It's been a while, let me catch you up.

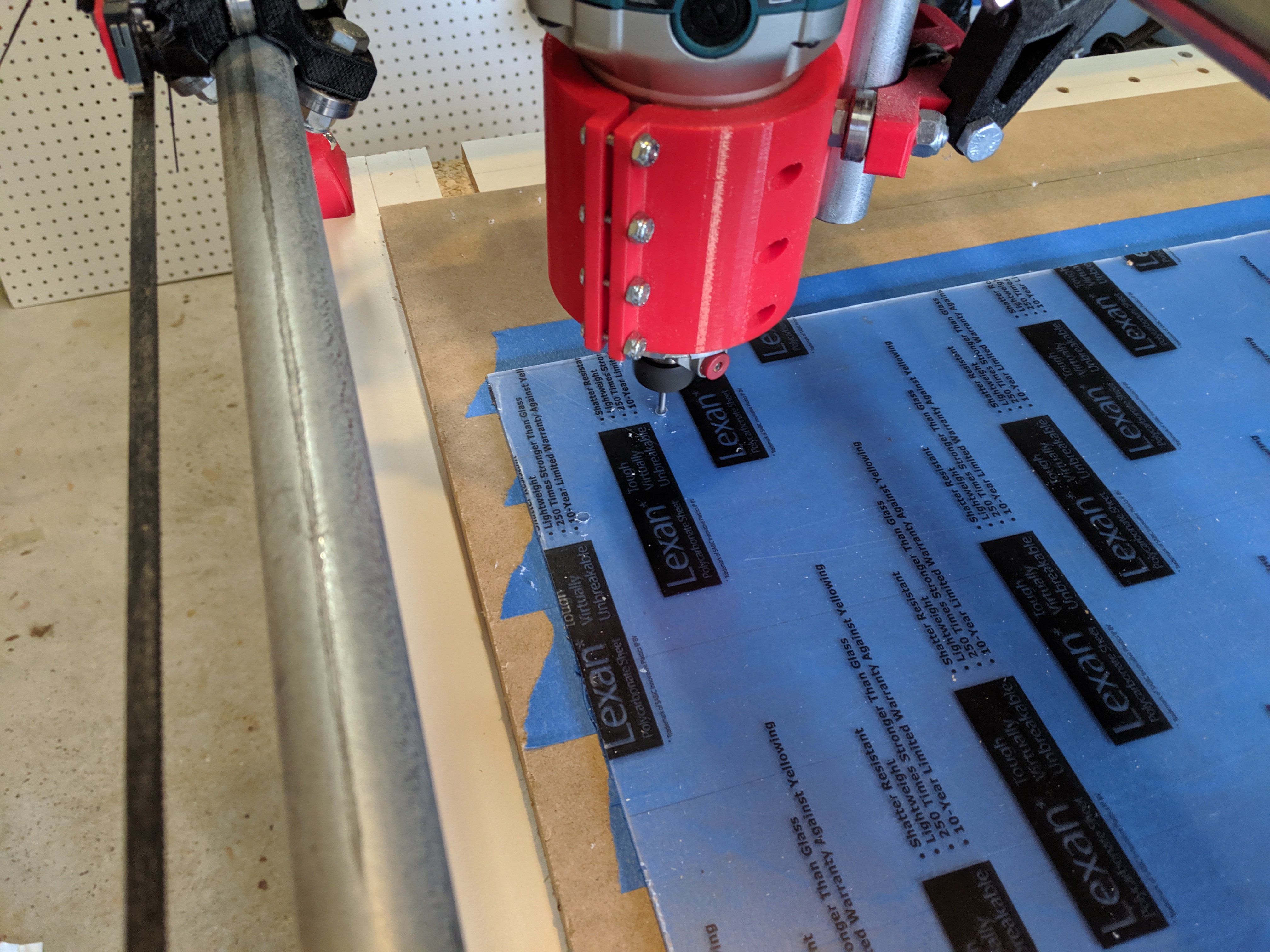

We left off failing at milling polycarbonate plates on the CNC machine. After that I tried a different technique for securing the work: masking tape on the bed and workpiece, superglue holding those to each other. It worked and I made the first base plate without any major flaws. To do this, I made a temporary waste board that bolted to my previous one. That was Sept 22, 2019.

On Sept 29, 2019 I trammed the new wasteboard for more consistent depths of cut on these plates.

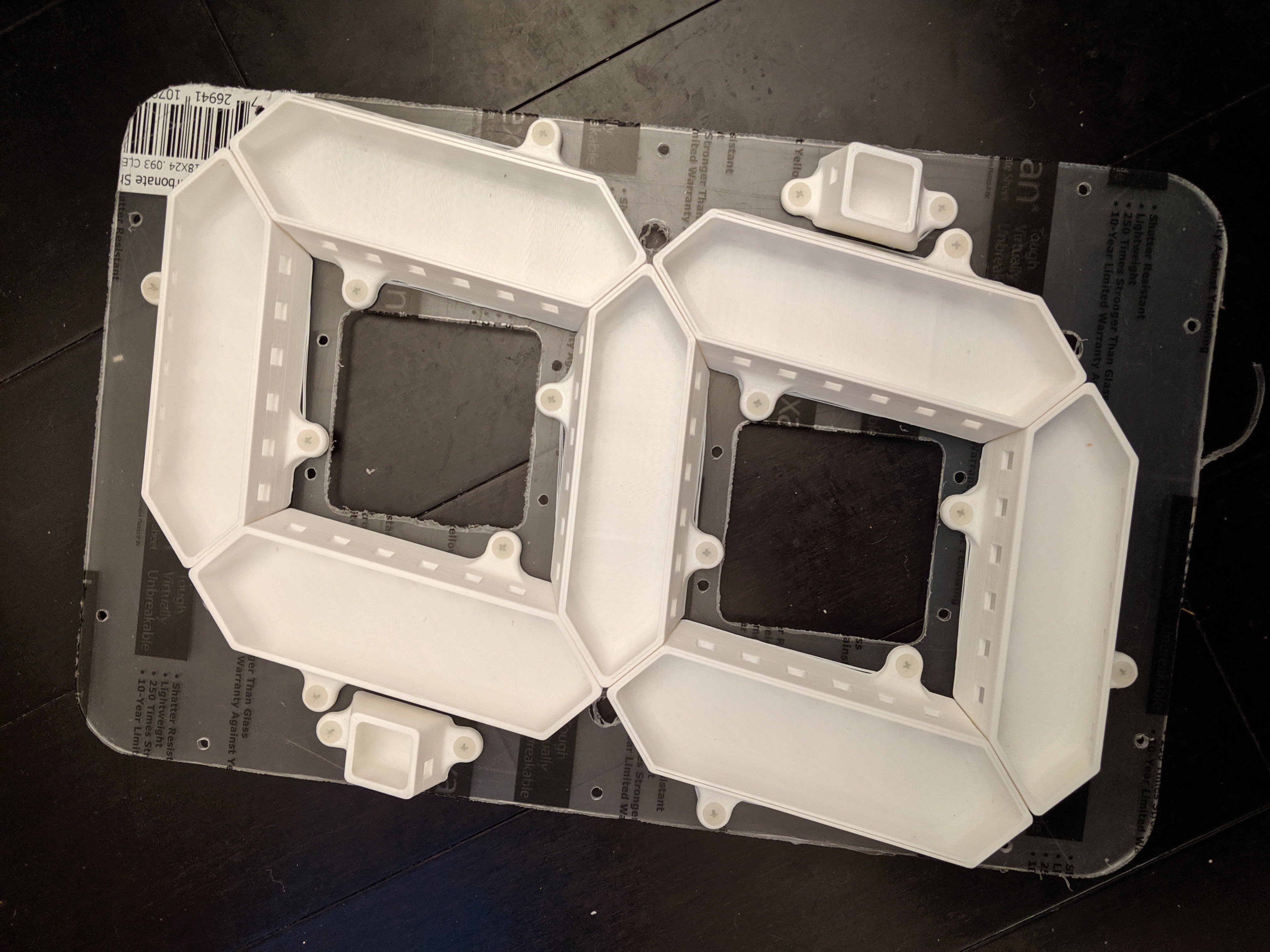

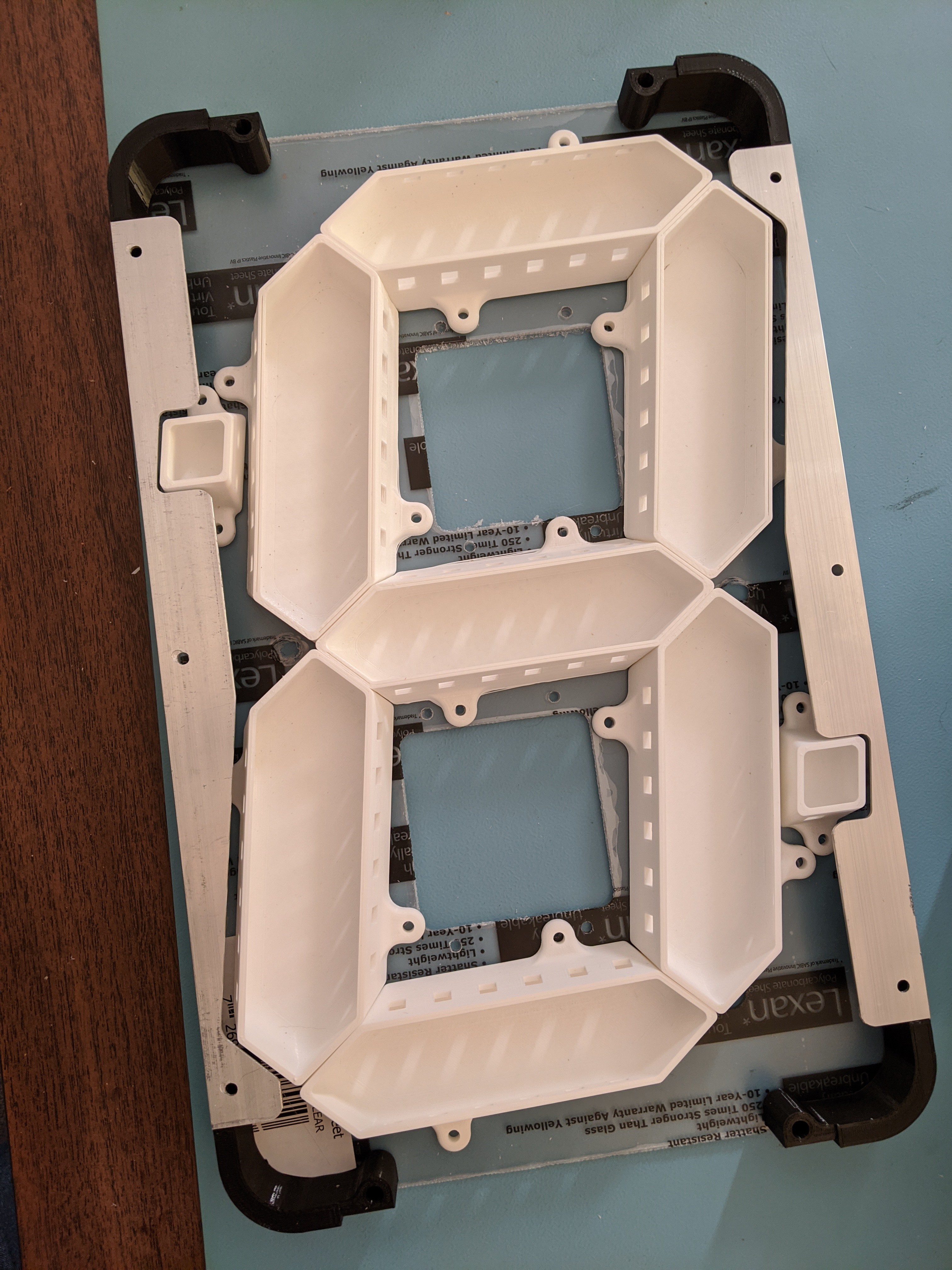

Oct 6, 2019: I was able to make all the base plates and top plates for the four LED signs.

With the plates pretty much done, I moved on to making the top and side pieces which are based on aluminum angle stock. I've never milled aluminum before and the angle stock is going to require a vice mounted under the CNC. So there's a lot of prep work before I can proceed.

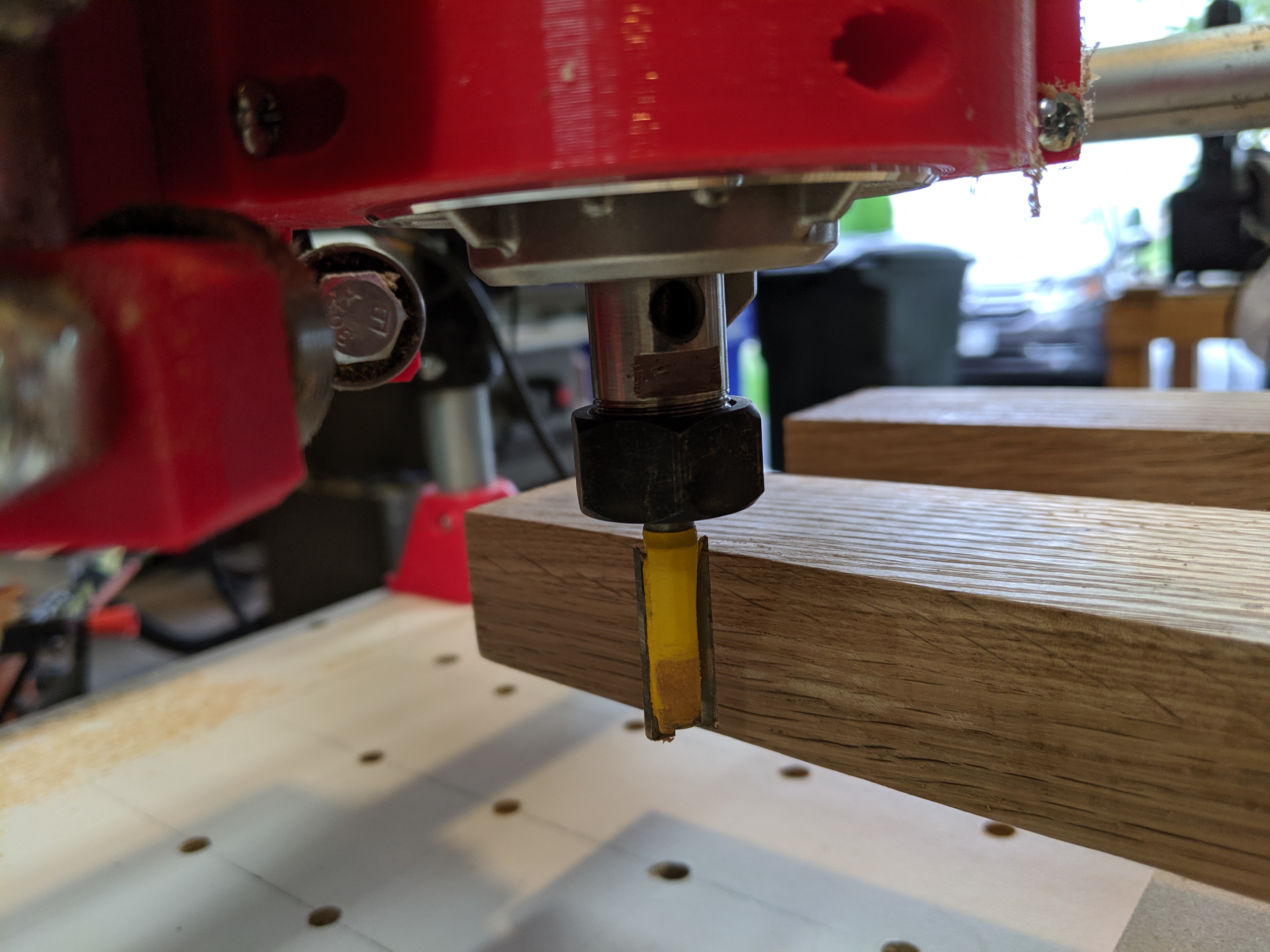

Oct 16, 2019: I started making a set of oak jaws to mount on a vice. This will be for work holding aluminum angle stock.

Oct 19, 2019: The jaws work but there isn't enough clearance in my CNC to use it! I'll have to modify the CNC table to accomodate it

Dec 31, 2019: I've moved up the CNC rails a couple inches and now the vice with oak jaws fits. I trammed the top and sides of the jaws to square with the CNC machine's reference frame.

Jan 1, 2020: New year, new maker skill -- I machined my first aluminum angle stock piece successfully. The jaws worked nicely.

Jan 18, 2020: I cut down some 8mm steel rod to use as alignment pins. Now I can place stock in the CNC vice consistently for repeating operations.

Jan 19, 2020: I made 6 of the 7 remaining side pieces. On the last one, the CNC process went wrong. I wasn't watching but it made a bang and then the workpiece was misaligned. I'll have to finish these another time.

Jan 26, 2020: I made the last side piece and all the remaining top/bottom pieces today. The CNC operations were uneventful. :-)

The aluminum angle pieces that were milled so far are for the front half of each enclosure. The back halves are the next thing on my hit list. I'm not sure if the CNC is the best choice for making those or just use the drill press -- these parts are simpler to make manually but more complex to CNC.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.