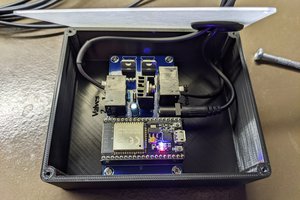

In the DIY hacker community, the ESP8266 microcontroller is the ideal IoT device for logging data. AGI-ESP8266 is intended to assemble a cheap, robust system for logging temperature/humidity, ambient light and soil moisture data over a long period of time.

Currently, several design challenges need to be overcome.

The first is regulating soil temperature on window sills. The problems that I have run into involve effectively reducing rapid transitions in soil temperature. The proposed solution involved bending copper tubing and circulating water under the planter trays to maintain the soil temperature at room temperature. However, I will need to design a rig for bending the copper pipe accurately into the shape of the planter tray before attaching aluminum foil to the copper tubing.

If anyone is interested in contributing a design using high torque stepper motors and a 3d printed assembly for doing that I would be extremely keen on building it and using it for that purpose.

However, that brings me to what I am currently exploring. I'd like to take the agi-esp8266 system I've assembled and putting the agi-esp8266 microcontroller prototypes to use growing plants in a self-contained coldbox.

The current idea that I have is to utilize advancements in insulation to assemble a coldbox for use in the arctic. The advancements in insulation I would like to test are Vacuum Insulated Panelling, silica-based aerogel and conventional polyurathane rigid foam insulation.

I'm looking at assembling several prototype coldboxes to test the different insulation materials and to test several small 3d printed Vertical Axis Wind Turbine designs to both heat the box and to supply power to multi-spectrum Chip-On-Board LED grow lighting.

The idea is to require zero outside energy and operate only using wind energy. I have yet to finalize a final design for the coldboxes or the VAWT designs, but I am open to suggestions.

hominidae

hominidae

YJ

YJ

Ben Brooks

Ben Brooks

Alexander Dvorkovyy

Alexander Dvorkovyy

Feel free to comment/ask questions here.