I bought this microwave oven in the year 2000 from a friend who was leaving South Africa to go live with her husband, who got a plush job at Microsoft. It's been a steady companion, moving with me to th UK and back. I like it because it is simple and robust, but mostly because it is a powerful machine with a 900 W magnetron.

I think I've had the magnetron replaced twice, and I am happy that we have a spares and repair shop who do a good job. But as far as keypads go, we're out of luck. The model KIC MWST 145 is no longer supported, so I can't buy a replacement keypad. (I was pleasantly surprised that LVB do stock keypads: not everybody is forced to ditch their microwave ovens because of a failing switch.)

I was lucky that I was able to diagnose the problem fairly easily. The symptom was that a "0" was displayed on the screen, and pressing buttons had no effect.

I think the most fortunate observation was about what happened when the power was switched on. From experience I knew that on power-on all the elements of the display was lit. When I had the cover off and the keypad unplugged, powering on showed the test pattern. From this I deduced that the microprocessor 'saw' a button being pressed, which prevented proper operation.

I cleaned up what I thought might be a short circuit, and then the keyboard worked. But the next morning it started beeping even when no-one was touching it, and the condition returned. This indicated that it was a dreaded intermittent problem: but I had solved worse intermittent and erratic problems.

My next step was to Google how keyboards worked. I knew what to look for, because earlier I had researched how many simultaneous key presses a computer keyboard could handle. <link to animation here>

My next step was to pull out my multimeter and rip the face off the keypad.

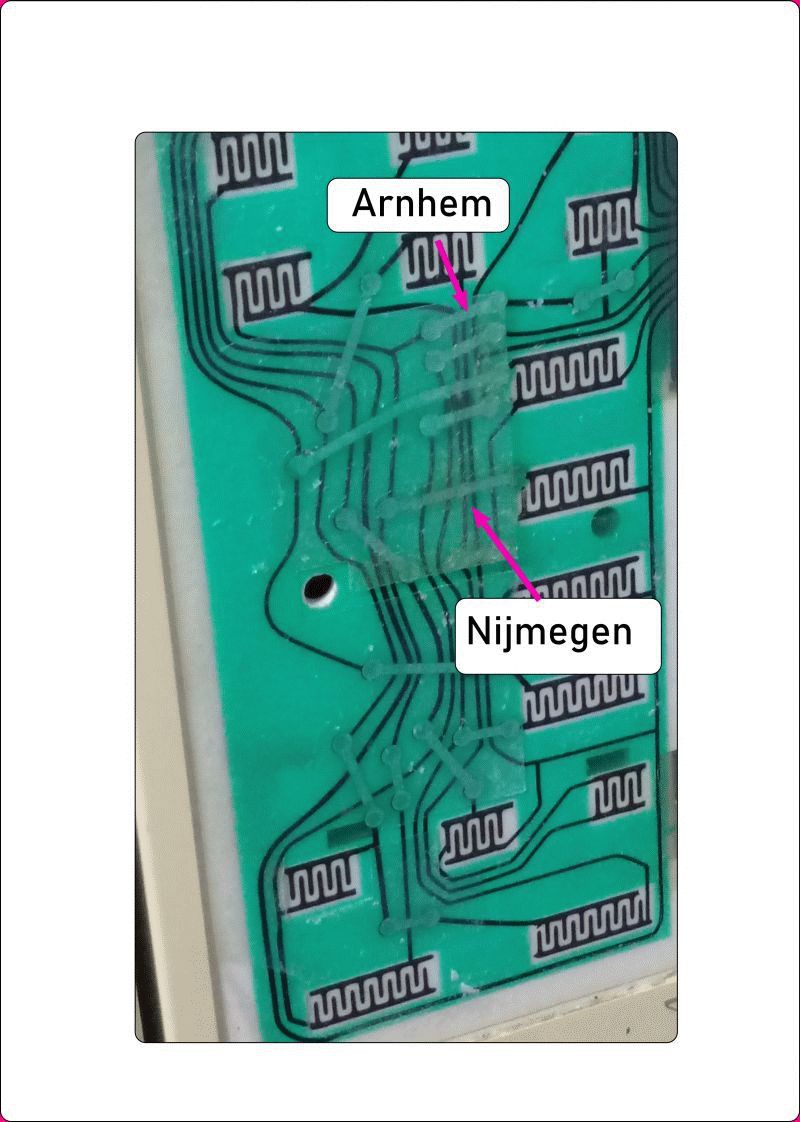

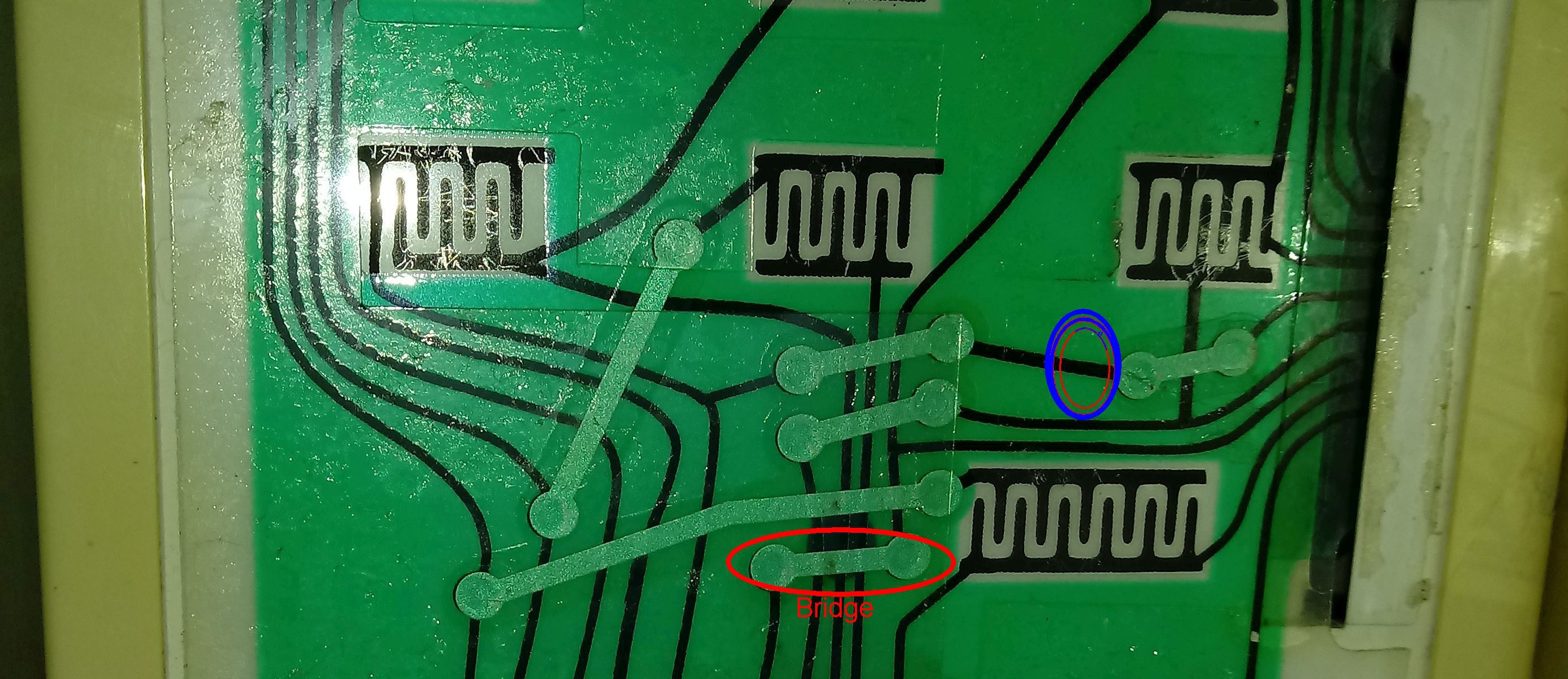

I mapped the traces on the circuit. There are 5 incoming and 4 outgoing conductors, giving a possible 20 keys, but only 15 keys. The layout is nicely consistent, with the incoming conductors grouped together and the outgoing conductors grouped together. In the switches themselves the little interleaved "combs" are similarly consistently oriented: downward for incoming and upward for outgoing.

Next I made a nice table of the buttons and their conductors. This is similarly well-organised.

Then I measured the voltages on all the terminals in the switch. It was immediately apparent that one of the outgoing traces had an anomalous voltage on it.

When I consulted the microwave oven's operation manual, I saw that the apparent button press was for 'Time Cook'. This button is on the trace with the anomalous voltage.

My diagnosis so far is that there is voltage leaking from one of the incoming traces on to one of the outgoing traces. Finding the location of the leak and fixing it i should fix the problem.

Niel Malan

Niel Malan

Nick Sayer

Nick Sayer

bryan.lowder

bryan.lowder

Hacker404

Hacker404

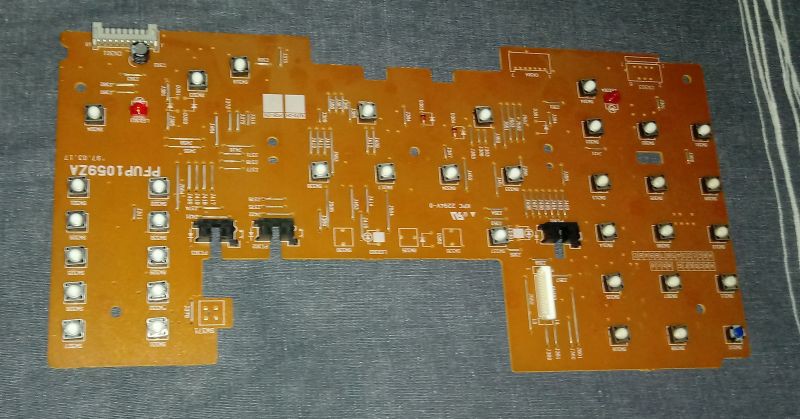

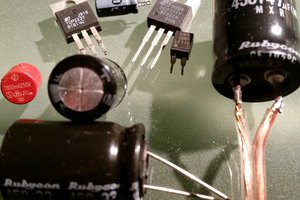

The worse case scenario is to replace the whole keypad. Something like this:

https://www.ebay.com/itm/1pcs-4x4-4-4-Matrix-Keypad-Keyboard-module-16-Botton-mcu-For-Arduino/141976900588

Traces on the PCB could be cut etc to match the key matrix if needed. There are other membranes ones, but they can't be modified as easily.

I used a 4x4 (from digkey) with snap on key caps (you can make printed labels) a long time ago and it was ~$15 US which is a large percentage of a new microwave hese days.

A custom PCB for dome switch that matches the overlay is possible, but can get expensive due to size.

https://2.bp.blogspot.com/-sGgDn4kMpl8/W3N4zEjiyeI/AAAAAAAACoY/ja-7KRGwgz8SC3zxShLH_57J_9WpKLoBgCLcBGAs/s400/IMG_2379.JPG