Sales Pitch

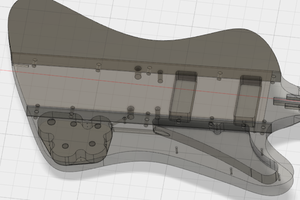

Many music stands can become old and hard to use after time, but not broken yet. We created the a gadget to help fix a broken music stand because we are both Orchestra students and have faced many struggles with our music stands. We decided to name it the Saving Triangle because it is shaped like a triangle and it saves your music from being knocked down. The Saving Triangle can help support a stand when it is raised so it doesn’t fall down and can keep it from tilting downwards when your music binder is too heavy. We designed it so it can hold a bow for Orchestra players and a mouthpiece for Band players. The clips on the sides would help turn down the corners of the stand when they curve up and get in the way of your music.

Our audience would range from music teachers, children learning music, professional musicians, symphonies, choirs, teachers who need to keep papers together, keyboardists (they do not have good stands), people who play music as a hobby, and anyone who wants to learn music or needs to hold papers. The Saving Triangle would even help people delivering a speech.

Design Process

We started by making a list of things that break. We wanted to do something music-related and started complaining about different problems, one of which was music stands. That’s when we decided to make a device to fix music stands.

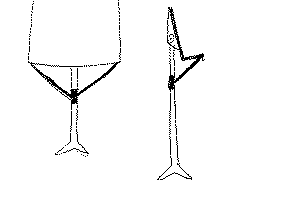

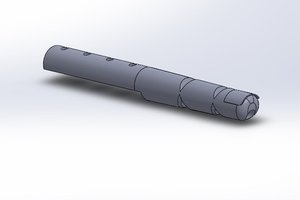

Our original design sketches had the bow hold above the stand, which we later changed because it would get in the way of the music. Our design consists of four main parts. The Clasp encircles the music stand and holds the Saving Triangle in place. It is the base of the machine and supports the Reinforcers. The Reinforcers are two poles that reinforce the stand. They hold the stand in place when it is tilted or pushed up.

On our first print we had to scale from our measurements in centimeters to Solidworks millimeters. Our printer nozzle got jammed midway through the print and we had to fix it. It was jammed for too long so the print ended up being a fail. We were going to reprint the initial model before realizing the clasp circumference was too big and wouldn’t fit the stand.

On our second print of the Clasp, we made the scale smaller. But, it turned out WAY too small. It couldn't even fit around the stand. So we went back to model the Clasp again. We couldn't move on to the Reinforcers of anything else because the size and scale of the whole product is based on the size of the Clasp.

So we were on to our third print of the clasp. Our print wasn't sticking to the bed of the printer, so we readjusted the temperatures and moved the print location to a different spot on the bed.

Dimensions of the Saving Triangle

Materials

How to Print/Printing Temperatures

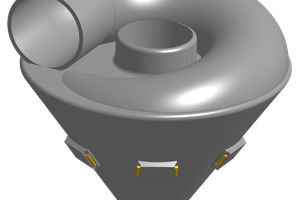

We printed our tests in PLA, which prints at 215-235 degrees Celsius for the nozzle and 60-80 degrees Celsius for the bed temperature. For our final project we printed in Nylon because The Saving Triangle needs to be sturdy.

66674

66674

67412

67412

Alan Chambers

Alan Chambers

Benchoff

Benchoff

Aaron P.

Aaron P.