I got a little time to work on this last weekend, and so I modeled some covers for the chain drive. This became frustrating as my current AL motor mounts were made from diamond plate, and so the surface I needed to mate the cover to was decidedly uneven.

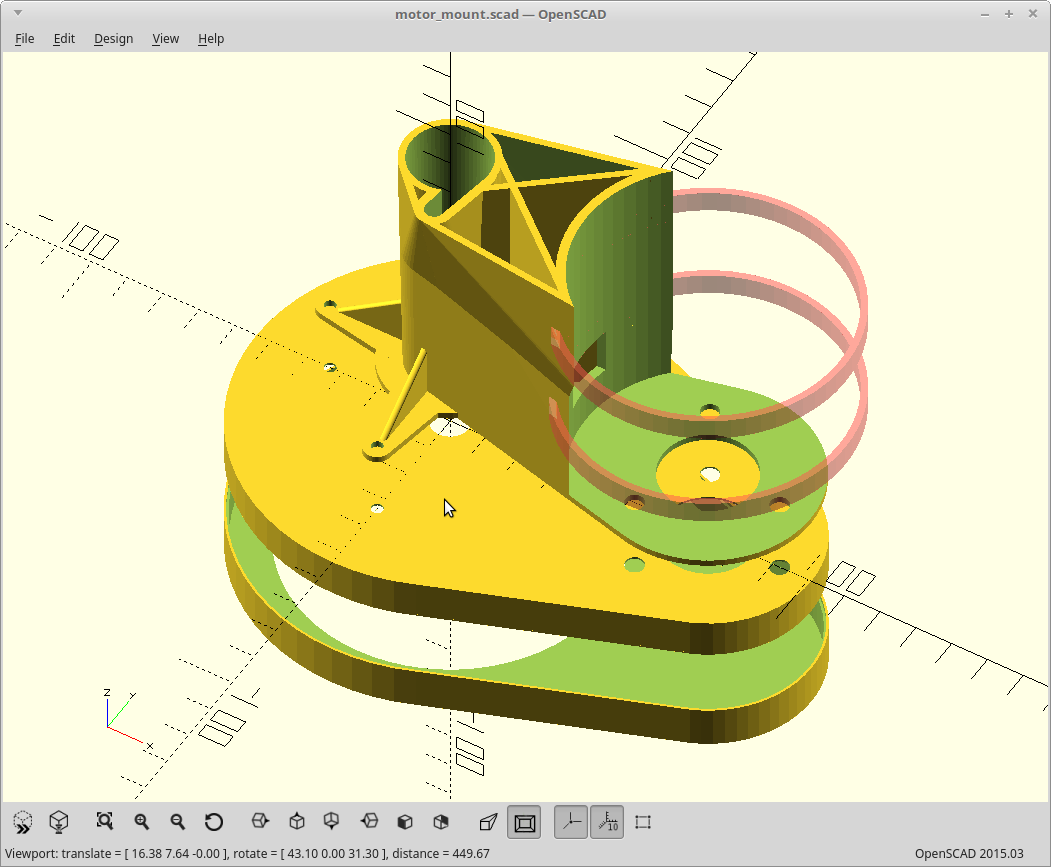

So.. some 3D printed motor mounts, happened. The up-front TL;DR image:

The red rings are where zipties go. This keeps the motor coupled to the shaft so that the mounting flange itself only needs to prevent rotation.

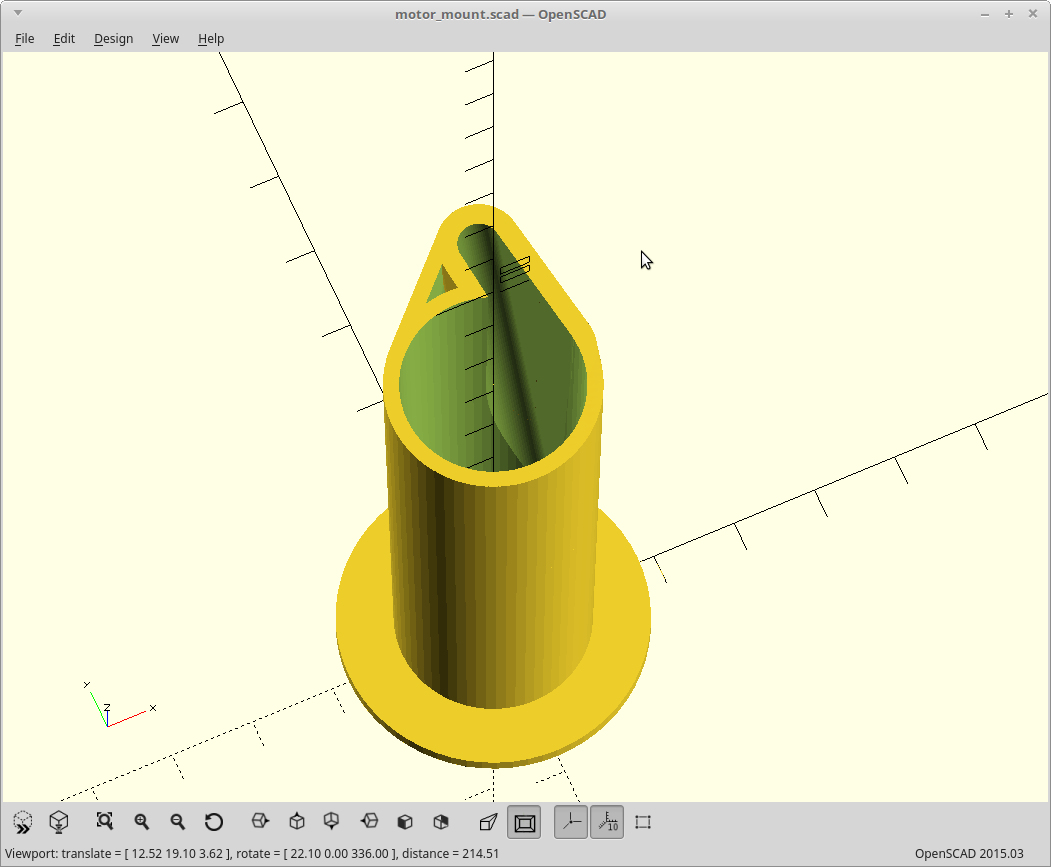

I needed to tightly fit the rib on the trucks to prevent rotation, so I modeled just that and printed it until I got the fit perfect. It only took 3 tries.

Once I had that done, I expanded the model to mount the motor the same distance from the hub as it is now.

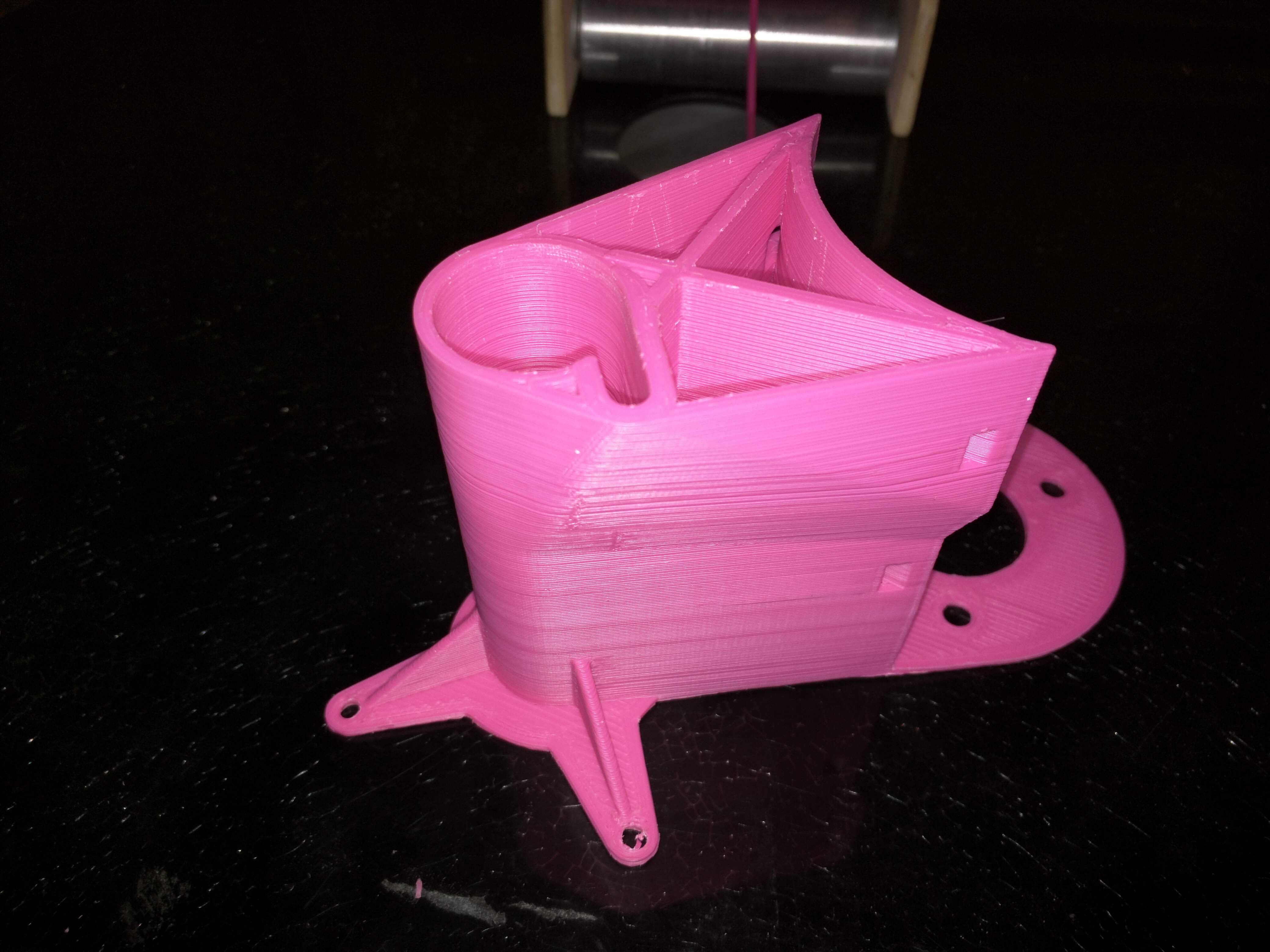

At first I tried relocating the motors to in front of the wheels/underneath the board. Notice the forward position of the rib from the trucks here.

That didn't work so well. To still clear the board when turning the mounts had to be angled down towards the ground when positioned under the board. This compromised my ground clearance.

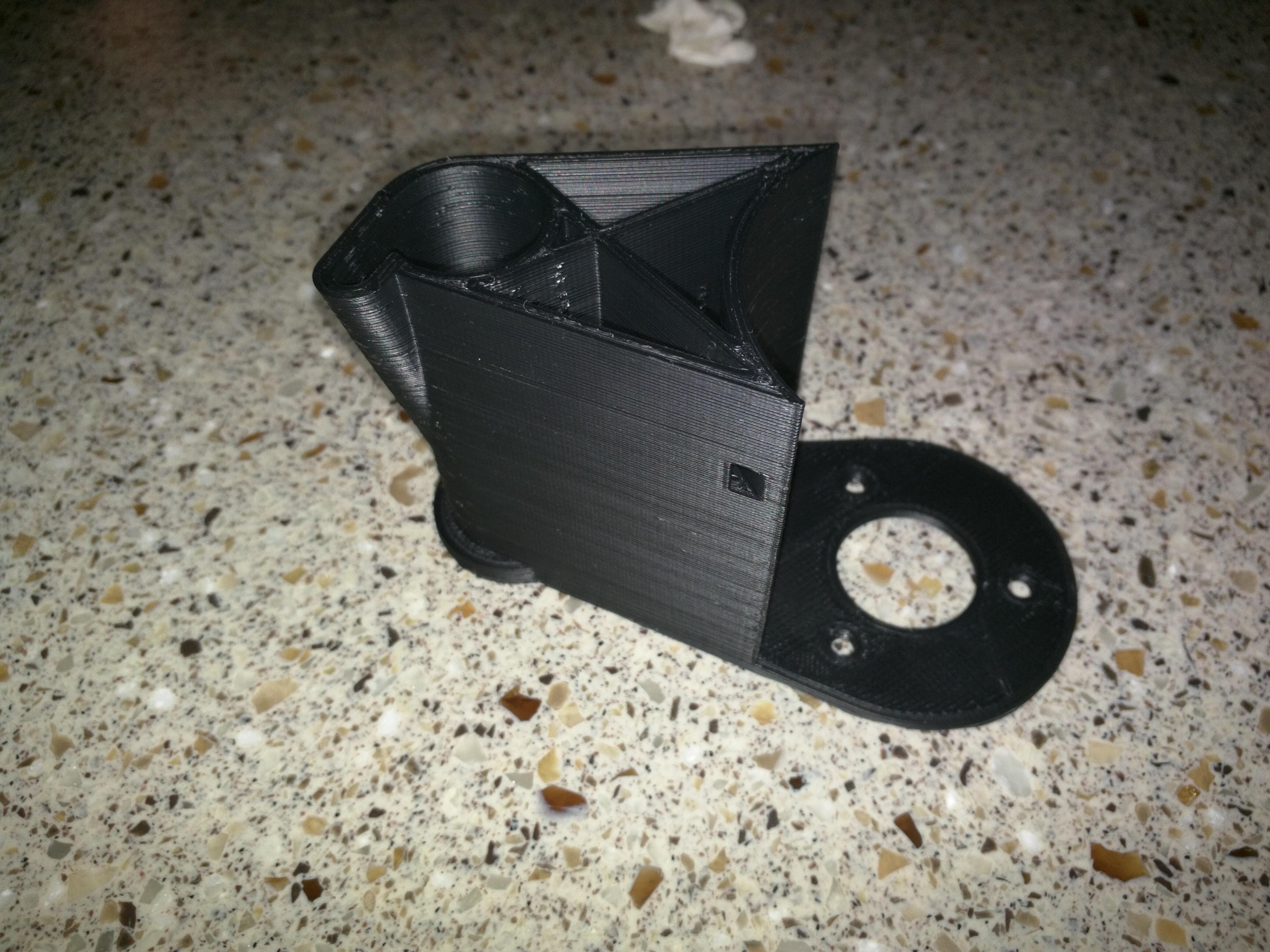

So I moved them back to where they were before: up and behind the rear trucks.

In the process here I did a bunch of test prints with various settings trying to get the strongest ABS parts I could using the least amount of material. That could and probably will be an entire log by itself but for now...

The best settings amounted to:

- Build surface: 110C

- Extruder: 280C

- +5% over-extrusion

- No cooling

- 0.6mm nozzle

- 3 walls, 8000 bottom layers (aka, print everything as a bottom layer)

- 45mm/sec for walls, 30mm/sec top/bottom

The 8000 bottom layers trick is how I print solid objects. It works better than actually using Infill: 100%.

Of course I got lost in the weeds here and so I still have yet to print the actual chain covers. :)

Daren Schwenke

Daren Schwenke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.