So one day my neighbour comes and asks for help. Why not ?

Imagine you play chess against your opponent. Sometimes one of your pieces falls into a trap that opens suddenly as you press the button of the timer.

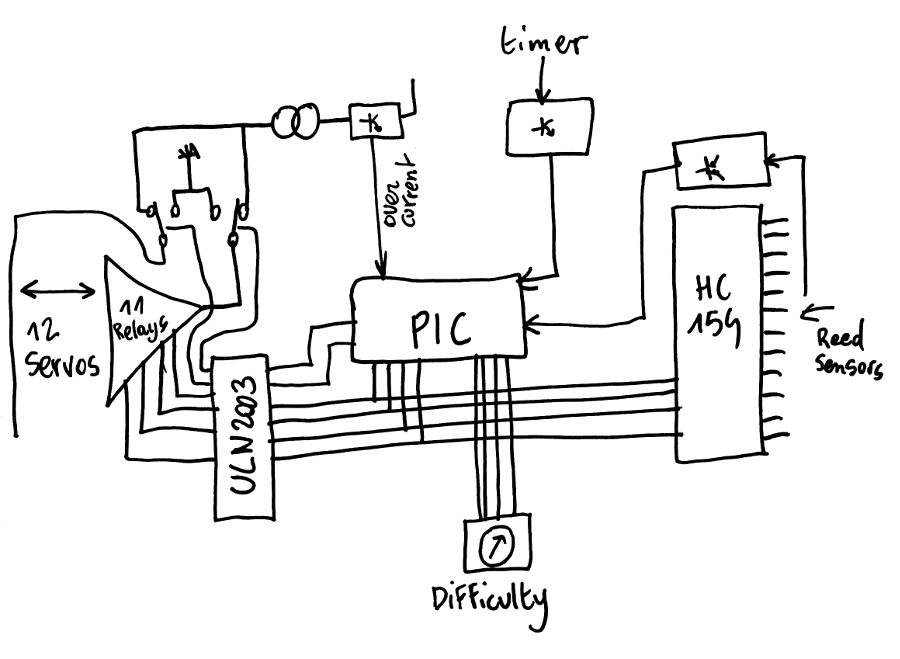

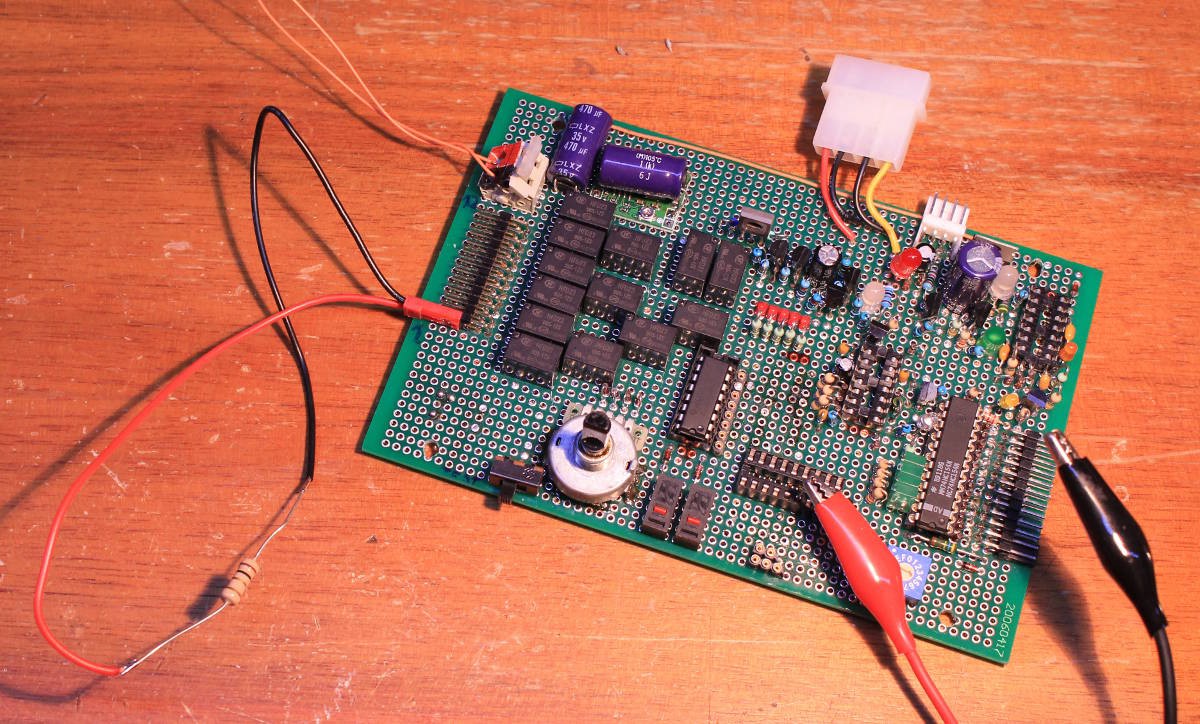

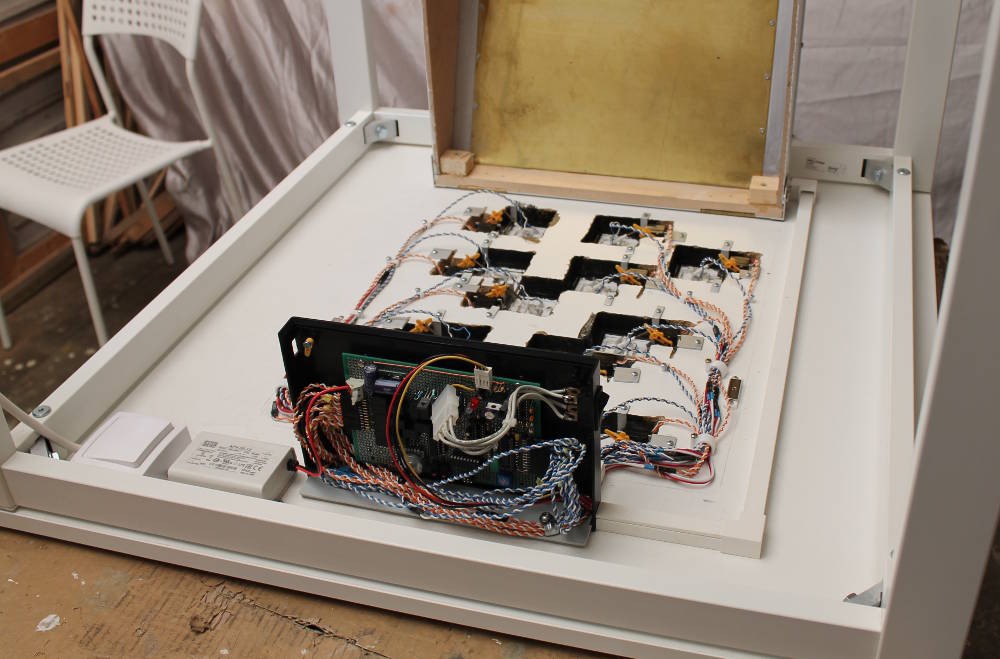

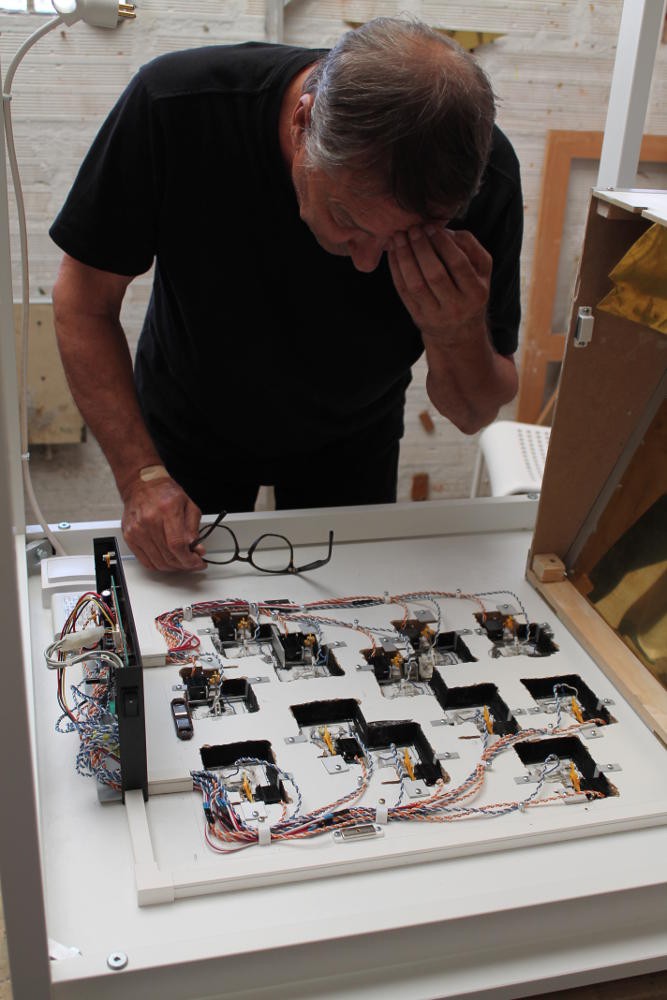

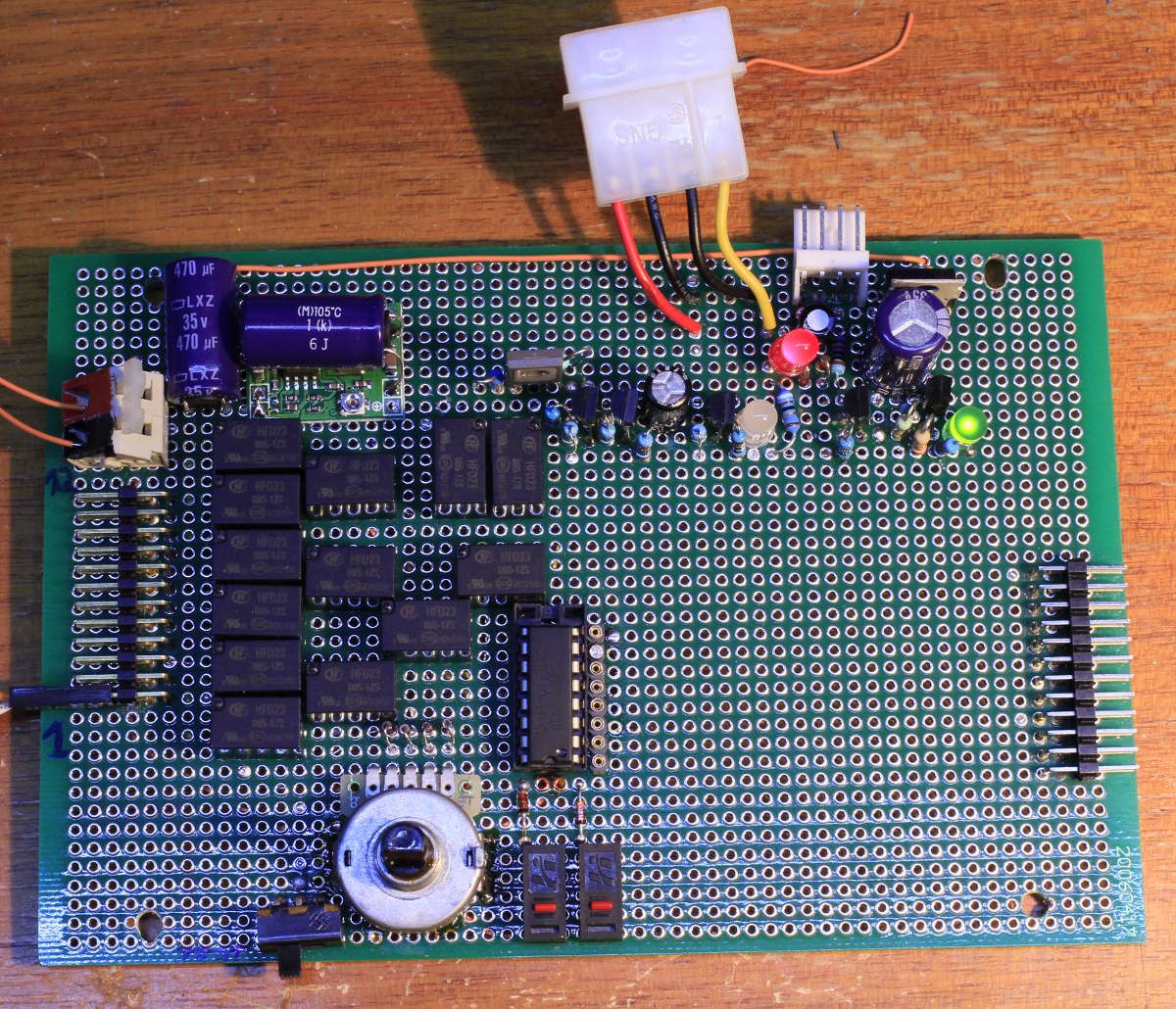

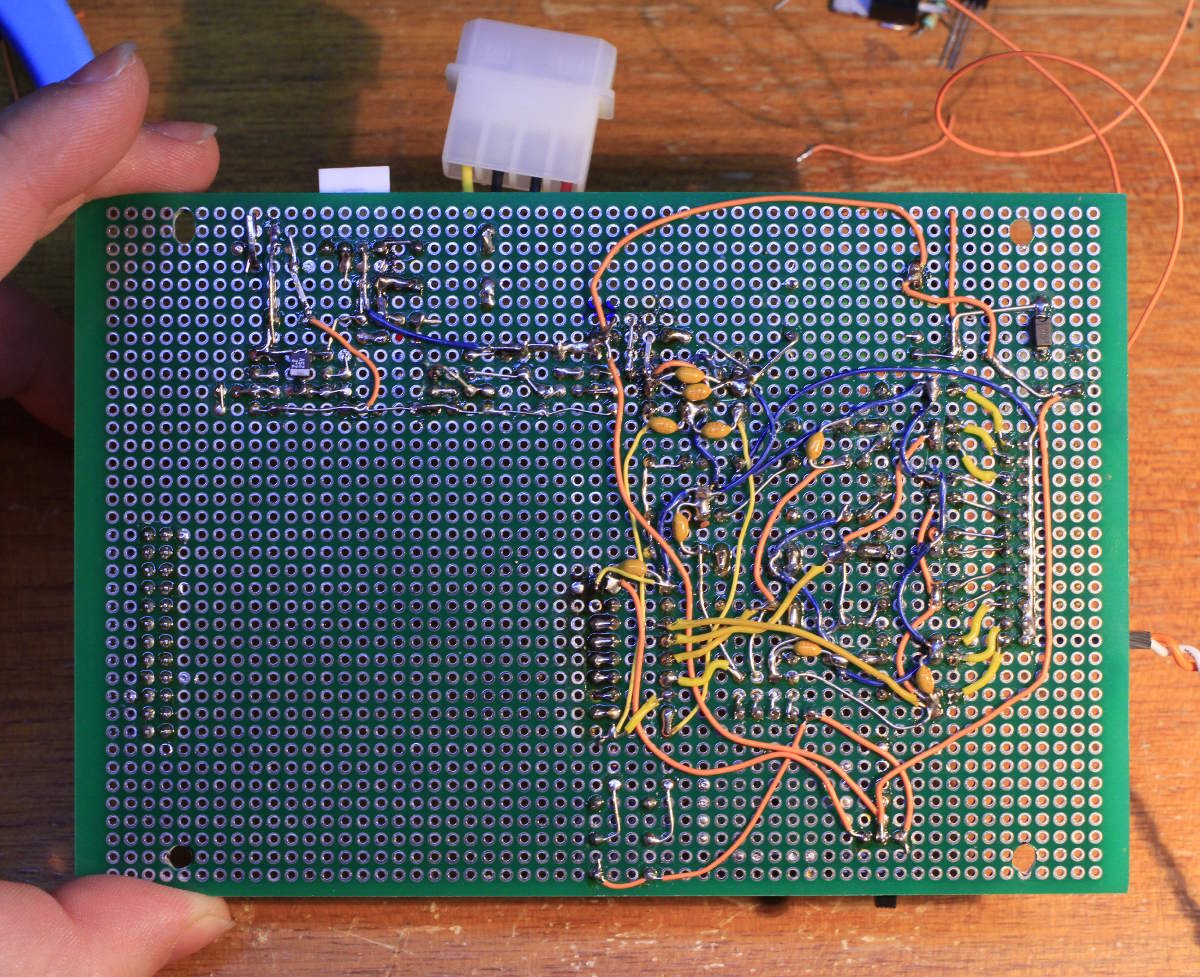

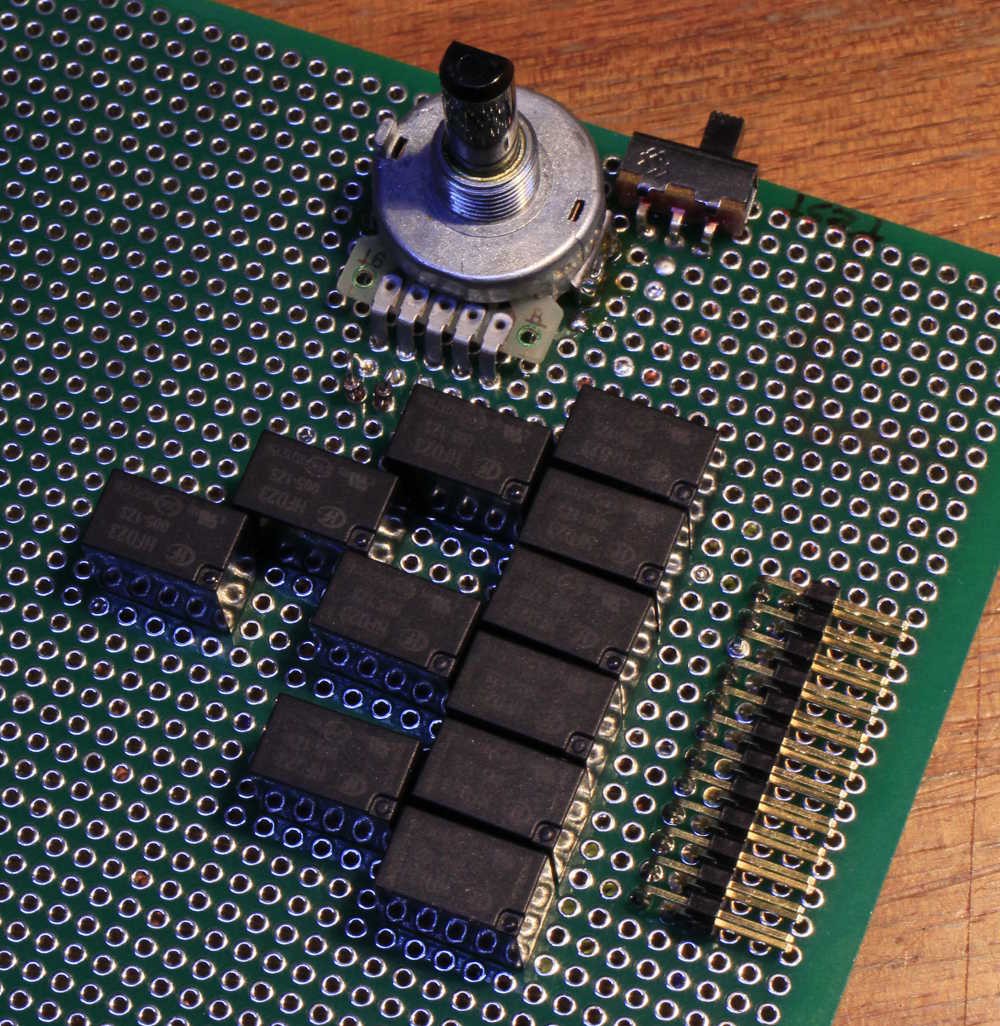

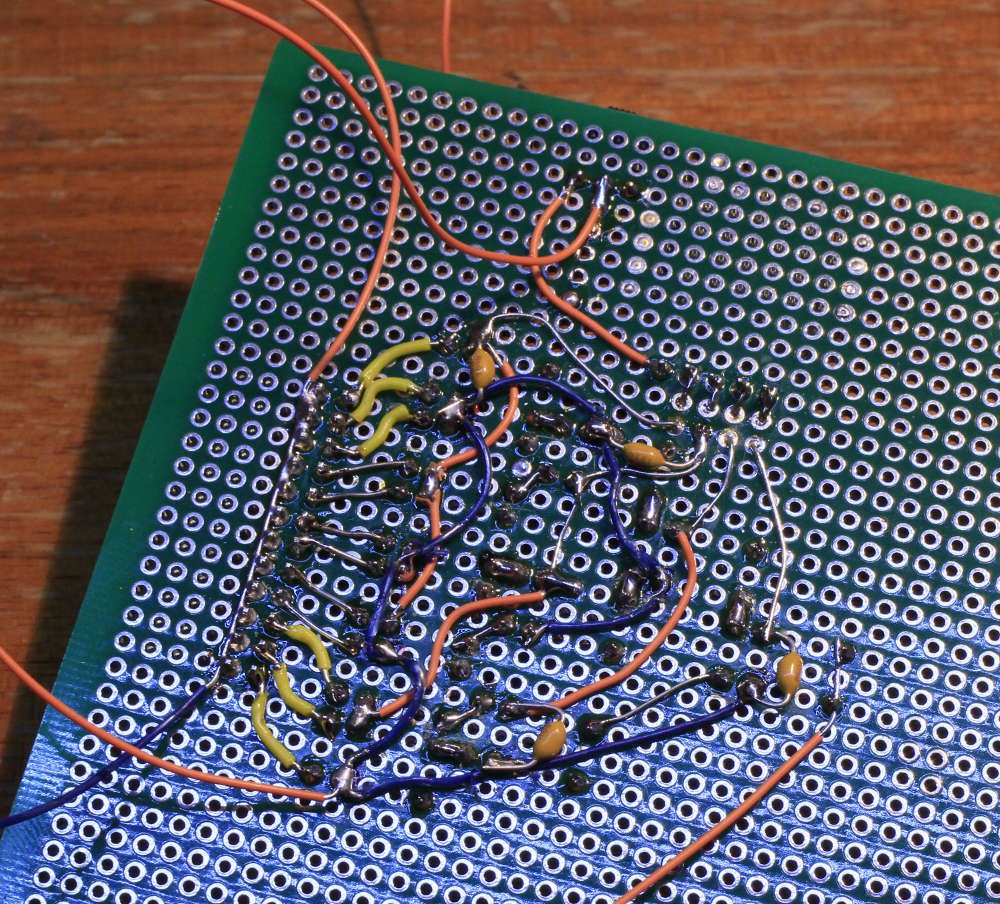

Bob has built two chess boards with traps, operated by individual servomotors. Each chess pieces has a magnet, that is detected by reed sensors. My mission is to create the electronic board to control the whole thing... Uncontrollably.

Logs:

1. Timing

2. Plot twist !!!

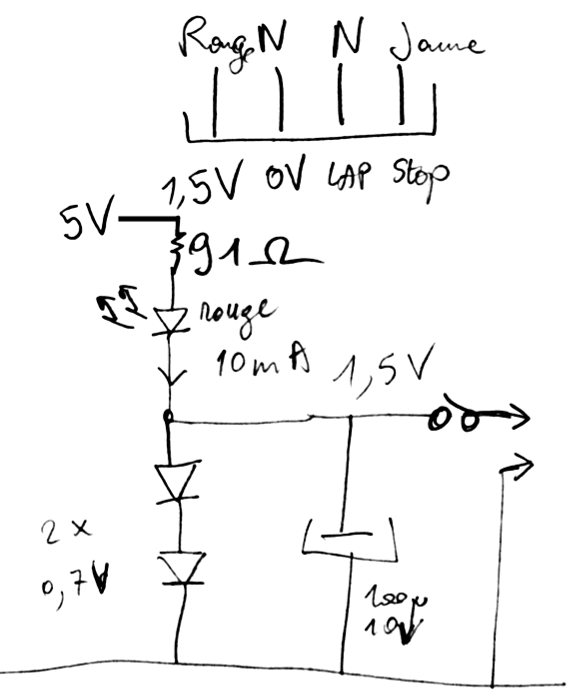

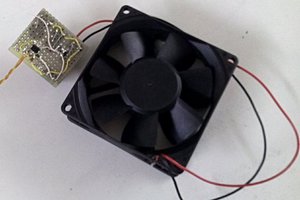

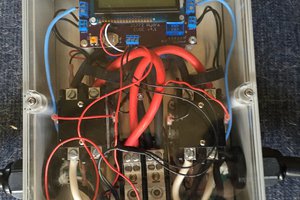

3. Power distribution

4. More work

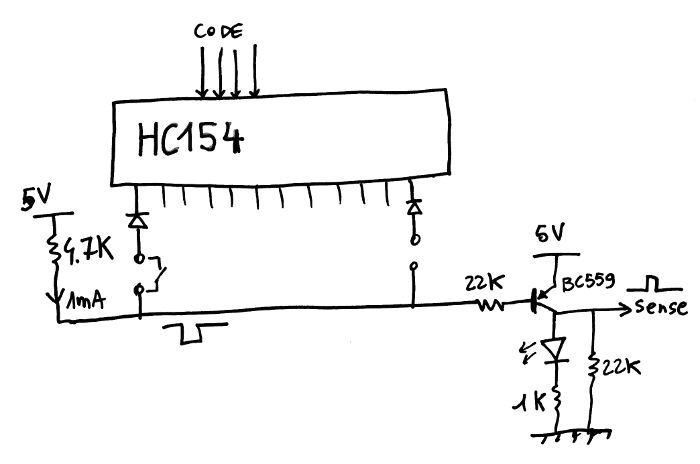

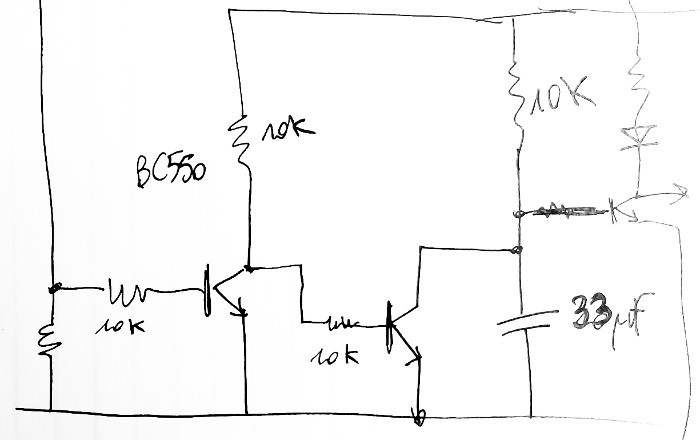

5. a not-so-basic current sensor

6. Connecting the timer

7. first tests with the checkerboard

8. More progress

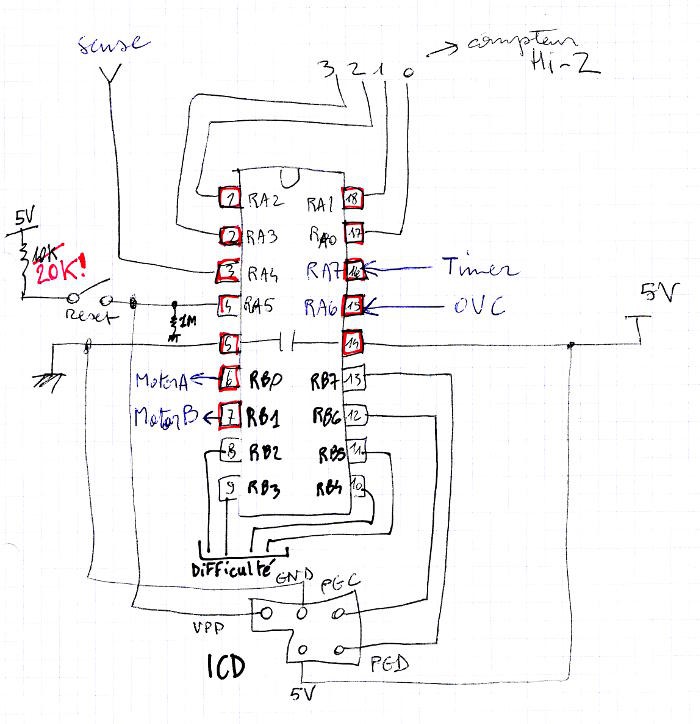

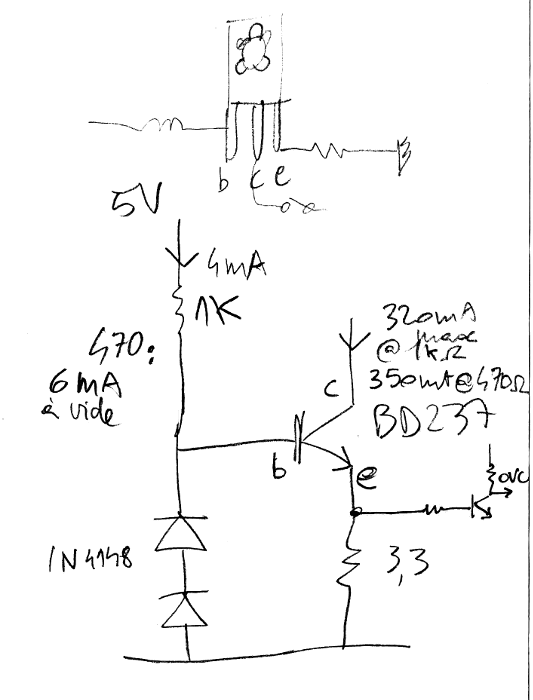

9. Power Supply redesign (20190331)

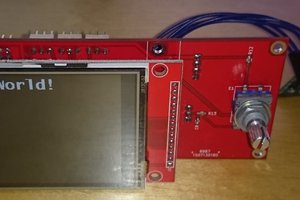

10. First prototype working !

11. Finished

12. Some schematics

Yann Guidon / YGDES

Yann Guidon / YGDES

Nick Sayer

Nick Sayer

Jose Ignacio Romero

Jose Ignacio Romero

SUF

SUF

Haha, that's great! Chess...with the element of surprise! Good effort on attempting to do it all in discrete logic...guess we can't give up our micro's just yet!