Engine and mechanical monitoring is well-established in industrial ("IIOT") settings and even on train networks, with small rugged sensor dongles that can be attached to things that move. Generally, with some modal analysis math, you can determine things like a single tooth in a gearbox being worn, or a loose bolt on a mount or wheel which will cause eventual failure. However, nothing exists for the consumer or hacker with one engine or a budget under a couple of hundred thousand of your local ringgits.

If we restrict the initial version to just marine diesel, i.e. the engine in a boat or small yacht, this will give a great basis for a successful product line later. This is because

- marine diesels are typically mounted in a place where maintenance is easy, by design

- owners of marine diesels typically do the maintenance themselves, and are basically comfortable with the layout and operation of their engine

- these engines are generally older and therefore entirely mechanical (i.e. not a Mercedes Sprinter that won't start unless all its sensors are 'good')

- diesel is a bit safer than gasoline, i.e. boom-boom, in case of stray sparks.

- marine diesels are just normal old diesels (i.e. Perkins 4-154: made by Mazda) with some special paint, (hopefully) better grade steel bolts, and a few extra bits for the salty air, no clutch, and a heat exchanger

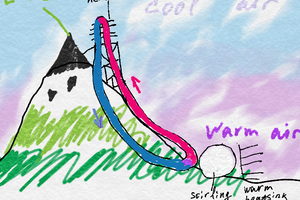

- Marine diesels also typically run cooler because they have an additional coolant loop where "fresh" water (mm, salty) from outside the boat is sucked in and takes away the heat from the green coolant water in a heat exchanger, instead of air, a fan, and a radiator.

What we don't want to do is add complexity that gets in the way of the engine just running. We *do* want to add a bunch of analysis and metrics to give warning of maintenance issues and insight into performance.

There are a bunch of things that could be possibly monitored on a simple diesel engine; some of these are just absolute levels, and some can only be analysed in the context of another metric. Some of these don't really matter at all and are just "huh, cool", and some are only useful later, after something explodes, to figure out why.

- coolant: reservoir level, temperature, pressure, presence of oil

- oil: level, temperature, pressure, filter status, age, presence of water

- drive shaft: propellor vibration, rotation chatter, bearing temperature, stern gland leak

- gearbox: chatter, vibration, temperature, lubricant age

- mounts: engine mount loose, starter motor loose, alternator loose, misc other bolts loose

- exhaust: temperature, gas analysis, leakage, presence of water

- fuel: filter state, level, pump temperature, flow and usage

- alternator: regulator failure, charge history, vibration

- mechanical: compression, knocking, injectors loose, valve clearance knocking

- zinc anode state

- relay: failure

- battery: electrolyte levels, state of charge, temperature, voltage

- starter: temperature, vibration, re-engagement

- fresh water intake flow, impellor status

Obviously this is a big list of things to check, but it covers almost everything that can indicate pre-failure or preventative maintenance. The most obvious need is a cheap, rugged vibration sensor that can be deployed all over the engine. So let's get started there.

Timescale

Timescale

DeepSOIC

DeepSOIC

mr.jb

mr.jb

Jan Zumwalt

Jan Zumwalt