.

.

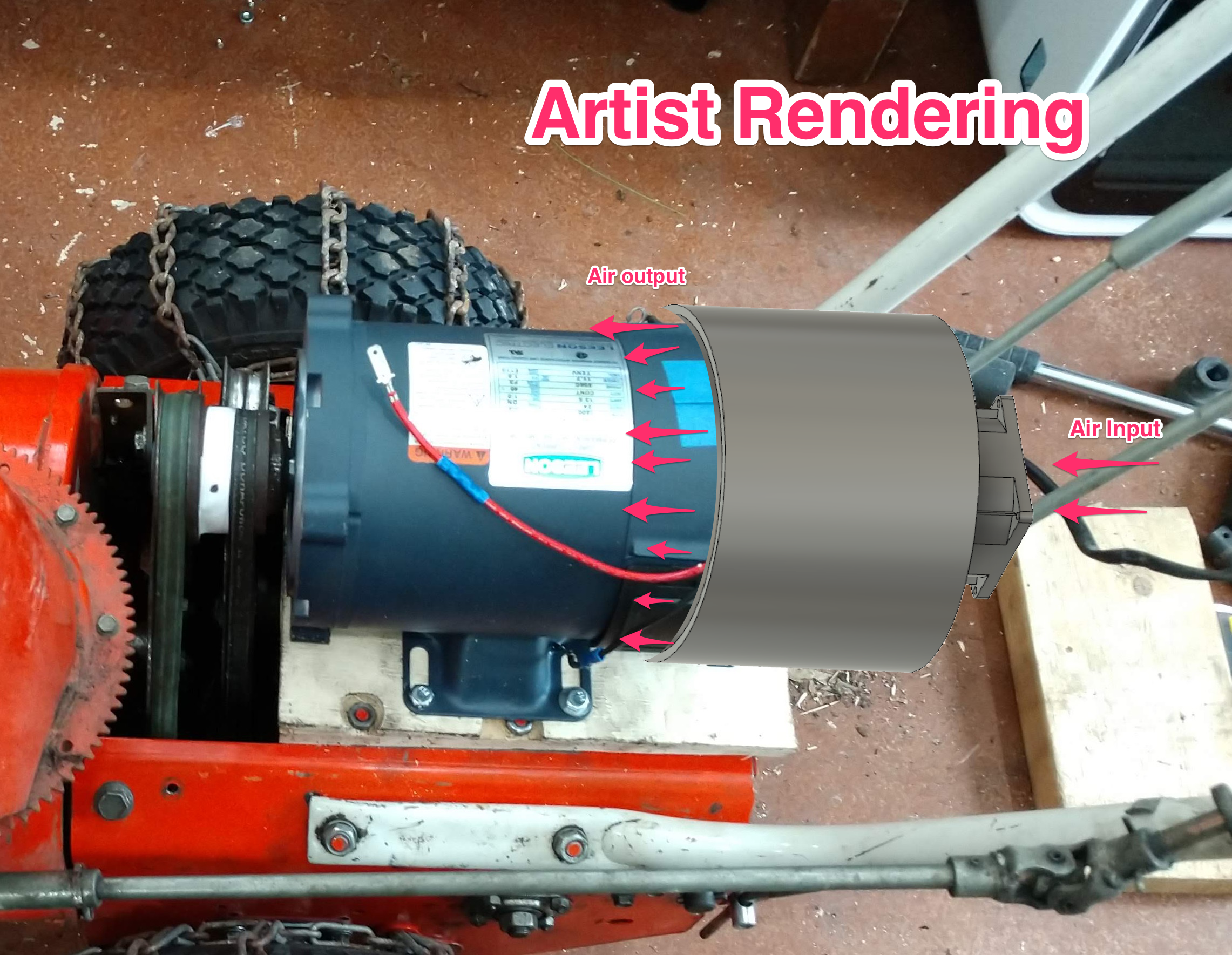

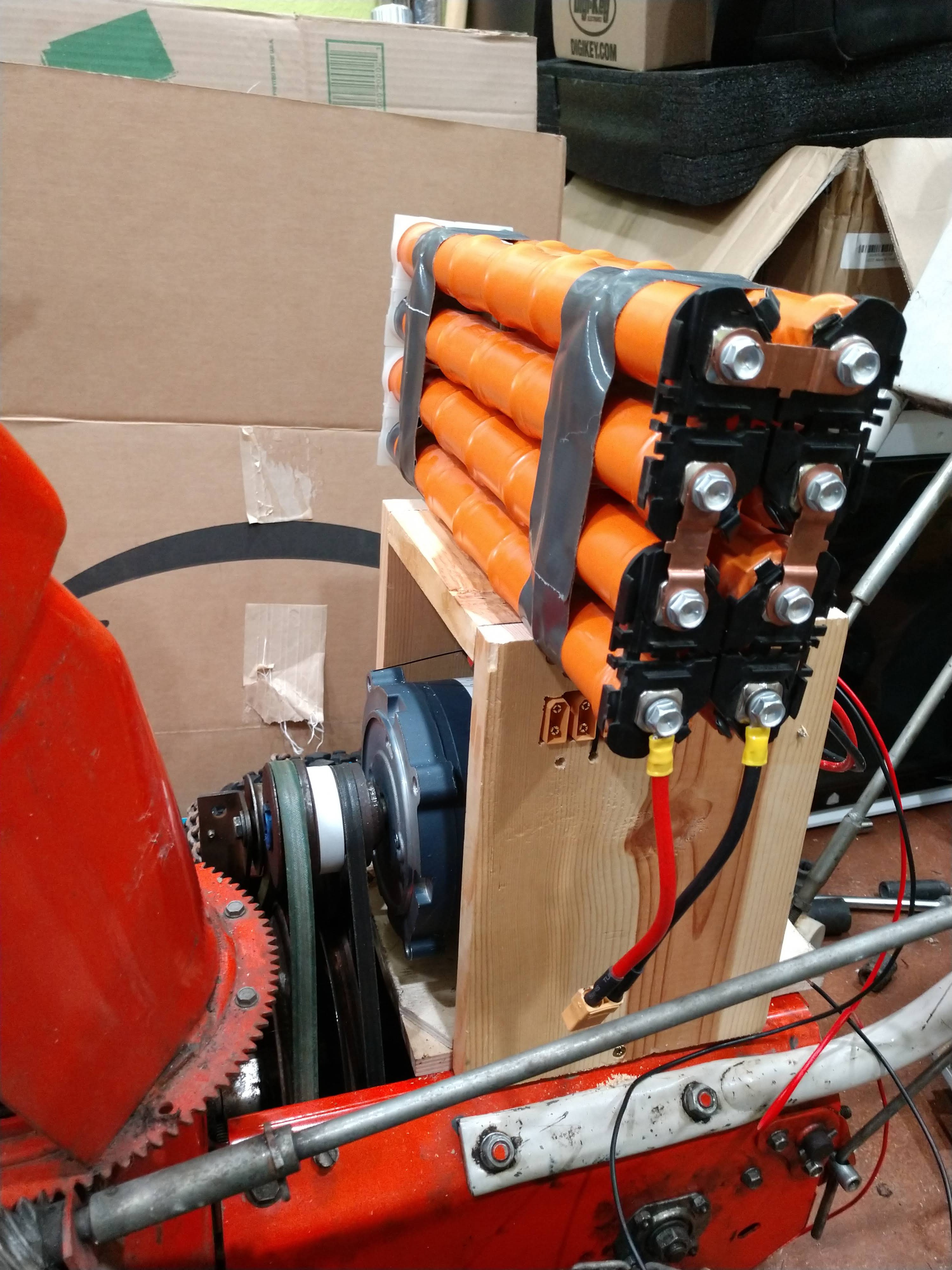

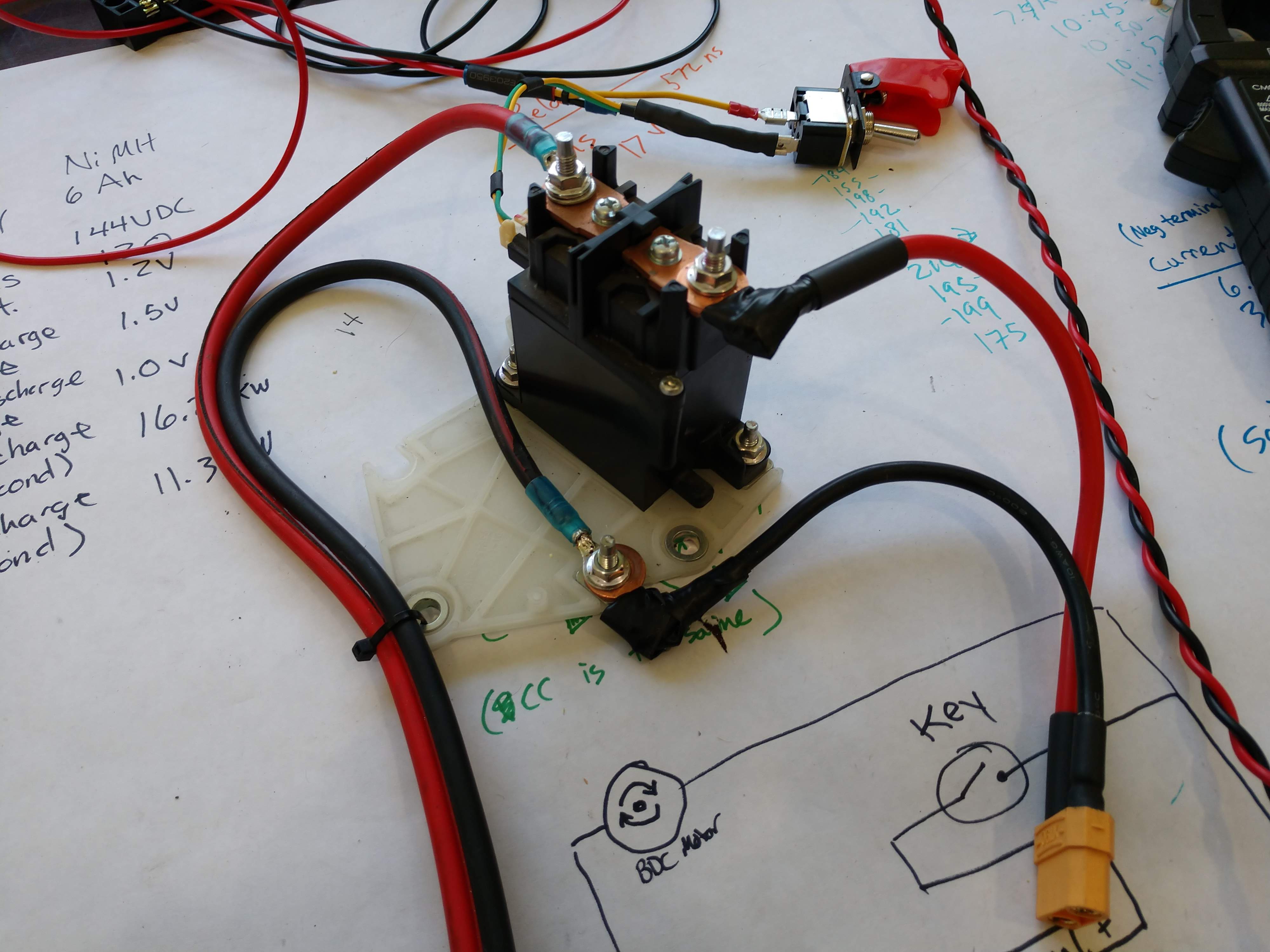

Current Configuration:

- Motor

- 57.6 volts (designed for 24v)

- 4080 RPM (originally 1700)

- Battery

- 48s2p configuration (originally 120s)

- all less than 50 mOhms internal resistance per 12 pack, or an average of 4 mOhms per cell

- nominal voltage 57.6 volts

Ryan

Ryan

Adam Curtis

Adam Curtis

Bud Bennett

Bud Bennett

Lucy Fauth

Lucy Fauth

TK

TK

Brilliant project! How is the weight balance with the battery?