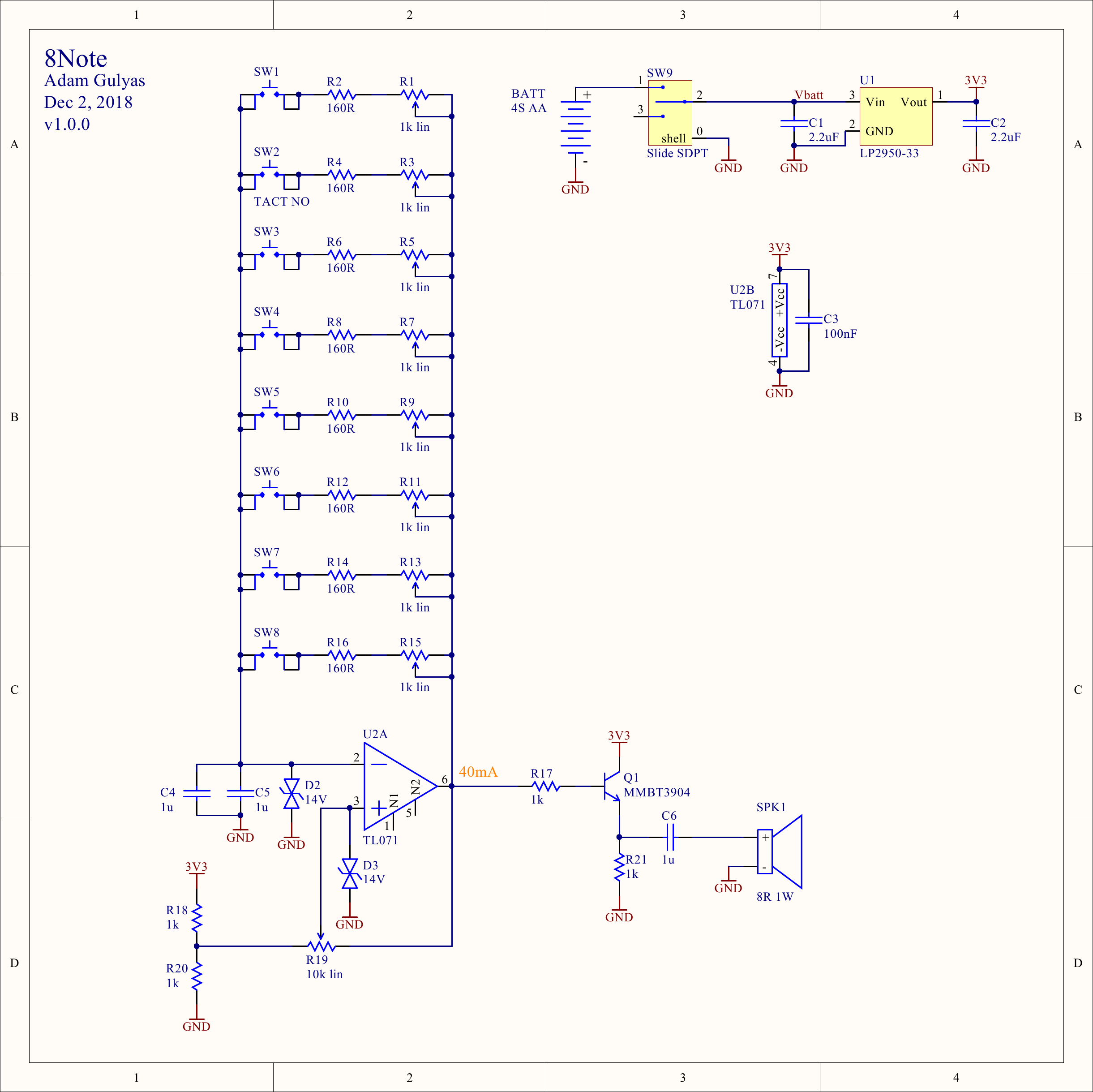

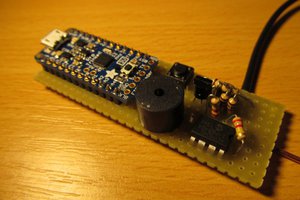

I've build previous versions of this circuit in the past, but always on a breadboard. One time it was for the tech display that was part of Geer Week, the annual competition between the engineering disciplines at the University of Alberta. Another time I helped a student who was job shadowing me to solder together a version on perf board. Since I kept using it, I decided to make an actual PCB and formalize it. I'd also been wondering about the feasibility of doing small run electronic projects, so I decided to make 10 and time myself.

I've put all the details of the project in the Project Logs on this page. However, since hackaday doesn't let you reorder them once made, they're in the order that I realized I needed each section, not a logical order. Here's an index with links, ordered as it should be.

Adam Gulyas

Adam Gulyas

Mile

Mile

jaromir.sukuba

jaromir.sukuba

Darian Johnson

Darian Johnson

Interesting project! Do you have any video or audio of how it sounds and operates? I'm curious!