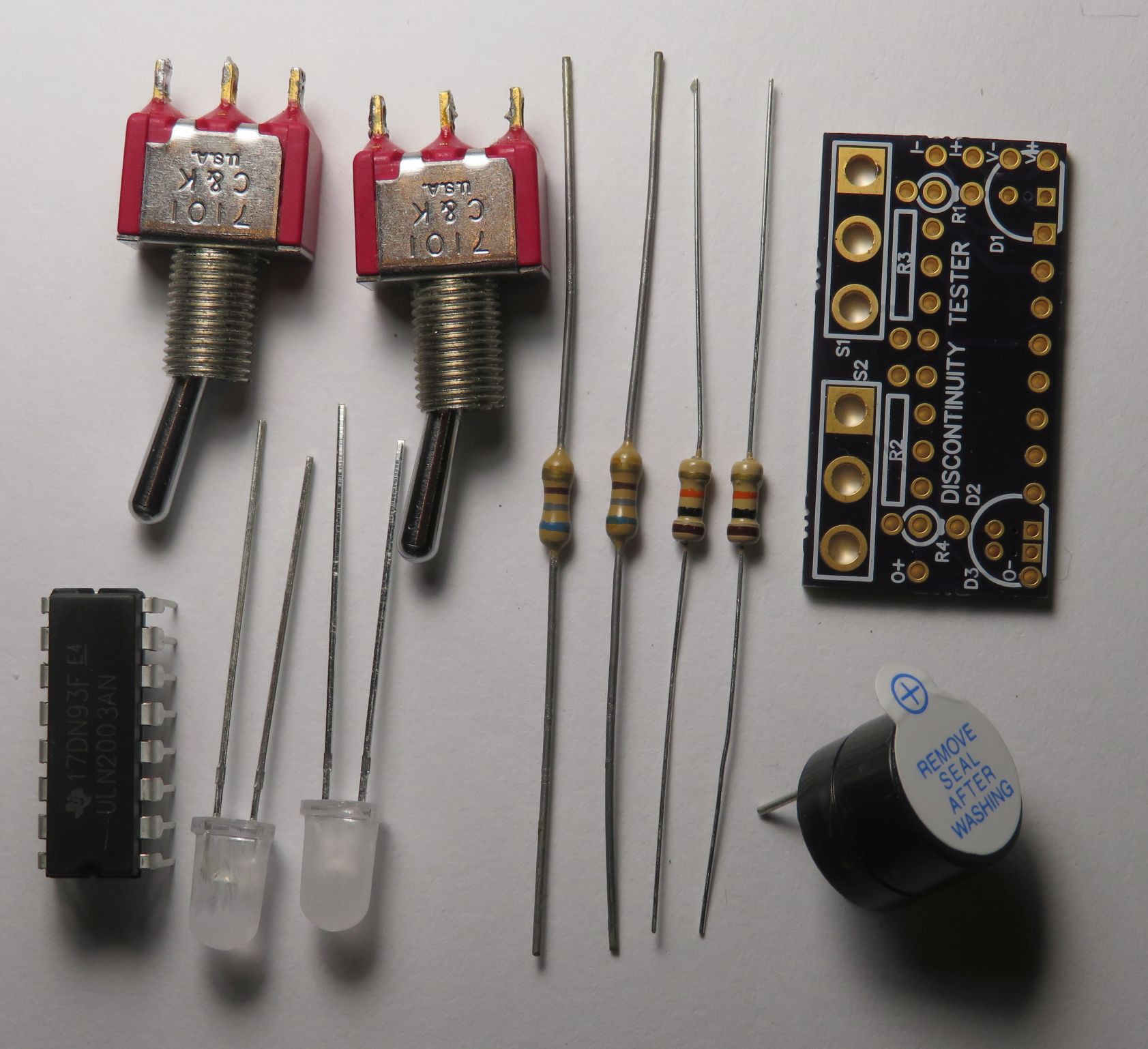

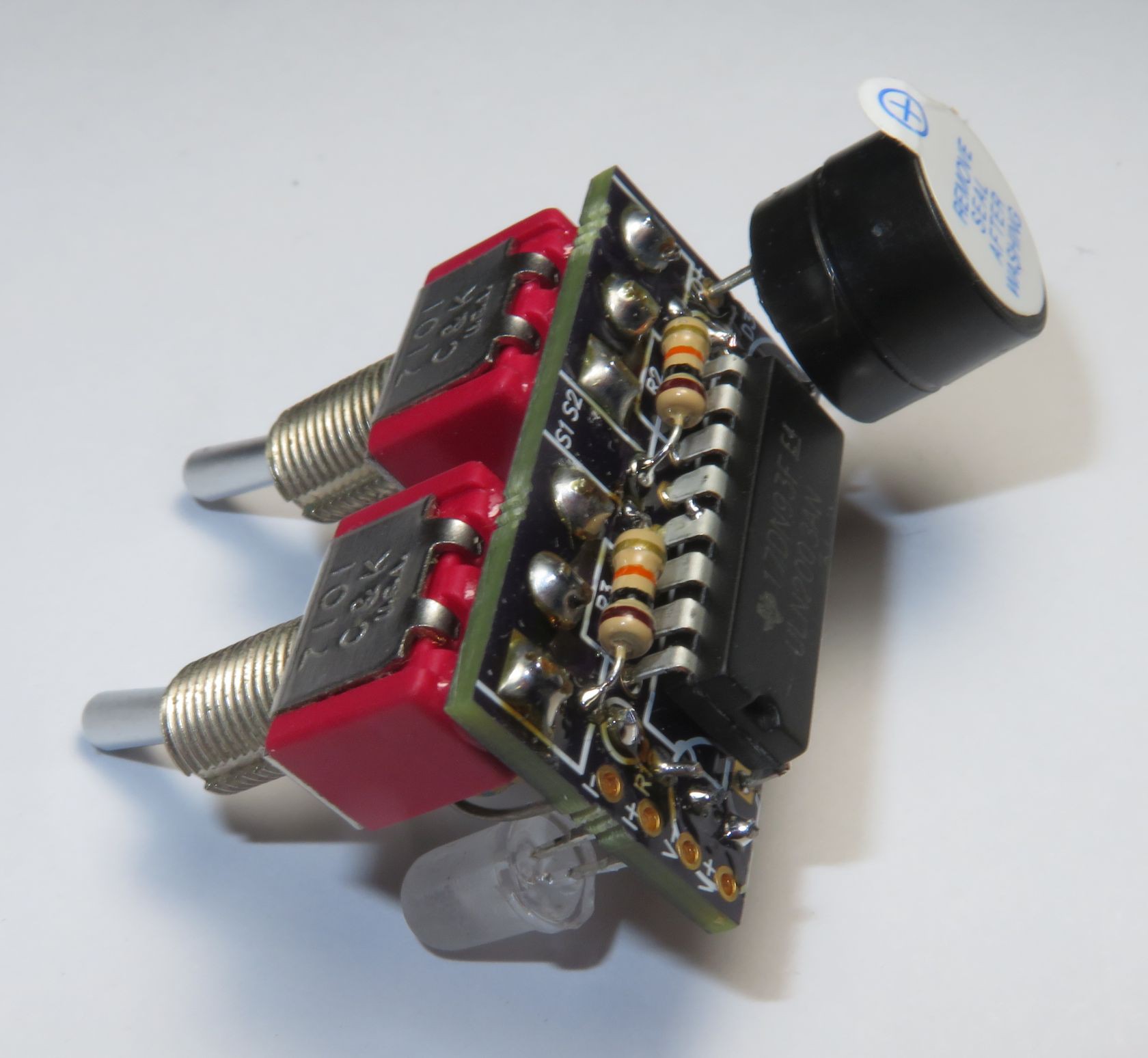

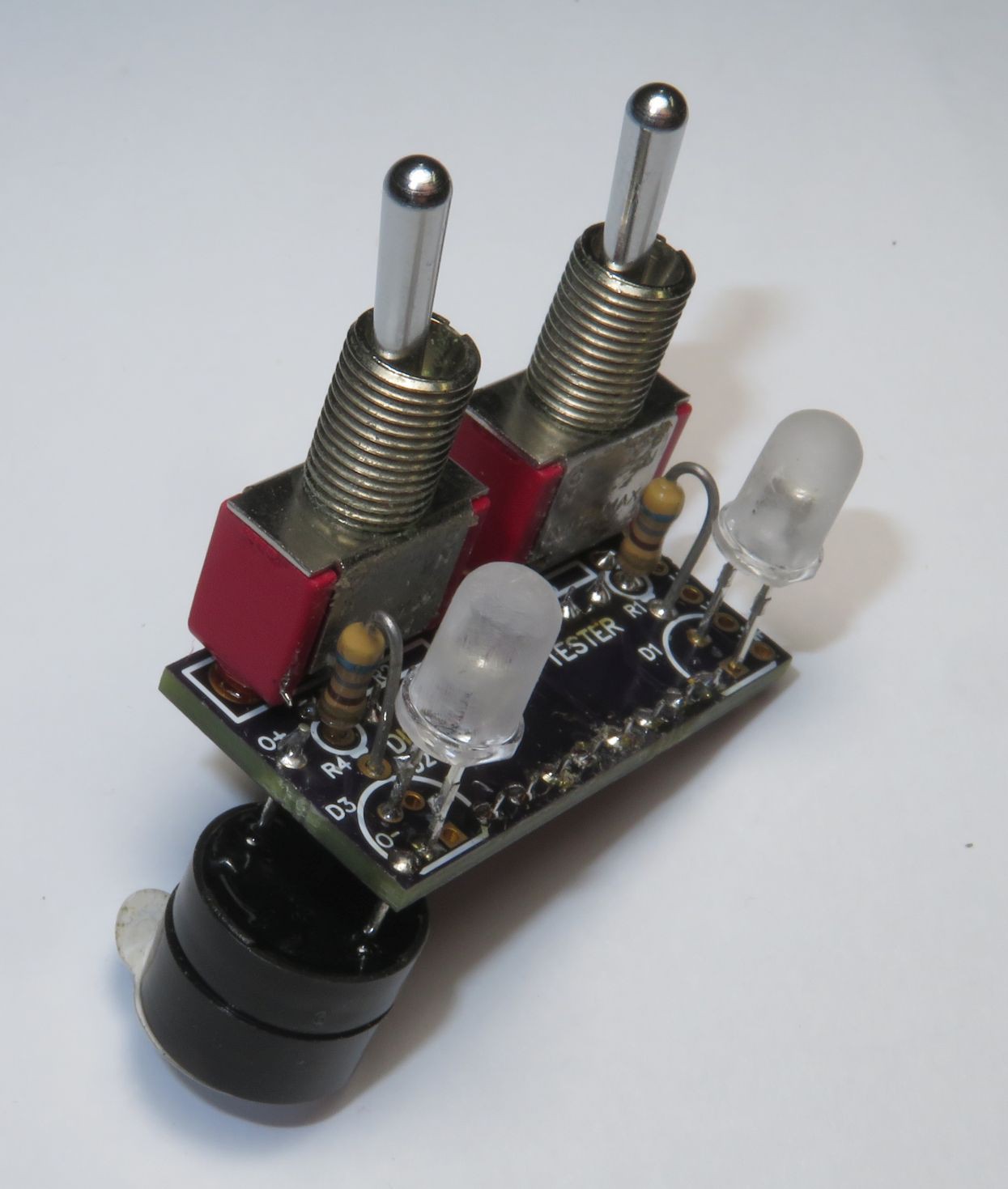

This can be powered by voltages in the range of 3.3 to 12 V or more but component values below are for a 5 V power supply (not included). The circuit board design is on OSH Park at https://oshpark.com/shared_projects/fKoGMBCK. This does not use a microcontroller so no program downloading is required. The main circuit element is a ULN2003A Darlington transistor array (16-pin DIP). The board is small to minimize board cost. Board mounting is intended to be done via the two panel-mount SPDT switches.

One switch (S1) is used to select between the continuity and discontinuity functions. The other switch (S2) is used to enable or disable the beeper.

The tester's positive test input terminal is the power supply and it's negative input test terminal is a ULN2003A input as described below. There is no extra circuitry for current-limiting, ESD protection, etc. (KISS principle used).

Build Options:

- LED D2 or D3 should be populated but not both because they share the same current-limit resistor and overlap on the PCB. D2 lights for test circuit continuity regardless of the setting of switch S1. D3 lights depending on the S1 continuity/discontinuity setting.

- Switch S1 can be a SPDT Center-Off instead of a normal SPDT to combine the function of S2 (beeper on/off) into S1 (continuity/discontinuity). However, the center-off position changes the behavior by disabling LED D3 in addition to the beeper. If the center-off switch option is used, a jumper needs to be installed between S2 pins 1 & 2 in lieu of the switch.

- The beeper, the LEDs, or the switches can be remotely mounted instead of directly mounted to the PCB.

- A power switch could be added to the enclosure to save power -- useful for batteries but very little power savings if powered by AC. The power-on LED D1 (and R1) is not required and could be omitted.

- This could also be used to show the state of a digital output by connecting the digital output to the input negative and the digital output's ground to the power supply negative/ground. The digital output must source current -- if it's an open-collector type output, a pull-up resistor must also be added.

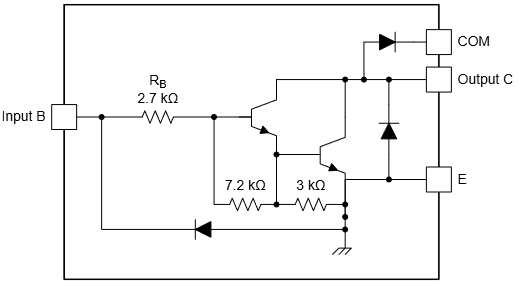

Key specifications of the ULN2003A Darlington transistor array are:

- Input current-limit resistor going to the base, 2.7 kOhm nominal.

- Input pull-down resistor to ground, total of 10.2 kOhm nominal.

- Because it is a Darlington, output saturation voltage is > 0.6 V and there's two diode voltage drops on the input before it starts conducting.

- Minimum operating voltage is limited by the input resistance and the transistor gain of >1000.

- Maximum operating voltage is limited by the 50 V Vce specification.

If a different power supply voltage or different LEDs are used, the LED current-limiting resistors (R1, R4) may need to be changed. The most accurate way to determine the resistor value is to use an adjustable power supply, a DMM, and a 100 to 1000 Ohm resistor. Hook the resistor in series with the LED and the DMM across the LED. and set to measure voltage Then change the power supply voltage until the desired brightness is reached. Then measure the LED voltage. Then set the DMM to measure current and put it in series to get the LED current. Then use Ohm's law: R = (Vs - 0.6 - Vled) / Iled, where Vs is the power supply voltage that will be used, 0.6 is approximately the ULN2003A Darlington transistor voltage drop, Vled is the LED voltage drop, and Iled is the desired LED current. Use the nearest available resistor value; precision is not required.

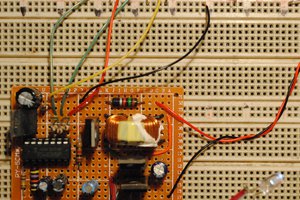

The PCB side with IC U1 ULN2003A is called the top side. The IC must be mounted on the top side for the PCB interconnections to be correct. All the other components can be put on either side or mounted remotely instead of on the board. What works well is as shown below: IC, beeper, R2...

Nicholas Amrich

Nicholas Amrich

W4KRL

W4KRL

Enrico

Enrico