I have used the PD 3.0 with 9V/3A for supply. It can be powered from an USB-PD power supply (even suitable laptop USB-C power supplies) or with an PD-Power bank for soldering on the go.

The heat up time from 25°C to 350°C is around 6s. Auto-standby temperature is around 180°C, by picking up from the rest around 3s are needed to reheat.

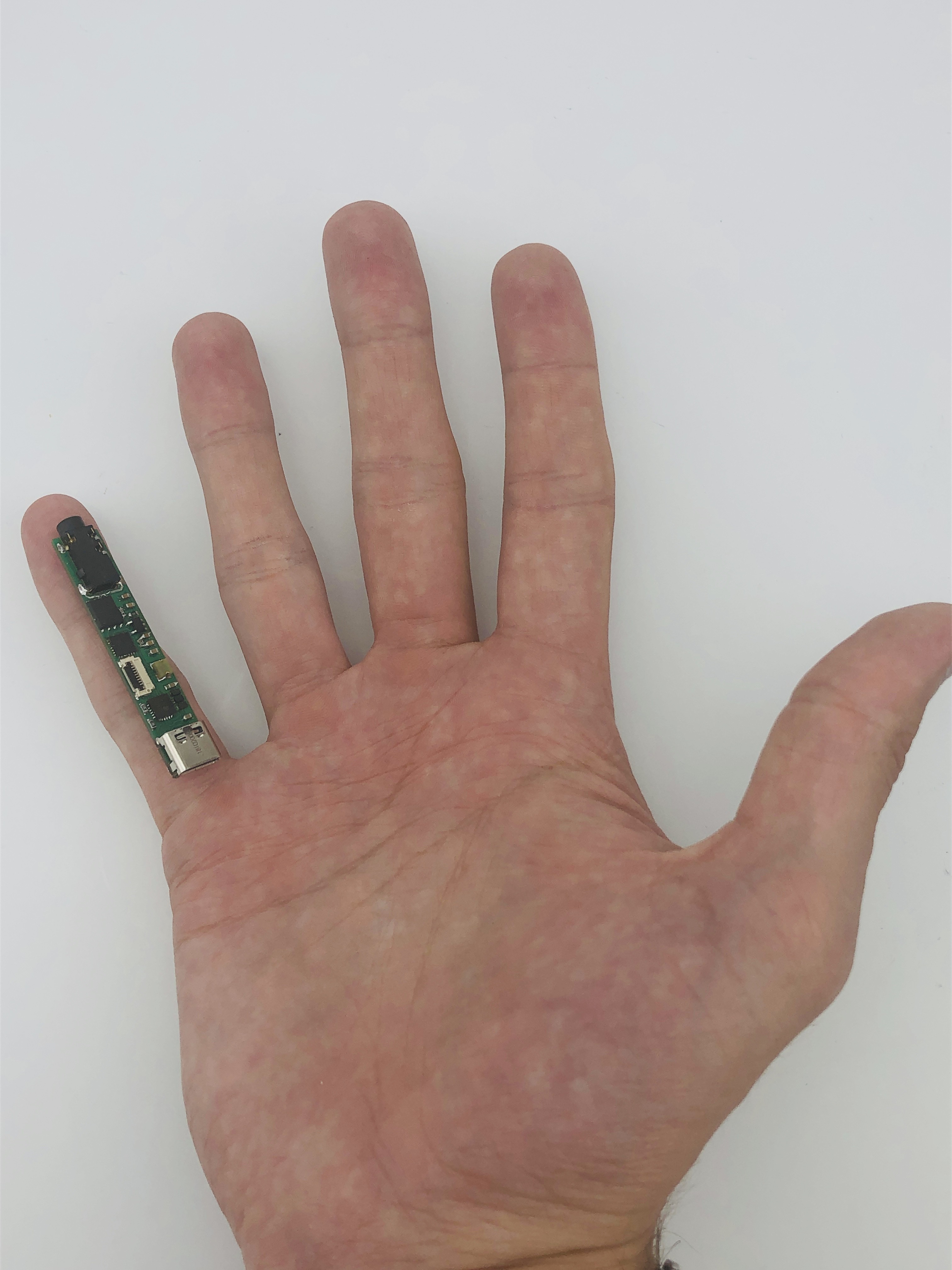

The main goal by the designing the PCB, Enclosure and UI was not to exceed the diameter of rubber grip to keep it as small, handy and portable as possible.

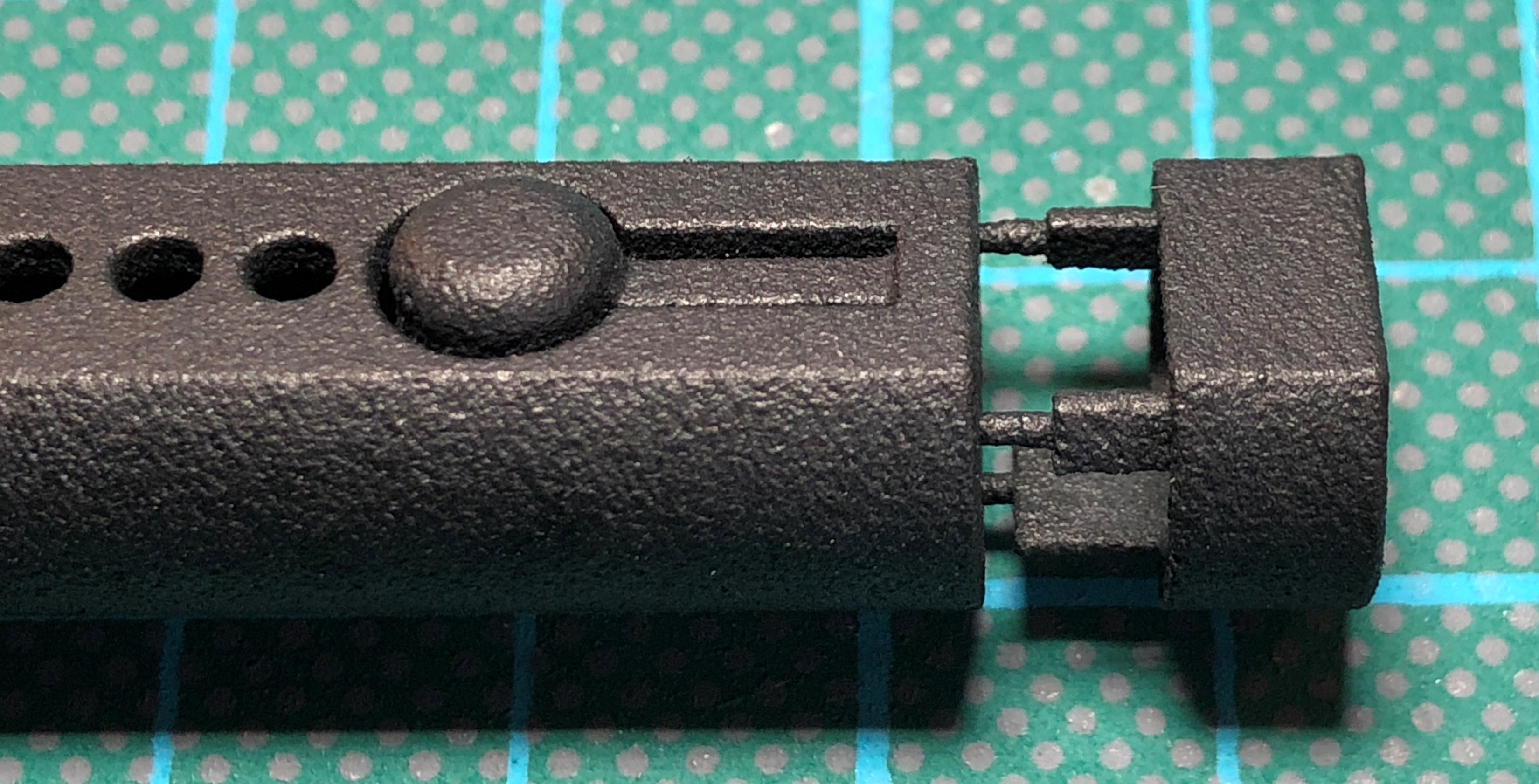

The user-interface consist tree LED's and two buttons. The LED's indicate which temperature profile is active (Low, Mid or High) as well as the operating modes (user-standby, auto-standby, auto-off, warm-up and overheat).

Its UI is simple! - If any LED blinks, the Soldering Pen is not ready or at the desired temperature range. Steady light than means that the pen is ready.

I have chosen the simple 3-LED-Display because there is no need to set or know the temperature in 1°C steps. There are three basic groups of soldering types:

- Very sensitive components(e.g. temperature sensors)

- Regular sensitive components and Wires (e.g. Resistors, Capacitors, most types of IC's)

- Not sensitive parts (e.g. large copper areas)

Based on this knowledge I implemented the three profiles.

One button controls the user-standby mode the other changes the temperature profiles.

The pen fits perfectly in the original Weller safety rest WDH 51.

When it comes to a regular transportation (eg. in tool cases) weight ist very important. The soldering pen itself wights around 9 grams, with tip (RT1) 19 grams. Complete set with soldering pen, tip, cable and power supply (DA45C) is just around 150 grams! Less than a modern smartphone.

Here are the video demonstrations:

Thomas Leputsch

Thomas Leputsch

Mirko

Mirko

William

William

HP (@banjohat)

HP (@banjohat)

How are you powering the top? Square wave, sine wave switched at crossing, something more distinctive? I want to strive something like this, and I need to layout it myself, but I need to ensure to do it proper. Seems like you are doing this right.

you can see here https://alightmotionmodapk.org/alight-motion-pro-apk/