Current mobile hardware is closed and monolithic. Repairs are hard and modifications or upgrades impossible.

This is unsustainable, keeps small companies out of the market and stops users from adapting devices to their own needs. I want this to change!

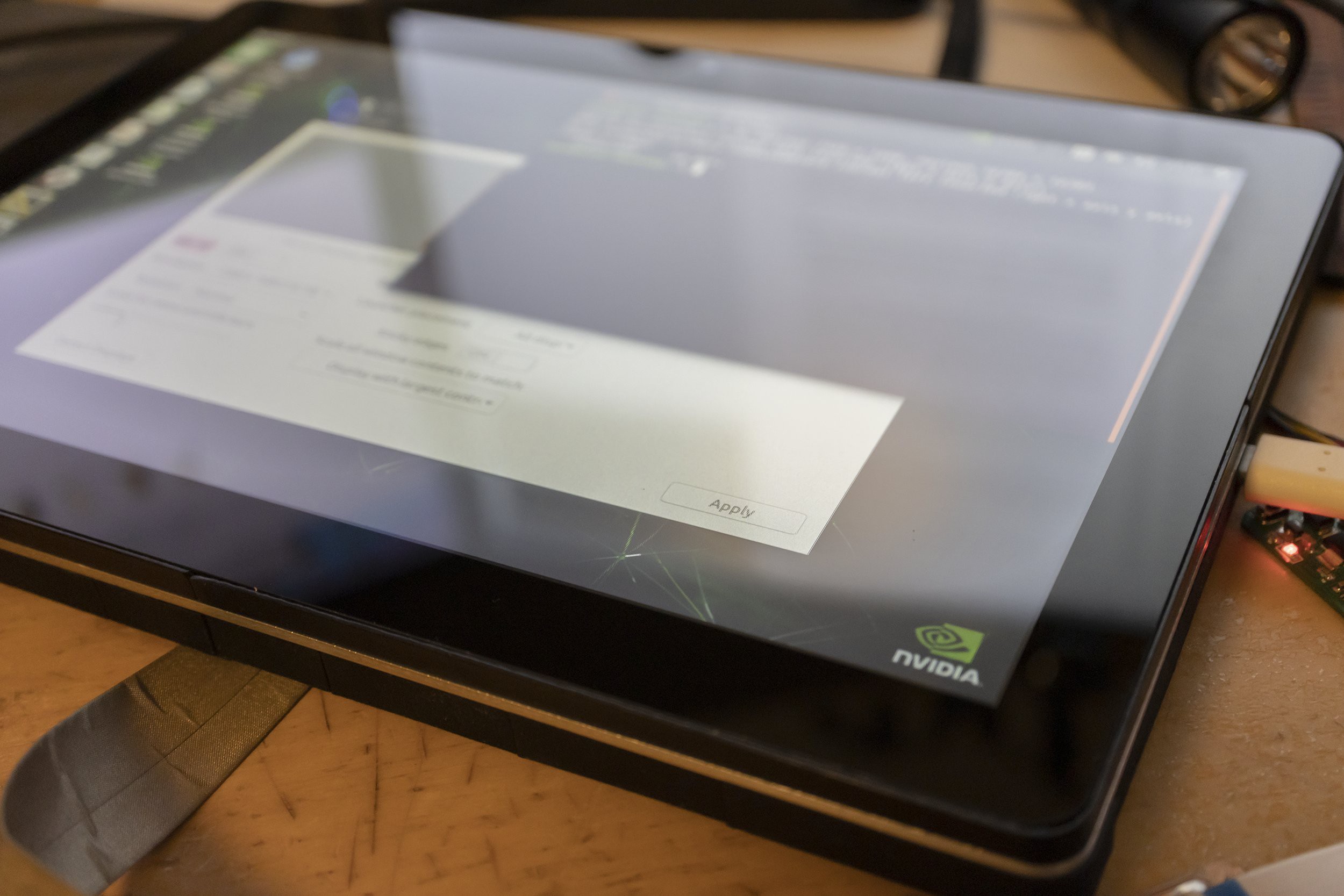

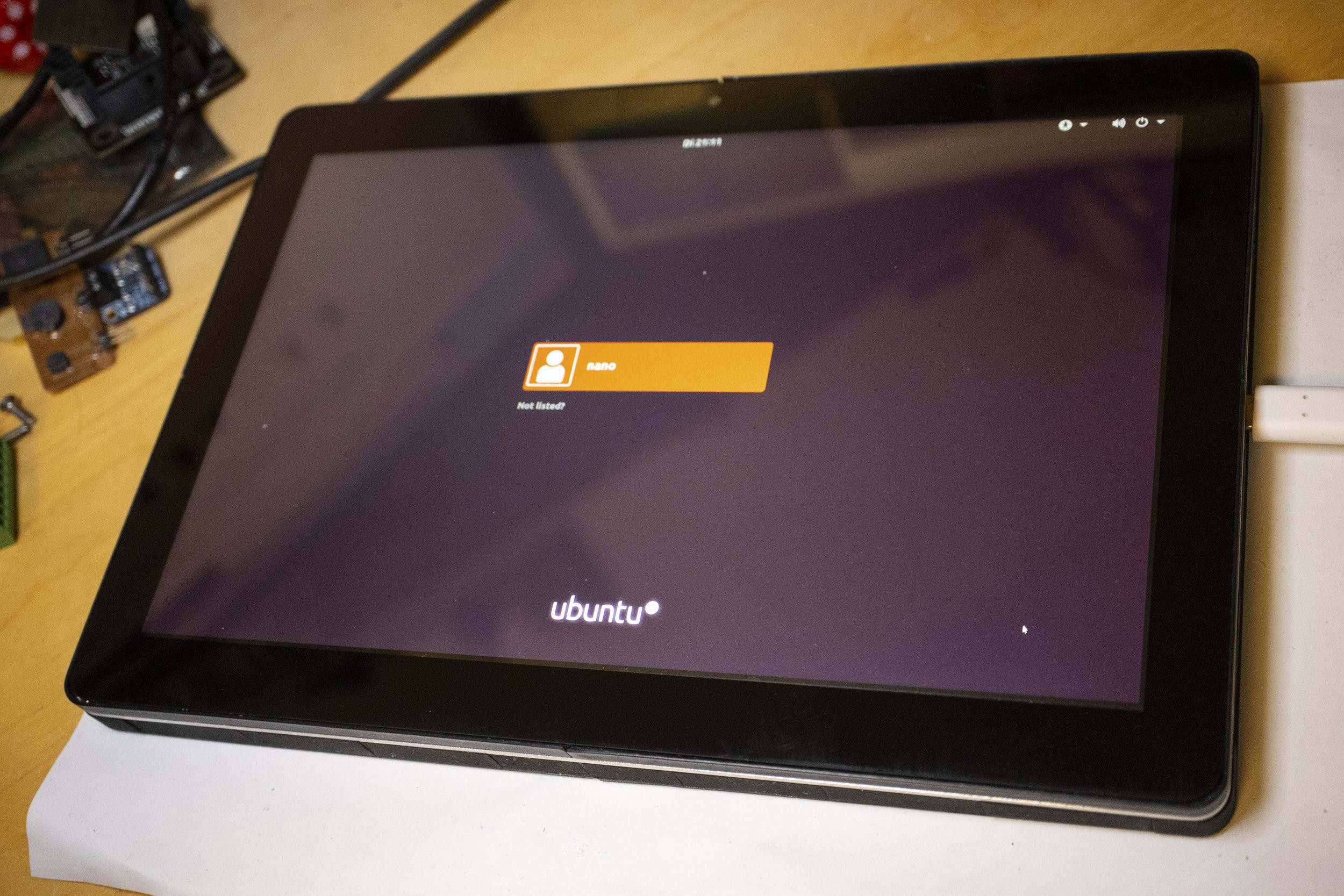

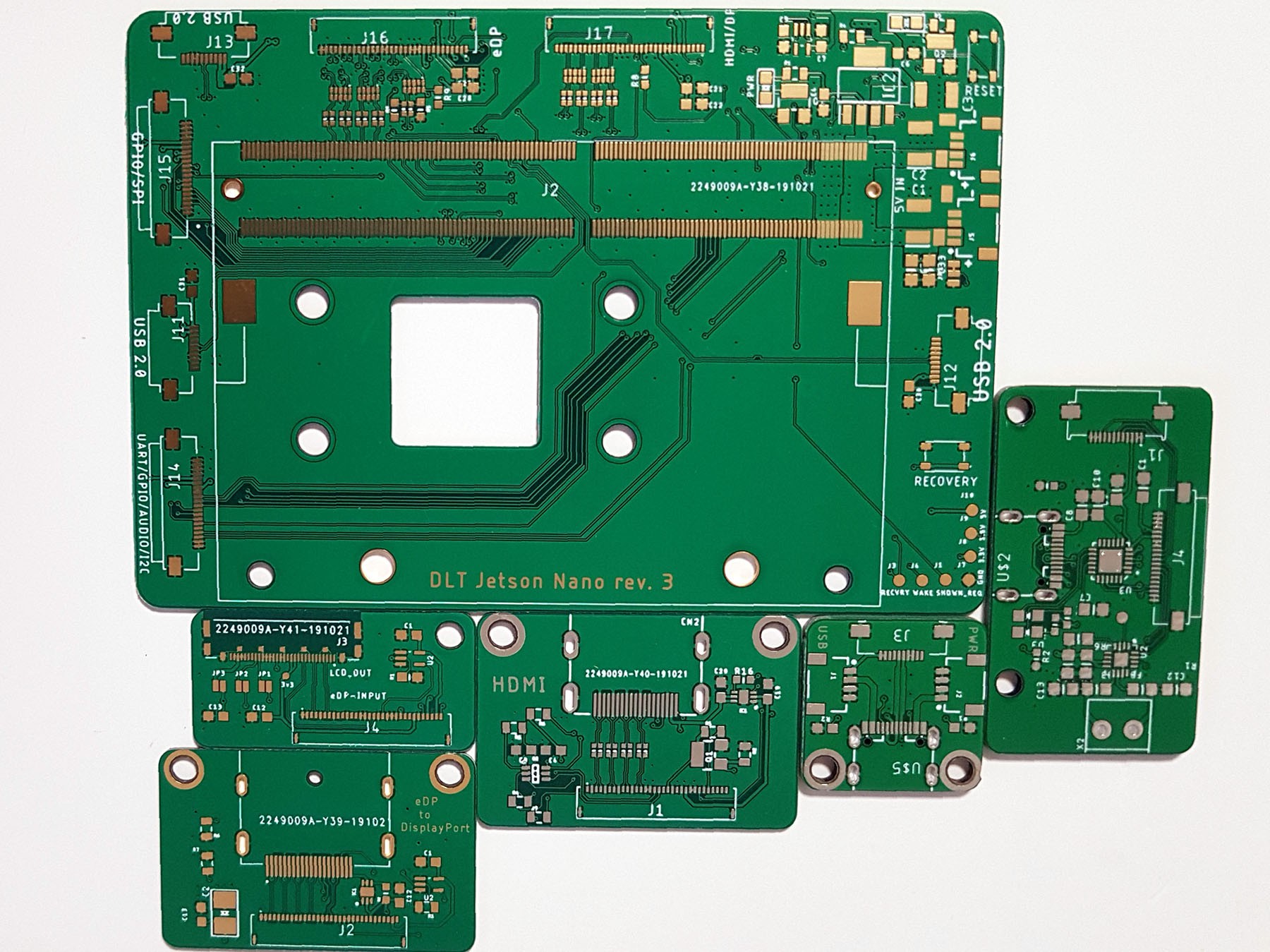

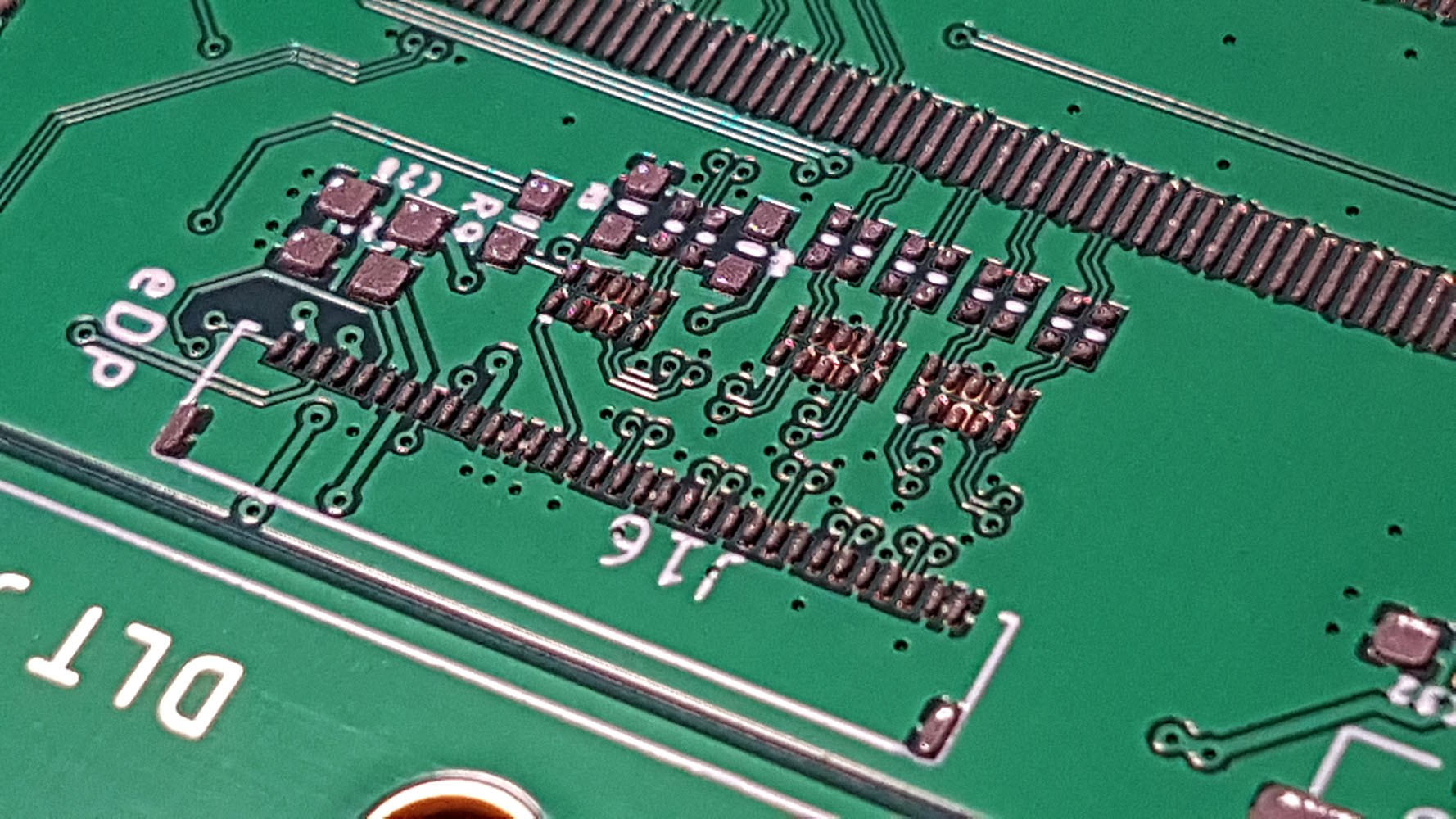

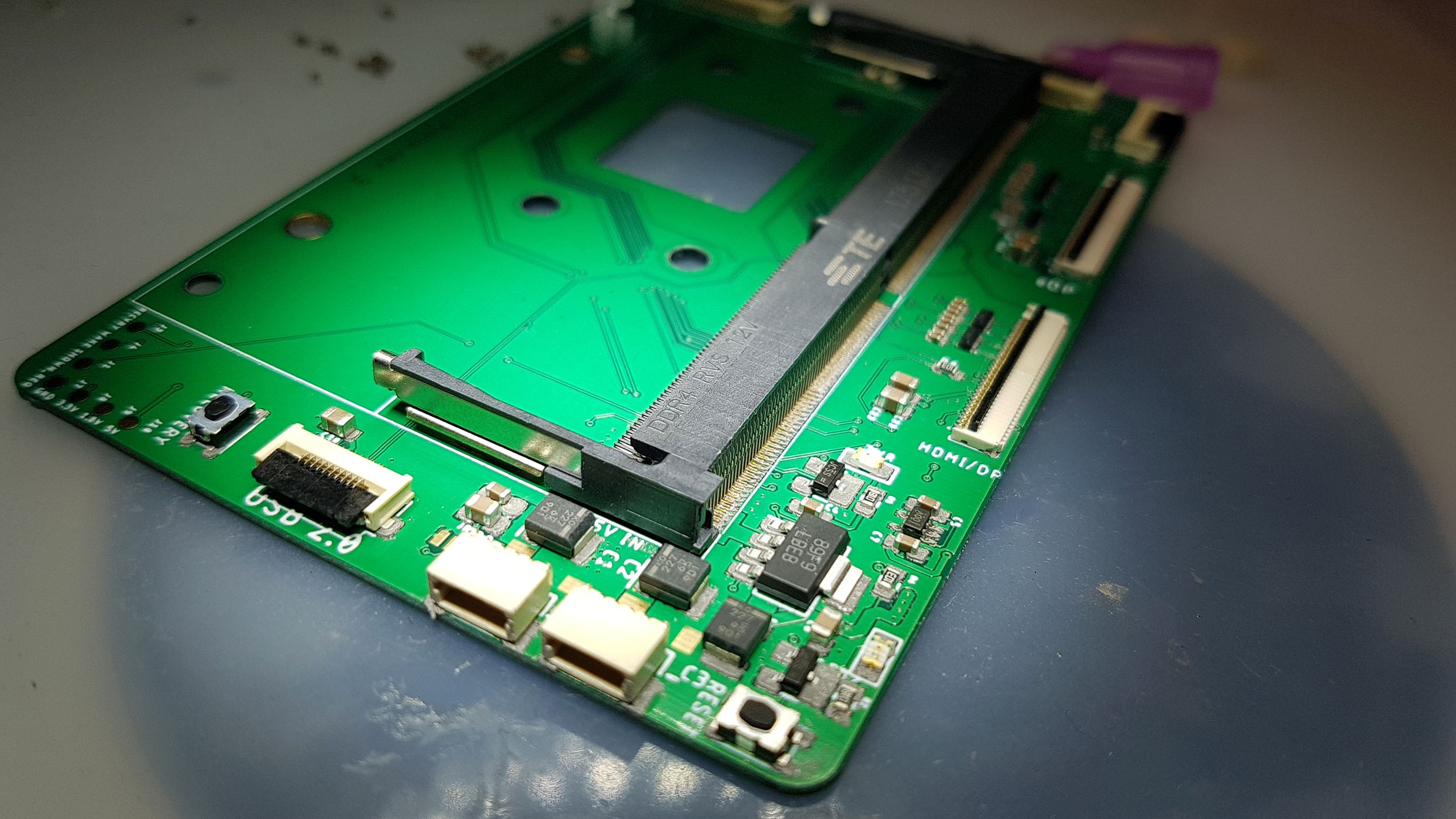

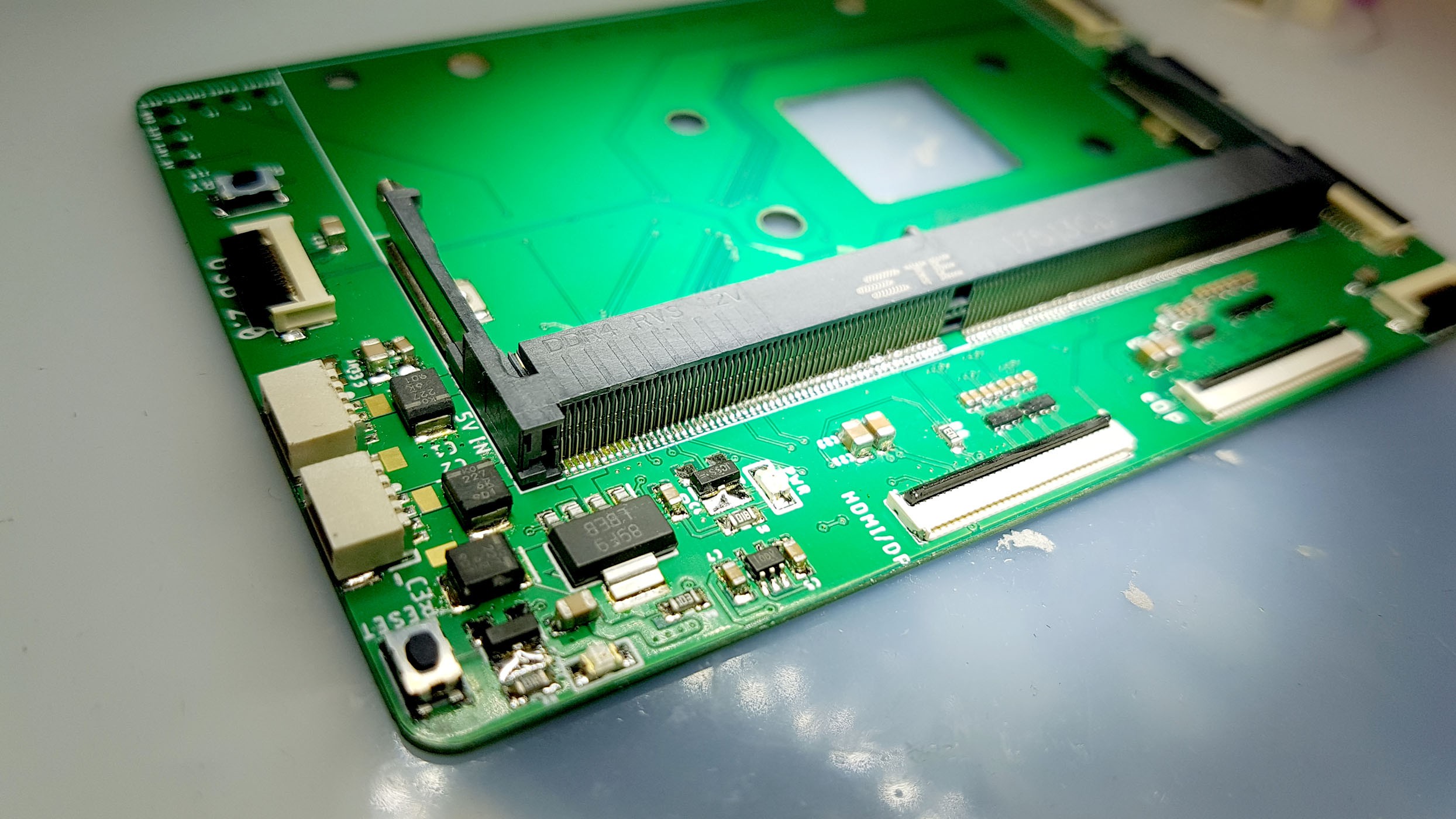

To do that I am creating a highly modular, upgradable and modifiable tablet with a clear standard for open mobile computing. This lets companies and enthusiasts change what they need and reuse the rest.

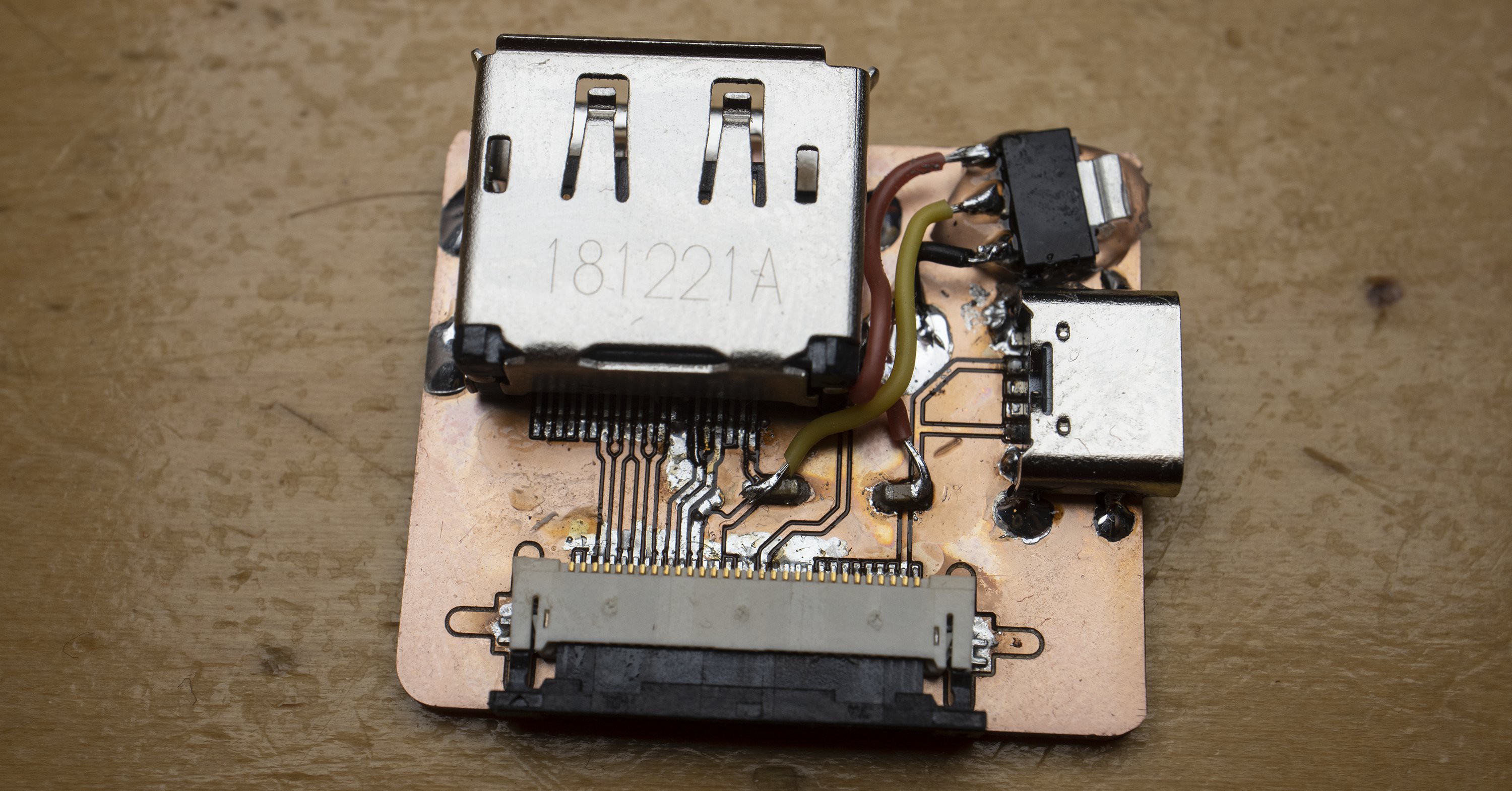

The highly modular, upgradable and modifiable design lets them spend more time and energy on the bits they care about (some niche sensor or a CAN bus perhaps) without being bogged down with the bits they simply need (a screen interface or battery management).

The clear and open standard provides a framework for community development to feed back into the ecosystem in a future compatible way.

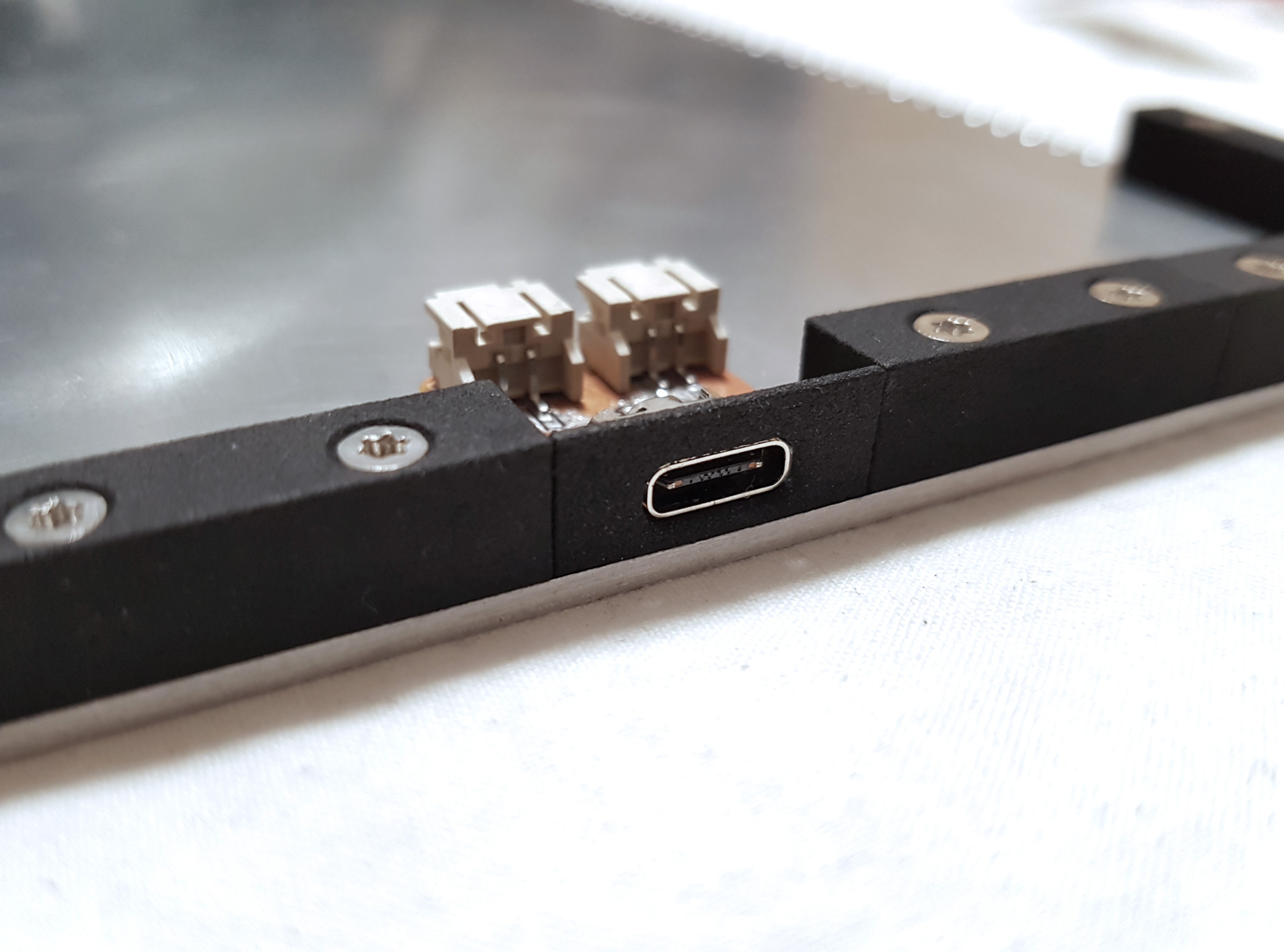

This will be achieved by defining a mechanical standard for creating cases and an electrical standard that defines interconnects, pinouts and behaviour.

This should enable the re-use of peripherals through different motherboards, housing different SoC's, from all kinds of performance spectrums, keeping the cost of replacement and repair down to a minimum and enabling very quick development of new features/peripherals for the ecosystem.

If you'd like to drill down into the details, here are the most important logs.

If you have time though I recommend just reading the complete logs in order :)

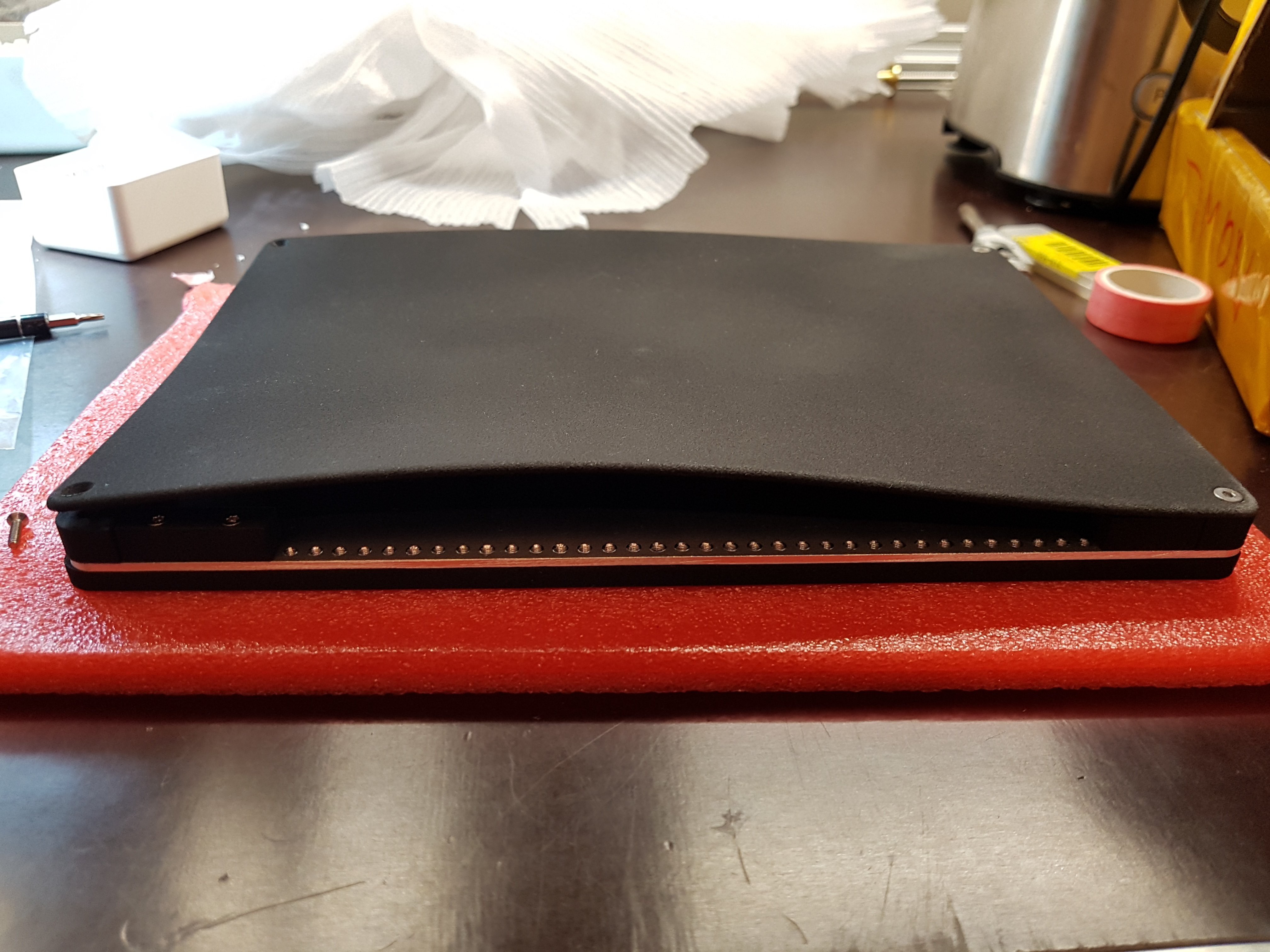

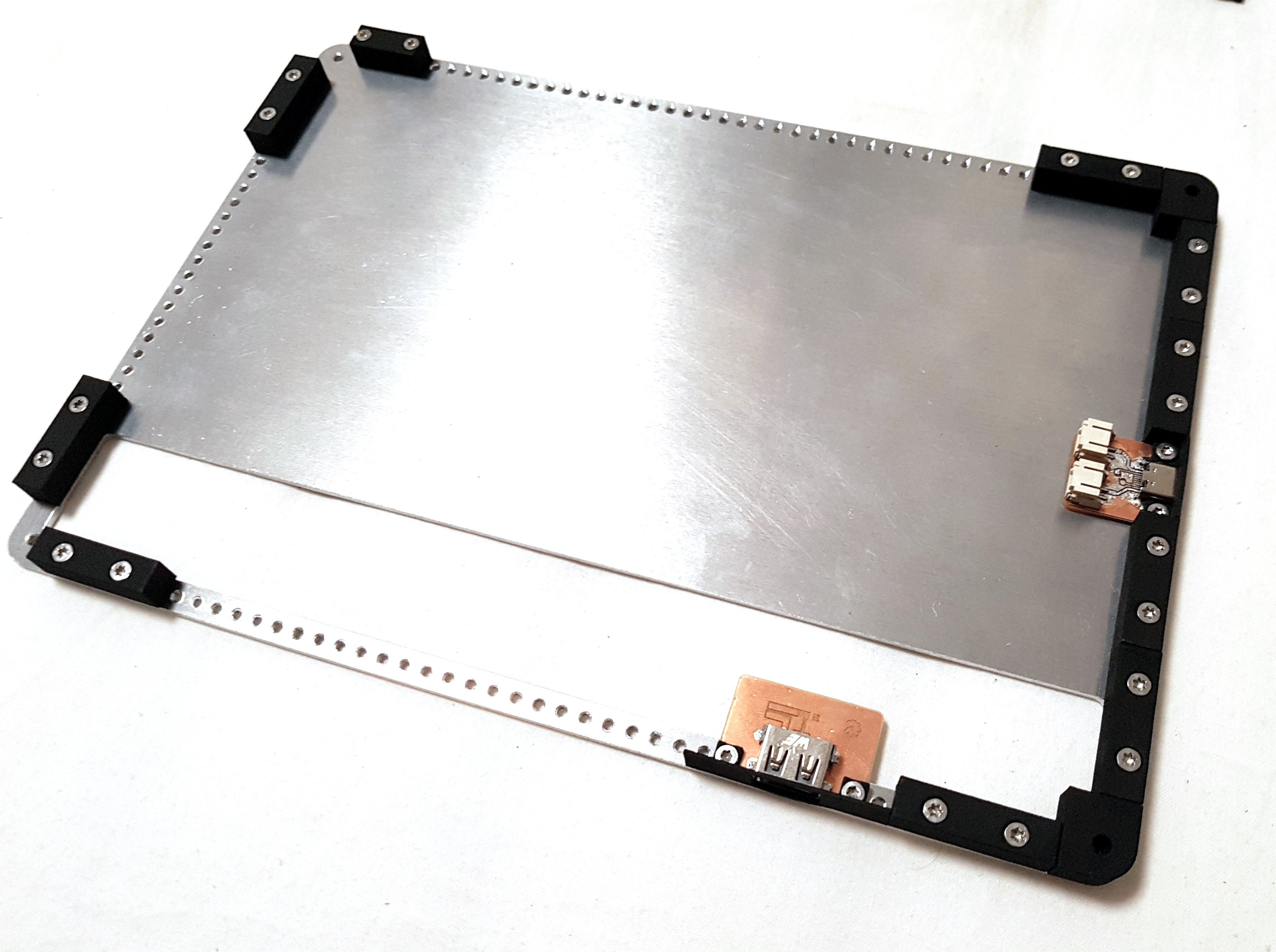

https://hackaday.io/project/164845/log/166748-mounting-plate-mock-up

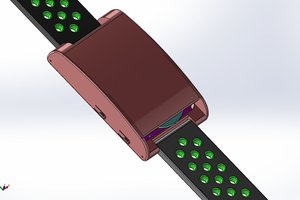

https://hackaday.io/project/164845-dlt-one-a-damn-linux-tablet/log/169428-modules

https://hackaday.io/project/164845/log/167049-peripheral-bezels

https://hackaday.io/project/164845/log/165497-manufacturing-and-the-target-audience

https://hackaday.io/project/164845/log/163897-mechanical-design

https://hackaday.io/project/164845-dlt-one-a-damn-linux-tablet/log/169433-pricing-and-high-level-bom

The standard is in concurrent development but wont see a release until the Tablet hardware itself reached a mature status because that's when the Standard will also be mature enough to be released. All the learnings from the development are important for the development of the standards, its not something I can just define beforehand or else it will be too narrow minded. I will share specific details on the standard before that of course to get input from others in the community but I will not release a white paper until things have settled. I had it happen too many times that people jump on the bandwagon during development and develop with incomplete information which becomes deprecated later on, I want to avoid that. If your are interested either way, have a look at the prototype design files which I update as they are being made but be aware that this changes rapidly. If you want to help with the design, get in touch!

Motivation:

For years I've been wanting to create a tablet like device based on a SoM (System on Module). Doing something from scratch, routing DDR3 RAM, eMMC etc. didn't seem realistic to me, this is not only really hard but also very expensive. So SoM it is, which comes with the additional benefit of user up-gradability if the SoM manufacturer stays true to their pinout with successor products, which they usually always do, at least for a few generations, which usually means you get compatible hardware for 10 years or more.

Back then I started out with the Raspberry Pi compute module but the more I thought about my specs the clearer it was to me that it just wont cut it.

I wanted something that can run modern applications, something that is actually very usable and is not just a cool thing on paper.

The past years I've been looking around for affordable SoMs that offer enough performance to be viable, until now there were either cheap outdated SoMs or ones that mainly target...

Read more » timonsku

timonsku

c.Invent

c.Invent

Chaz

Chaz

Victor Dedios

Victor Dedios

Can't wait to see how this evolves!