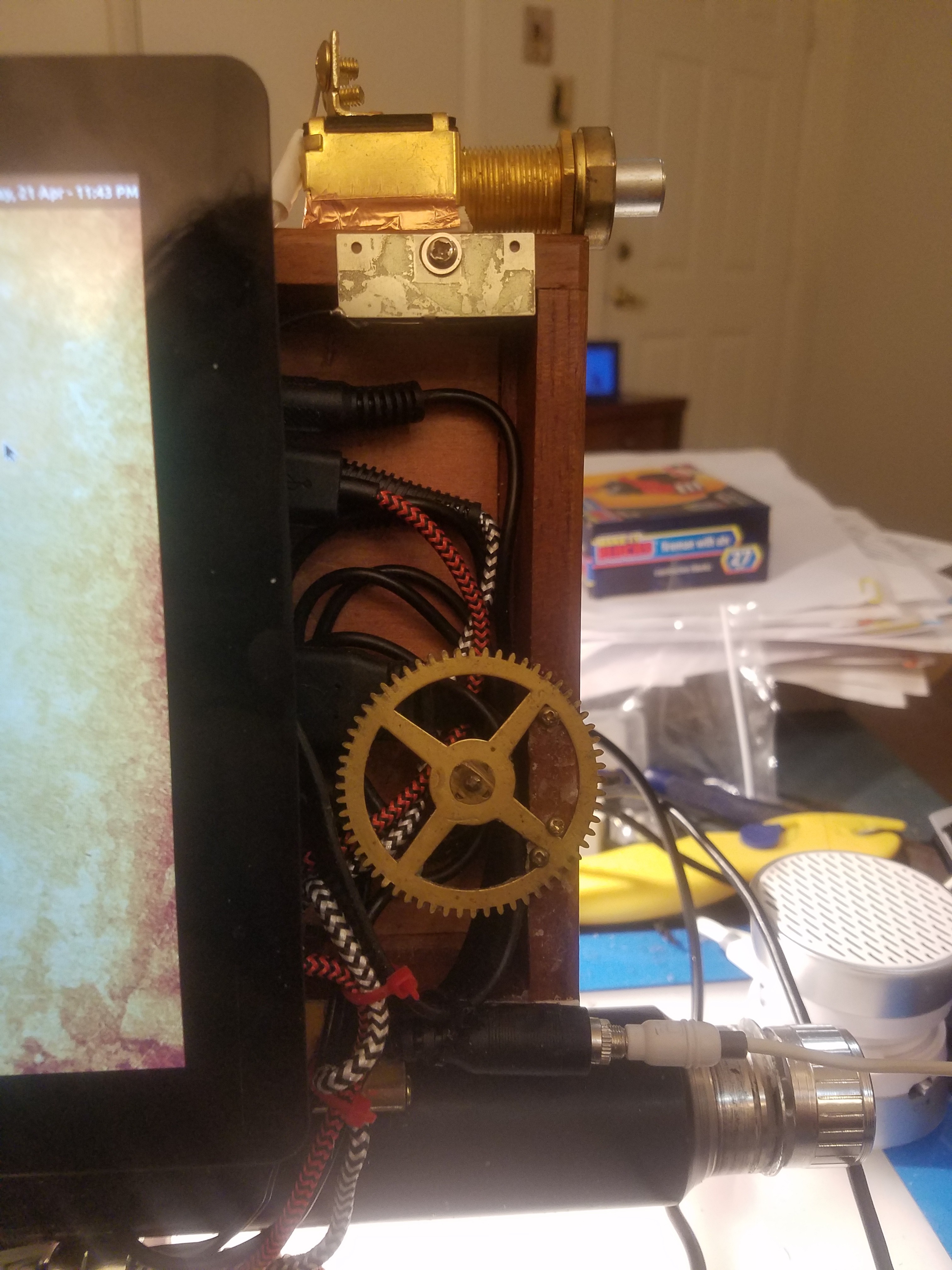

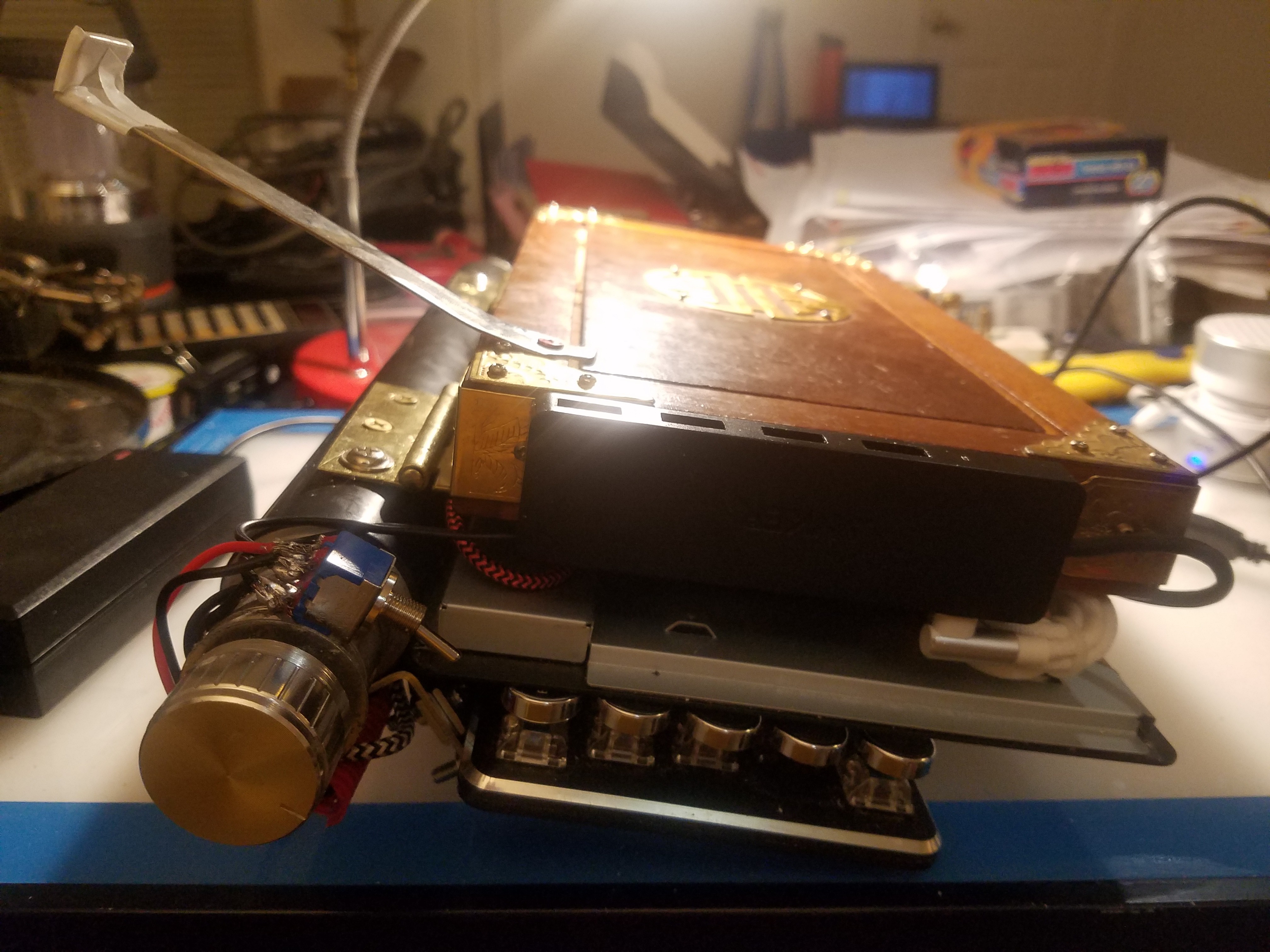

There once was a Homebrew Steampunk Laptop. I built it. One day I was rewiring the USB hub's power input and I got something very, very wrong, and I destroyed the machine completely -- the circuit board for the hub is now a dead short (!) and the motherboard has let out the magic smoke that makes it work.

Oooooooooooops! (...or, as Big Clive on YouTube would say -- "Well, that's not good!")

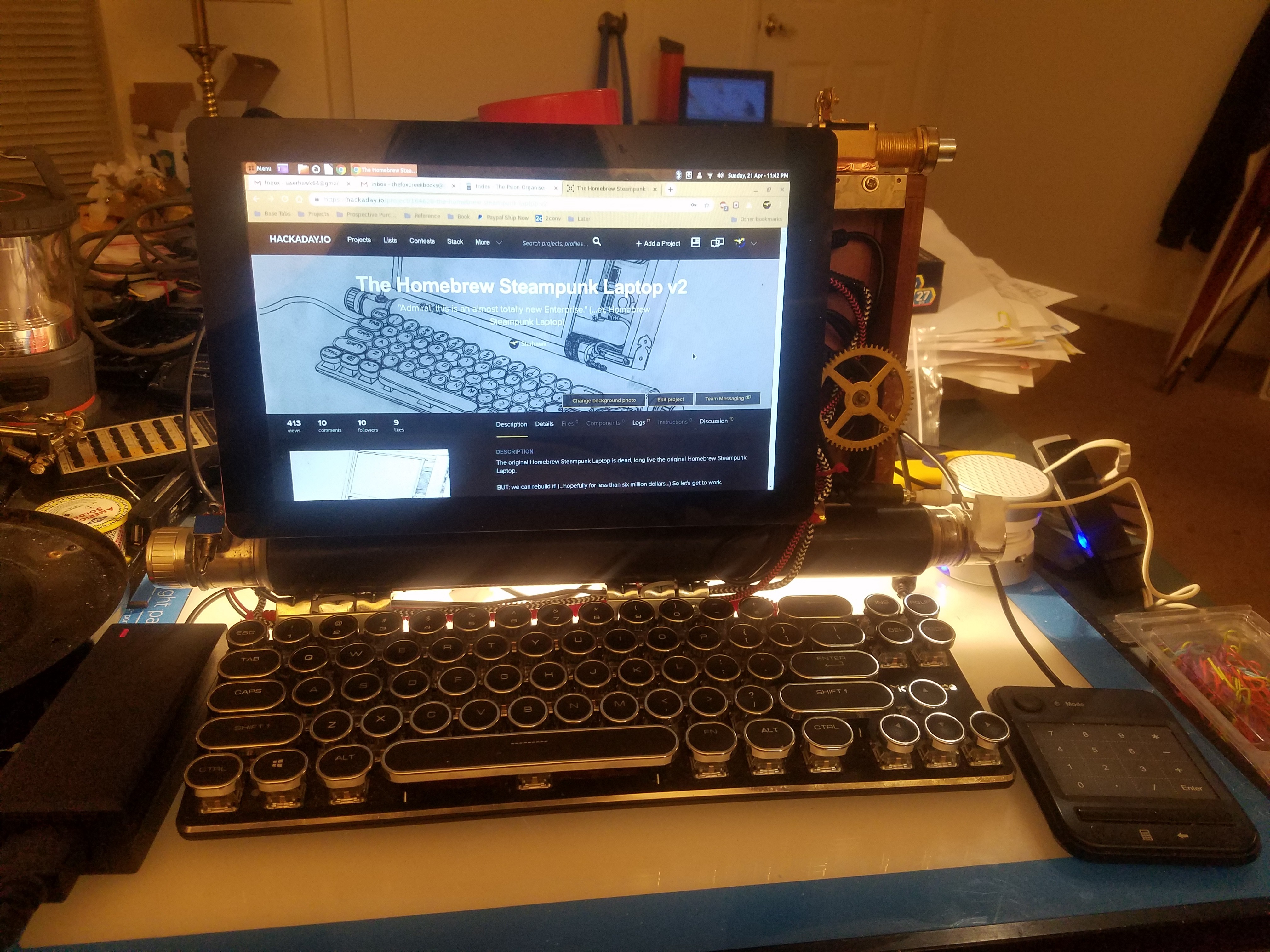

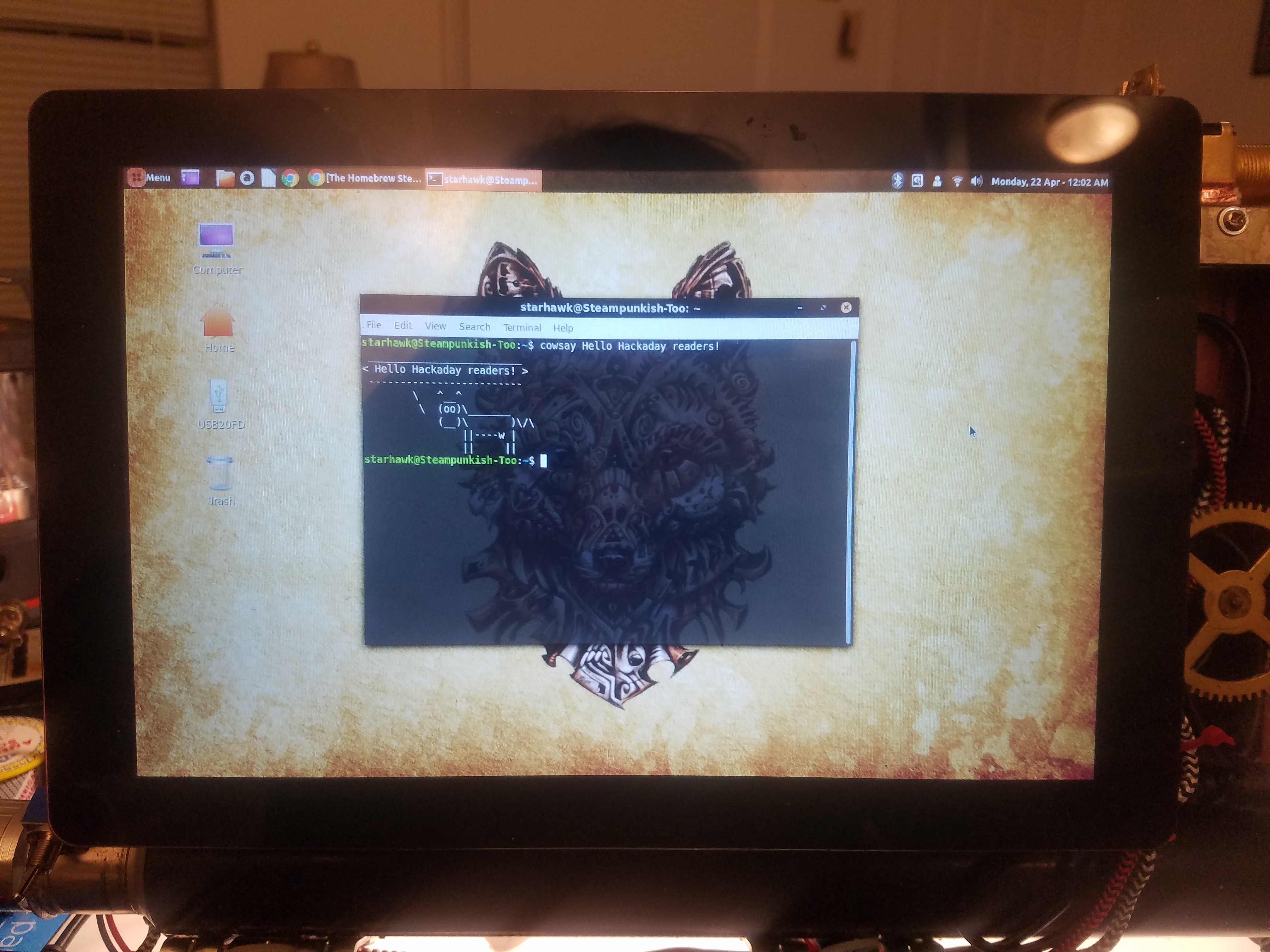

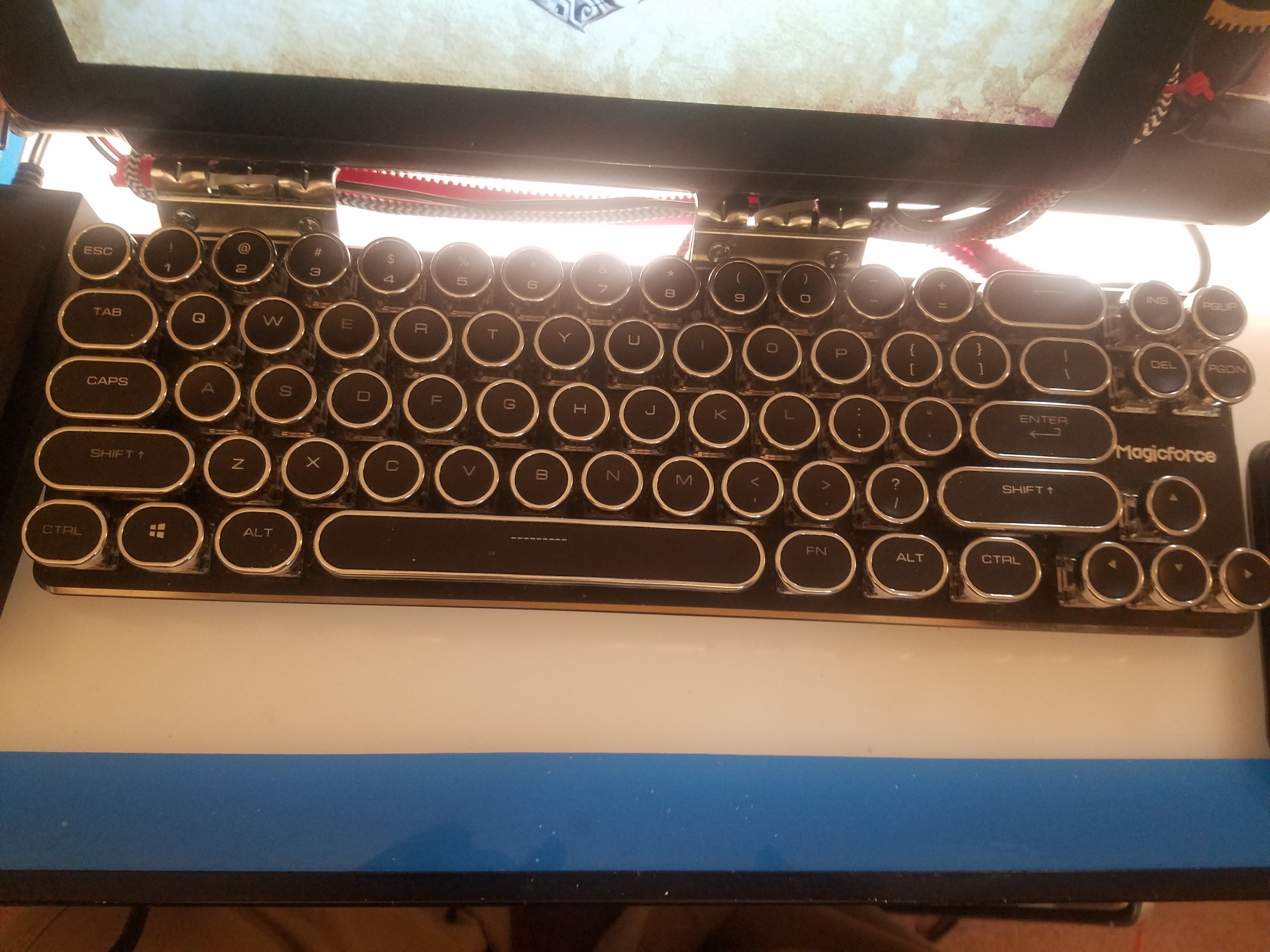

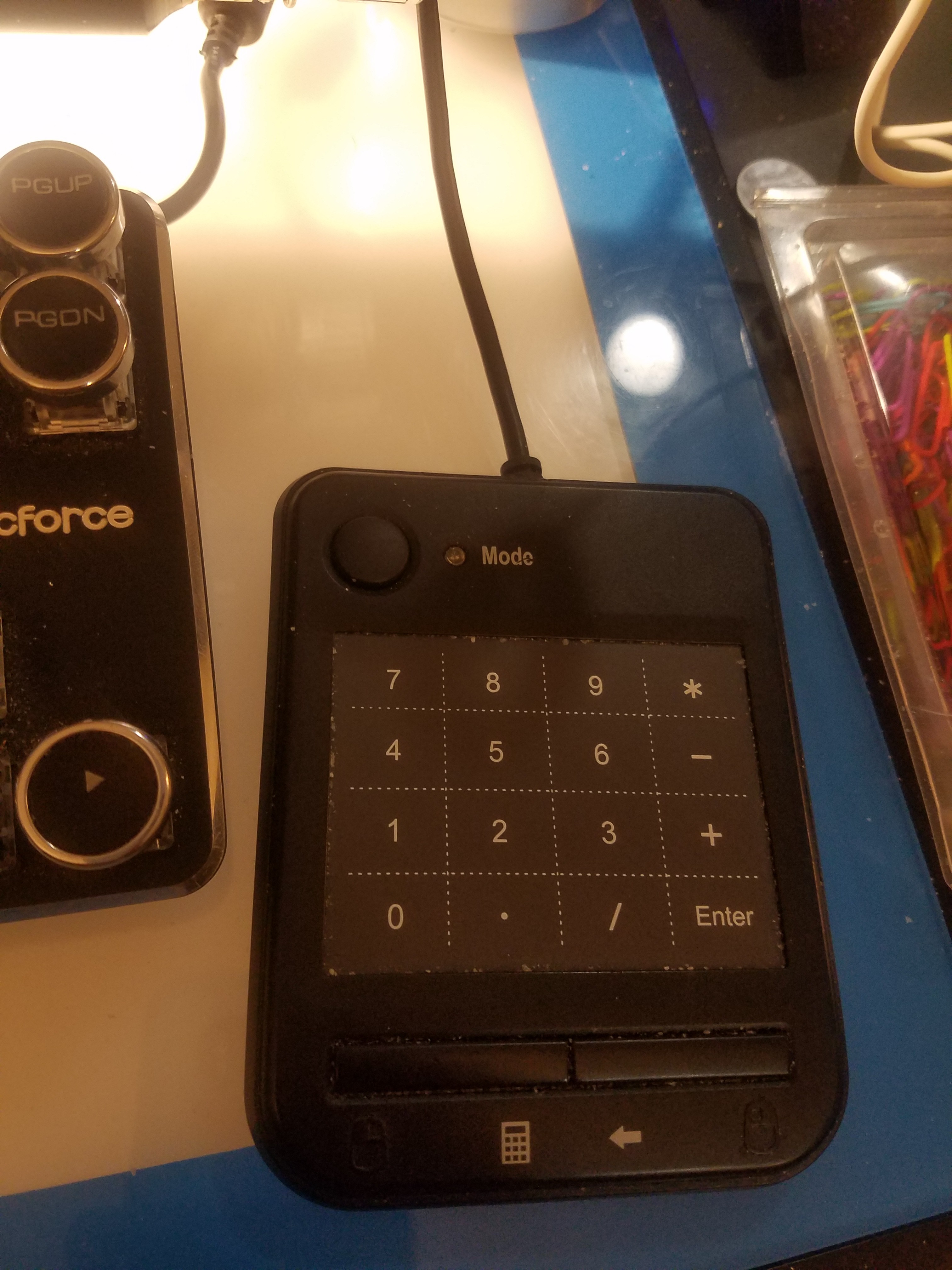

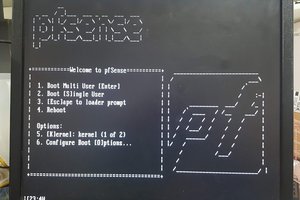

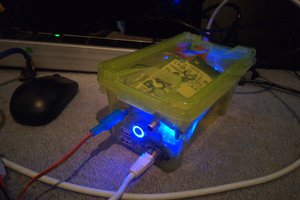

...or, well, something like that. It occurred to me, very rapidly, that the original could be significantly improved on in certain ways, both aesthetic and functional. So I began to plan -- and, eventually, I began to buy and to build. This project page, and in particular, the logs within, do the work of documenting my journey (as all worthy projects really are more of a journey than an event) to bring about a "Harder, Better, Faster, Stronger" Homebrew Steampunk Laptop.

I will not be listing parts or code to replicate this work exactly, specifically because I do not believe that it should be replicated exactly. Build your own Homebrew Steampunk Laptop if you want -- don't if you don't -- but "for the love o' Pete" (thanks, Shrek), if you're going to do it, do it your way. This may not be a Burger King franchise in here, but that's no excuse -- steampunk is about individuality every bit as much as it is about brass cogwork and angry pressurized water-vapor, and if you don't respect that, then you just turn it into something for every factory in China, and that's not cool.

Starhawk

Starhawk

novak

novak

Tom Nardi

Tom Nardi

Quite a wonderful work of art!