I had absolutely no intention of posting this on Hackday. It's a small one-day hack (well, two-day, if you count the time waiting for the epoxy to dry) that piggybacks on all the other blinkylight fun I've had. New code? Nope; I'd already abstracted running strings of WS2812s from a Moteino. New technology? Nope; I have little black boxes I build for the WS2812s in my house already. It's purely the aesthetic that's different here.

So on December 2nd, I sat down with my spare parts bin and pulled this thing together.

And of course Hackaday posted a circuit sculpture challenge. On December 4th.

If I were building this *for* a sculpture challenge, I'd probably use the brass rods in my basement to give it more of the rectilinear mid-century look. Maybe it's better that I was just knocking this off as more of a Seussian sculpture.

Anyway - down to business! I don't have many photos of the build itself, but I can describe the process.

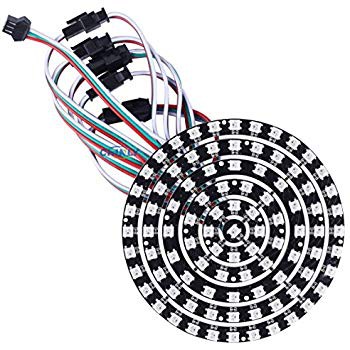

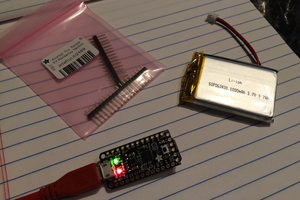

I have a lot of WS2812 blinky things in my life, particularly around Christmas. We use them for Christmas tree lights (driven by a Teensy 3.1 and OctoWS2812). We have lights around some of the house windows (on the inside). We have over-cabinet lights in the kitchen. There's the purposeless LED display I built a few years back. I have strings of 2812s around my office windows at work, and around my office door. Clearly, I have no shortage of these things; and last year, while looking for cheap and reliable 2812 strands to augment my supply, I stumbled across this gem - the "CHINLY 93 LEDs 6-ring WS2812 RGB LED Ring".

I could easily see how breaking out the rings on a cone-shaped form would make it a tree shape. We spent some family time last year talking about what it would look like, and trying to shape pieces of styrofoam for the form.

Well, that styrofoam ($3 from Michaels) is the right width at the bottom, the wrong height and angle, and is very hard to shape reliably. After a few failed attempts, I bought a second hunk of foam but shelved the project for the season. So the pieces were ripe for the pickin' this year.

Given that the form had turned out to be the most difficult part, I decided I wanted to *abandon* the form itself. What about making it a floating sculpture, where the rings are just hanging in mid-air? You'd be able to see the far side of the tree, which sounded more appealing to me anyway. No pesky heat issues (unlike the purposeless LED display - let me tell you, putting a pile of LEDs in a glass jar is just not a good idea). No fighting the styrofoam. No building or finding a new form.

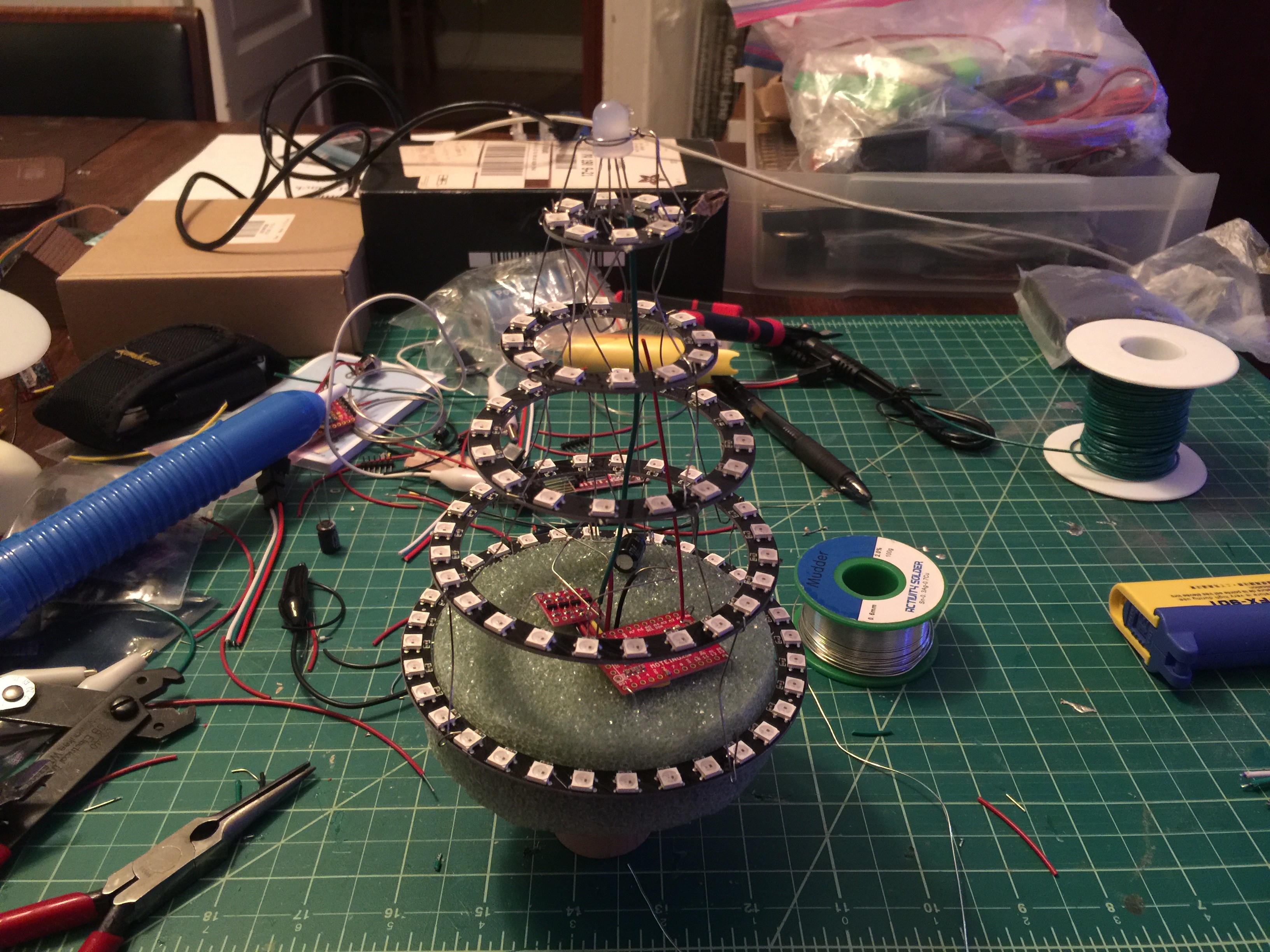

I happen to have several rolls of spring steel in stock in my workshop (I'm tired of saying "in my basement" so let's go with the more pretentious, ok?). One is 20-gauge Malin stainless steel, bought for some amateur radio antenna projects more than a decade ago. I figured that would be a good start here. There are small holes around the edges of the LED rings; you can see above that they're not exactly aligned, but they're close. I pulled the spring steel through each of them and, with much cursing and fussing, looped the spring steel around and back through each for some stability. Of course each time you do this with one, you're upsetting the balance of the next; there's not much structural stability here (effectively you have a little less than one dimension of stability, holding each at the point of inflection but with a lot of compressive wiggle room). This was by far the longest and most tedious part of the build; there's a lot of balancing to be done with each piece of spring steel added. The result is fairly solid, and the steel comes off looking a little like tinsel. At least that's what I tell myself. ;)

I do have this one mid-build photo that shows the misalignment in progress. You can see it's clearly trying to lean to the left...

And at the end of the build:

Jorj Bauer

Jorj Bauer

Rich Morrissey

Rich Morrissey

Ian Norton

Ian Norton

Morning.Star

Morning.Star

Korishev

Korishev

I'm unable to find the video for this project. I'd like to see this arbolito in action.