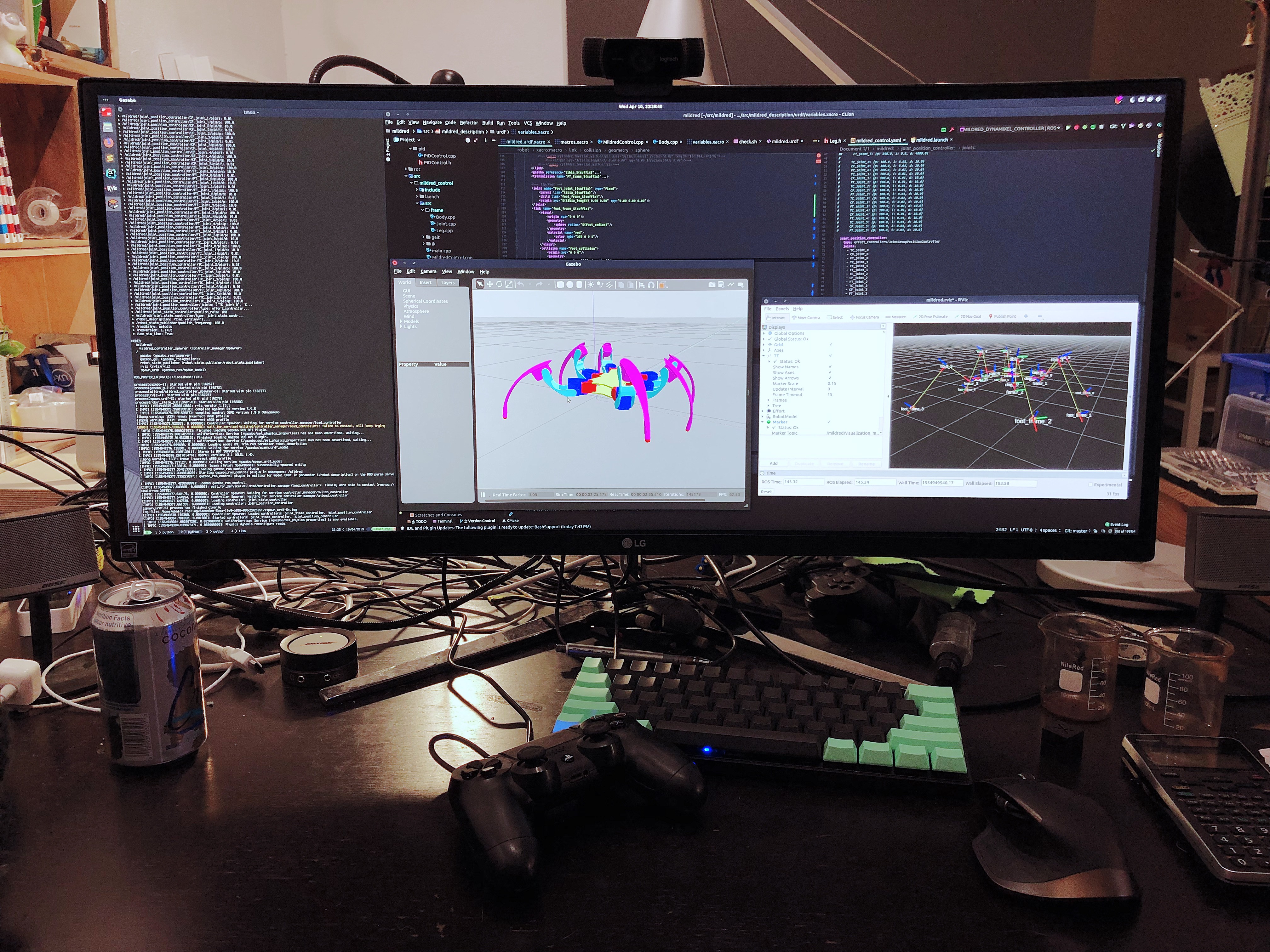

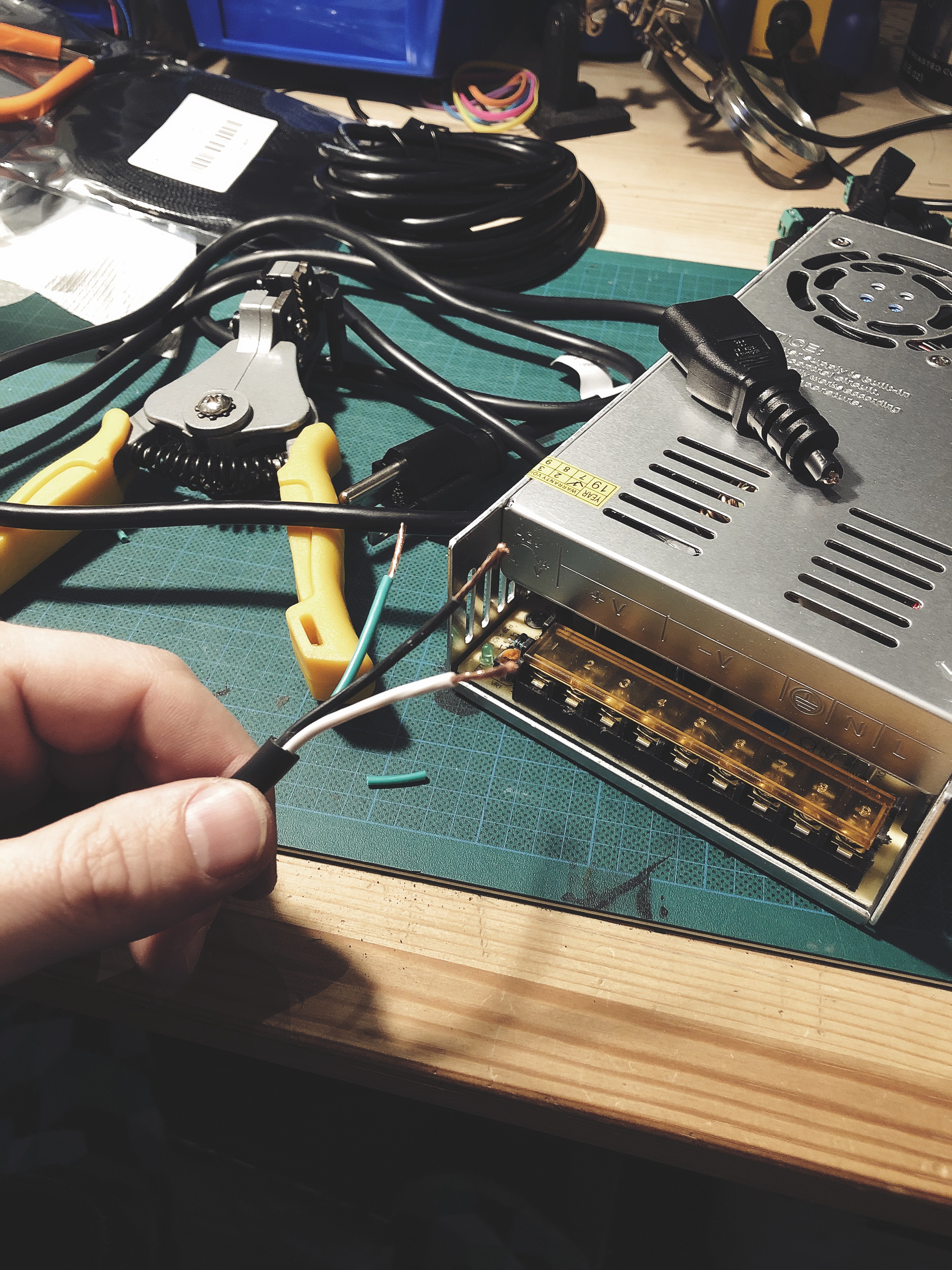

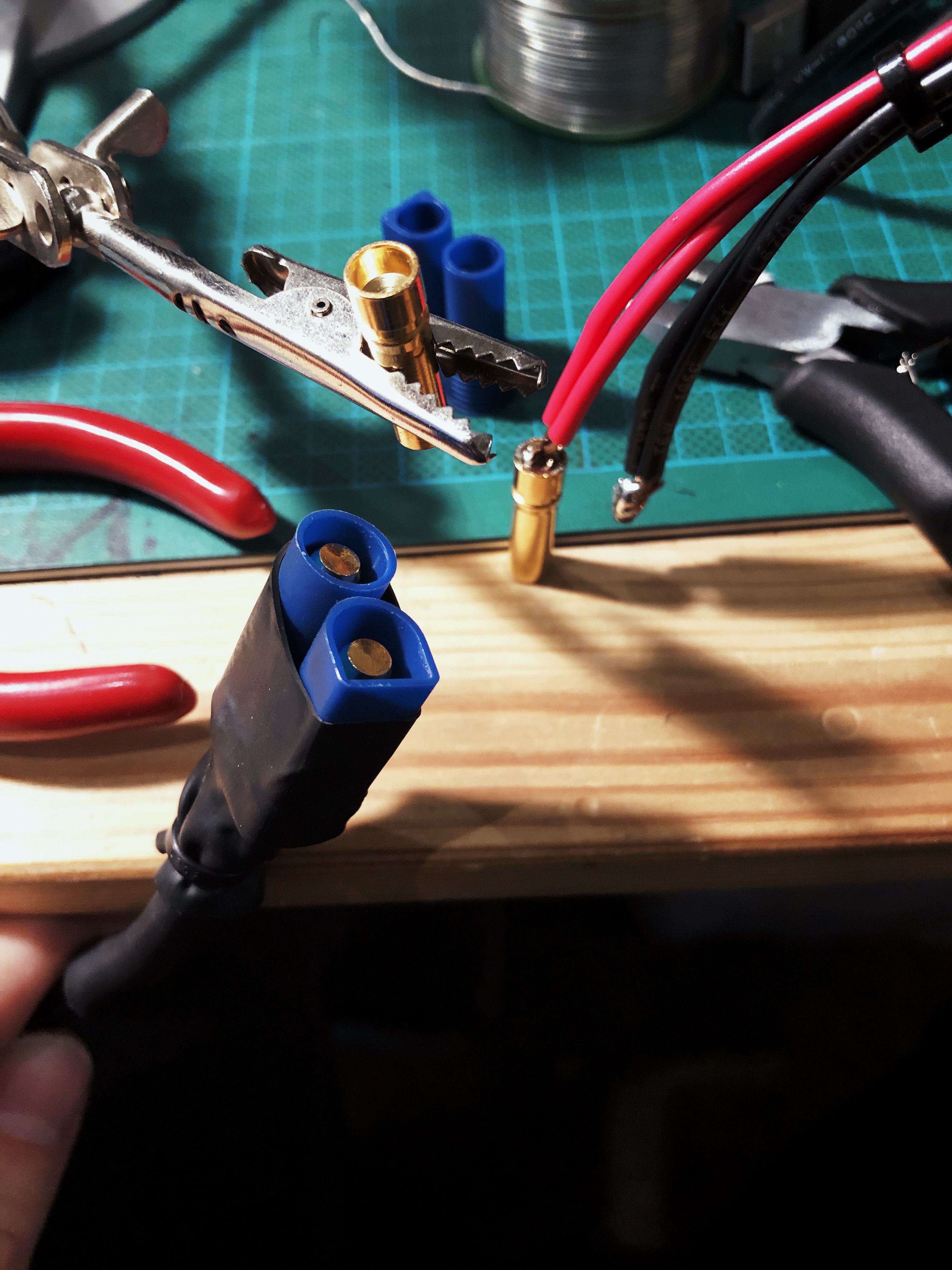

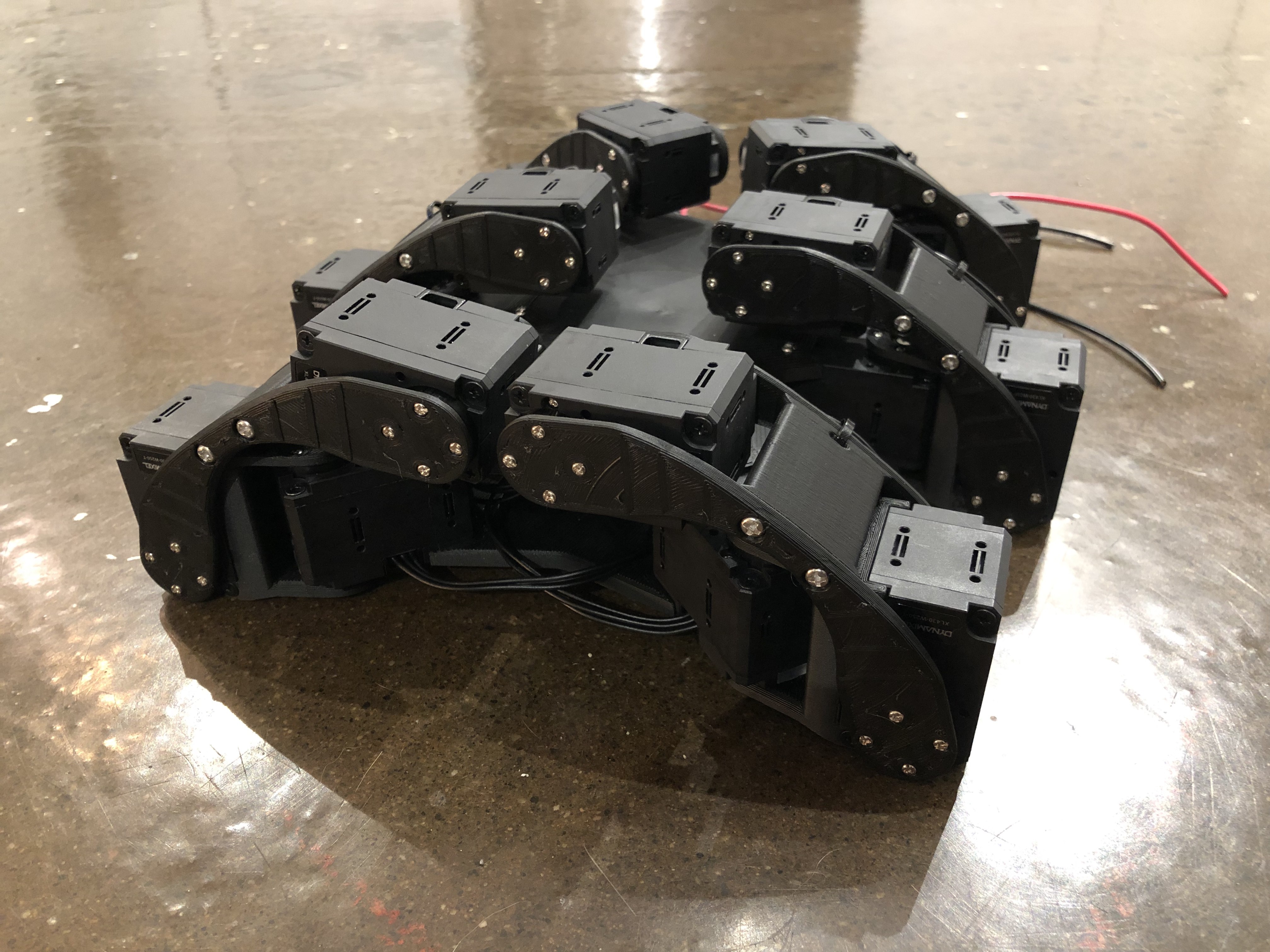

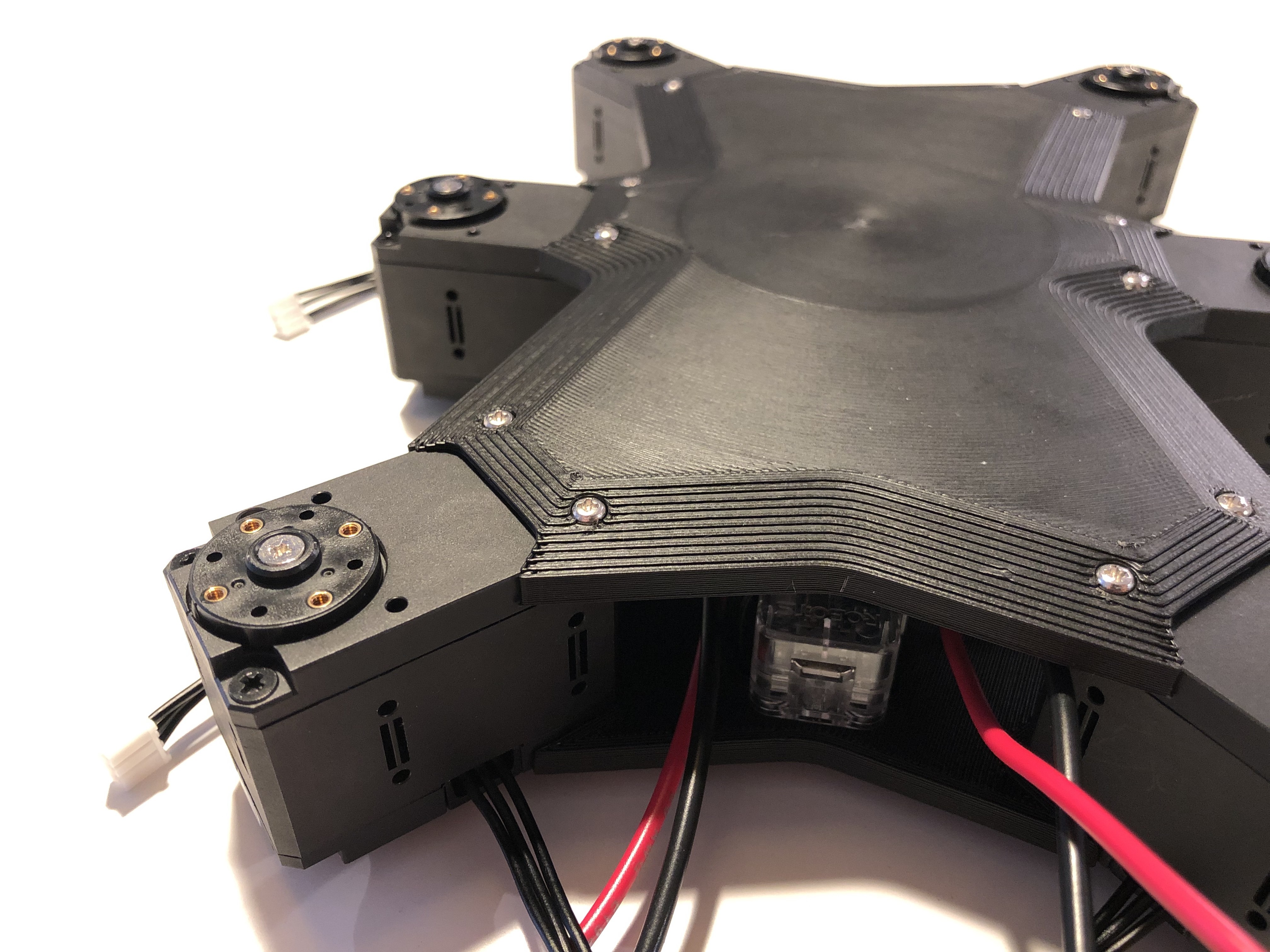

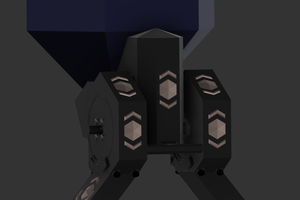

The robot will first run tethered to a computer and PSU while I develop the software for it. It runs on ROS Melody using Ubuntu 18.04.

I will eventually upgrade it to have a LattePanda Alpha on it's back so that I can run ROS on board and experiment with vision/SLAM and an IMU.

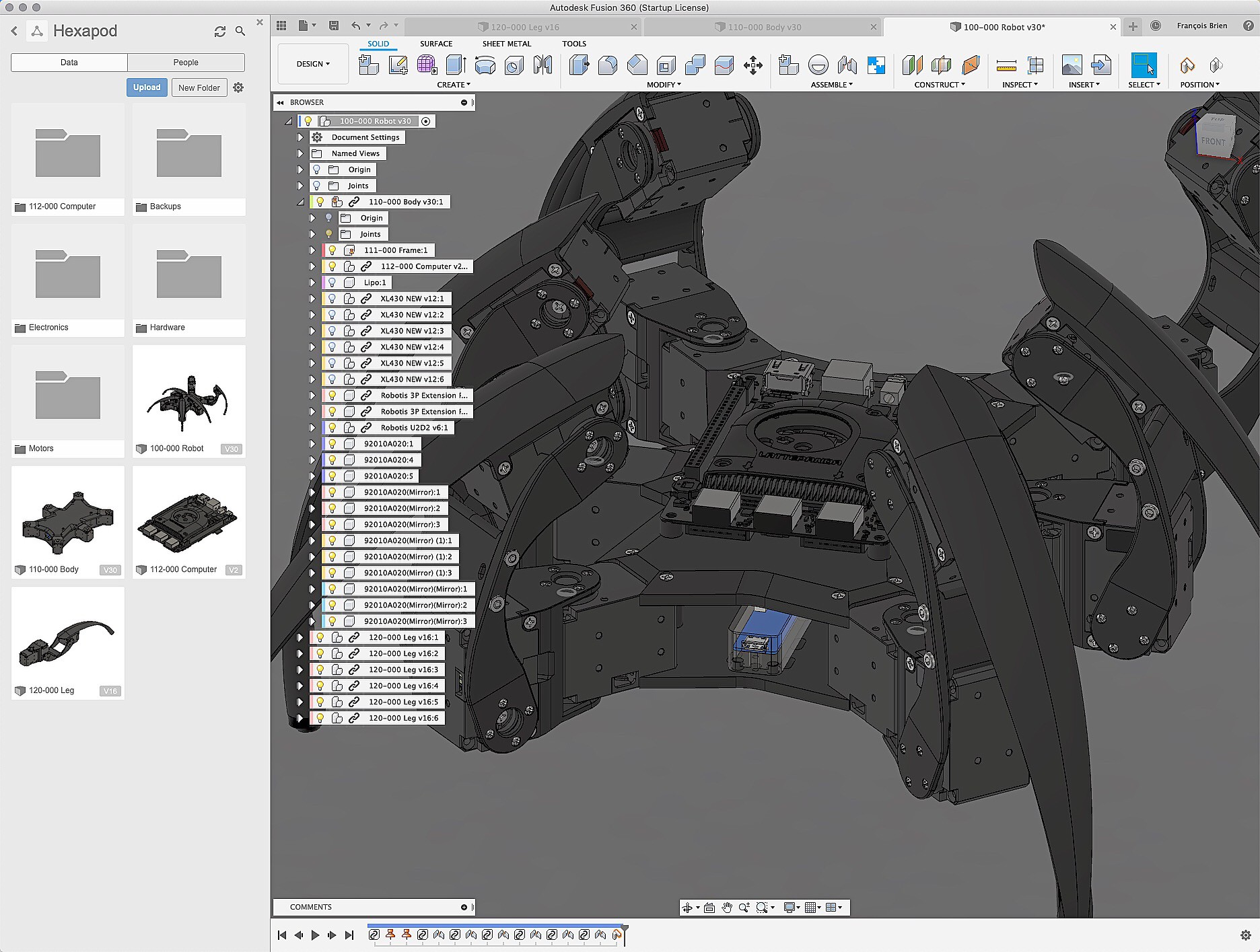

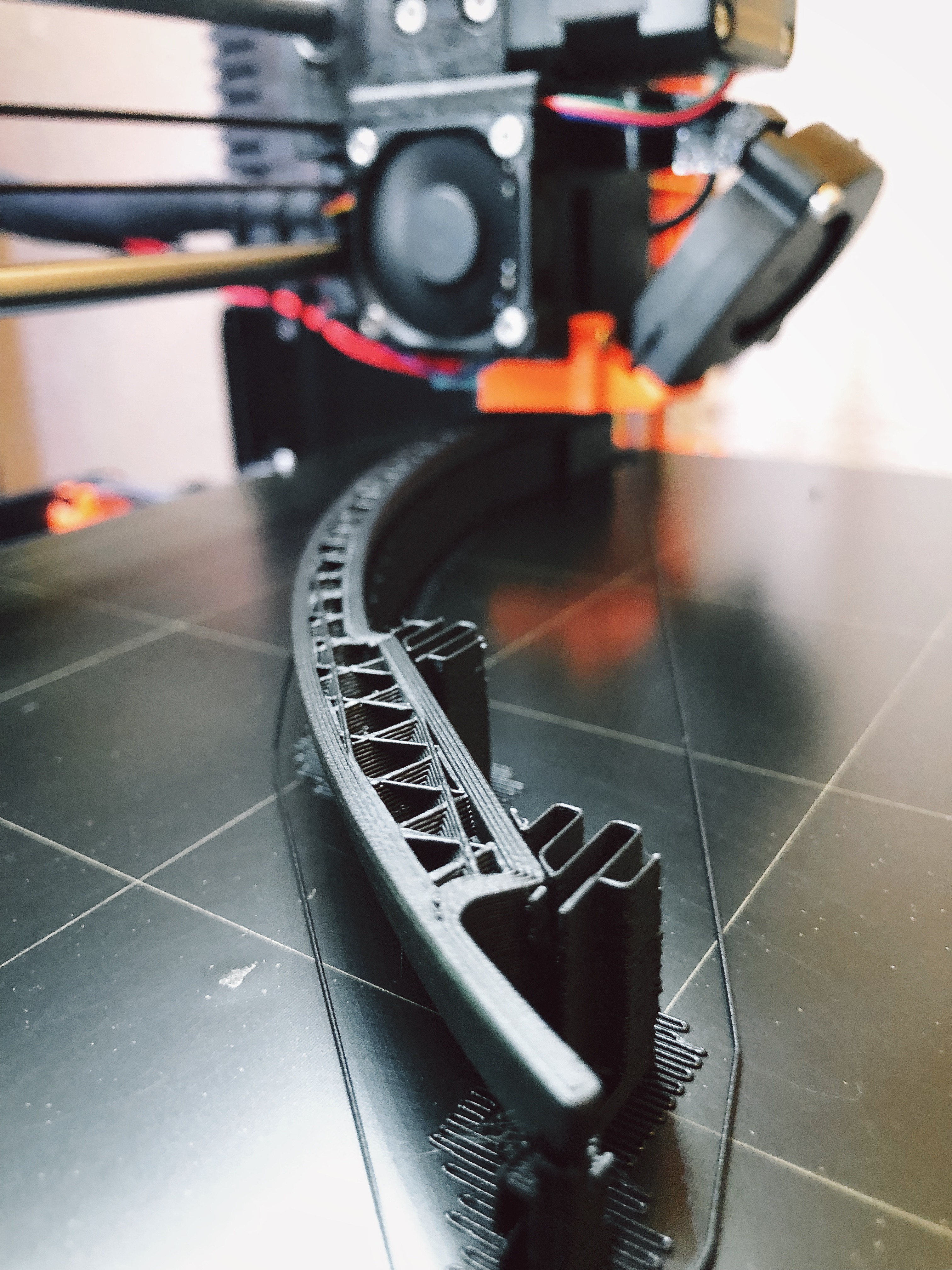

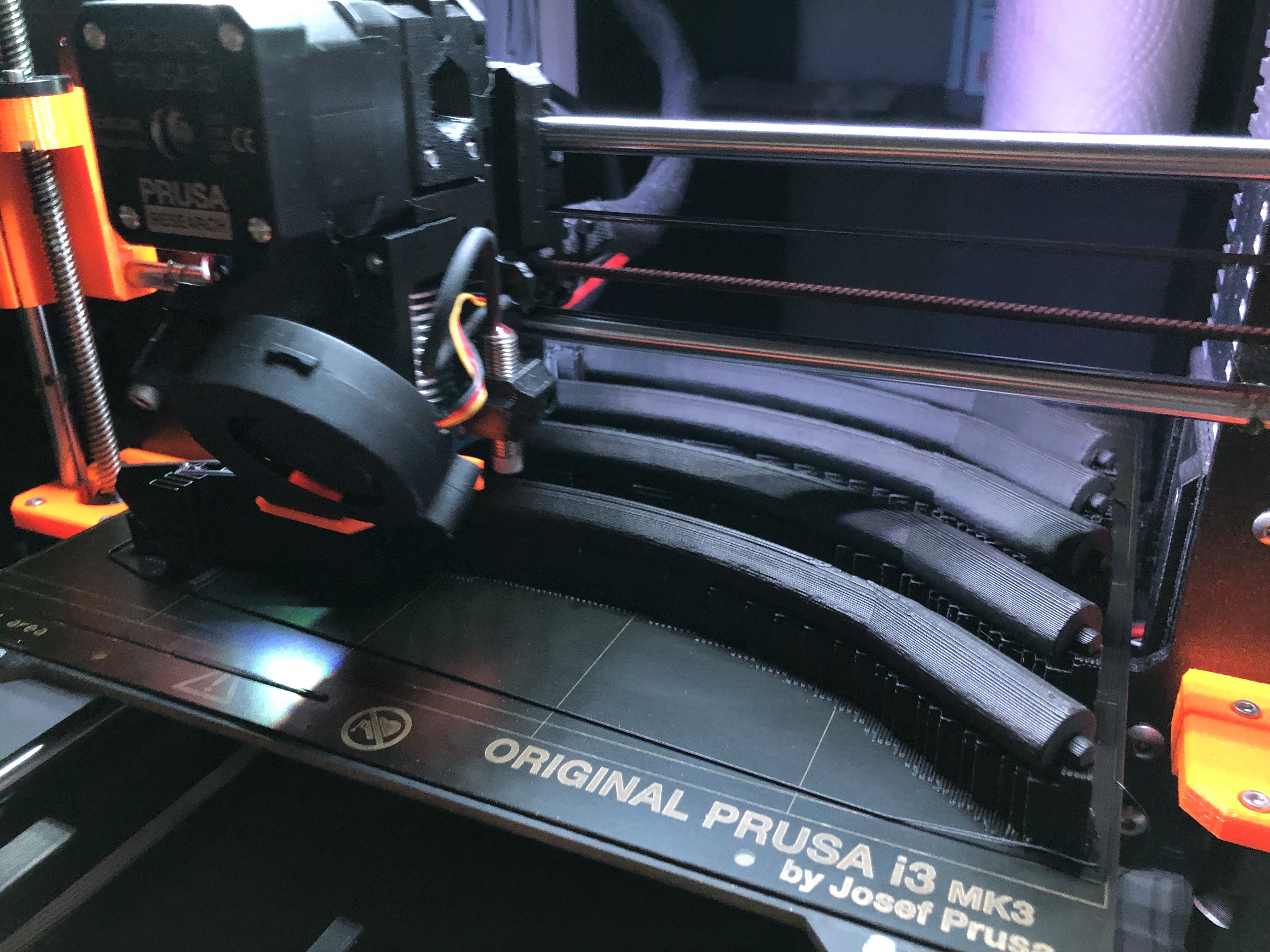

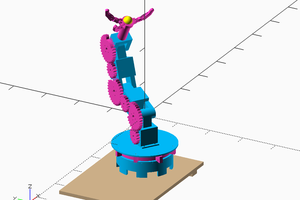

I plan on making the CAD files available once all the issues are fixed.

François Ubald Brien

François Ubald Brien

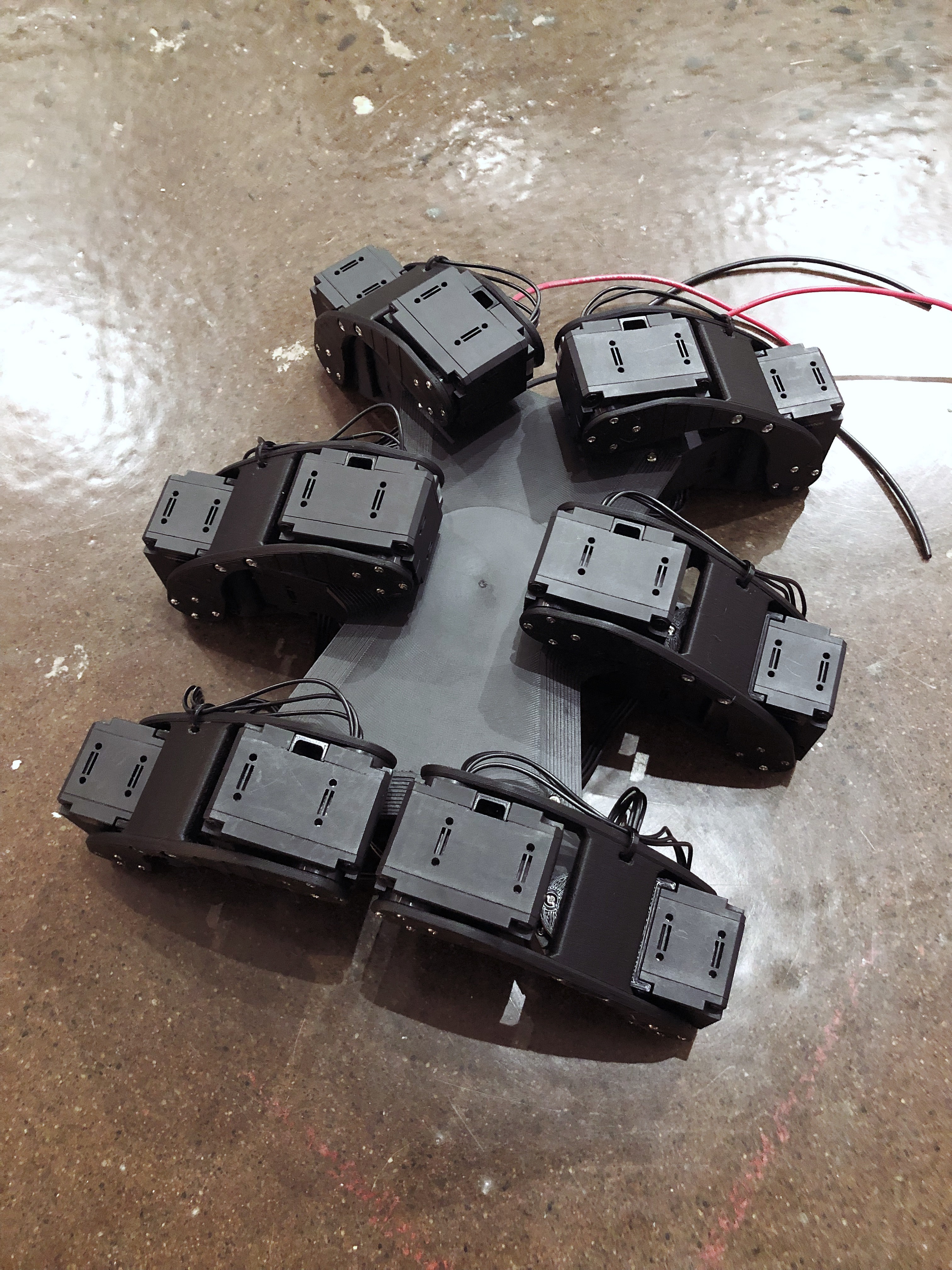

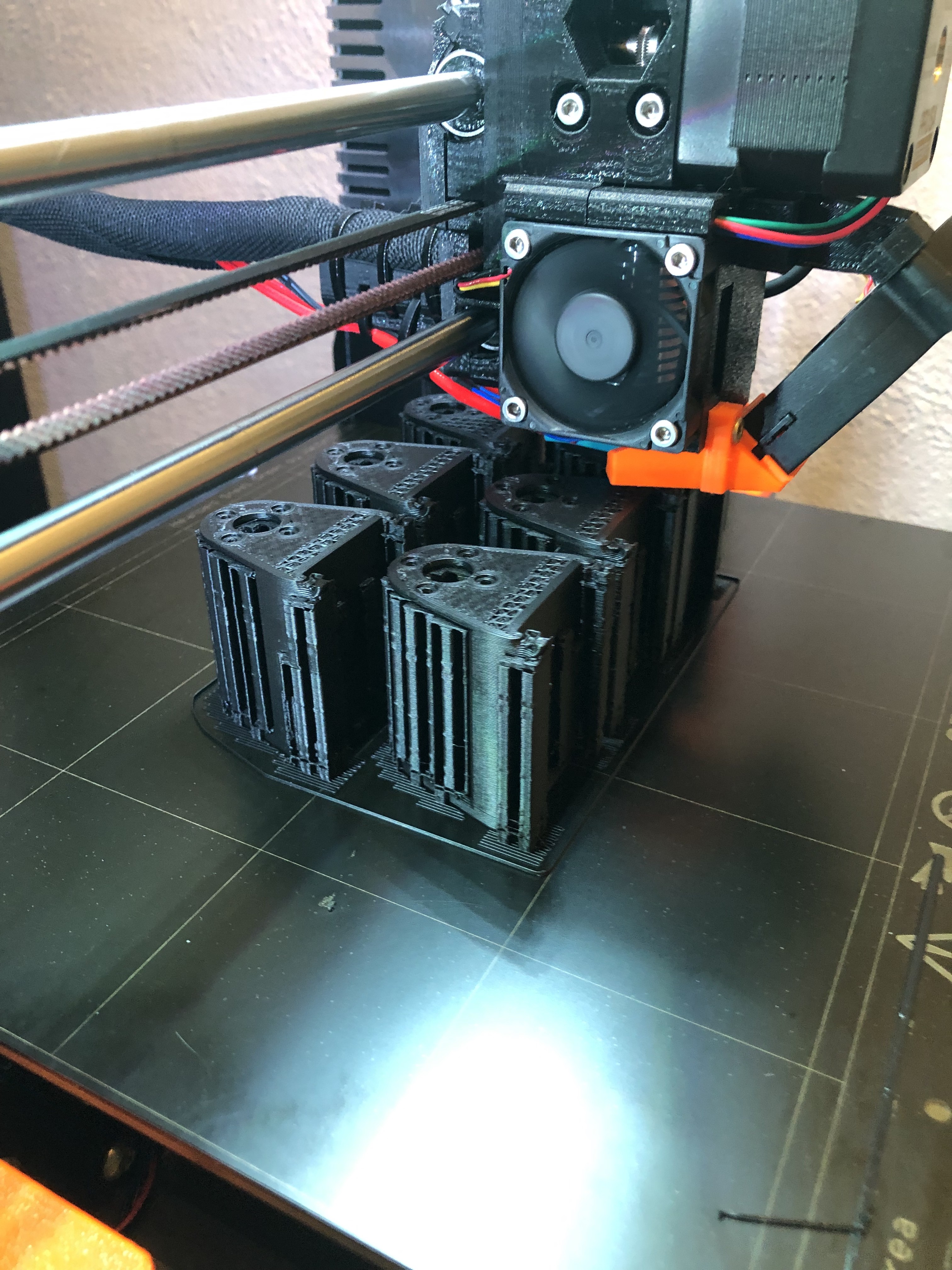

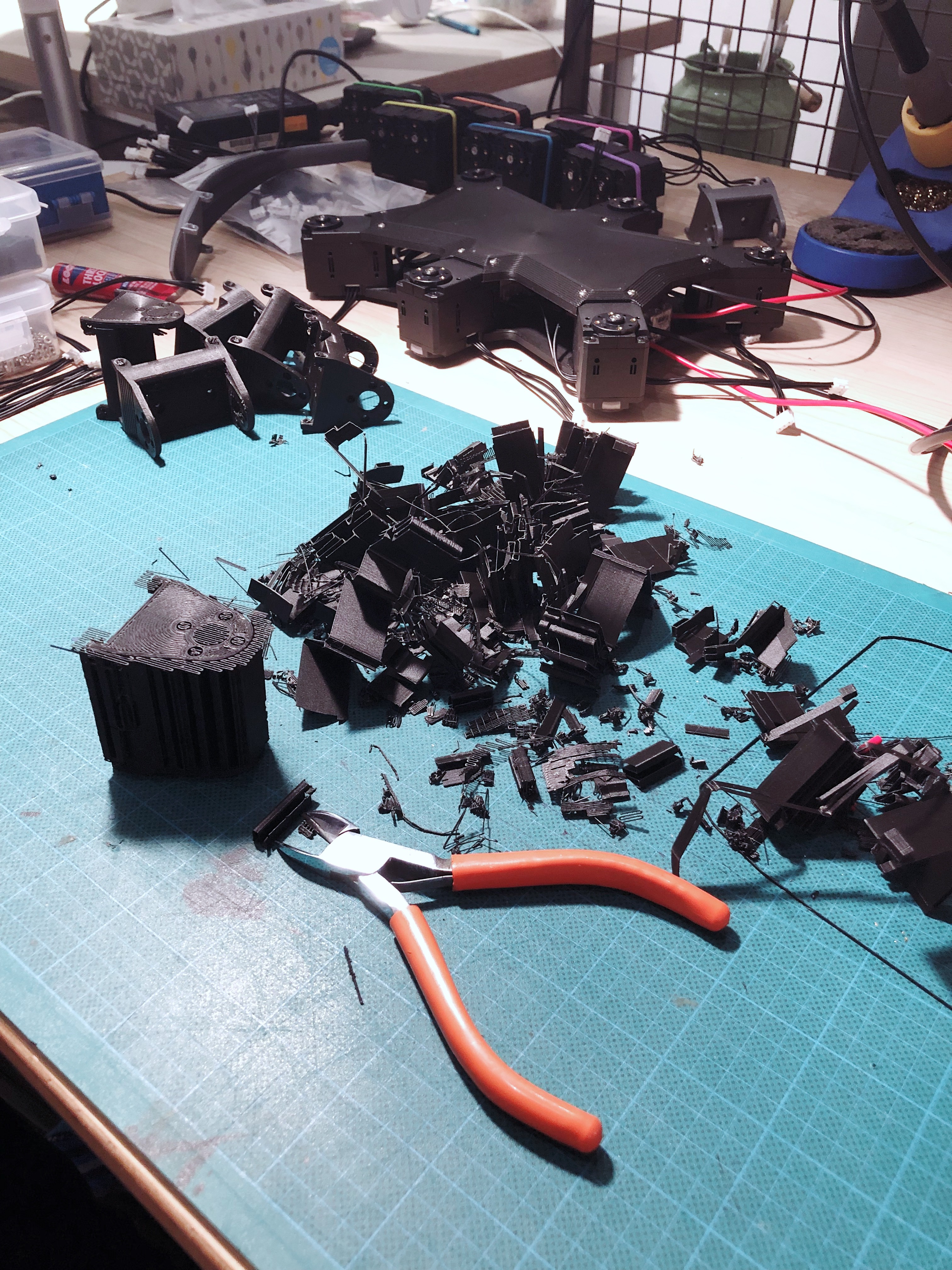

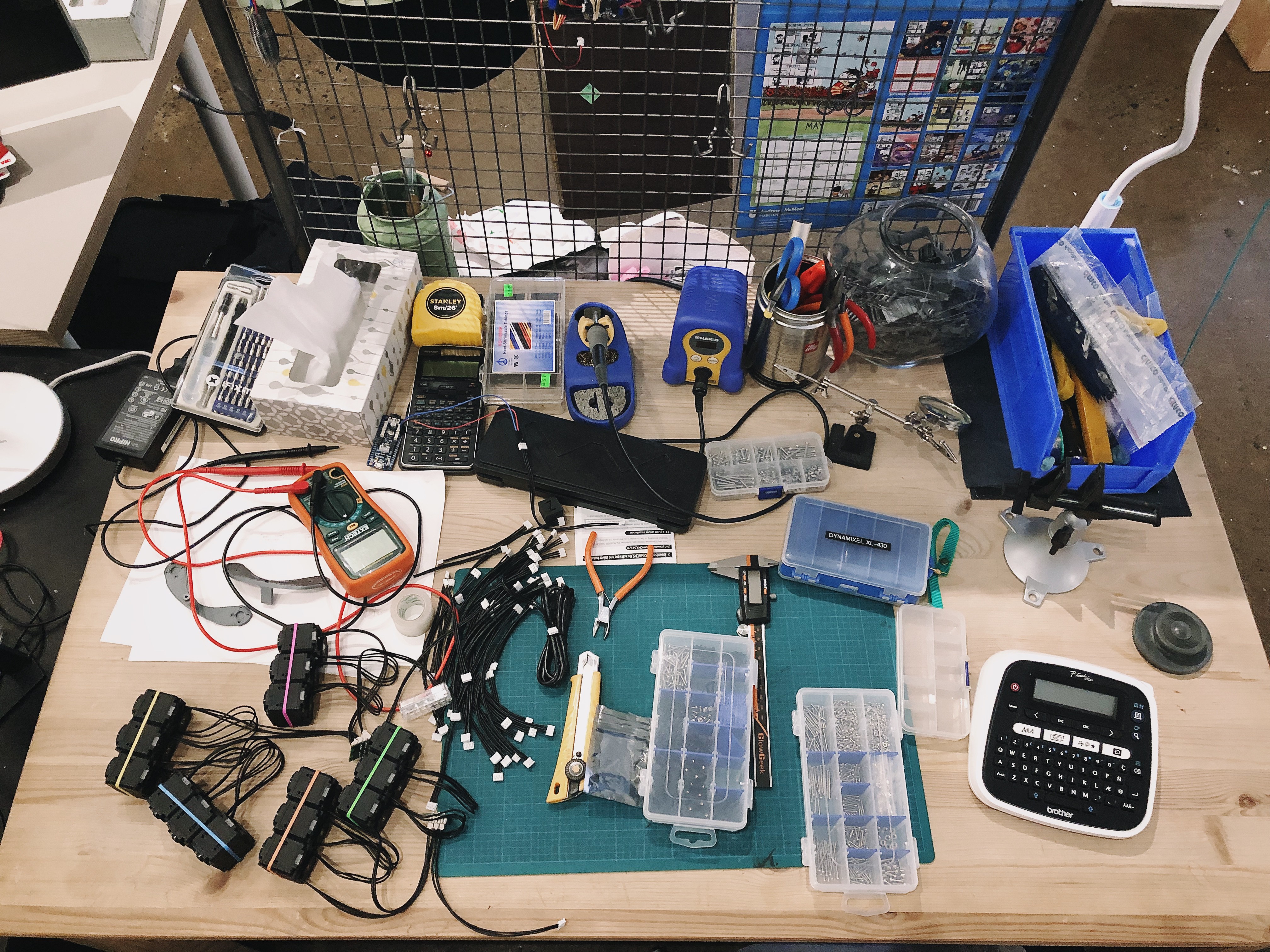

I don't know why, I always enjoy having a bunch of similar objects that pack nicely together.

I don't know why, I always enjoy having a bunch of similar objects that pack nicely together.

Apollo Timbers

Apollo Timbers

Les Hall

Les Hall

Joseph Marlin

Joseph Marlin

Ahead

Ahead

Looks awesome! Do you share your 3D Model/3D parts of your hexapod. I'm planning to use dynamixel xl430s too, but cannot find 3D parts anywhere! Thx