I made a rendering of this before but I now laser cut a mock-up out of acrylic (the real deal will be aluminium).

It's purpose is mostly to test out how well the positioning of the peripheral works out and to experience any issues when working with a real display and PCBs. It's also the first illustration of the whole modular peripherals idea.

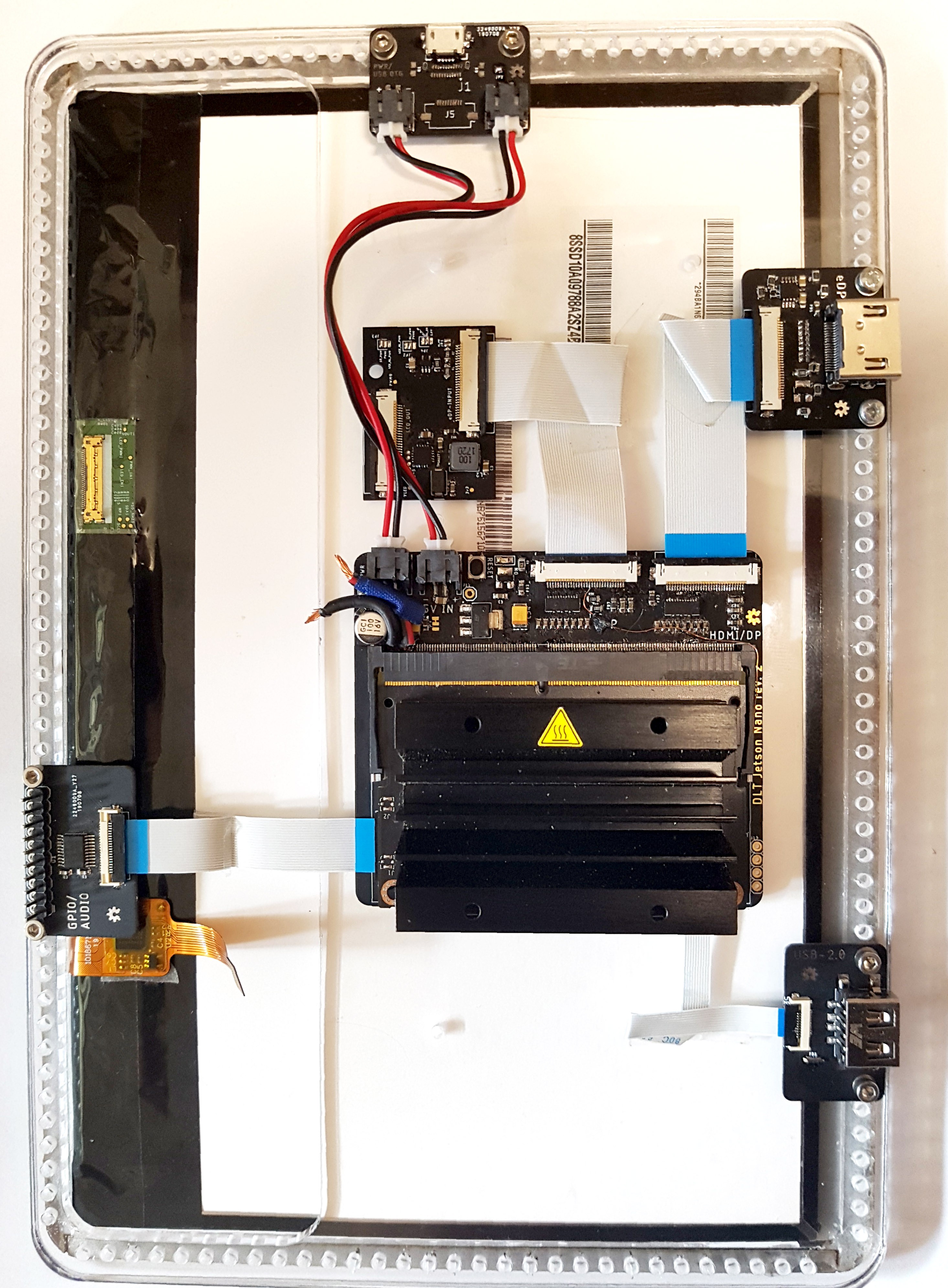

The result was quite promising. I also realized that I could slim down the thickness of the shim layer which raises the mounting plate high enough so it can sit just above or on the back of the LCD. I had concerns because there is always a part of the LCD that is thicker than the rest where the connector comes out (usually all covered up with black tape). I can just leave a cut-out there as the touch screen offers enough supporting area and lower the overall height of the shim. Here a picture of the whole mock-up assembly.

Placing the peripherals worked pretty well! The hole raster on the edge (and to a degree in the middle) is all threaded 2.5MM holes in a 5mm pitch. This gives nice even distances of 5mm increments for both positioning as well as hole placement on the peripheral PCBs.

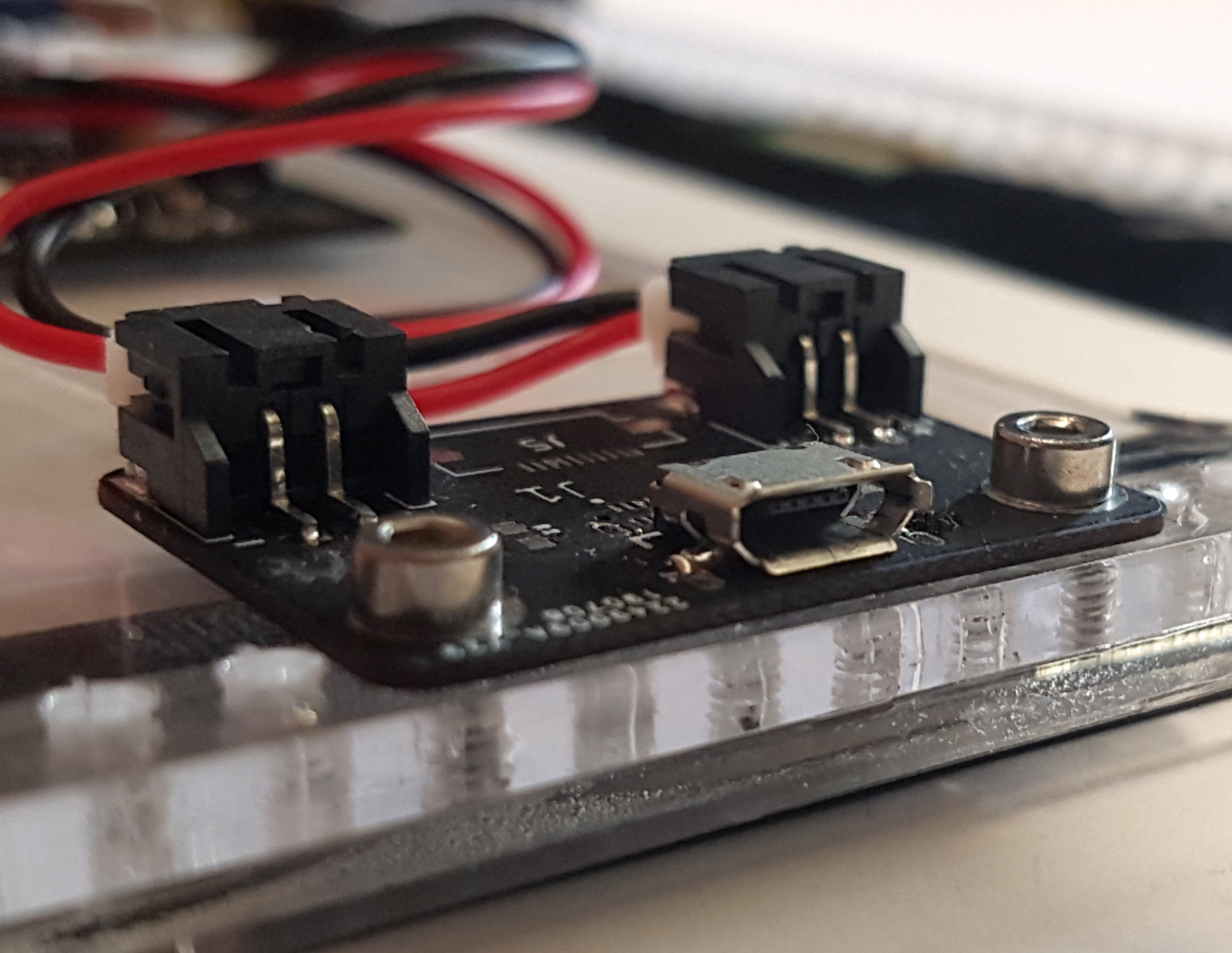

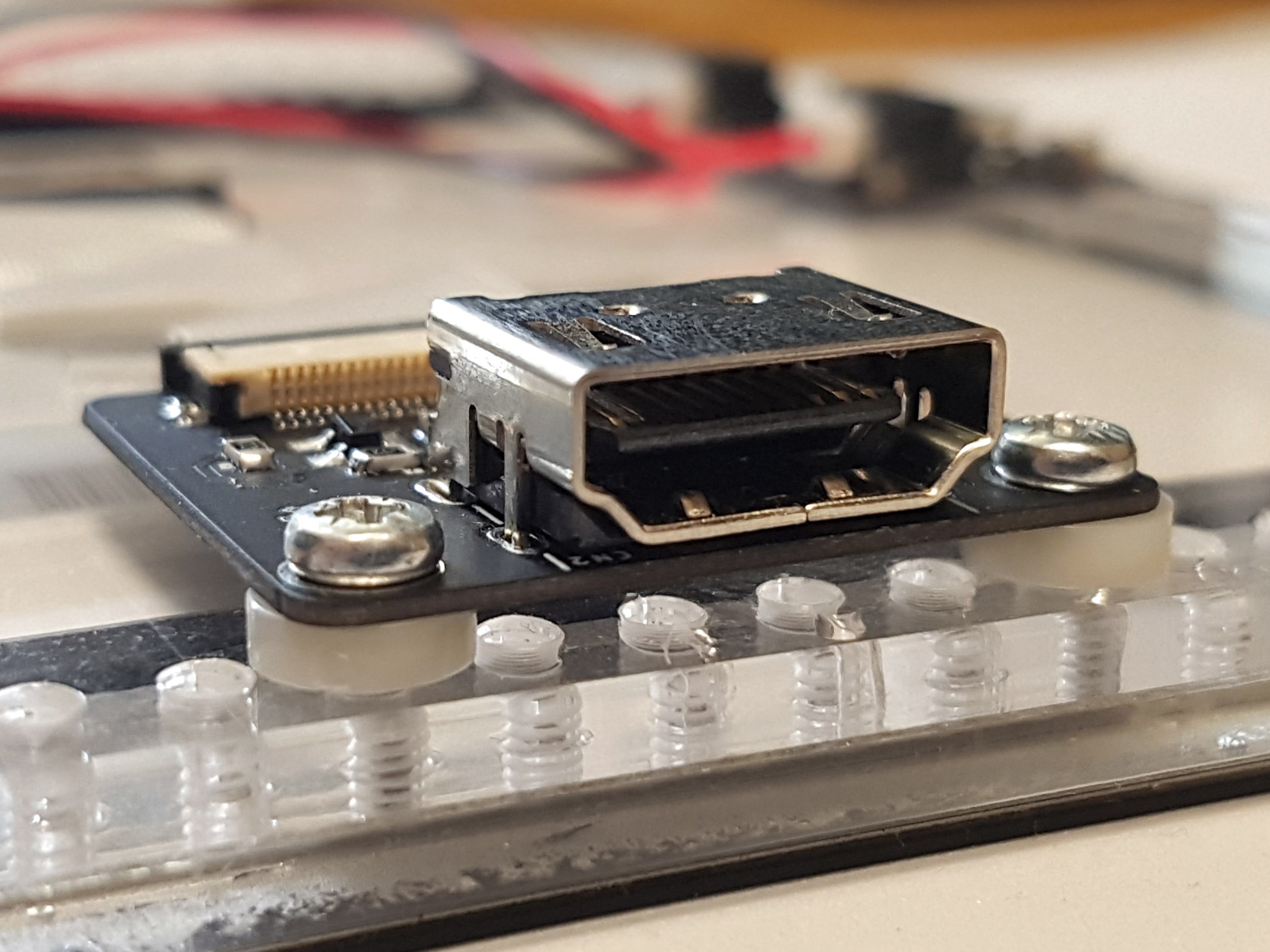

Here a few close ups of some peripherals

It is crucial that pure SMT components are used for this. With hybrid components like this HDMI connector below, you need spacers to raise them enough, those spacers are a bit too much but still, it will always add a 1-2mm to the overall thickness of the assembly.

This hopefully illustrate how the whole modular peripheral concept is supposed to work. This is of course an early stage but it shows where it is supposed to go.

As you can see there is always a slight offset from the edge for each PCB. This space is intended for the faceplate that each connector will receive and will make for closed side surface, even with a modularized back instead of a pretty but fixed injection moulded back.

I will print mock-ups of these face plates in the coming week. So the next update is hopefully showing those off.

timonsku

timonsku

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Looks good, will the same aluminum plate be used as a heat sink?

The promise of this project gives me hope that one day I'll own one too. Keep it up!

Are you sure? yes | no

Yes exactly! That's the idea with having it aluminum so it can transport the heat to the outside of the case.

Are you sure? yes | no