The current display has 12 flaps, meaning 10 numbers, a blank face and one other character.

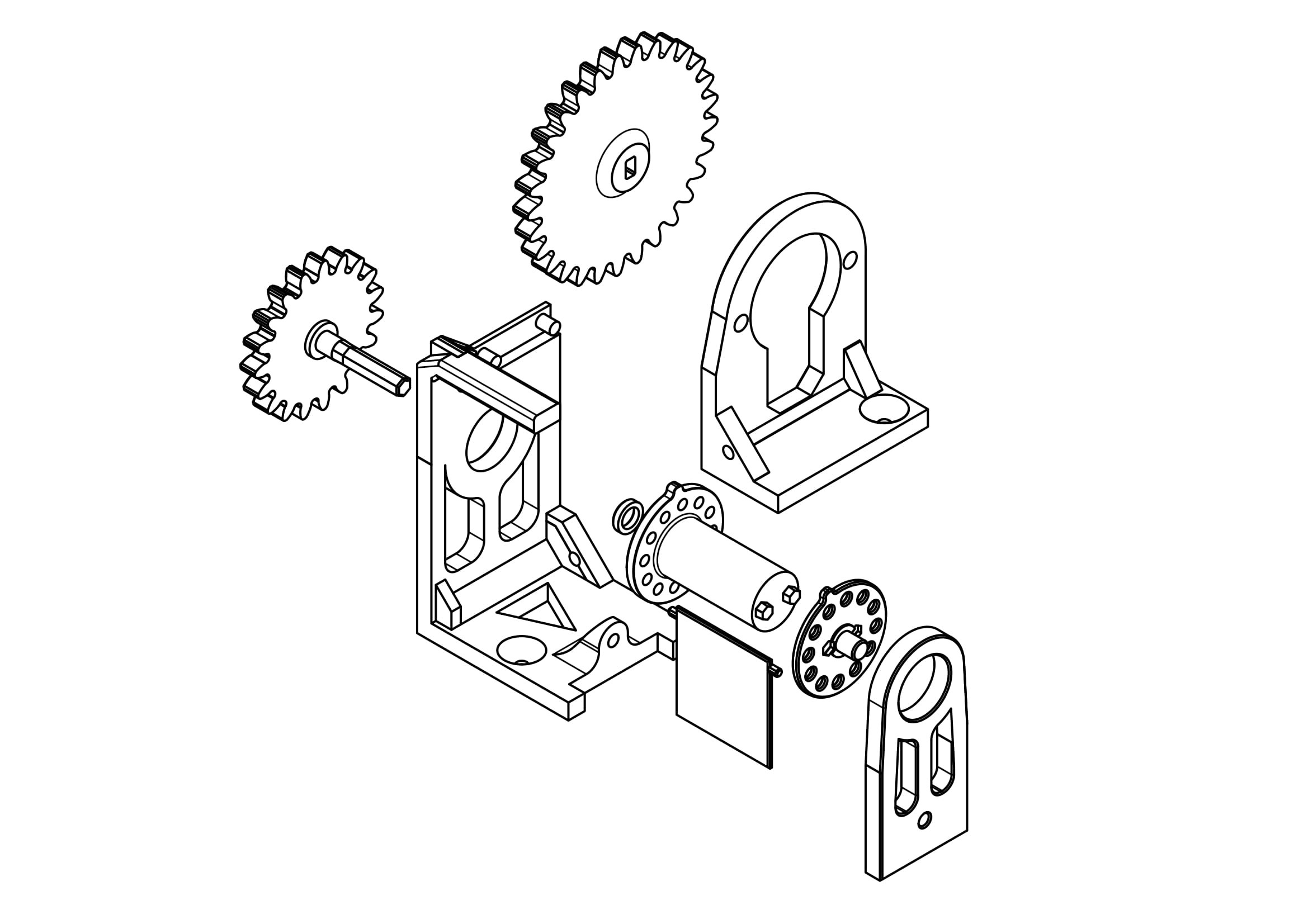

The mechanical part of this project is finished, next up is code and electronics in order to create a clock out of these. The plan is to modify these cheap steppers to a bipolar layout, seen here. And then use off the shelf electronics used in cheap cnc/3dprinter/plotter such as these or just plain stepsticks.

Since I've entered this in the 3d printed gears contest, I'll mention that the gears used to drive the mechanism were generated using Fusion 360's build in gear generator. I've used this generator in multiple projects and can recommend it to easily generate simple spur gears.

jonas

jonas

Vijay

Vijay

Miguel Ángel Casanova

Miguel Ángel Casanova

SephenDeVos

SephenDeVos

Sanjay Johny

Sanjay Johny

Neat project. I didn't realize that Fusion had a built in gear generator. Off to try it now :)