Power Stacker Specs:

* Time to Fully Charge: @5 Watts 3350mAh: 3 hours | @8 Watts 13400mAh: 7 hours

* Capacity: 3350mAh, 6700mAh, or 13400mAh / 3.6V

* Type: Panasonic NCR18650B Lithium-Ion

* Input - Current: 450 to 2600mA | Voltage: 5 Volts

* Number of USB Ports: Depending on the number of 5V adapter modules

* Output - Current: Up to 2000mA | Voltage: 3.6 Volts direct or 5 Volts with DC-DC converter module

* Battery Life Under Typical Use: 5-10years

* Replaceable Batteries

CONNECTOR OPTIONS:

One of the most difficult design decisions is choosing the right connector that is compact yet sturdy enough to last hundreds of insertions and provide enough current. Maybe this style of mini power connecter can be used when going in to production:

https://www.samtec.com/products/umps

https://www.te.com/usa-en/product-5787253-1.html

SERIES OR PARALLEL?

Connecting battery cells in parallel seems like the easiest way to increase capacity because series increases voltage but not capacity while parallel keeps the voltage the same and increases capacity. The only issue is that there is energy loss through the 5V step up regulator and the diode that is required on each cell pack connected in parallel to the bus bar in order to prevent back current. This diode voltage drop on each cell pack between .3 - 1V is equivalent to a significant reduction in runtime.

However, it may be better to connect cells in series in order to increase the voltage and then use a high quality switching regulator like the following:

https://www.maximintegrated.com/en/products/power/switching-regulators/MAX16952.html

https://www.maximintegrated.com/en/products/power/switching-regulators/MAX1791.html

with a large input voltage range (for up to 10X3.6V cells) to step down to the USB 5V voltage. Higher voltage means lower current through most of the PCB assembly allowing for a more compact design. Even though there is loss in the regulator and cut-off voltage, it may be more efficient than cell packs connected in parallel through a diode then stepping up the voltage to USB 5V.

WHICH BATTERY?

For all my battery projects, I tend to use the Panasonic NCR18650B batteries because they are the highest quality with the largest capacity for its size. In my 5 years of working with these cells, I've only seen one fail permanently due to over-discharge for about a year. Even though it doesn't have the highest current output, it makes up for it with capacity and reliability. Stacking cells together also reduces the need for high current from a each cell since the total output current is divided amongst all cells.

However, I am thinking about using the smaller version of this battery called the Panasonic NCR18500A, which does have a lower capacity due to its reduction in height, but if I'm making a stackable battery system with circuity built in to each cell, then a lower profile can help reduce the size of each stackable cell assembly. Especially if I choose to go with a series stackable design, I would need at least two cells anyways for the step down regulator to function properly.

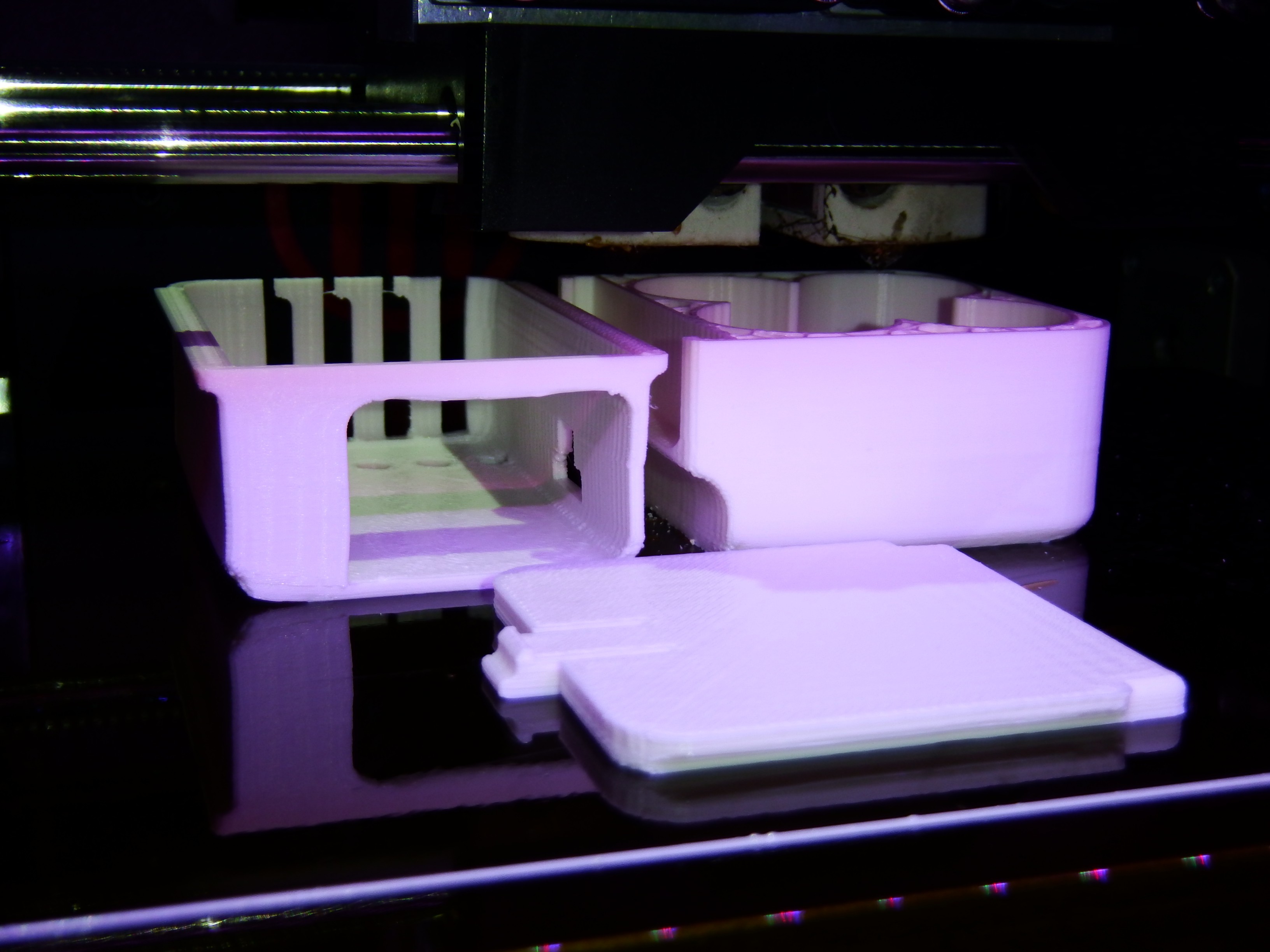

2nd POWER STACKER CASE CONCEPT

Here's another style of a case where the cells are separated from the PCB. For the future, I am considering a design for a case that encloses each cell and PCB assembly for easy assembly and disassembly like Lego bricks.

isaacporras

isaacporras