While there are several commercial toy grade FFB steering wheels and some higher end simulator grade producs these are very expensive and and are often not moddable or come with their own expensive ecosystem.

It makes sense to focus this project on a simple open source force feedback interface as this is the part where the community lacks a good and open solution.

Therefore the main goal will be to develop a universal FFB controller (Open FFBoard).

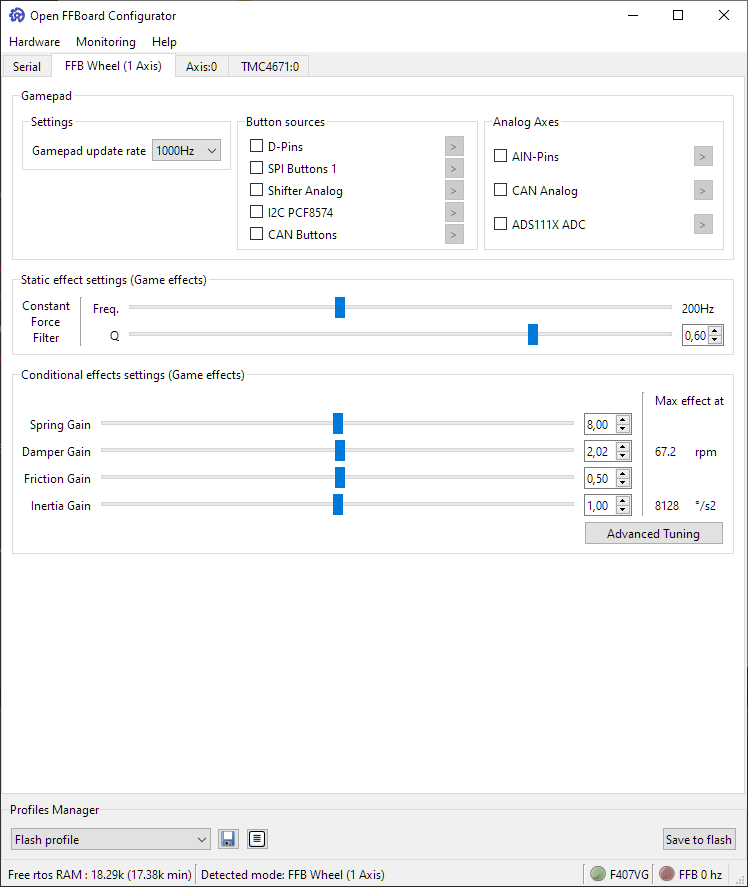

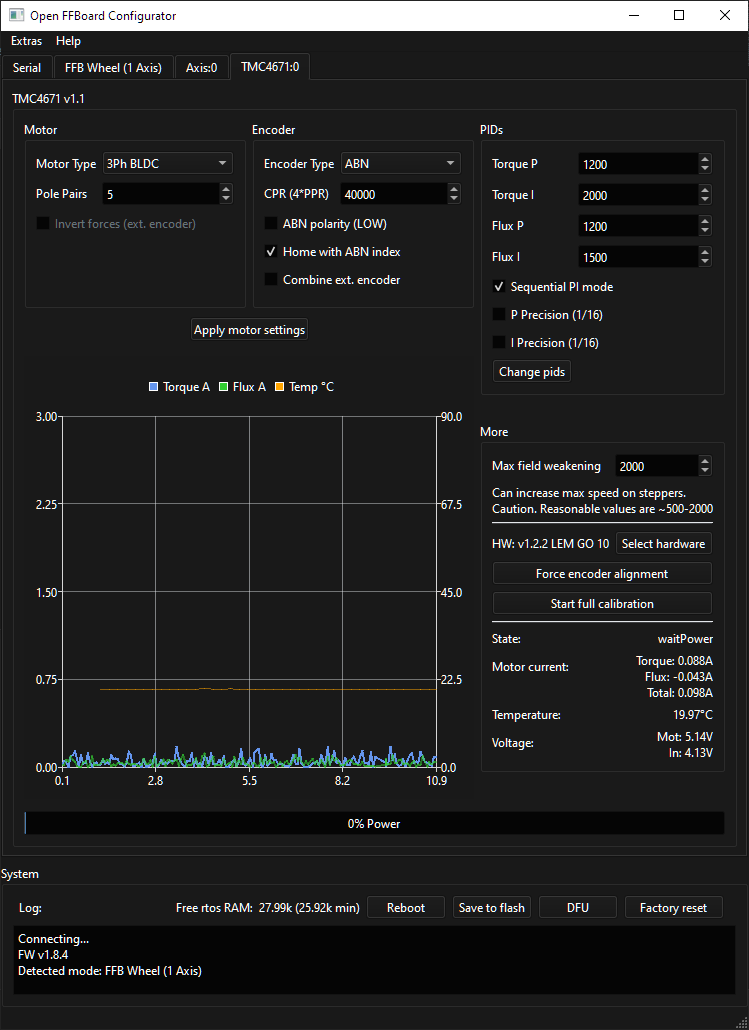

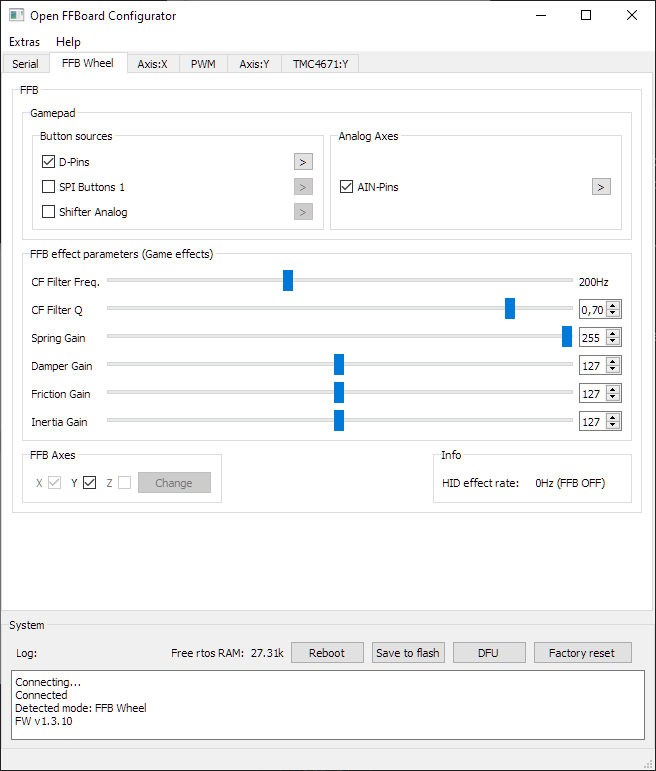

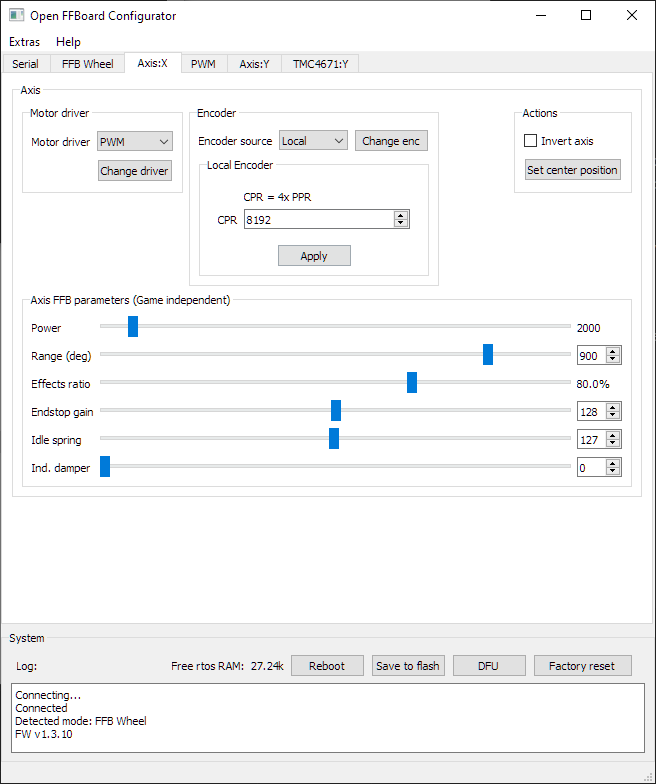

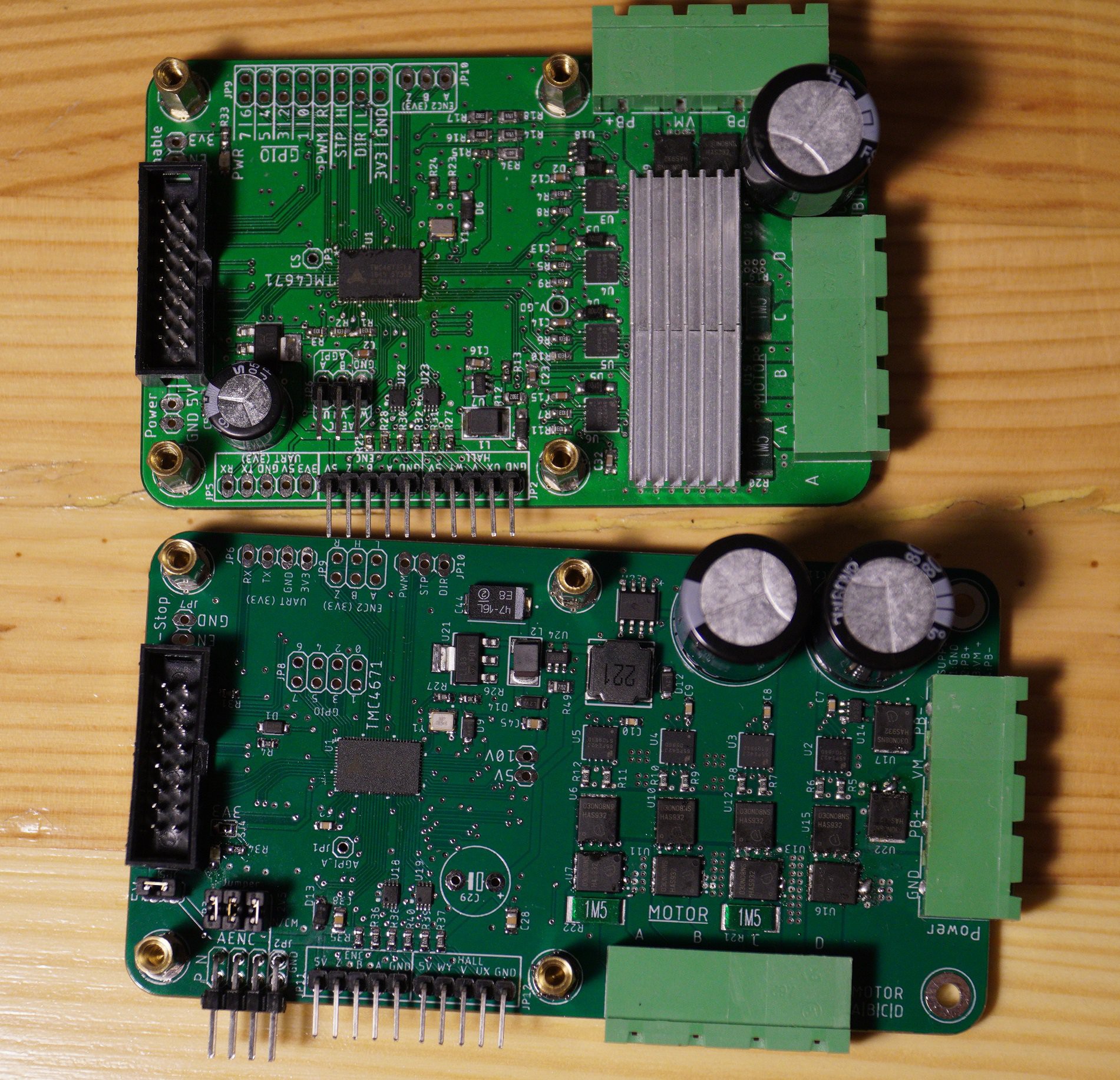

It will provide a modular architecture and interfaces with multiple motor drivers and a reference motor driver board based on the TMC4671.

The FFBoard is just an interface for USB HID, encoders, buttons and pedals. It can interface with almost any sensor or motor.

The software is modifiable for different motor drivers and control outputs.

Also supports 2 axis joysticks with the ODrive.

Currently supported motor drivers:

- FFBoard TMC4671

- ODrive (CAN)

- VESC (CAN)

- PWM (centered, pwm+dir, RC ppm, dual PWM)

- Granite Simplemotion (Ioni,Argon, original Simucube 1)

Currently supported encoders:

- ABN incremental (PWM)

- BISS-C (PWM, TMC, requires external transceivers to SPI3)

- MT6825 (PWM, TMC)

- Encoders supported by VESC and ODrive

- SinCos (TMC)

Yannick (Gigawipf)

Yannick (Gigawipf)

Daren Schwenke

Daren Schwenke

John Taylor

John Taylor

Josh Pieper

Josh Pieper

Christopher Xu

Christopher Xu

Hi Yannick, i'm looking to make a diy nema 34 based steering for over 2 years, i'm now in first year of electronic school (hopefully i would be able to created circuits like you one day :) ). I'm looking at your project for several months now and i would be glade to be one on the first to try this circuit when it will be finish.