This is a quick update on my progress with the 1-servo drive train.

Earlier this week I finally managed to get a grasp on how to to construct an elegant mechanism for driving all four legs with just one servo. I've since realized that while I had the basic idea right, I was a bit off on the details.

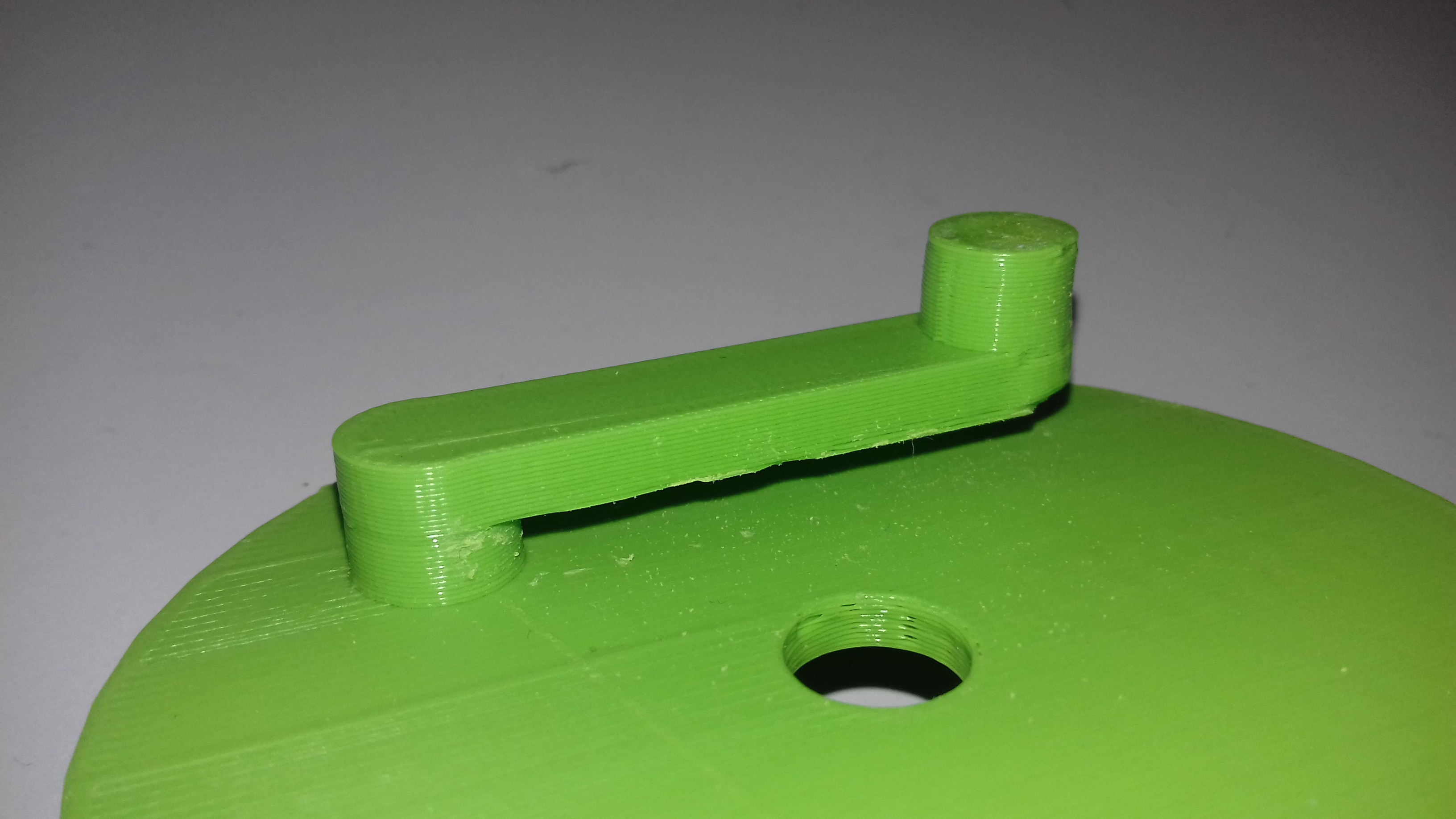

I've now thought it through and modified my solution. To convince myself that it actually works I printed this mechanical model:

The jig transfers rotary motion to the linear actuators in order to cycle through the four leg poses discussed in previous logs. The actuators takes turns moving while the other one is stationary. Turning the wheel in the opposite direction will cycle the poses in reverse which will be used for walking the robot backwards.

The whole thing looks pretty simple once it's there in front of you. But I'm not ashamed to say that I find this mechanical stuff a bit challenging to visualize and as a result I've had a few "what was I thinking"-moments before I got this to work.

Another thing that had me stumped initially was how wide to make each dwell of the yoke, in order to have the actuator pause exactly half of the time. Turns out that's not rocket science either—I believe the right answer is one third of the wheel diameter minus half the cam diameter. EDIT: I think that should read "one fourth of the wheel diameter minus half the cam diameter". But don't take my word for that either.

The main thing that might need improvement is how the cam that moves the top actuator is tacked onto the bottom actuators cam:

That looks a bit fragile doesn't it? I think a better solution would be to have one cam on each side of the wheel. But with the current design the yoke isn't wide enough and would bump up against the wheel axle. However if I were to use substantially wider cams I might be able to use that solution (since that would also make the yoke wider). Such a design would be more compact and also less prone to break. EDIT: The yoke will hit the axle regardless of cam diameter. But it's still a good idea to make the cam thicker for added strength.

Now it's time to leverage this amazing new tech with the next Landbeest prototype (LB-201). I hope to have it up and running within the next few days.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

That's a pretty cool mechanism! I'm an mechanical engineer myself and often have to find a translation from this motion to that motion and can assure you: you've done a good job. It ain't easy, but you get better at that stuff the more often you do it!

Are you sure? yes | no

Hey thanks for the encouragement!

Yeah, it feels like this stuff is taxing parts of my brain that's been idle for years. I'm sure eventually those neurons will start making new connections if I keep at it.

Are you sure? yes | no