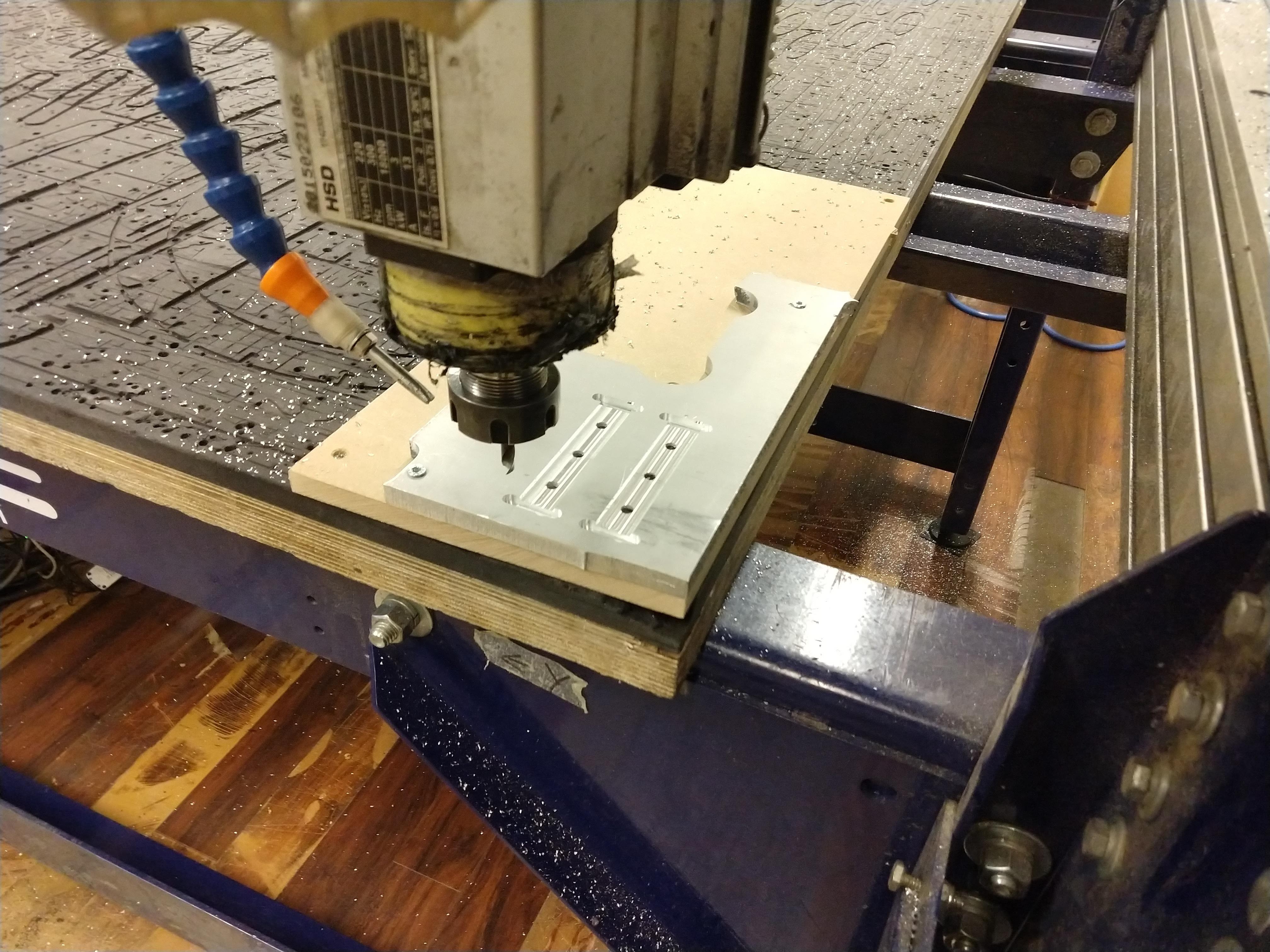

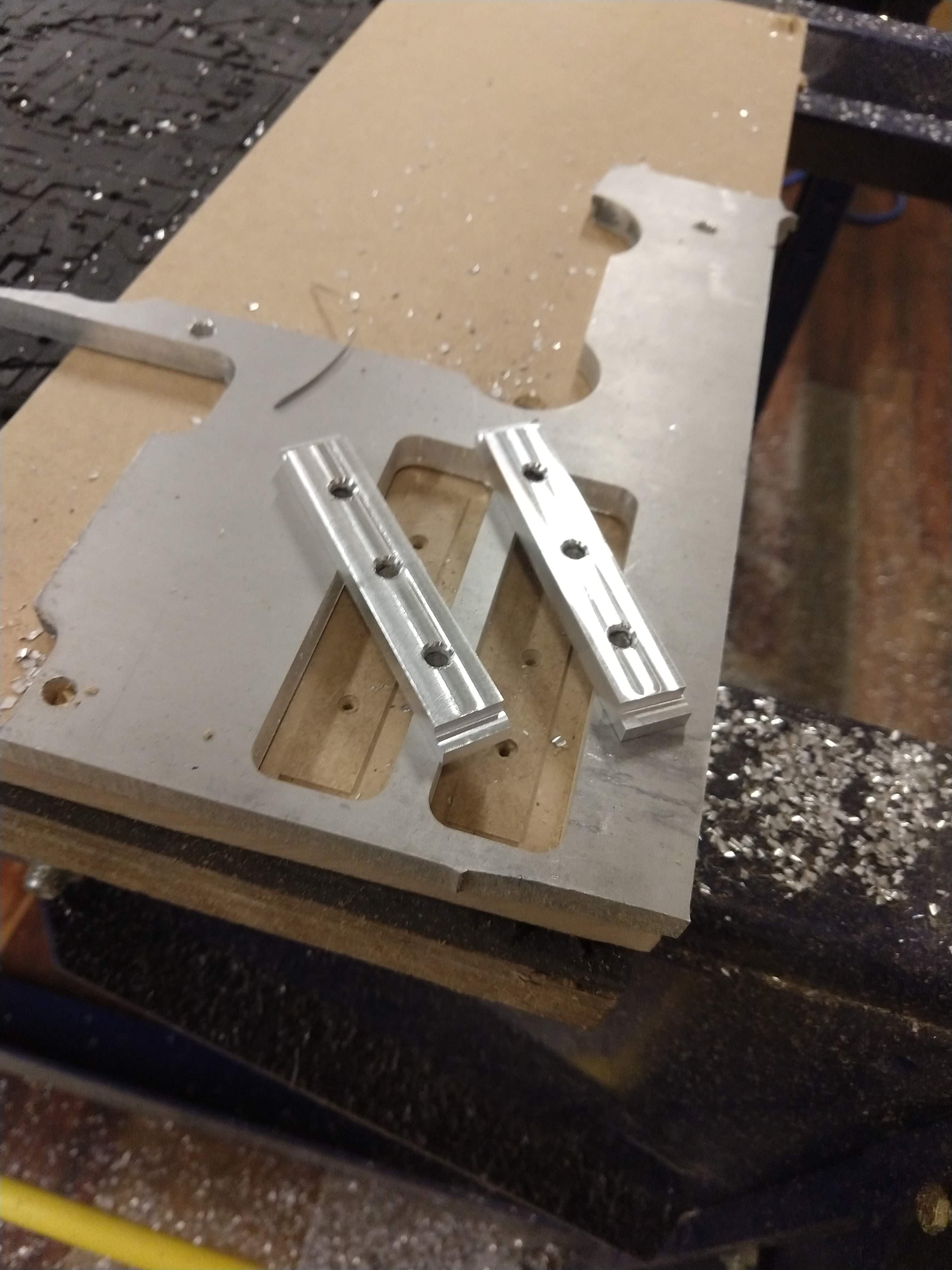

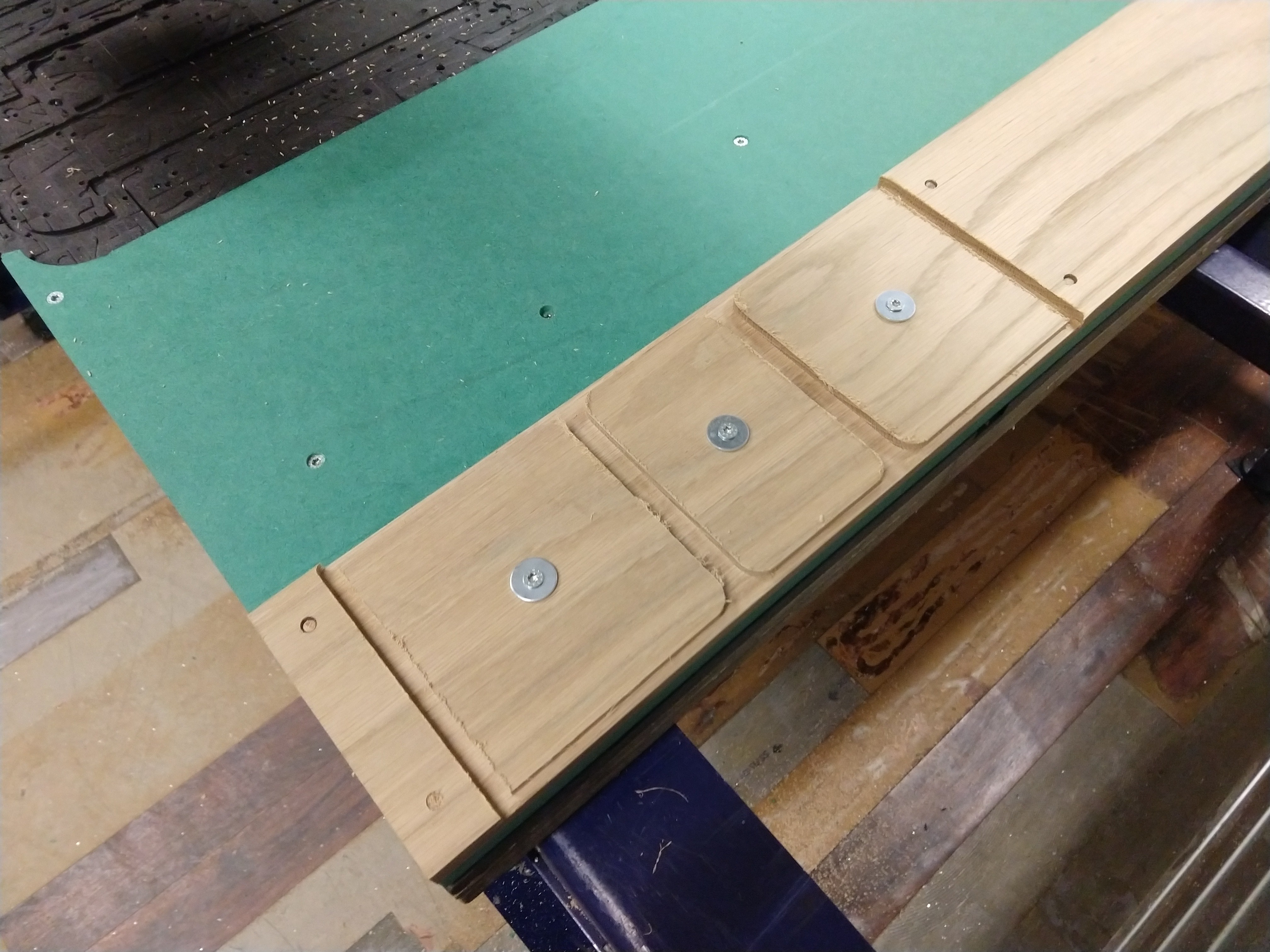

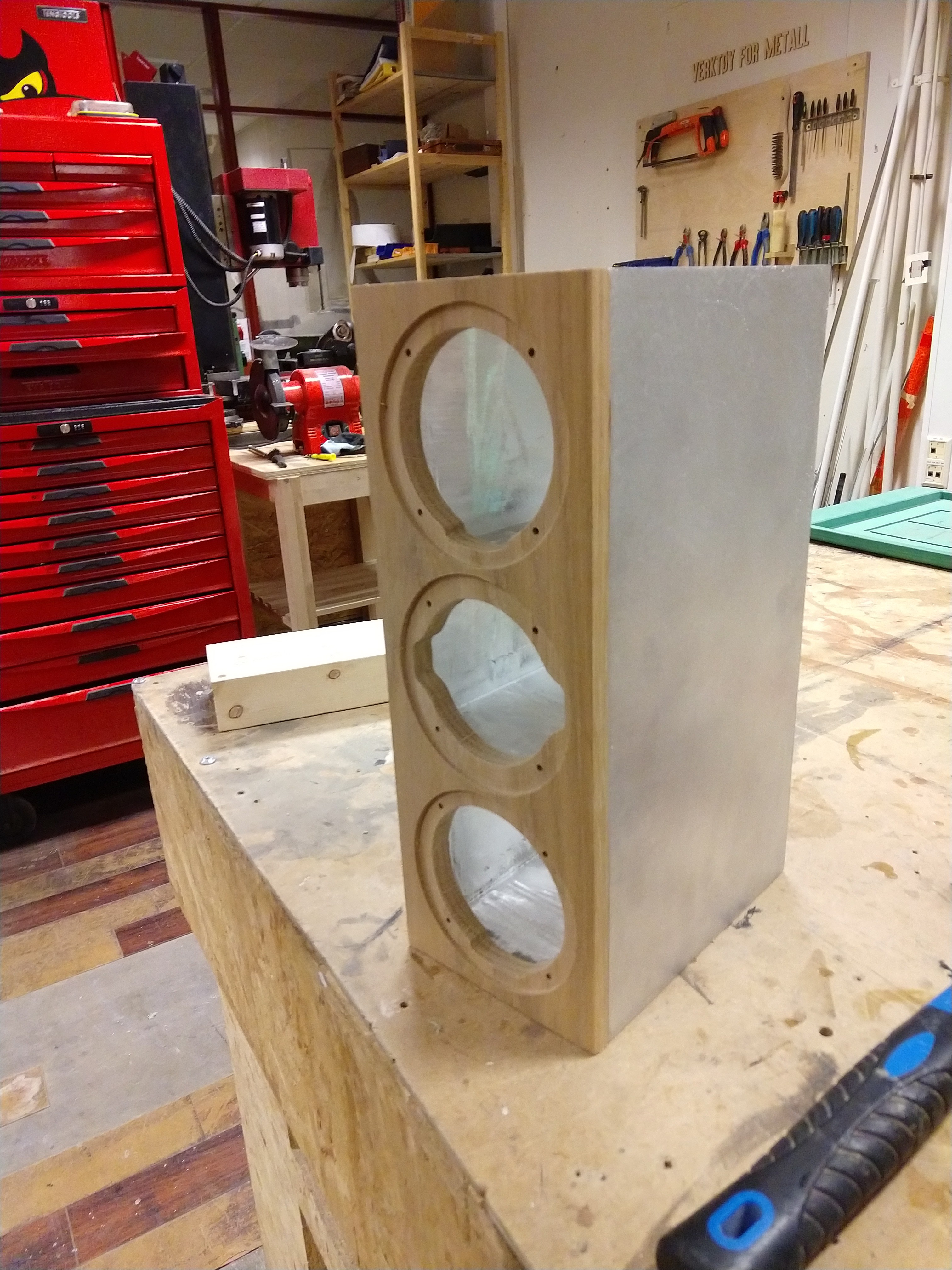

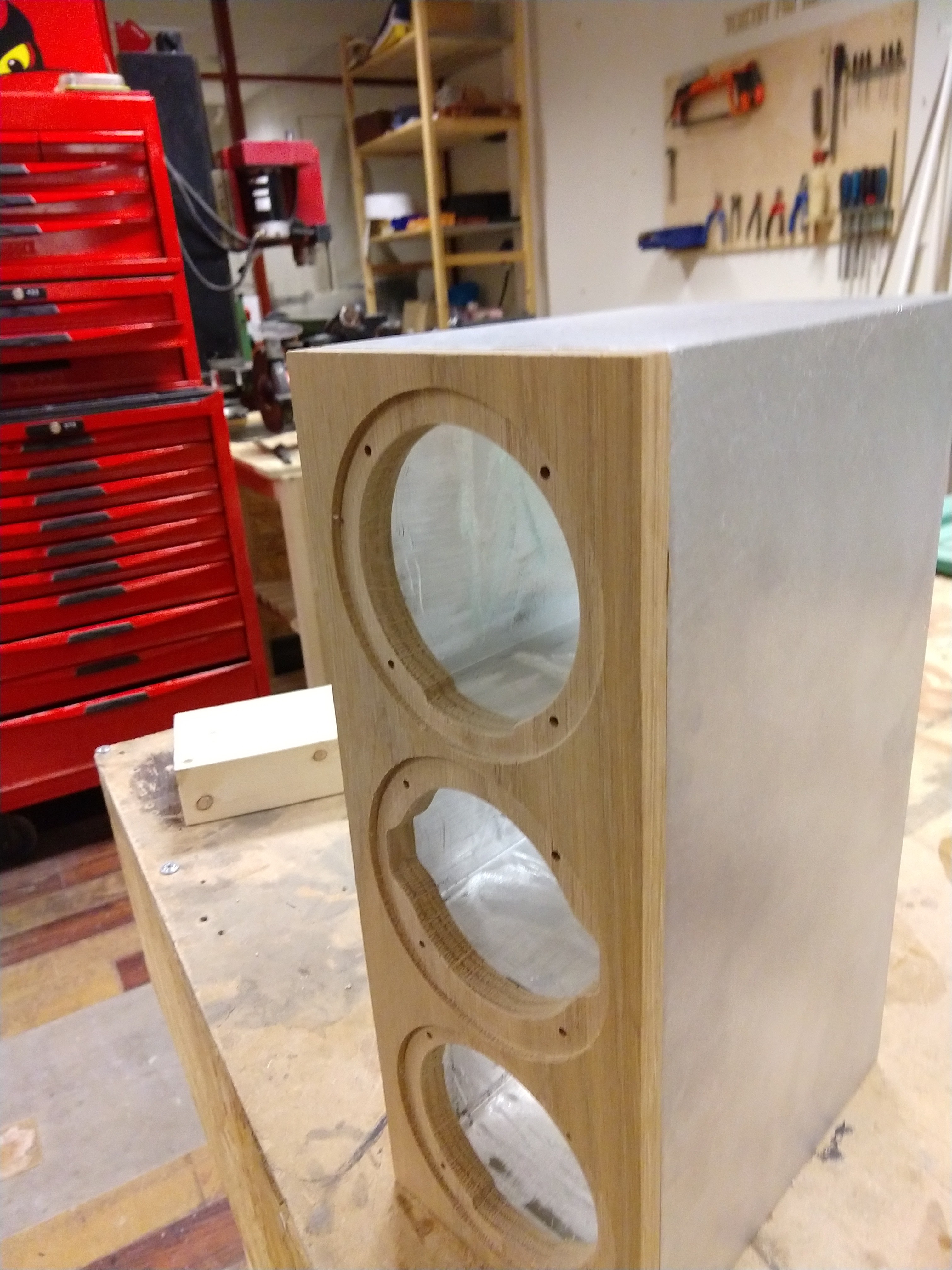

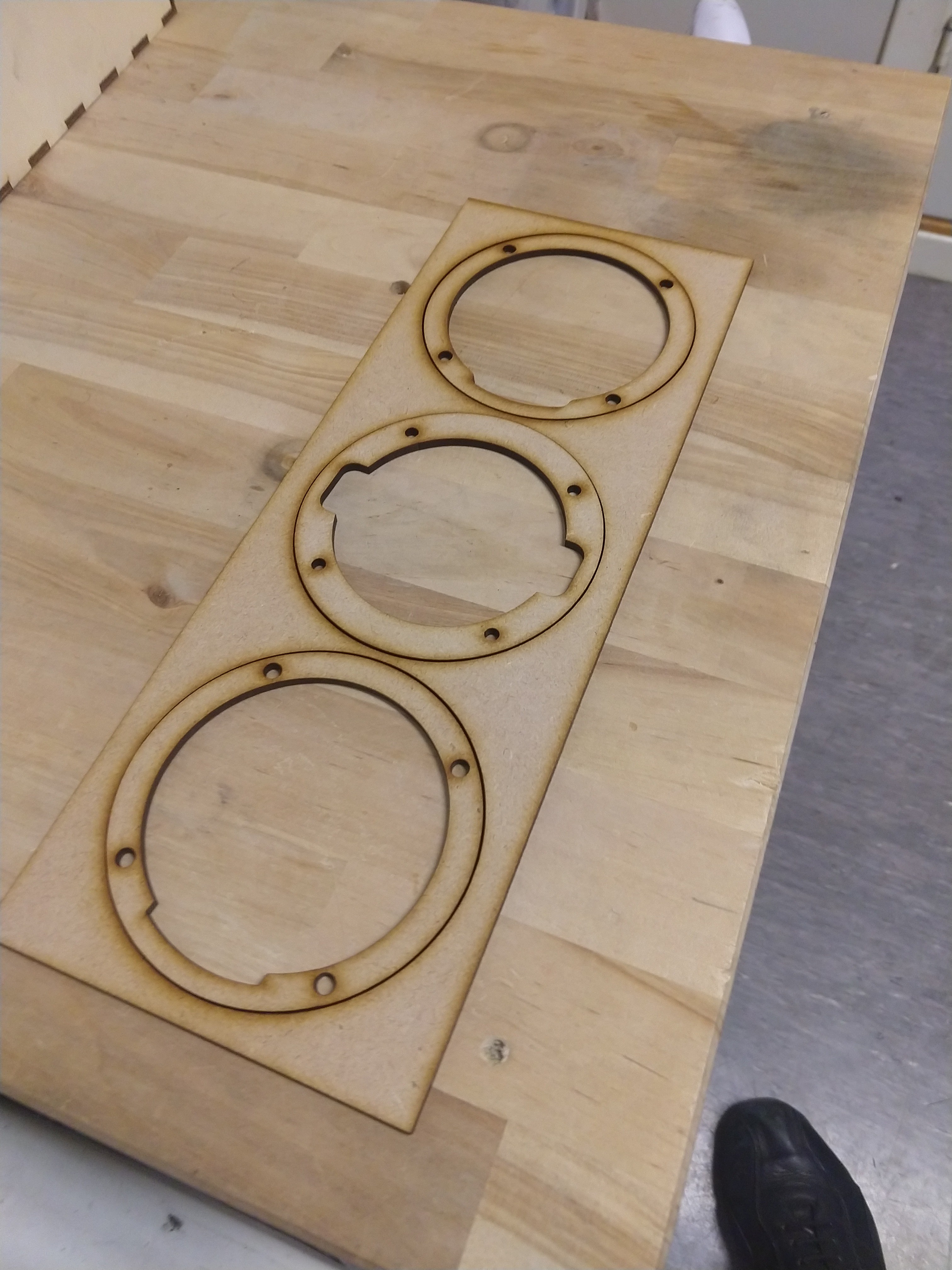

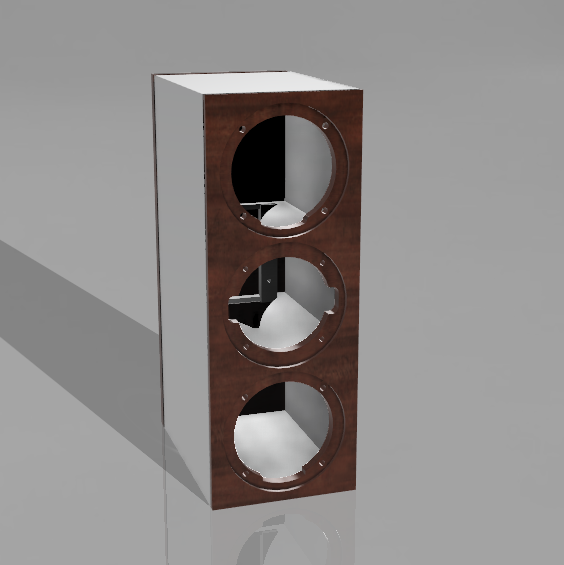

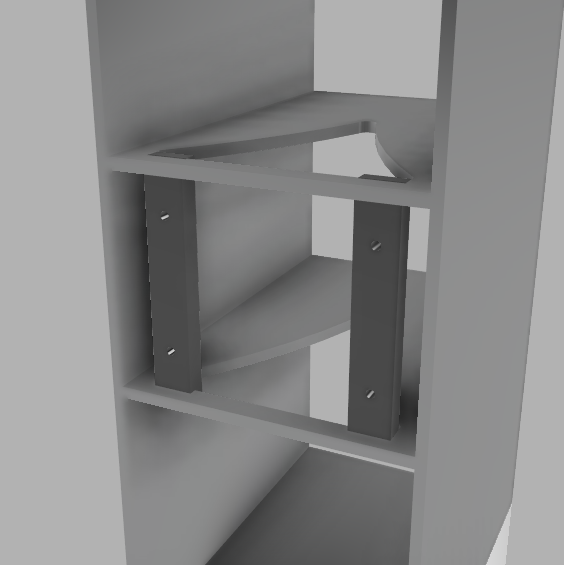

Turning a destroyed Bang & Olufsen cx 100 into a new speaker. The only thing that will be left of the old speaker is the aluminum body. New speaker elements and custom oak panels will be made.

There will be experiments with two-sided milling, lasercutting foam and more.

Øystein

Øystein

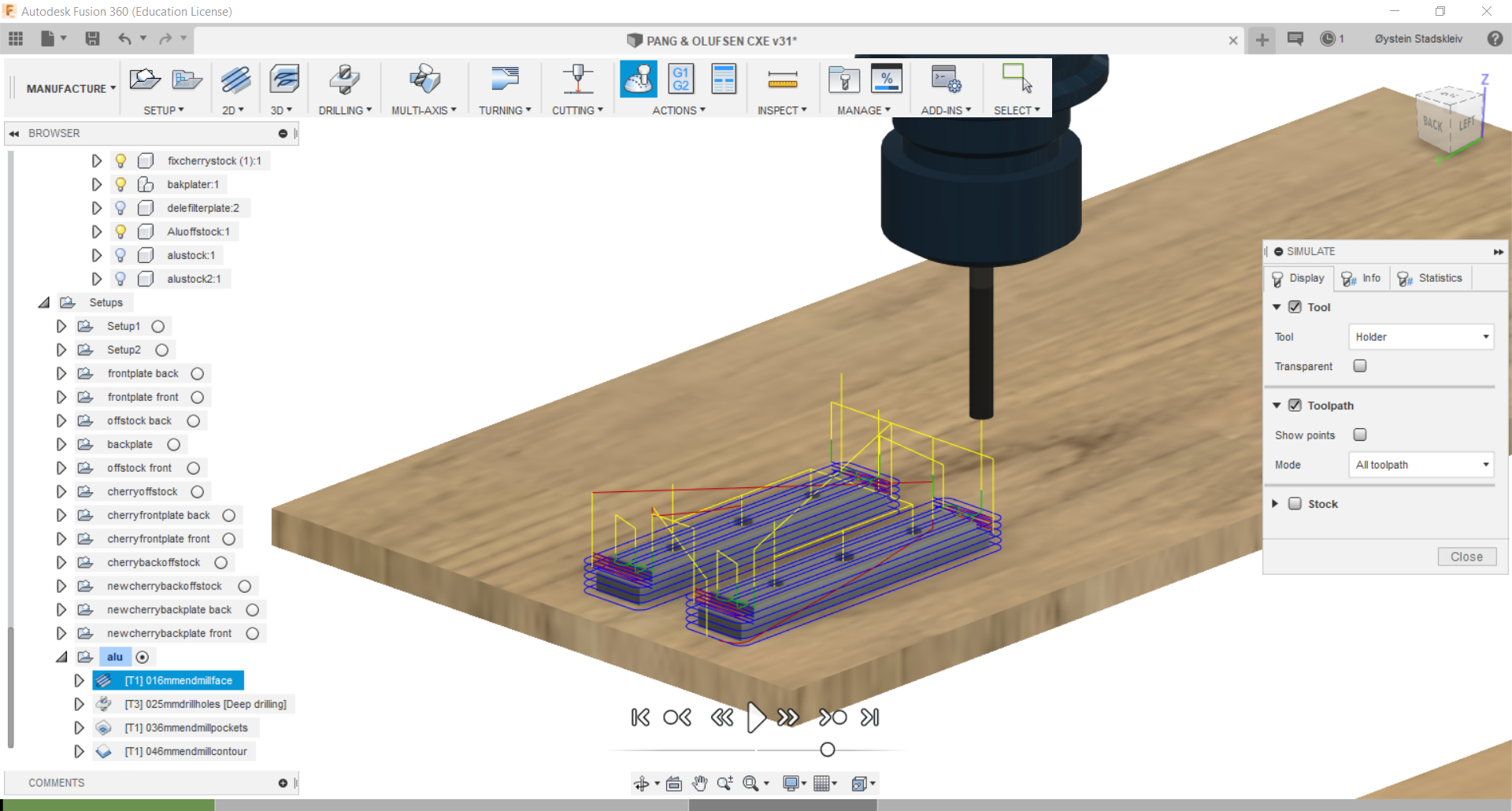

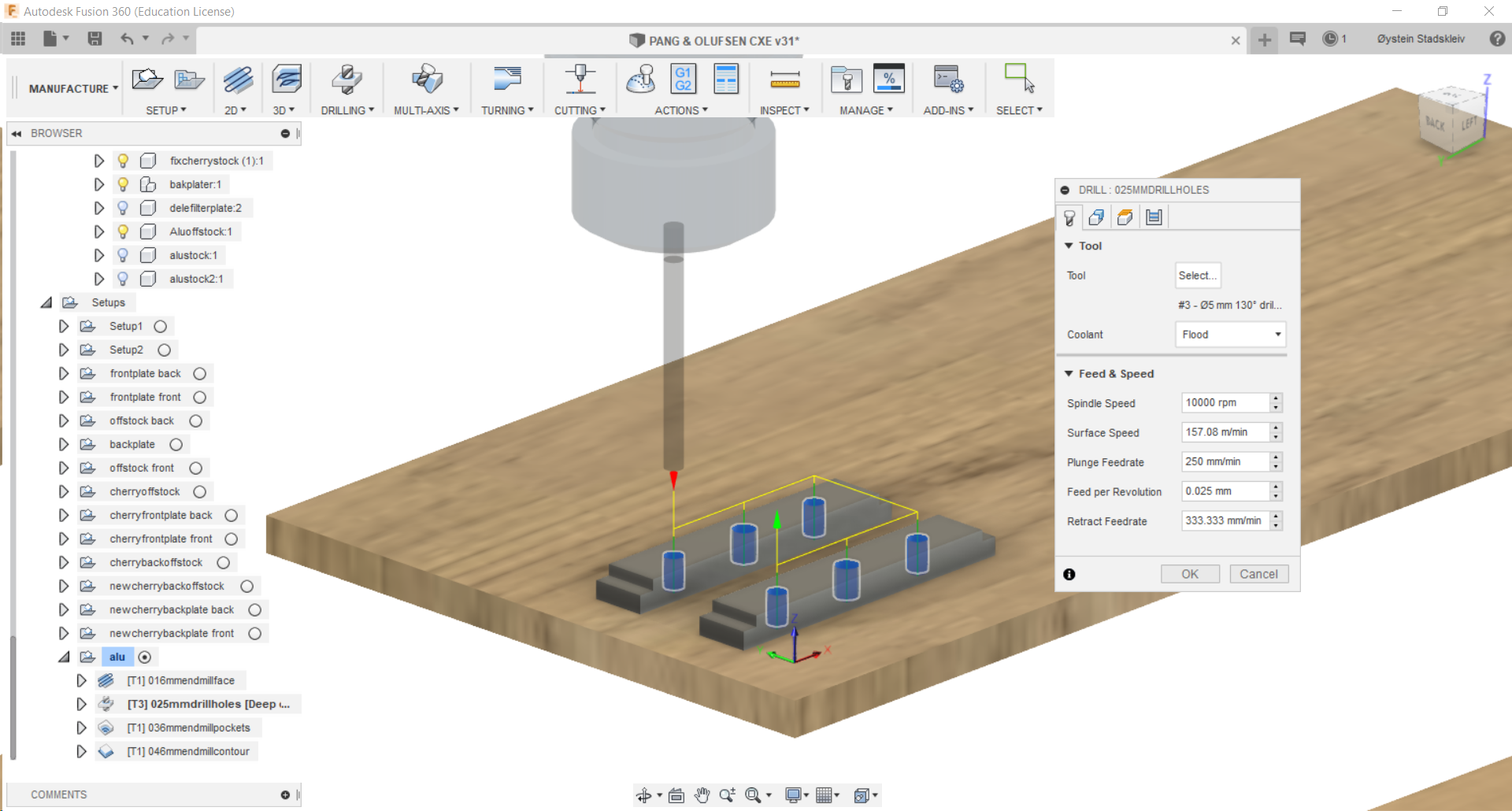

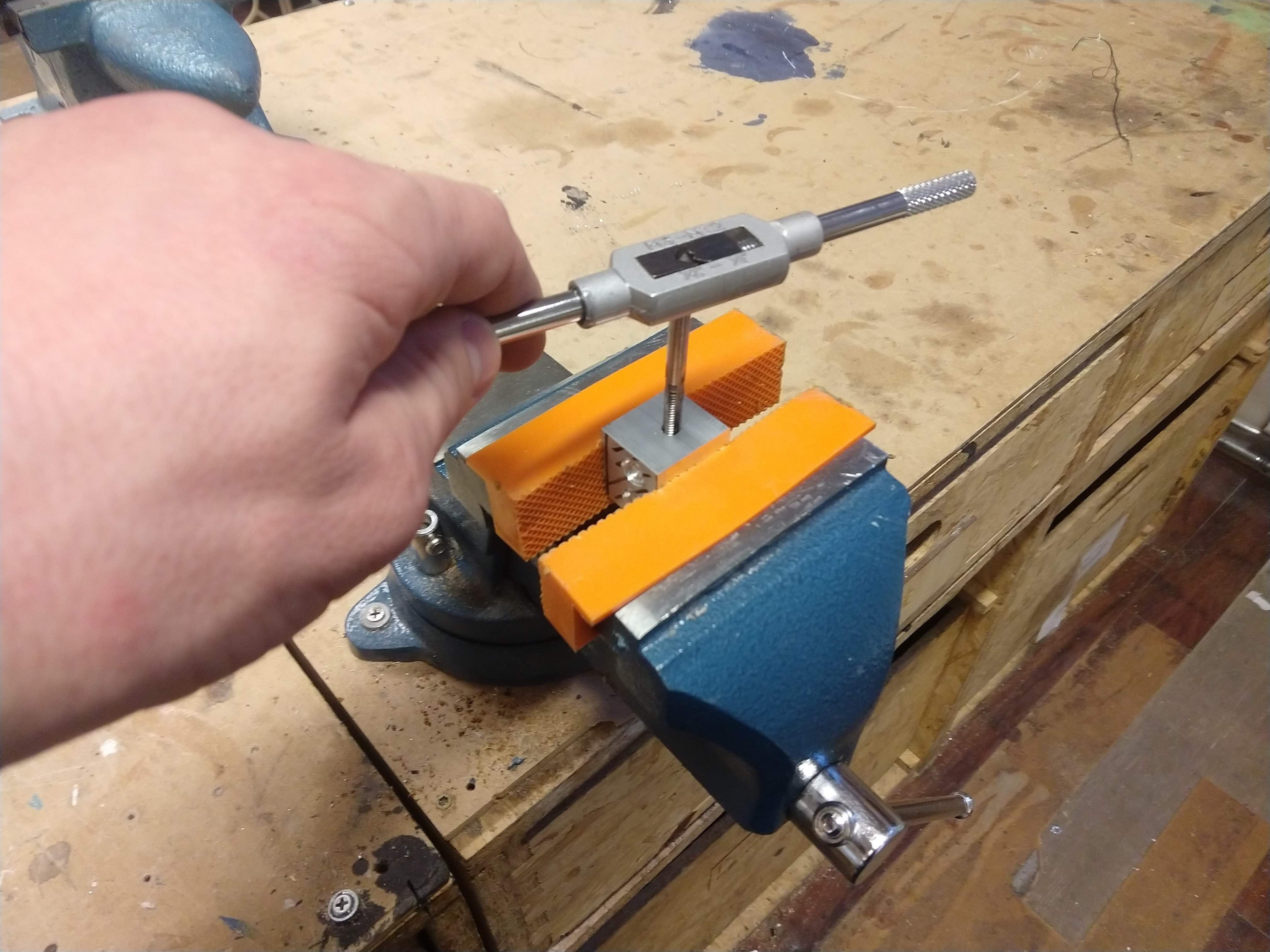

When drilling, remember that the drill bit has a tip angle. the tip angle is well, the angle of the tip in degrees. I found out my tip angle at the Würth website. Fusion 360 automatically calculates how deep it needs to go to make shure one drills through the hole. I made a bottom height offset of -2mm anyway since I had an extra sacrificial layer underneath the aluminum stock.

When drilling, remember that the drill bit has a tip angle. the tip angle is well, the angle of the tip in degrees. I found out my tip angle at the Würth website. Fusion 360 automatically calculates how deep it needs to go to make shure one drills through the hole. I made a bottom height offset of -2mm anyway since I had an extra sacrificial layer underneath the aluminum stock.

David Matthew Mooney

David Matthew Mooney

T. B. Trzepacz

T. B. Trzepacz

kristina panos

kristina panos