Oxygen inhibition is a constant problem with UV glues and resins. When the glue or resin is exposed to oxygen, it can diffuse in the superficial layer of the glue or resin and inhibit the polymerization reaction. This results in a tacky surface layer, even after curing for the specified time.

In my case, given that I originally developed this chamber to cure resin 3D prints, this surface tackiness was absolutely inadmissible. The "brute" solution to this problem is to cure harder and longer, that is, to use more UV light power and/or cure for longer times.

Of course, this is an inefficient approach. A more efficient way of preventing oxygen inhibition is to... well... exclude oxygen from the surface. With resin 3D prints, what I did is to submerge the part in a big transparent flask (without the lid) full of water. It is important that the flask has a big opening, since glass can absorb a substantial amount of UV light.

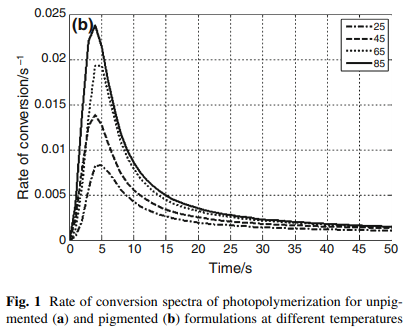

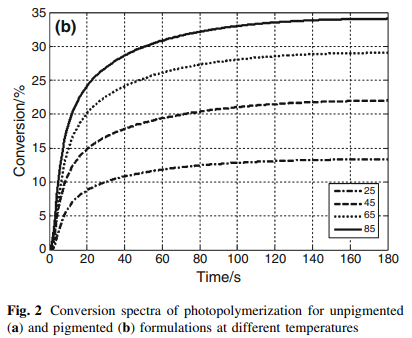

Additionally, the water in the flask can be heated to further accelerate the polymerization reaction. A good temperature for curing is 65ºC, as can be seen in the following figures, that were taken from Kardar et.al.:

Of course, the highter the temperature, the better, but in the case of standard UV resin, temperatures higher than 70ºC can have adverse effects on the material.

Andrés Lopez Pulzovan

Andrés Lopez Pulzovan

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.