To make our cutsheets for the skidplate I unrolled our digital model, this will be included in the files section.

It's not very complicated but annoying to cut out with scissors. A laser seemed like it should do the trick.... And yes, we're including the hole.

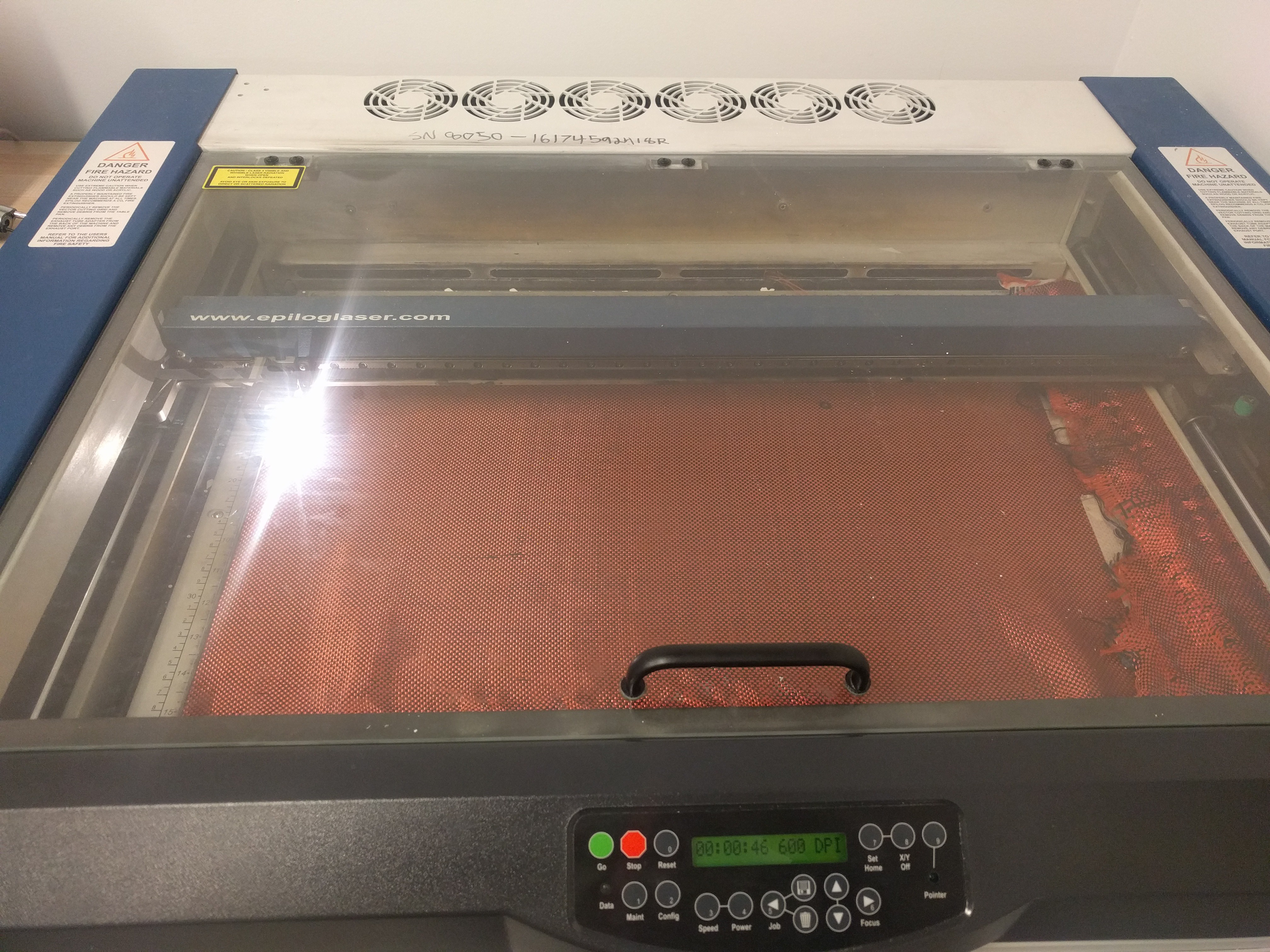

Each sheet takes about a minute and a half to completely cut out. It takes much longer to just get it off the bolt.

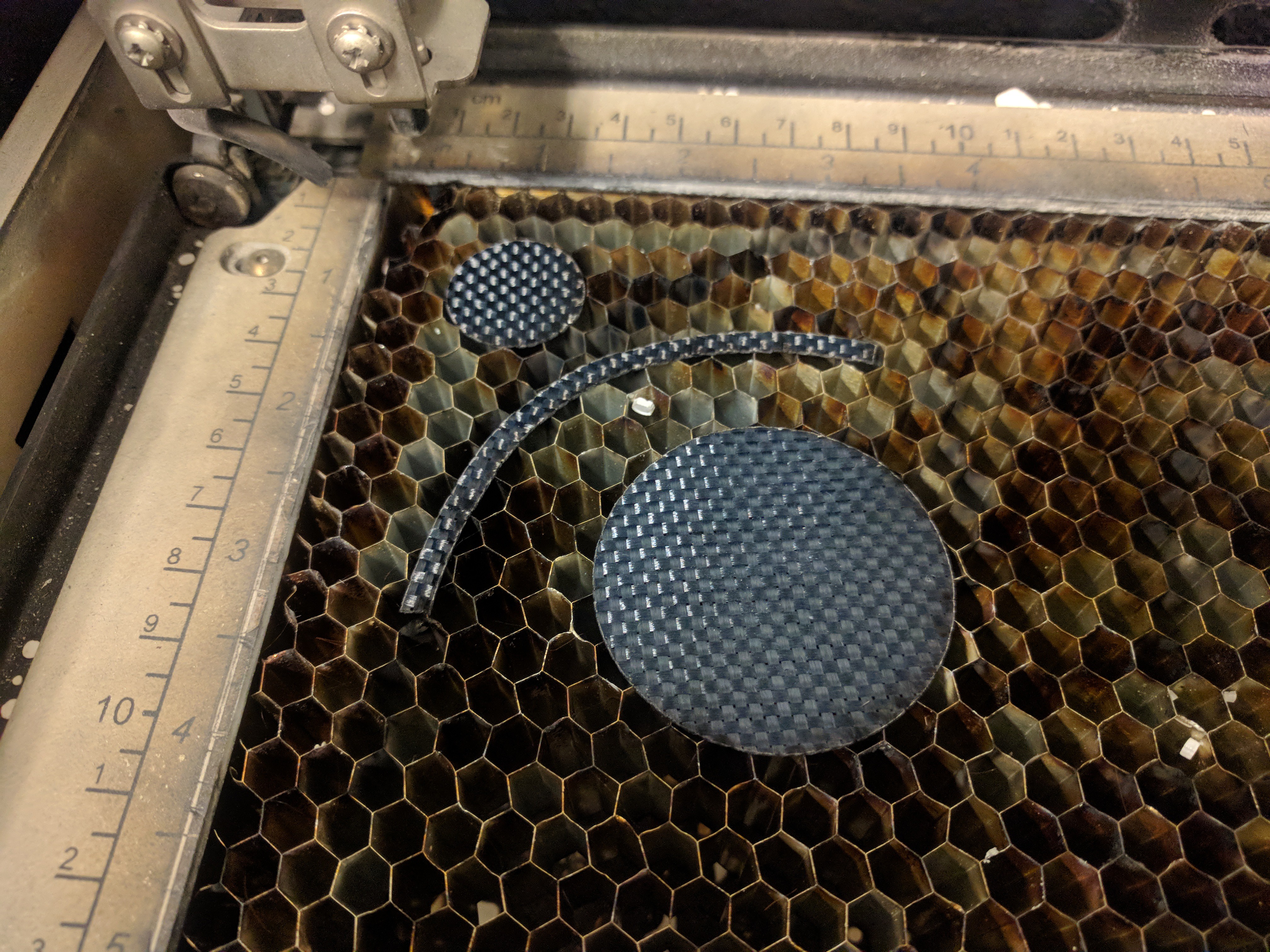

We are able to get very precise cuts. Burns could probably be minimized by going a little faster, I had the settings up pretty high. Ahem, shameless plug:

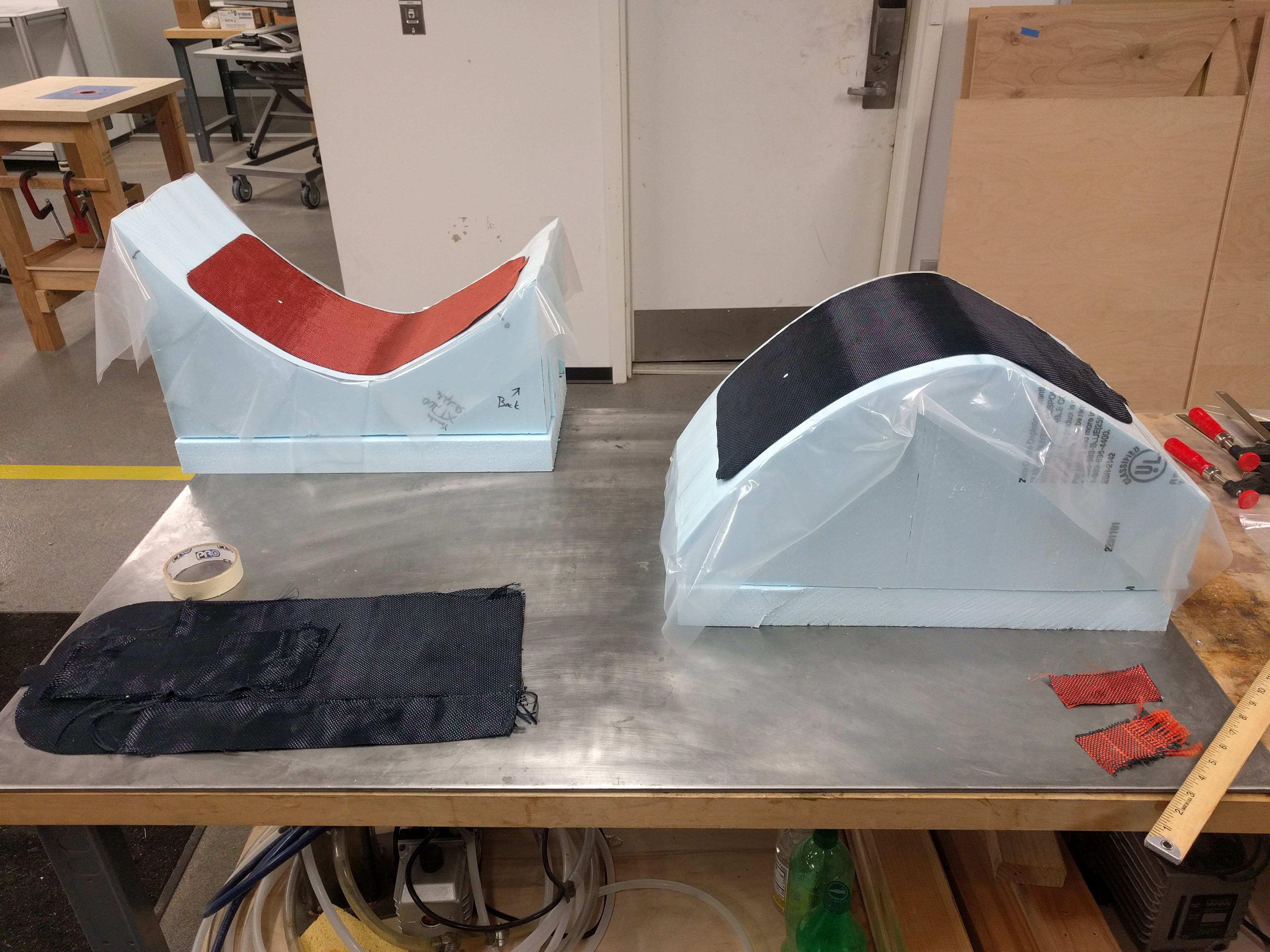

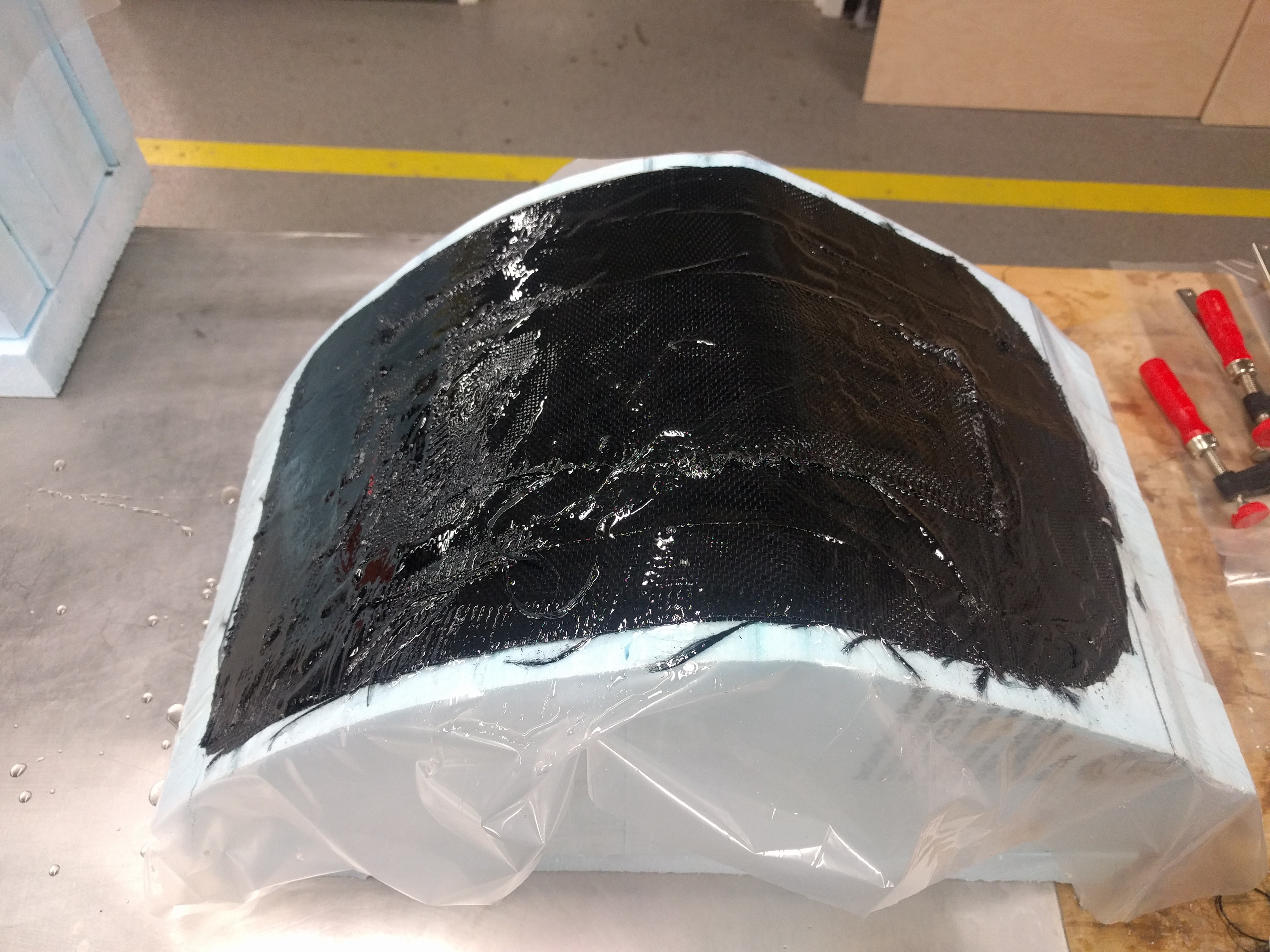

Then actual lay-up began.

Some cut-sheets got messed up because of tape, going to have to minimize that in the future.

Here you can see some kinda ugly patch-working:

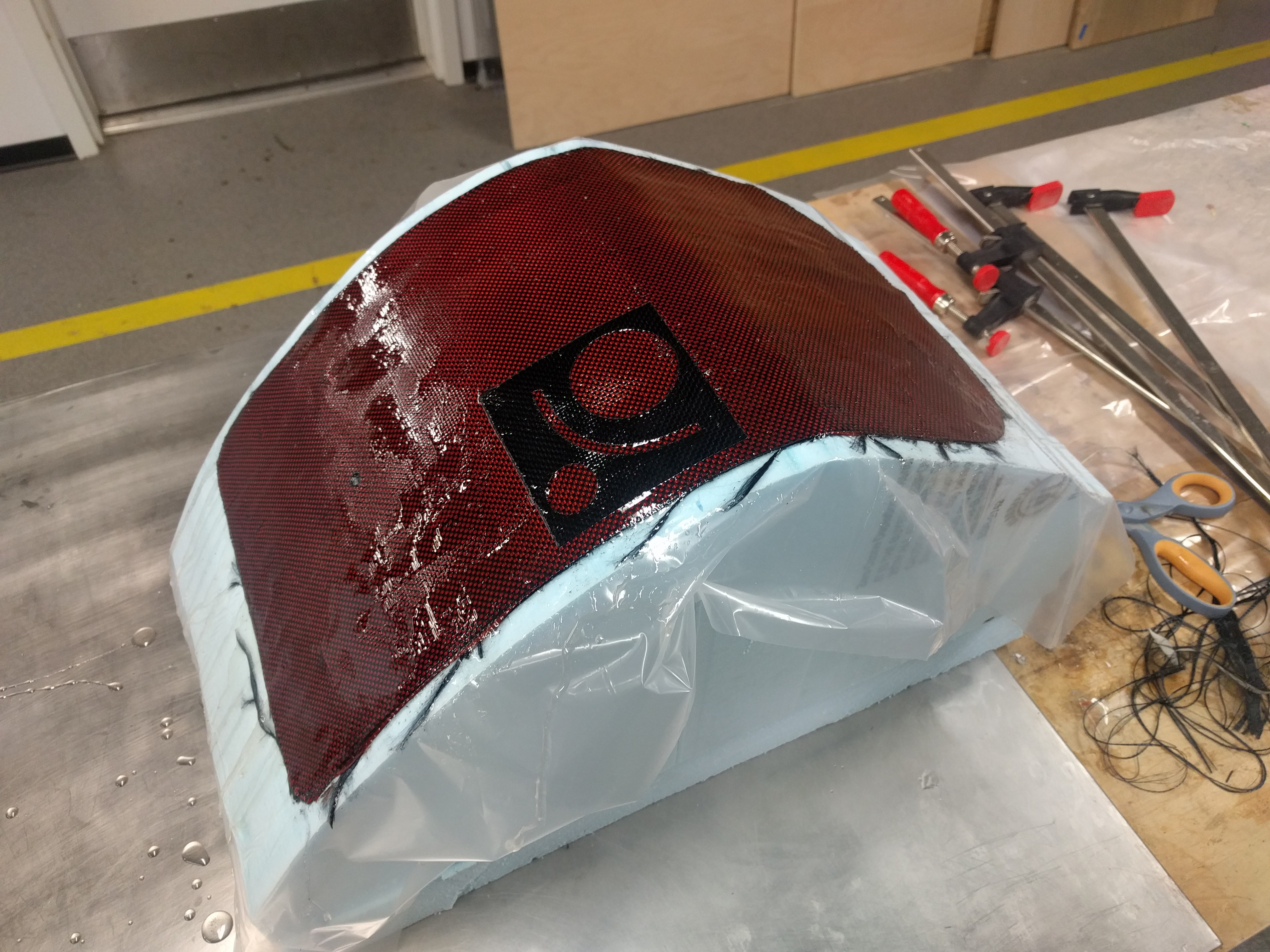

The outer most layer is 50/50 Carbon and Kevlar. Kevlar doesn't like UV light very much but since this is a semi-disposable component I'm going to give it a shot to see if it helps with scratches and such. I also added the Wallfacer Design logo, because I can.

The end tab was folded over into the insert and then the top half of the mold was lined up and clamped down as hard as we could.

To help with clamping force in the future we should cut the mold exterior faces flat.

David Troetschel

David Troetschel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.