There has already been 2-3 iterations of this idea before this post.

It all started 3-4 years ago when I started looking for cheap boxes to sort my components. The best boxes I found with the highest segments/$ where fast food plastic boxes. So I brought a good 20 boxes and put things in boxes. It stayed that way for a few years.

Then I started accumulating more components and overfilled the 20 odd boxes. So I went online and found a new type boxes that was a much better shape and size, and then went about buying 3000 of these boxes. I do not have a box storage count issue anymore :)

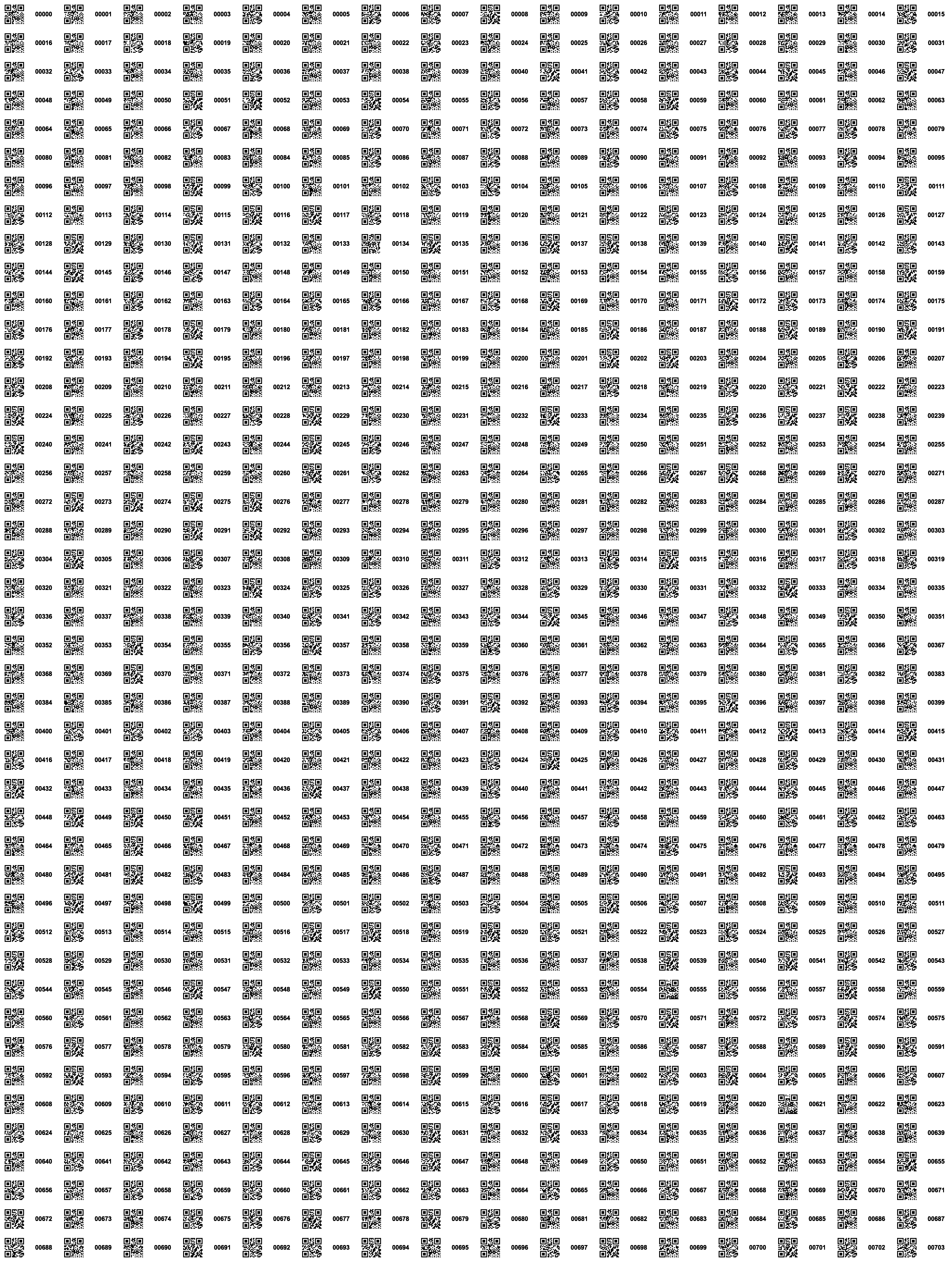

Now that the box count issue was resolved, keeping track of all the boxes became the main issue. First the boxes where found to fit snuggly into some packing boxes and created convenient segmentation of the small boxes. This lead to a small program that took a set of photos of the boxes and their locations in the big boxes.

This worked for a bit but as boxes moved around, that was the end of the system... Here then starts the rabbit hole below.

JLAM

JLAM

Dominik Meffert

Dominik Meffert

mmiscool

mmiscool