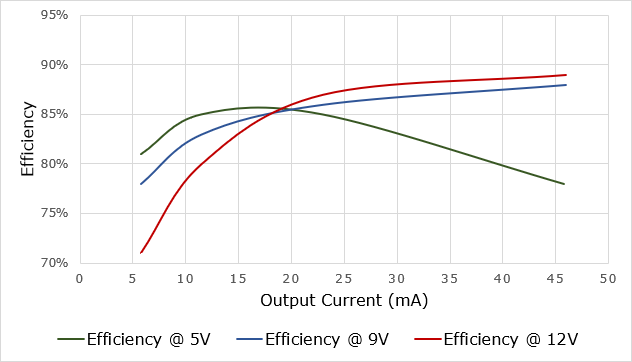

- Part 6: Efficiency

- Part 7: Production Run

- Part 8: Selling & Conclusion

Tony

Tony

Nathaniel VerLee

Nathaniel VerLee

Brian Lough

Brian Lough

c.Invent

c.Invent

Yann Guidon / YGDES

Yann Guidon / YGDES

Thanks for spending the time documenting this. It was very interesting and informative.