Because the Thor robot has multiple long duration 3D prints I tried to reduce the noise of the printer because some prints goes into the night. I don't think my neighbors can hear it but I prefer to prevent it is I can.

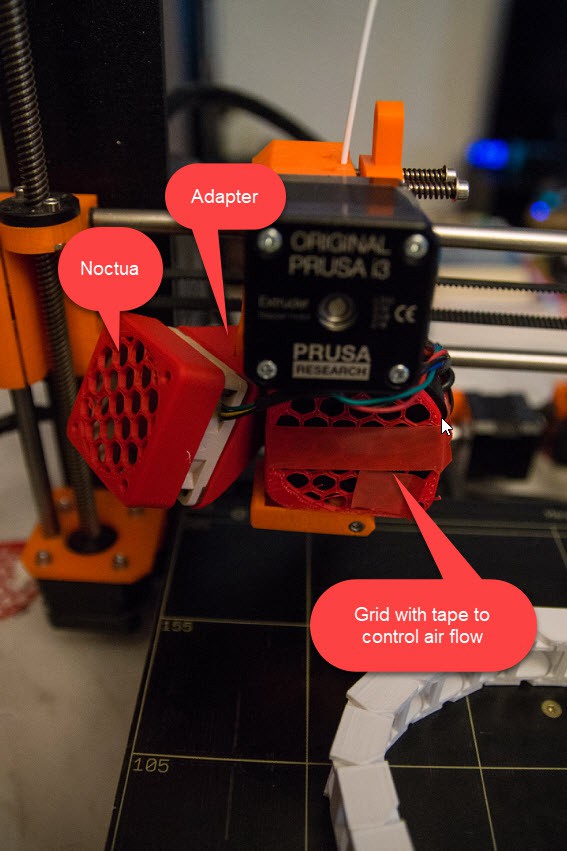

So upgraded my Original Prusa MK2 with a Noctua fan that needs an adapter.

The adapter I used is : https://www.thingiverse.com/thing:2076234

The fan used is http://noctua.at/en/nf-a4x20-pwm

The NF-A4x20 is 20 mm thick and I paid 14 euros. It is really that silent.

You also see that on the right I have a 3D printed fan cover that I can control the air flow with by adding or removing tape (even during printing). The fan itself caused in many cases a Termal Runnaway and ruined the print.

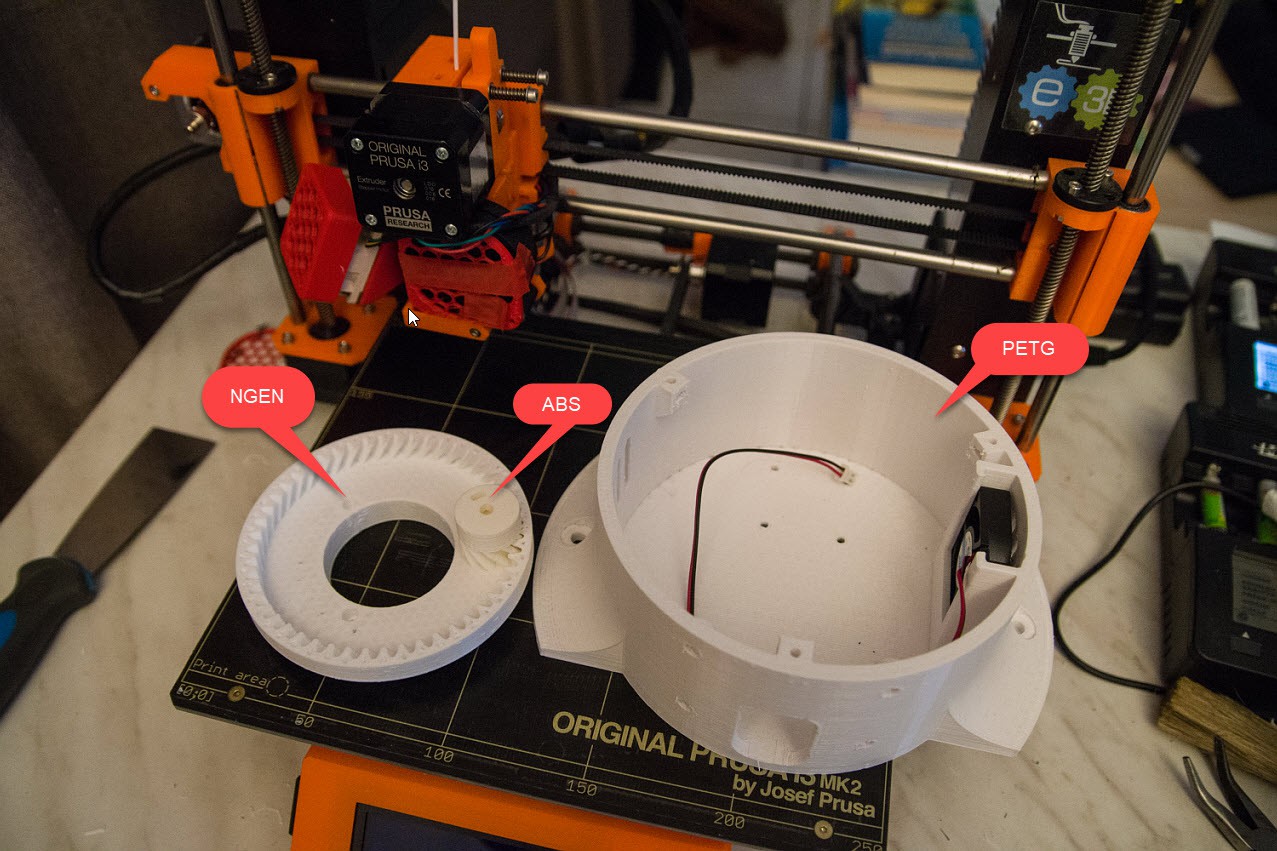

The Prussa MK2 printer has big issues with warping when I print with ABS.

Last time I tried PETG, which is more flexible than ABS but also more droopy. The filament support structures are hard to remove.

Danny pointed me to ColorFabb NGEN, more expensive but I gave it a try.

http://www.omd3d.com/omd3deshop/co-polyesters/63-ngen.html

(Remark, the site seems to have a bug in its javascript. You have to press the browser refresh page every time you selected something in Firefox)

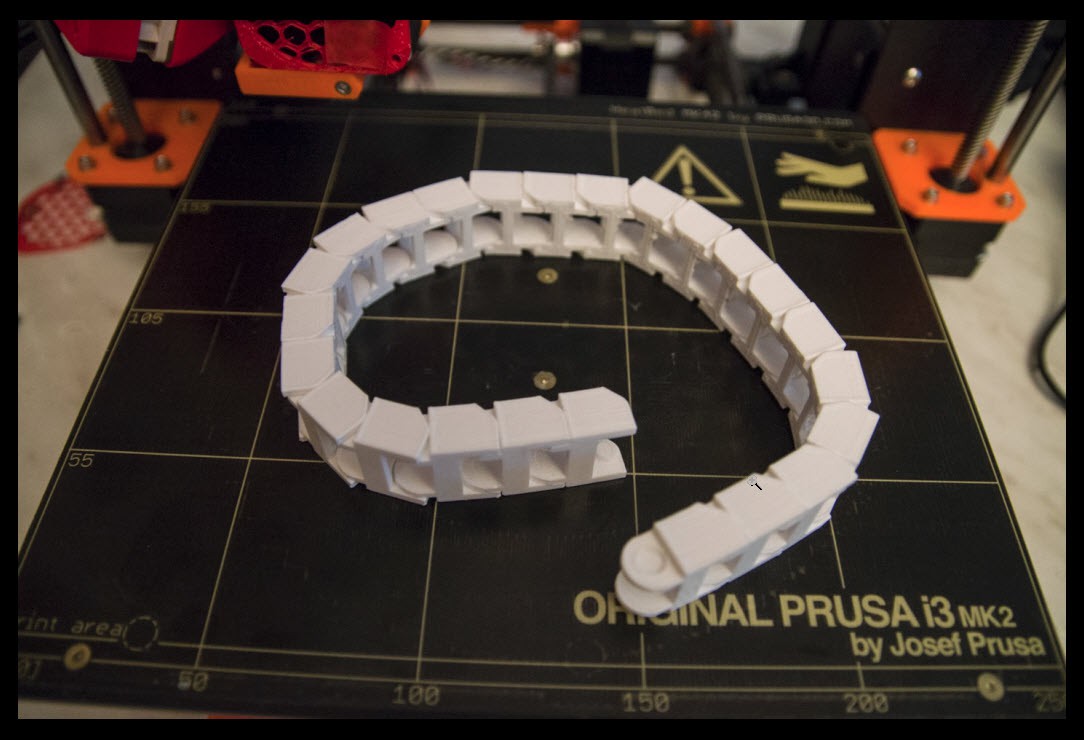

(Assembled cable train)

(Assembled cable train)First print was parts to have a cable train.

With ABS they all came lose of the bed during printing. But with NGEN they did stick and the print worked out nicely. I printed at standard 2400 mm/min and even 4200 mm/min.

The first things you notice is that the NGEN plastic is as hard as PLA. So far it seems not to break as fast as PLA, but it does break when you bend it too far.

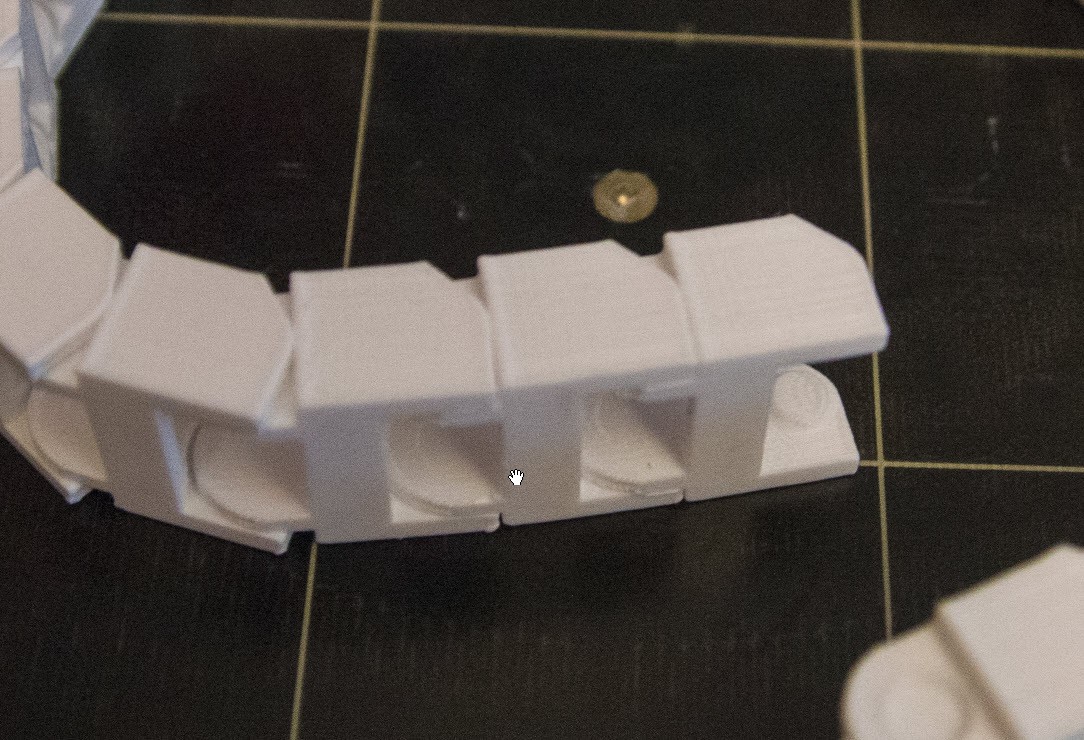

Detail of the cable train.

A comparison of Thor printed parts in different materials.

I had to break of the left part (ART1BOT) printing job because it was well into the night and it took longer than what Simplify3D predicted (I think the Prusa printer moved slower than 4200 mm/min)

I am redoing this job at this moment since this part had a sensitive thin wall part that easily broke off in ABS.

I tried to print this part with CarbonFil but my printer stuck its head several times on the parts and I got an offset error and a failed print. I think this NGEN can do the same thing as the CarbonFil.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.