I am developing for the Ultratronics v1.0 which is a Arduino Due.

This is done in Visual Studio 2015 and a tool: VisualMicro.

Developing the code is not easy because I have been slamming into a wall for a few days before I started to realize that the compiler may not produce correct code for what I wanted.

It seems that inside classes the C++ does not like "MyClass* myClass=new

MyClass()" on the Arduino Due. Dynamic memory allocation seems not to

function nicely. Something that would have worked correctly on a Windows C++.

It forced me to a redesign. Less dynamic assigned memory and more static compile time determined memory.

But I have results:

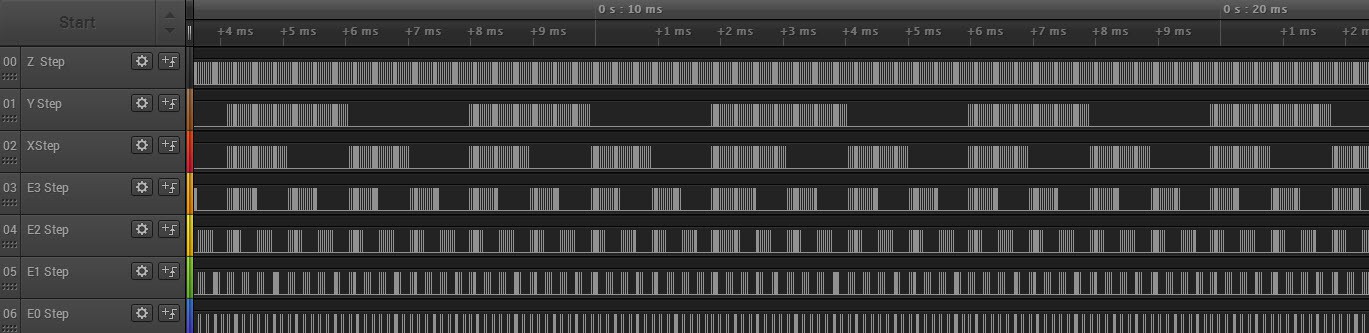

Hooking up the logic analyzer shows the clear test pattern.Each puls is a stepper motor step command.

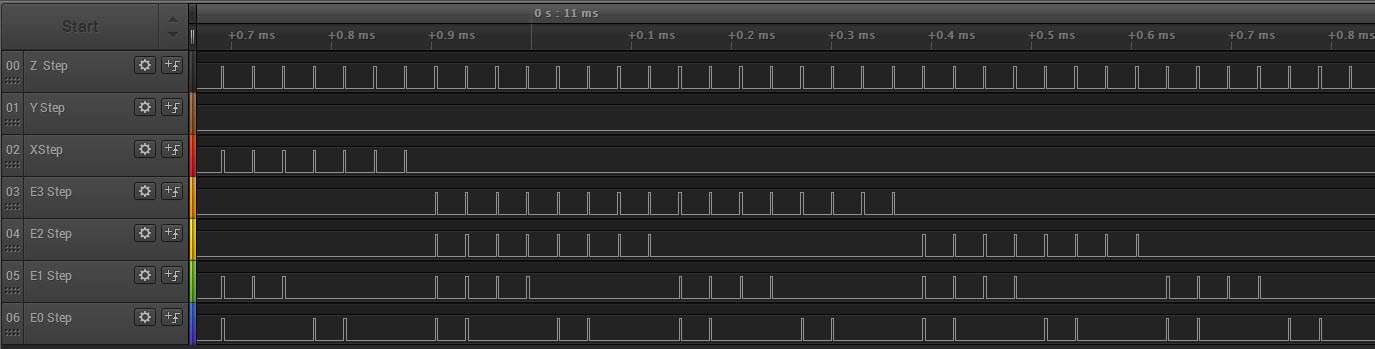

Zoomed in

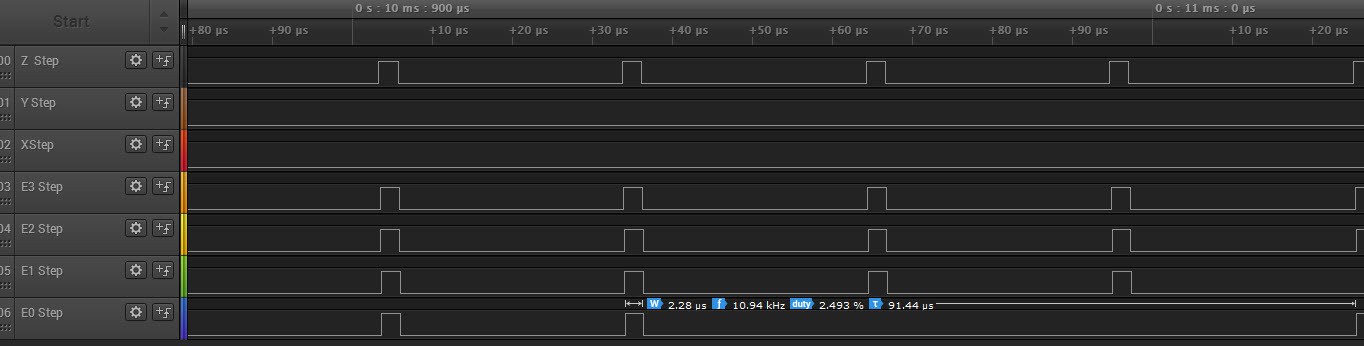

Zooming even more in you clearly short pulses that are a bit higher than 2µS.

The code that generates the puls is below. I use one bit per motor to drive the simultaneously. Then a silly loop with a "nop" in it that generates a pulse with that is a bit higher than the required 2µS

void MotorCommand::StepMotorPulseDelay2Micros() {

// Code blow should be about 2 µS on a 84 Mhz Arduino Due

for (auto i = 0; i < 36; ++i) {

asm("nop \n");

}

}

void MotorCommand::SendMotorStepCommand(byte step_command) {

// Make the signal high

SendMotorStepHighCommand(step_command);

StepMotorPulseDelay2Micros();

// Make the signal low

SendMotorStepLowCommand(step_command);

StepMotorPulseDelay2Micros();

}

void MotorCommand::SendMotorStepHighCommand(byte step_command) {

byte level = step_command;

level = step_command & MOTOR_BIT_Z;

if (level != 0) REG_PIOD_SODR = PIO_PD0; // Z_AXIS_STEP set to high, bit 7

level = step_command & MOTOR_BIT_Y;

if (level != 0) REG_PIOB_SODR = PIO_PB26; // Y_AXIS_STEP set to high, bit 6

level = step_command & MOTOR_BIT_X;

if (level != 0) REG_PIOC_SODR = PIO_PC3; // X_AXIS_STEP set to high, bit 5

level = step_command & MOTOR_BIT_E3;

if (level != 0) REG_PIOC_SODR = PIO_PC7; // E3_AXIS_STEP set to high; bit 4

level = step_command & MOTOR_BIT_E2;

if (level != 0) REG_PIOA_SODR = PIO_PA19; // E2_AXIS_STEP set to high, bit 3

level = step_command & MOTOR_BIT_E1;

if (level != 0) REG_PIOC_SODR = PIO_PC19; // E1_AXIS_STEP set to high, bit 2

level = step_command & MOTOR_BIT_E0;

if (level != 0) REG_PIOC_SODR = PIO_PC16; // E0_AXIS_STEP set to high, bit 1

}

void MotorCommand::SendMotorStepLowCommand(byte step_command) {

REG_PIOD_CODR = PIO_PD0; // Z_AXIS_STEP set to low

REG_PIOB_CODR = PIO_PB26; // Y_AXIS_STEP set to Low

REG_PIOC_CODR = PIO_PC3; // X_AXIS_STEP set to Low

REG_PIOC_CODR = PIO_PC7; // E3_AXIS_STEP set to low

REG_PIOA_CODR = PIO_PA19; // E2_AXIS_STEP set to low

REG_PIOC_CODR = PIO_PC16; // E0_AXIS_STEP set to low

REG_PIOC_CODR = PIO_PC19; // E1_AXIS_STEP set to low

return;

}

The idea is to have pre-calculated motor bits ready in memory that can, be read at a fast rate and executed by a timer. The time above is at 32Khz, which means that a 200 Steps motor, at 32 microso-steps has about 5 revolutions per second.

This may seem fast but the Thor robot has geared steps with a 5:1 ration and then we have another gear X:1 slowing it even more. I image think about having to have only 16 or maybe even 1 micro step per motor.

Next step direction and enable control.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.