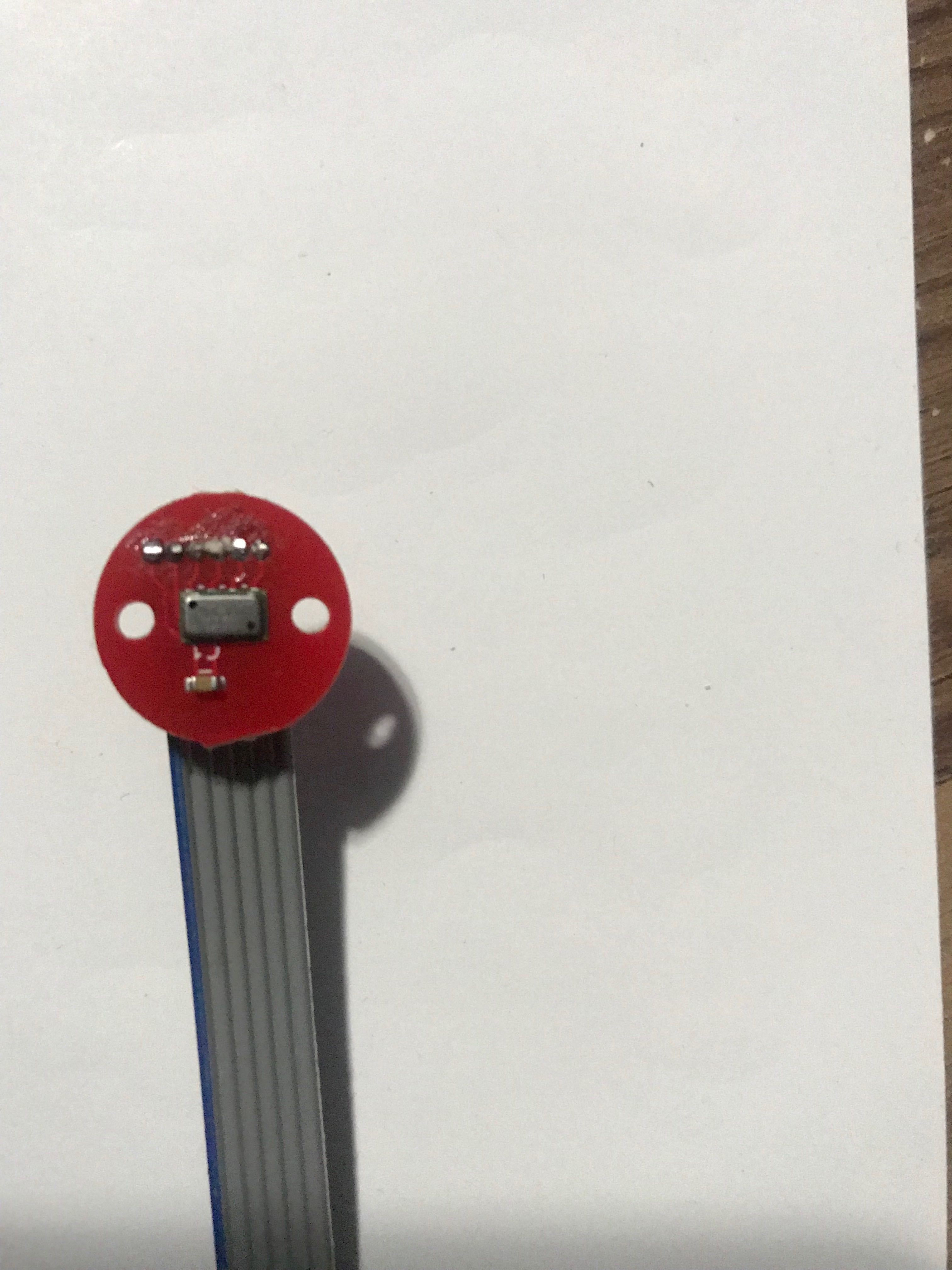

While brain storming sources of feedback that could be put onto the robot, We came up with a barometric pressure sensor encapsulated in a form of rubber. After researching a number of pressure sensors a highly sensitive, 24bit MS5611 pressure sensor was chosen with a resolution of down to 0,0024 mbar communicating through SPI. A board to mount to the end of the ankle joint of the robot was made so it could be encapsulated in the rubber.

This board was mounted to the ankle join and cast in a variety of rubbers to test the sensitivity and resolution of the data. Two durometers of Smooth-on silicone rubber (Durometer 10 & 20) and Smooth-on Vytaflex 20, a Durometer 20a poly-urethane. These materials were cast into a 3 printed mold and placed into a vacuum chamber and a vacuum was pulled to remove any air from the system that may result in any inconsistencies in the density of the material.

The silicone rubber was tested and the results were very promising of the Durometer 20 rubber, however the Durometer 10 rubber was too soft to provide reliable and repeatable data. However the attempt to use silicone rubber stopped here, it was eliminated due to the inability to have silicone bond strongly to any material other than itself.

The poly urethane casts despite having a number of failed attempts at the beginning gave excellent results in both casting quality and pressure transmission to the sensor. For this reason as well as its durability we continued with this material.

Keion Bisland

Keion Bisland

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

a pizio sensor is inside the pressure sensor, so in a way, yes. the MEMS of the pressure sensor acts to give us 14 bits of resolution, and the potting of the feet in polyurethane makes it robust.

Are you sure? yes | no

But is the MEMS Piezo exposed to the upper surface based on your experiments?

Are you sure? yes | no

After casting that foot we can sense a 14 bit swing between loaded and unloaded. the update can be read over spi every 2ms. This gives us an accurate and roughly linear value for pressure as well as a real time valuable foot contact timing.

Are you sure? yes | no

@Kevin Harrington awesome!

Are you sure? yes | no

It would need amplification, this sensor is a piezio sensor on the inside, the rest of the foot acts as mechanical shock separation and mechanical amplification.

Are you sure? yes | no

Would not a piezo sensor do the same thing?

Are you sure? yes | no