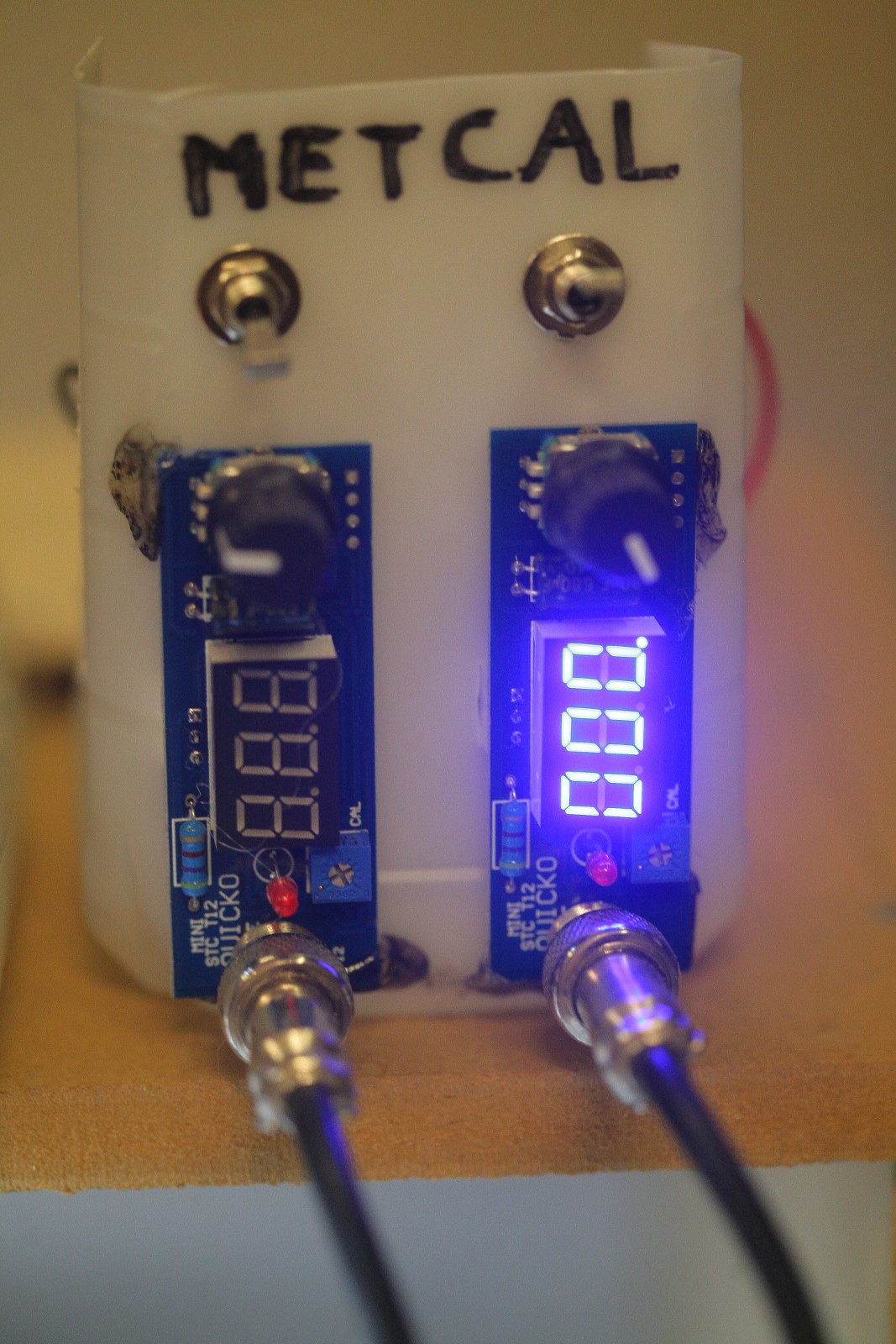

After using the T-12 for a while, the honeymoon was over. It has a very short timeout for the complete powerdown. You'll be frequently seeing 000 & power cycling it to turn it back on.

For the 200C powerdown, the timeout is shorter & it relies on a tilt sensor rather than a full motion sensor. It always senses being pulled out of the stand, but during a long solder job with little movement, a part with high thermal mass, & lead free solder, it usually times out. You have to frequently take it off the part & shake it again.

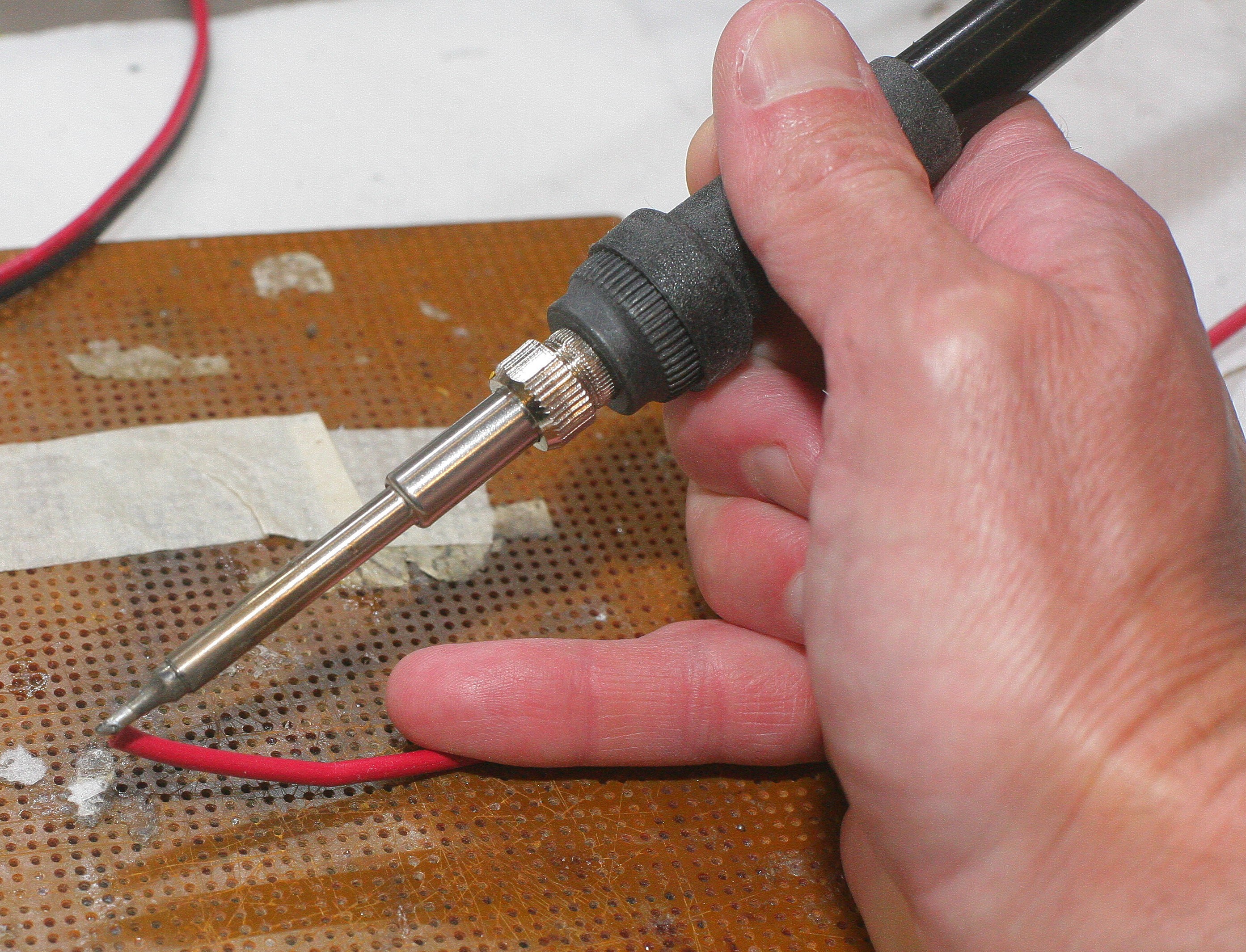

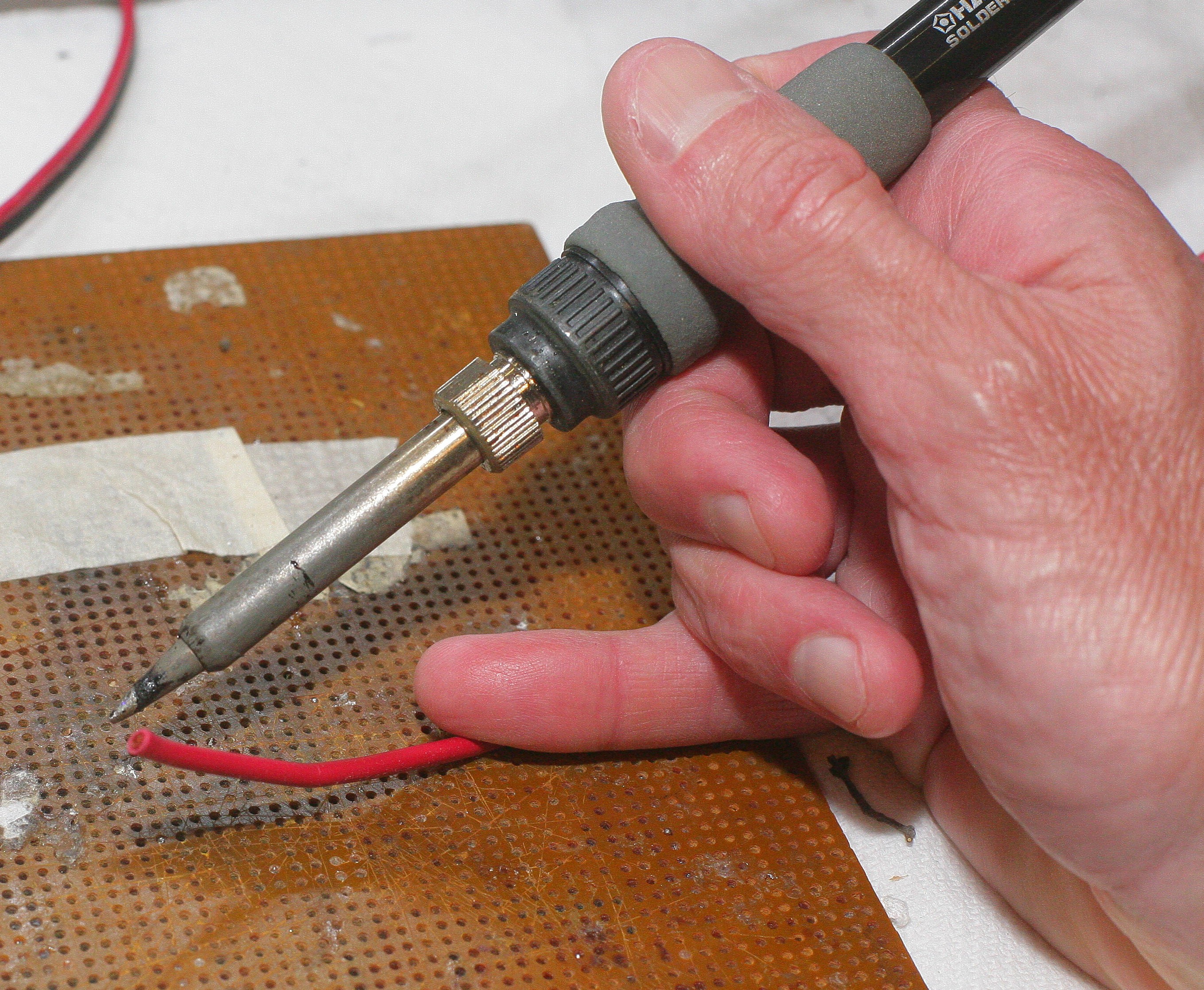

The tip length is so long, the ages old technique of holding down a part & soldering with the same paw doesn't work anymore.

T-12

Old tip

A handle can technically choke up around the tip, but it would be expensive. The long tip also makes it shake more. The lion kingdom is forever missing the Metcal in this department.

The only useful tip for through hole has been the hoof tip. The chisel tip provided is too wide. The knife tip is useful for feeling powerful, but doesn't transfer as much heat as the hoof. Of course, most people only have the stock tip for it & only 1 iron. The lion kingdom got a complete set of tips & 2 irons.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.