I completed the thinner version of the petals and tried retracting by drawing it into the base.

It works, but requires a lot more force than I thought it would. It also requires more depth than I gave it. I can solve both problems with a minor change to the petals I think.

However...

I have been contemplating one more competing idea I'm going to try here first and see how it looks.

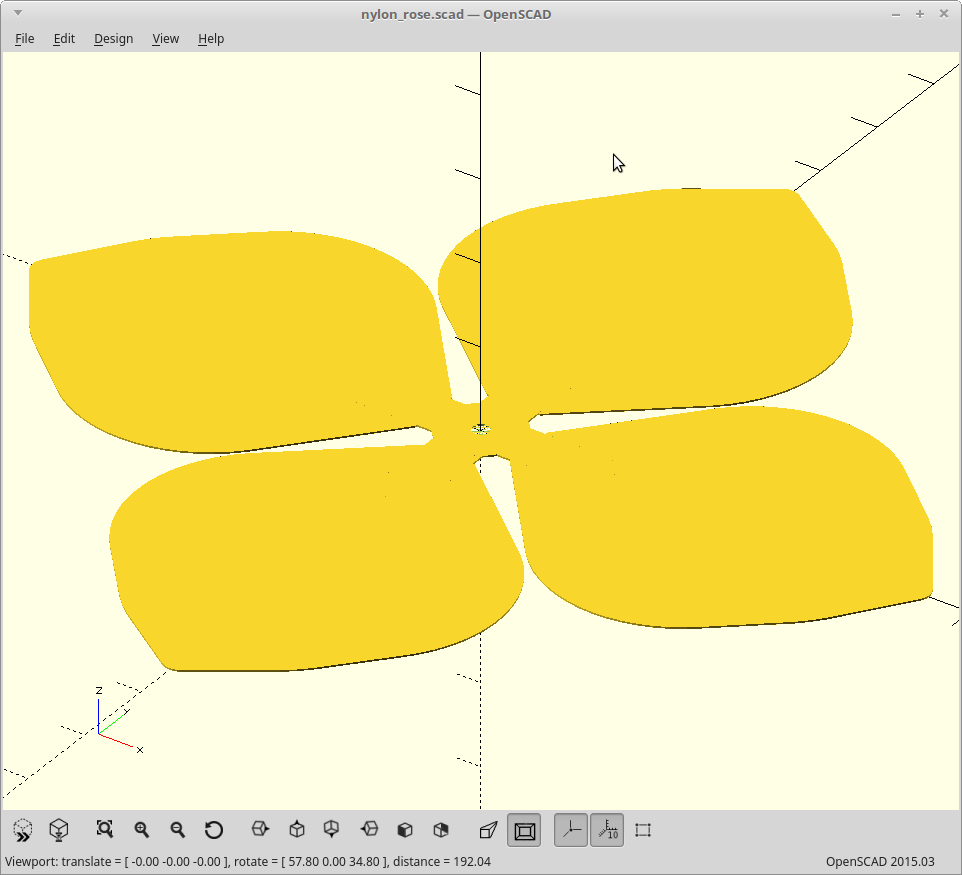

I'm going to print 3-5 petals flat, already joined to a hub, in nylon so I can use that as the hinge. Then I'll stack those. Pulling on the center, into a ring, will close the rose. The ring will be the greenery lower part of the rose bud. <insert Citizen Kane reference here...>

The nylon is way more flexible than my PLA, is pretty translucent when printed thin, and will readily slide against itself as its self lubricating. Heat forming it may be challenging. (read as initial attempts at this have all failed...)

I need them to be as thin as I can possibly print them and hold together... I think. I may be wrong. I may actually need to make some parts thicker to give me the spring tension I need to have them open on their own.

My nylon needs to spend a night in the dehydrator it seems. Snap, Crackle and Pop are having a party in my printer. Turning up the temperature worked, but that cost me translucency. I'll wait the one day.

As for the servo needing to push to open, I think I have a simple solution. I'll put a pen spring on the shaft below the petals. Then I'm back to pulling, with the spring pushing locally just where needed. Much nicer. I would like the petals to do it on their own, but if not... solution.

If this works, I'll be able to use more petals which will give me a much more realistic looking rose. With the hinged version, I ran out of room for the hinges at 12 petals.

Daren Schwenke

Daren Schwenke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.