Project Logs

General

| Alive and Kicking |  |

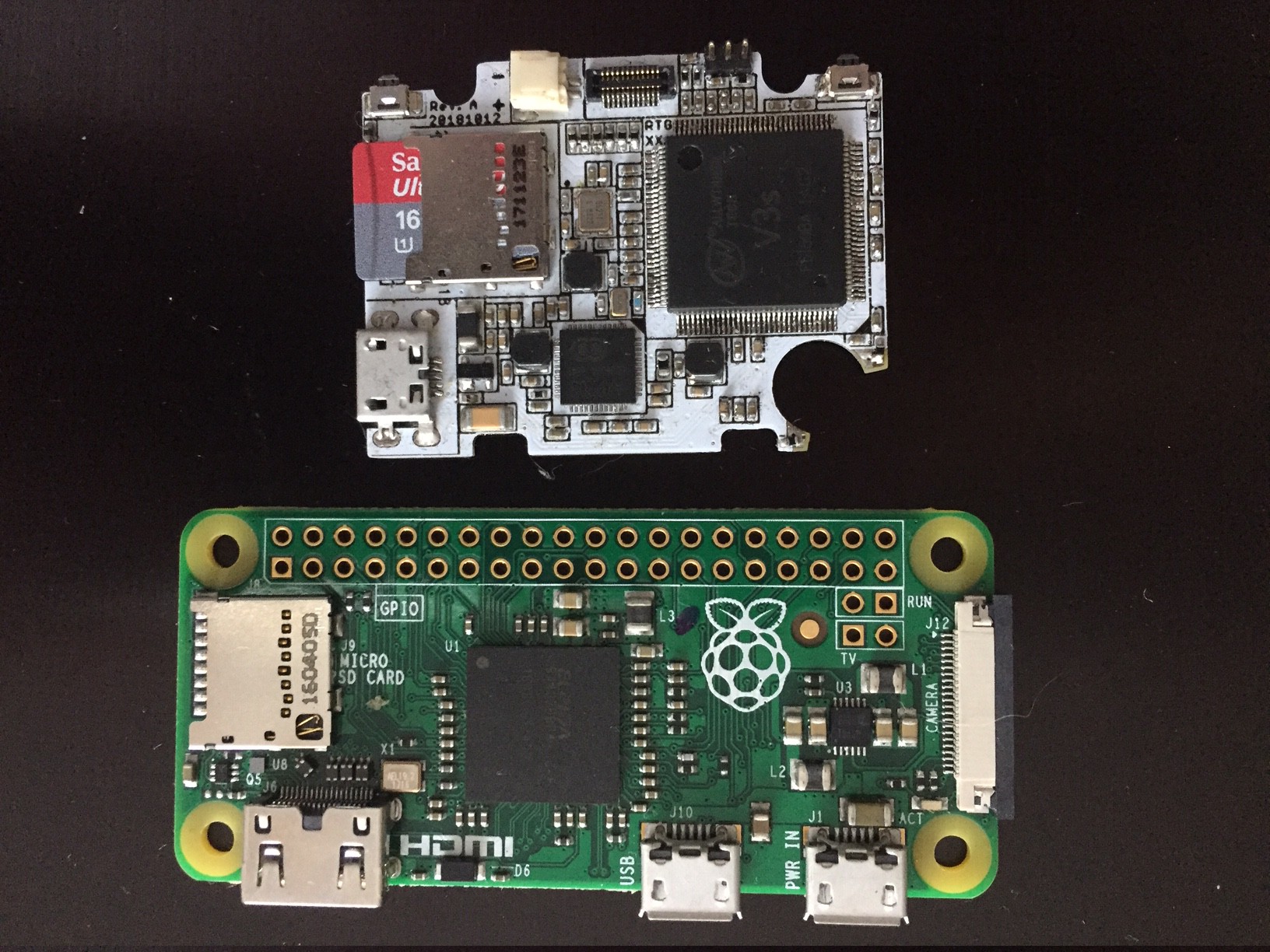

| Photo shoot side by side with PocketSprite |  |

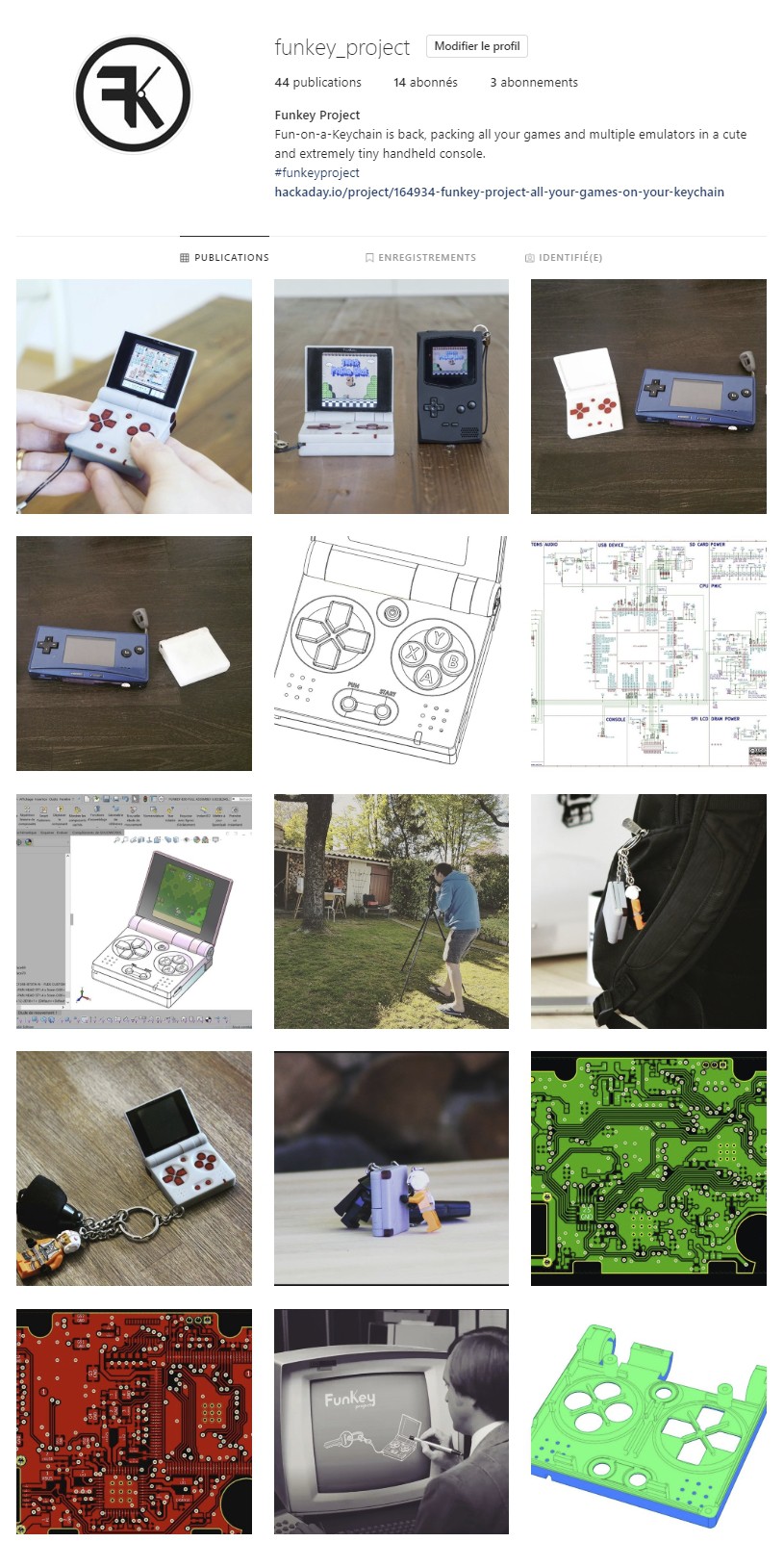

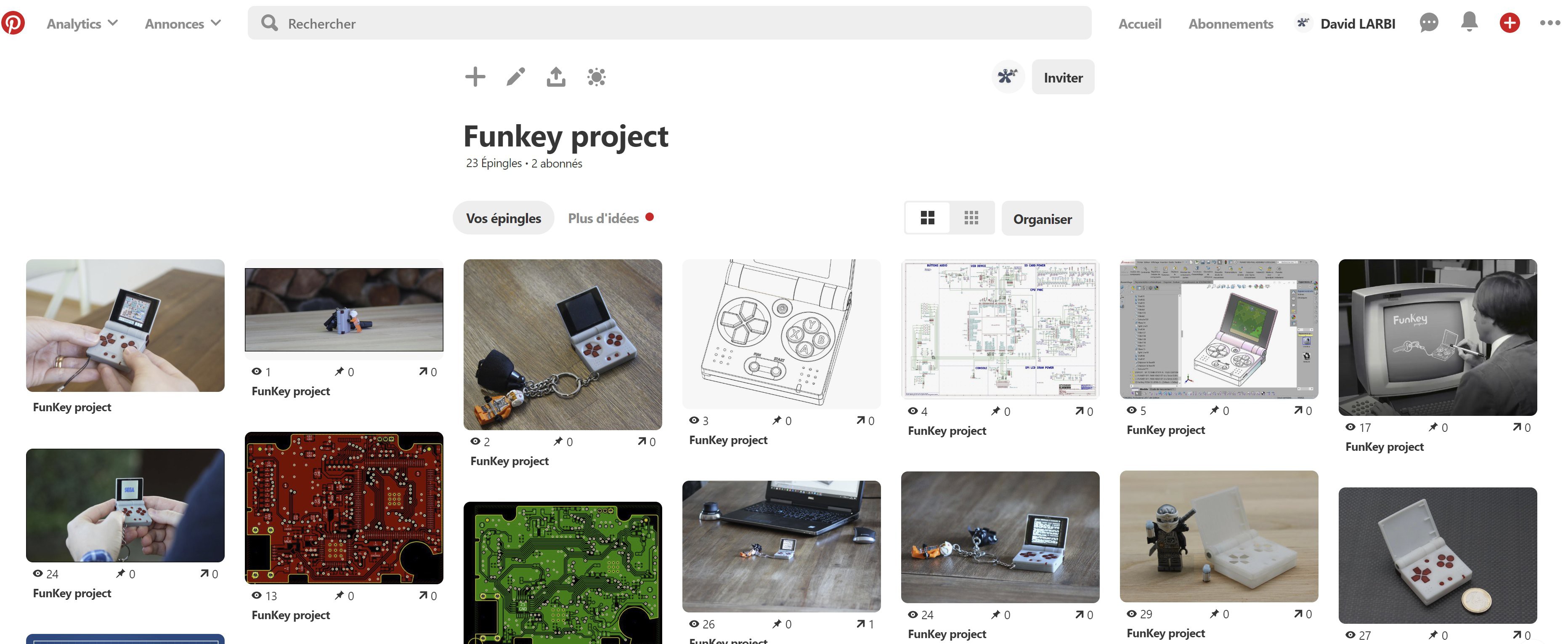

| FunKey gets social ! (Website, newsletter and social networks) |  |

| FunKey Revision B is out! |  |

| Meet the team |  |

| Project roadmap |  |

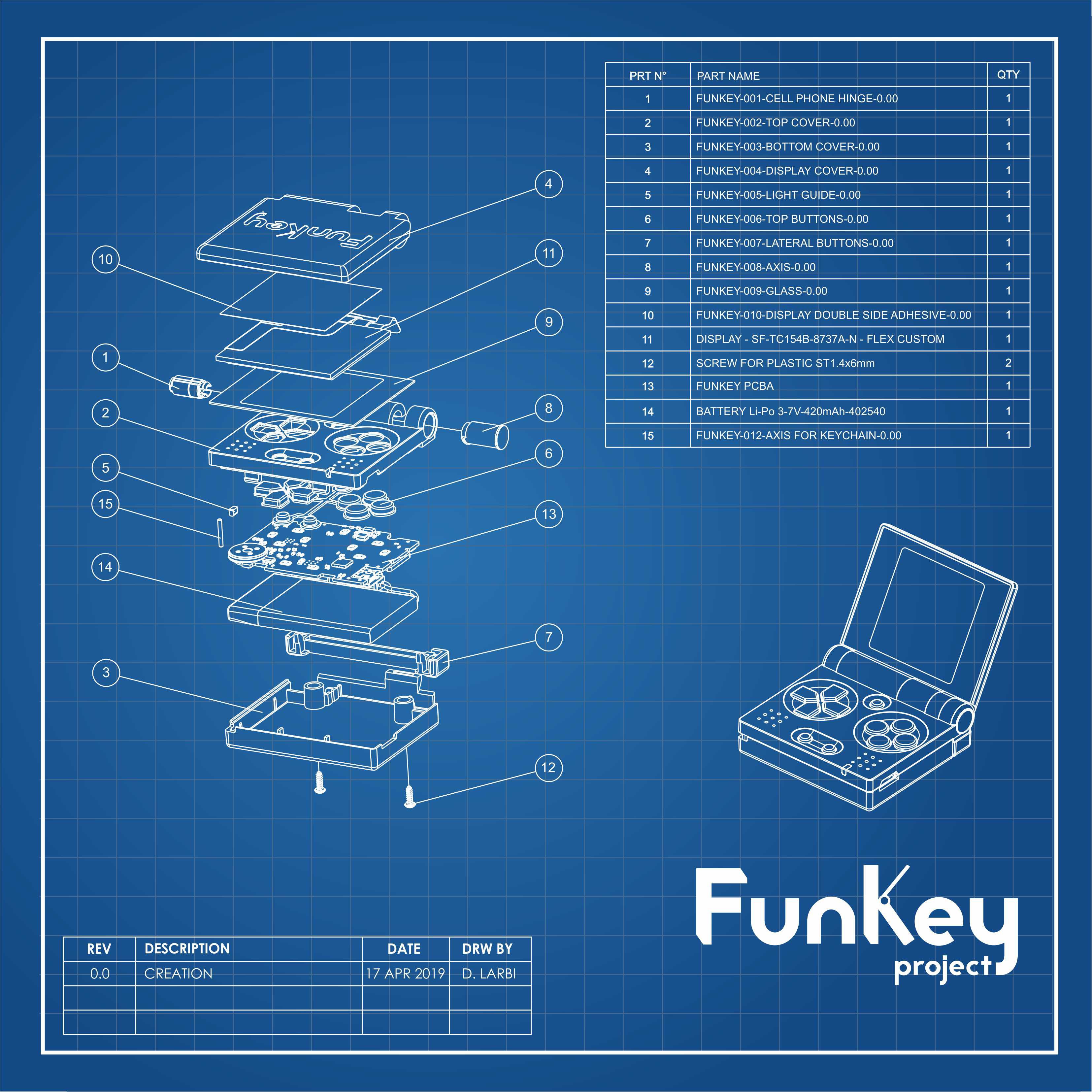

Mechanical design

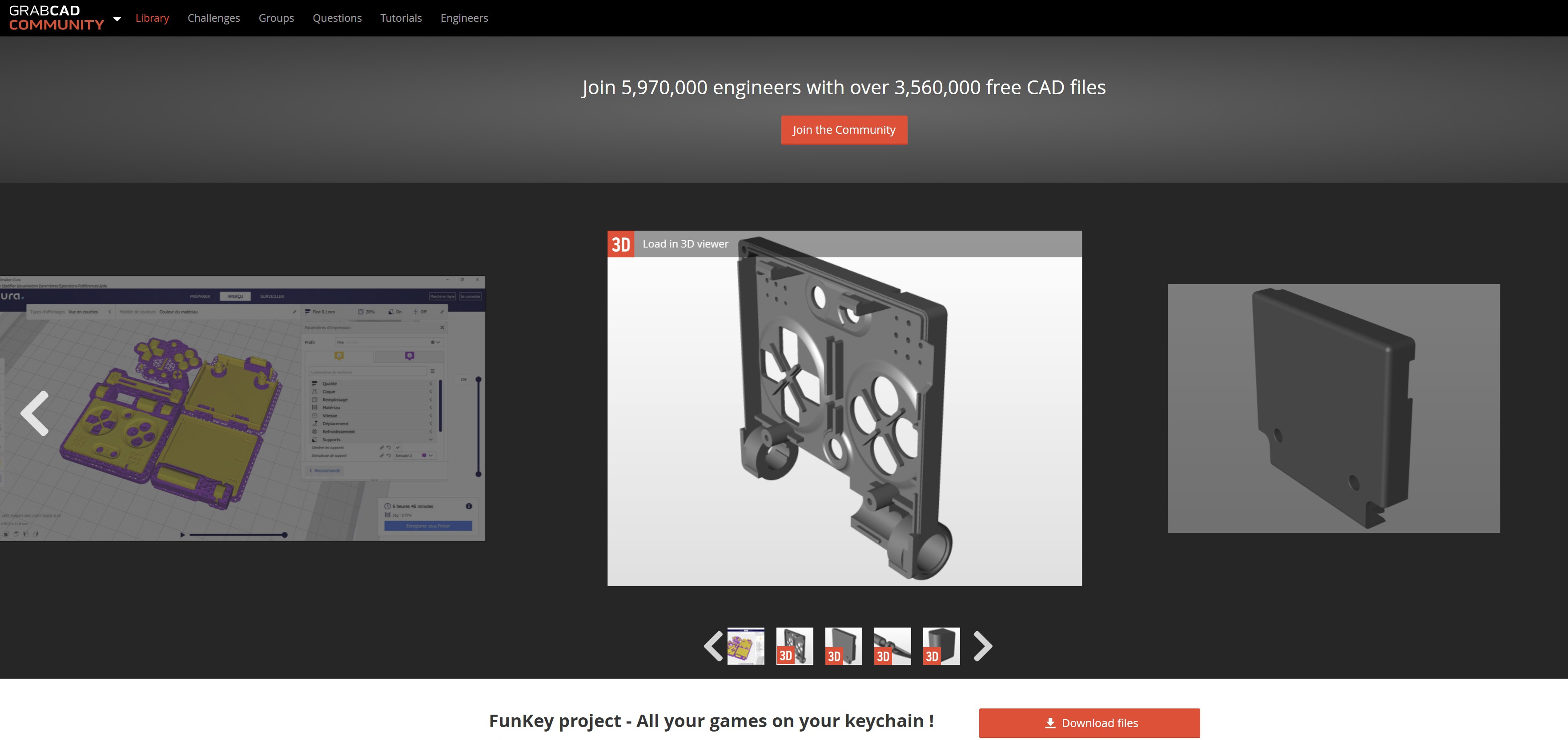

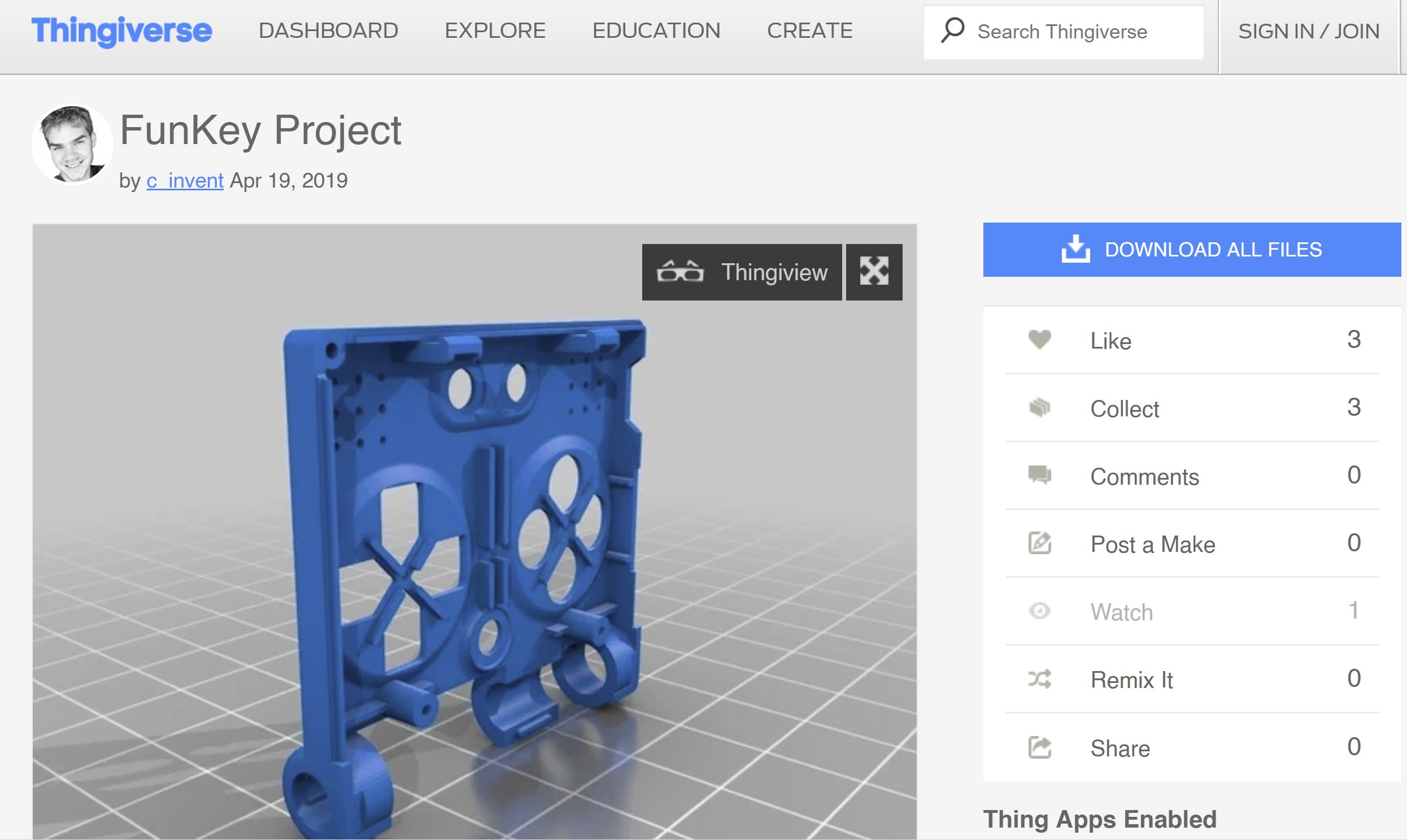

| STL files and Exploded view |  |

| 3D Printed prototypes before injection molding |  |

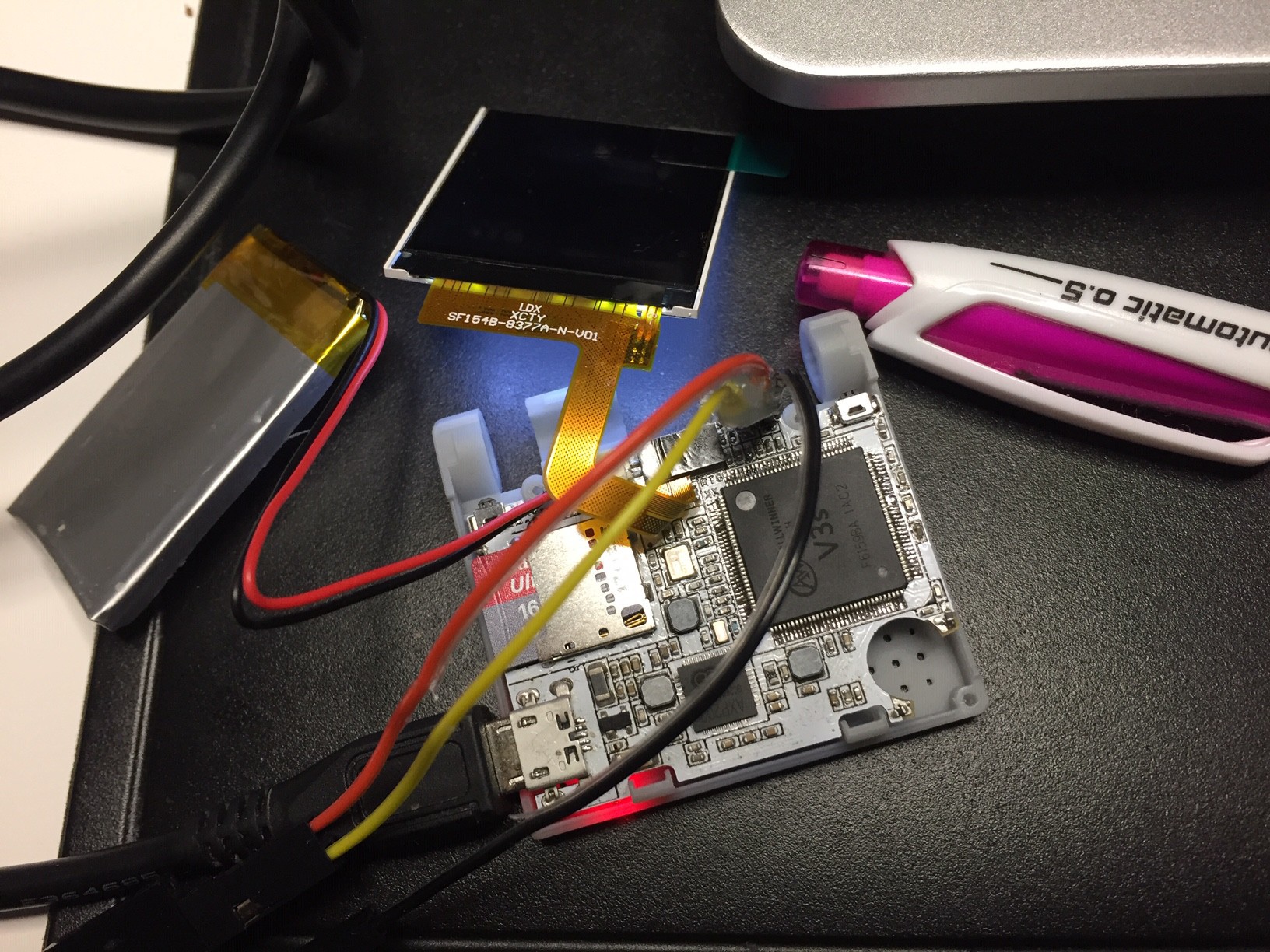

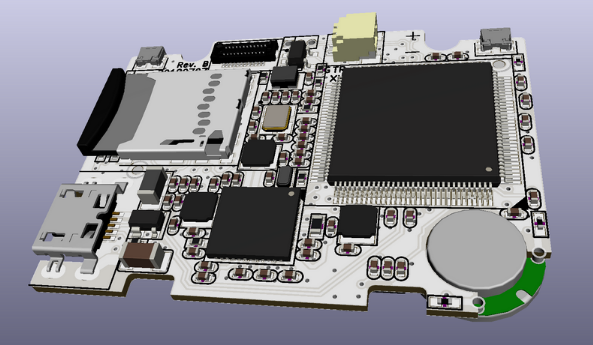

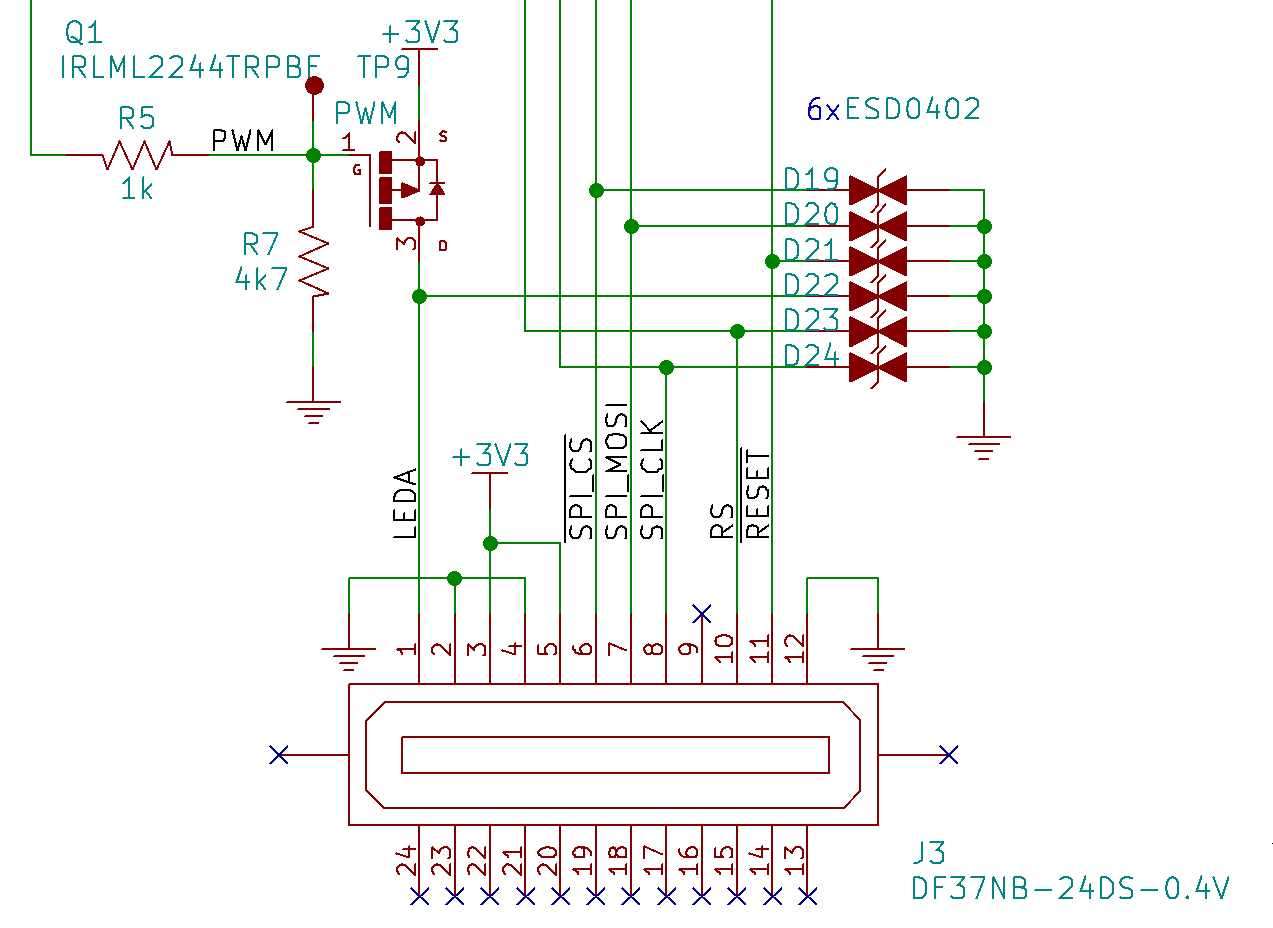

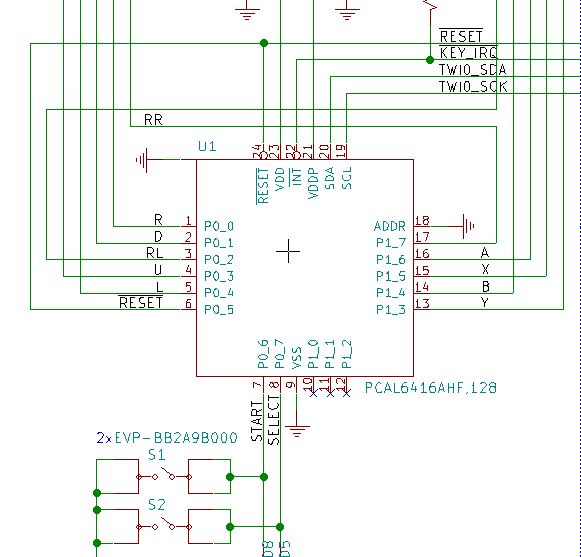

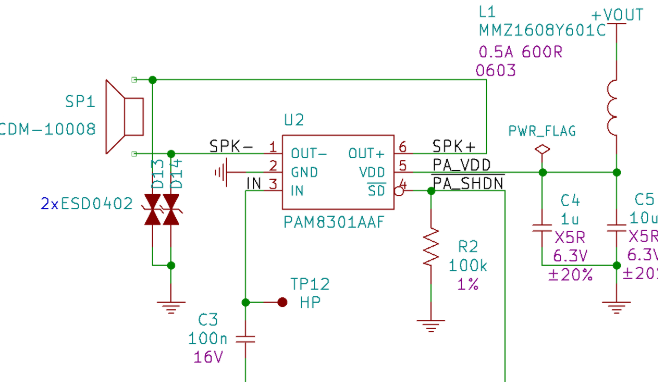

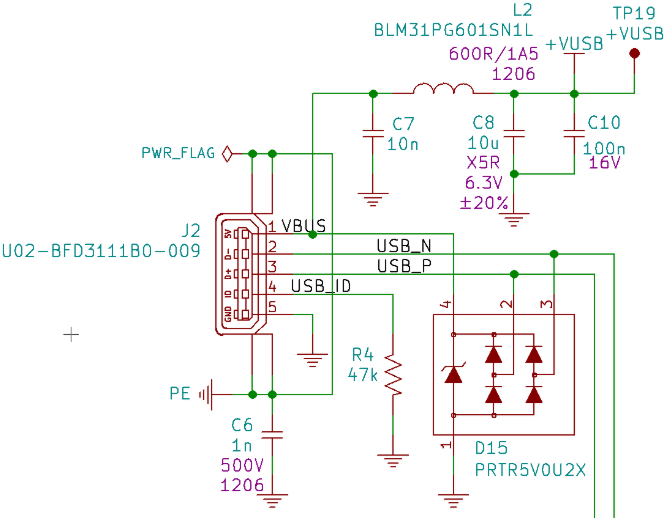

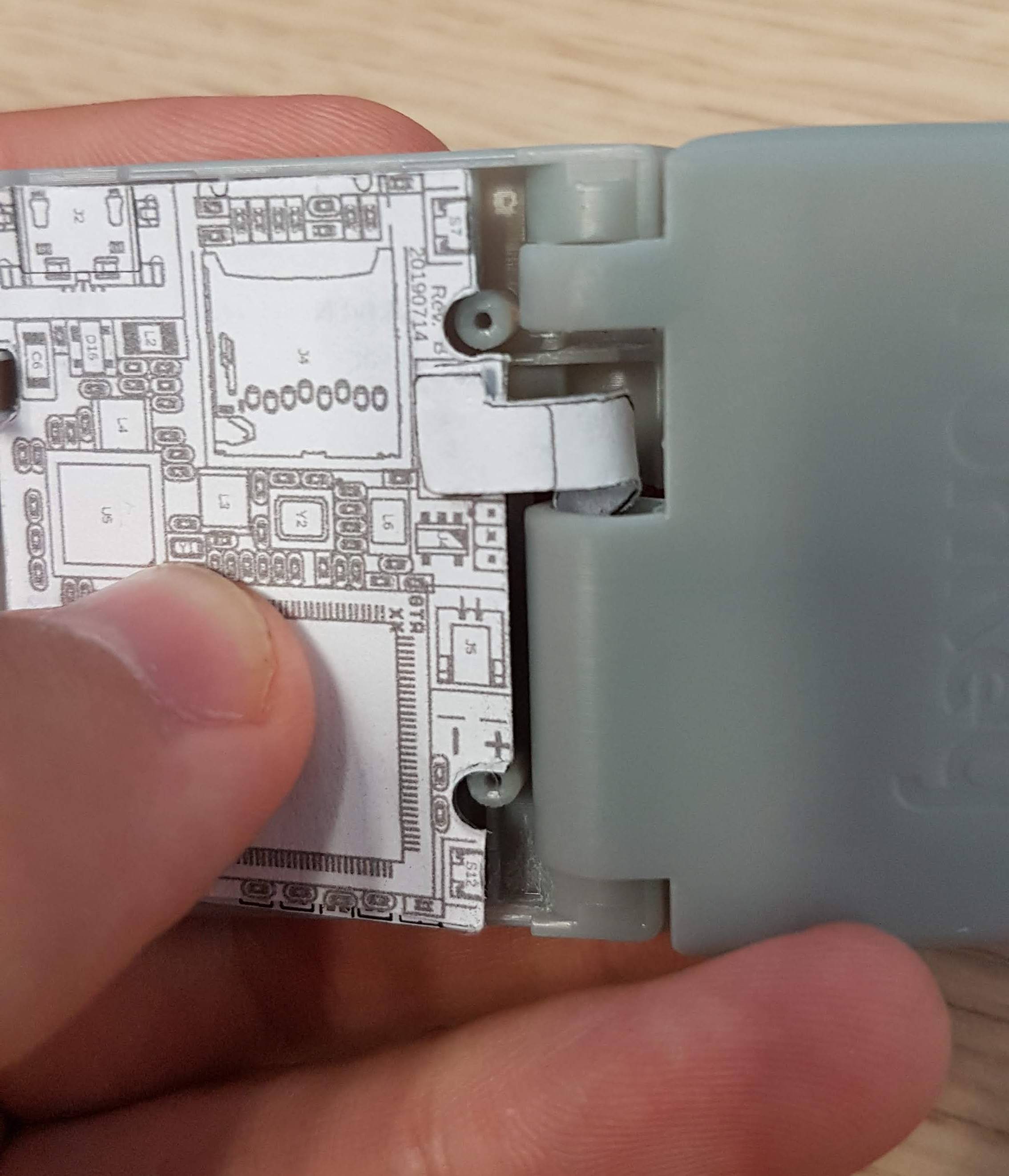

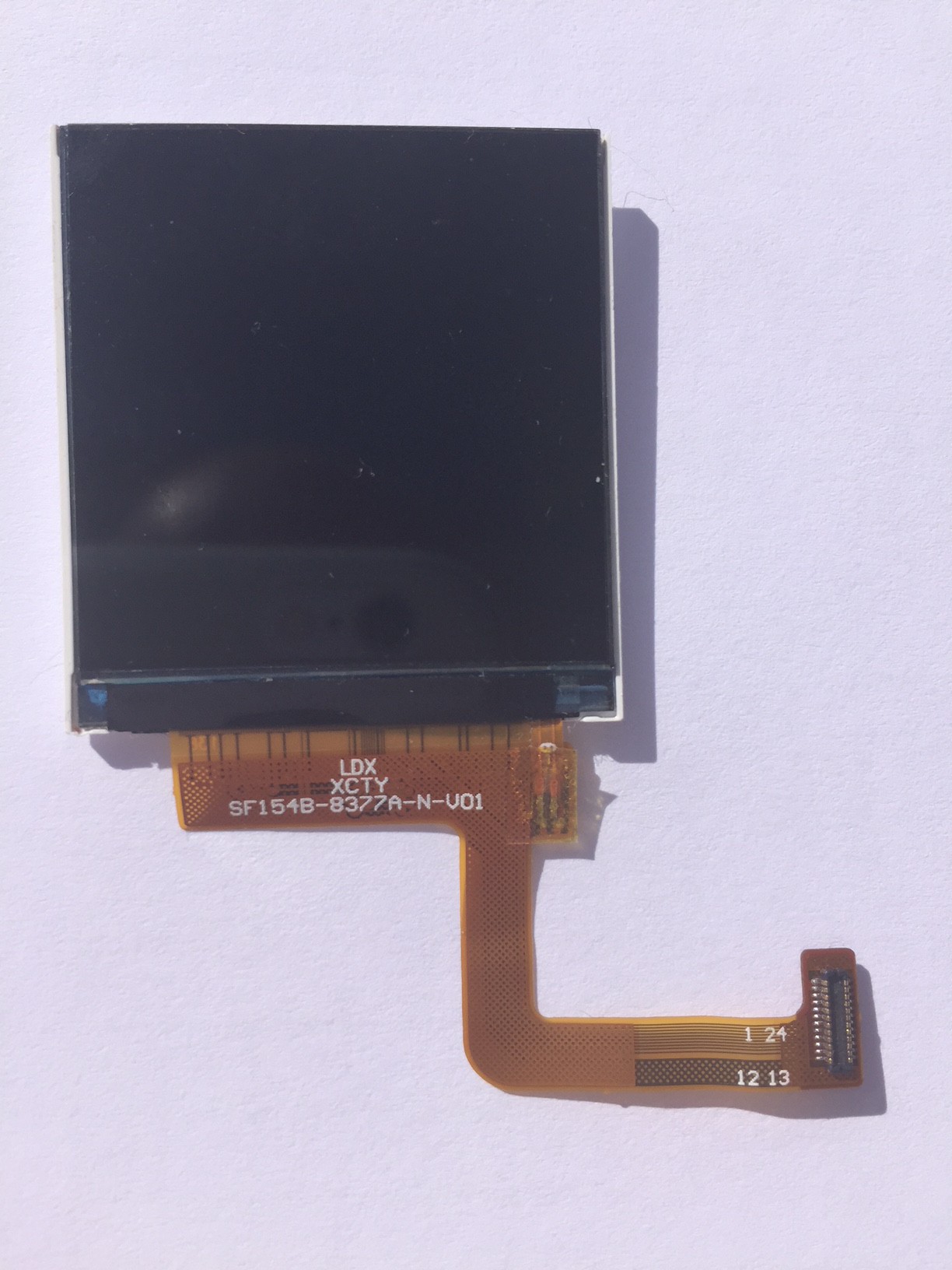

Electronic Design

A bit of History

It’s now been a bit more than two years since we entered the HaD contest with Keymu: an open-source keychain-sized multi-emulator handheld console which received quite an unexpected success.

Keymu did not pretend to be more than a prototype destined to be built by anyone willing to get their hands dirty. And even though it was often asked to be produced and sold, the world of difference between prototyping and producing kind of humbled us into taking it slowly.

We first needed to focus on correcting electrical and software issues Keymu had, that is why we started working on a new prototype without a foldable design but with almost everything new under the hood. The prototype turned out pretty great, so much so that we decided to give it a name and enter once again the HaD prize: this was last year’s FunKey Zero.

A lot has happened in a year, among which the expansion of our team of enthusiasts to the grand number of three, now bringing together the much-needed professional mechanical hindsight to our electrical+software knowledge.

Keymu and its optimized design can now be born again, merging with all FunKey Zero’s improvements, thought for production and readier than ever to bring fun on your Keychain, meet the FunKey Project.

Characteristics

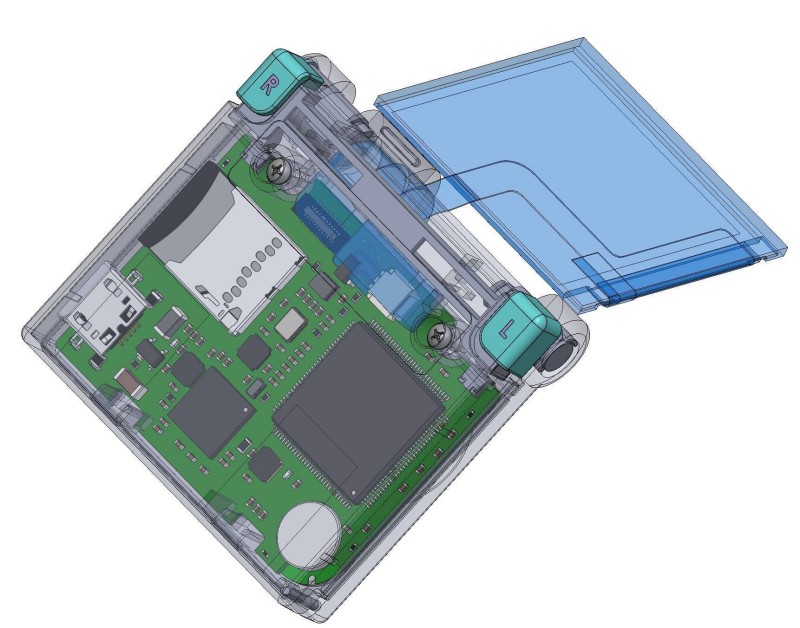

| Dimensions | 42.5x44.5x13.8 mm |

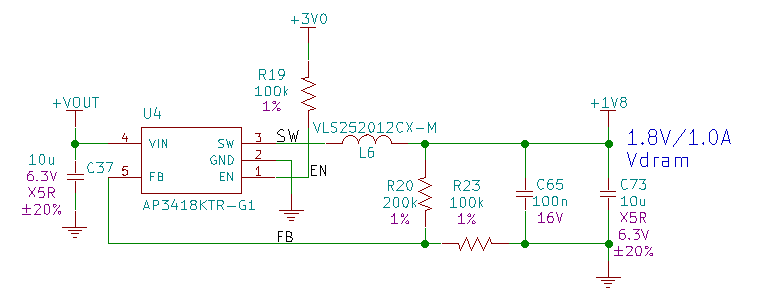

| Processor & RAM | ARM Cortex-A7 @ 1.2GHz. Extensions: NEON, VFPv4. 64MB of RAM DDR2 up to 400MHz |

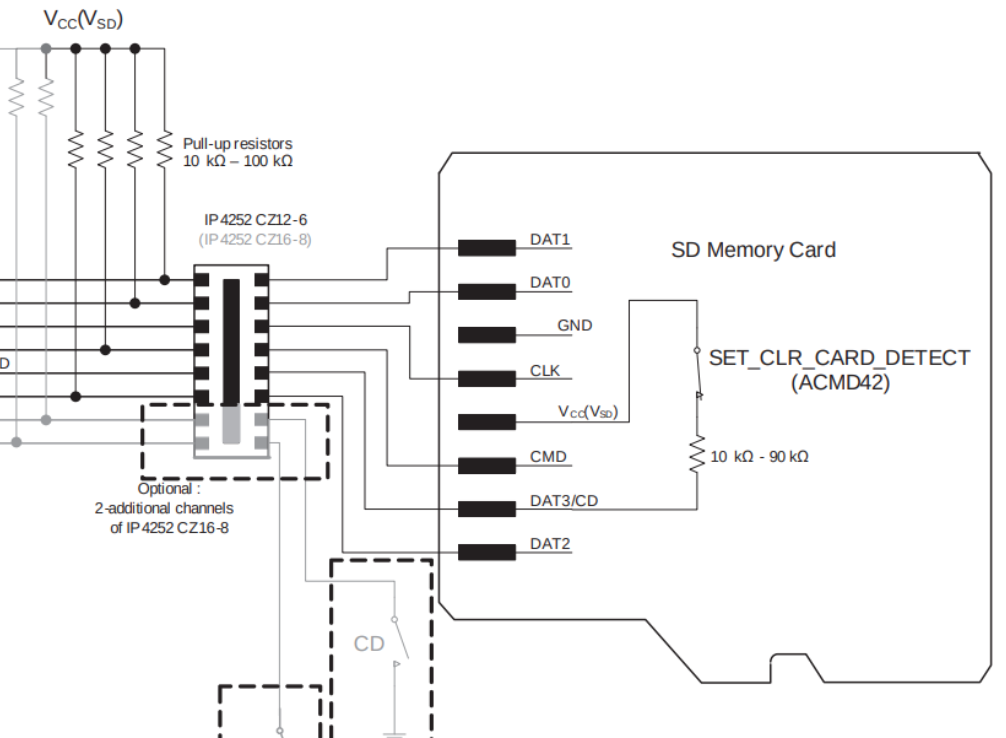

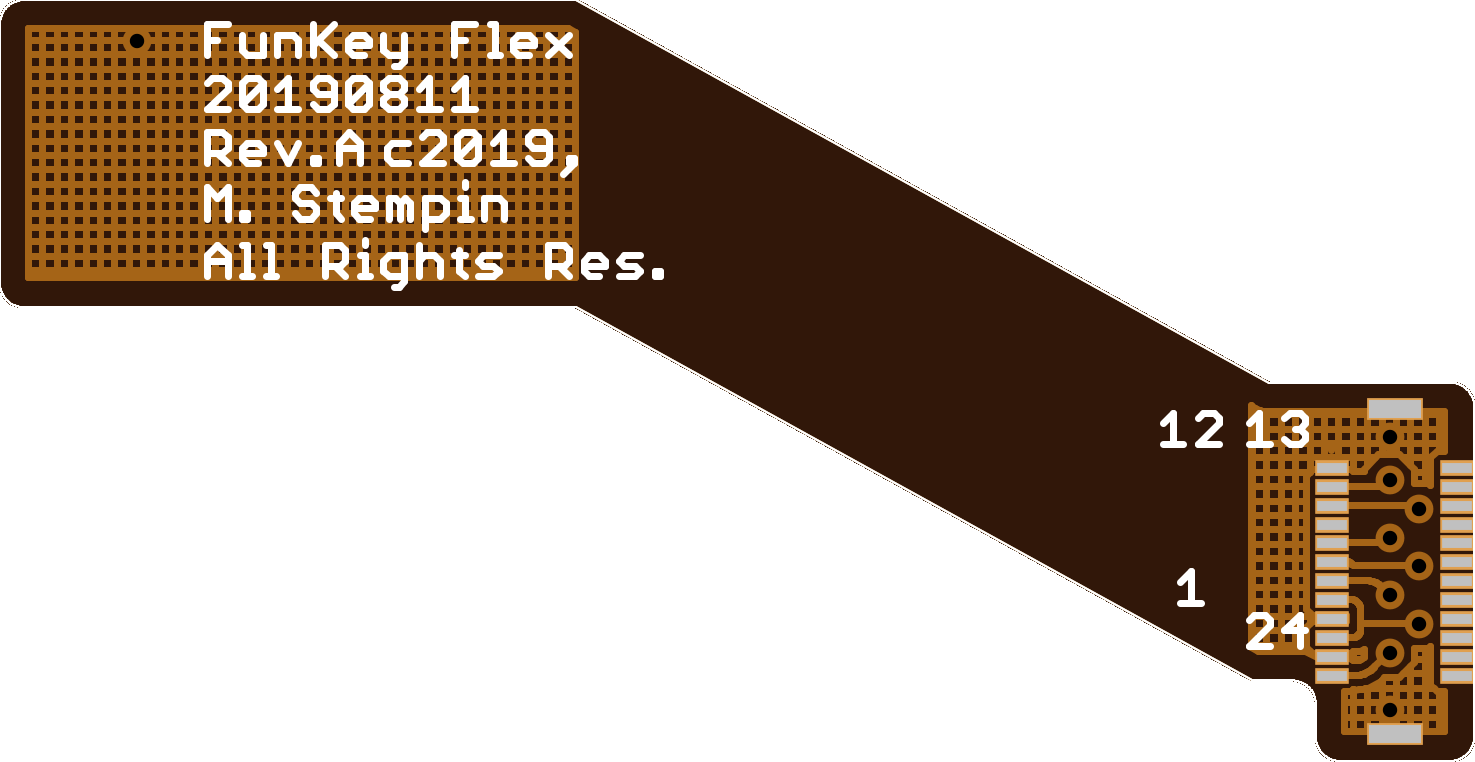

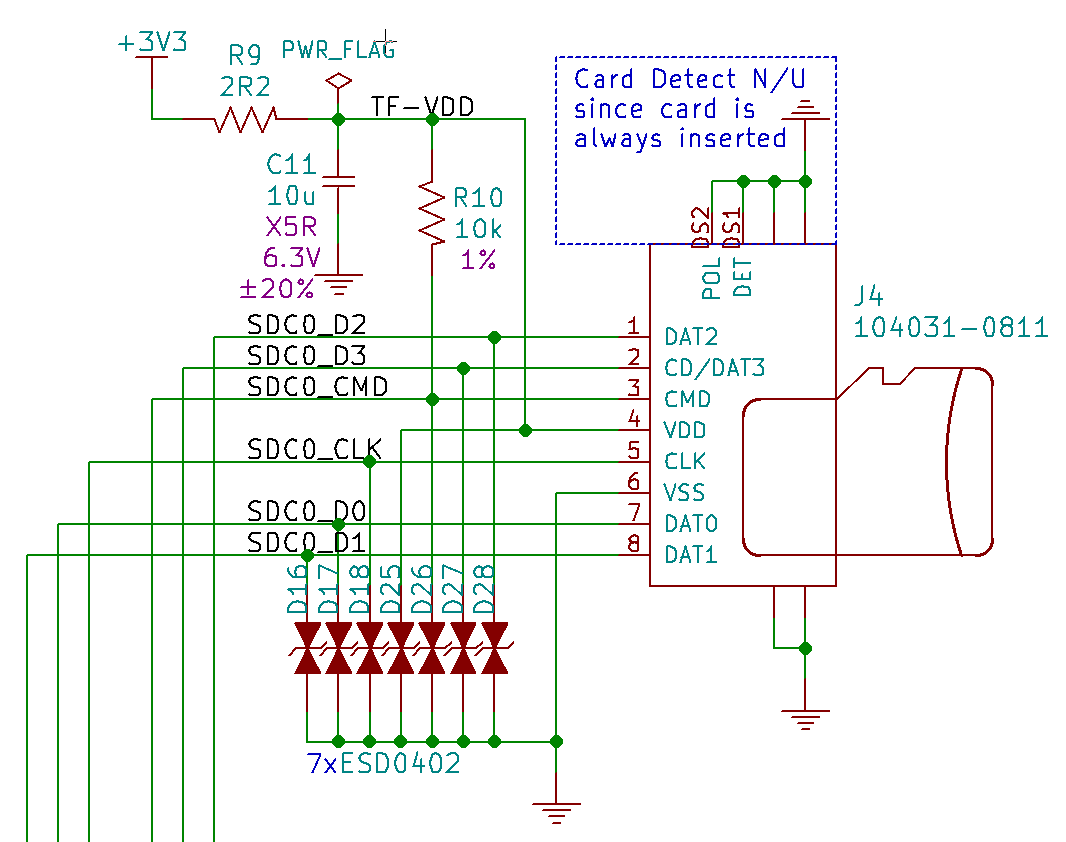

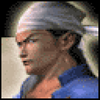

| Storage | SD card 16GB |

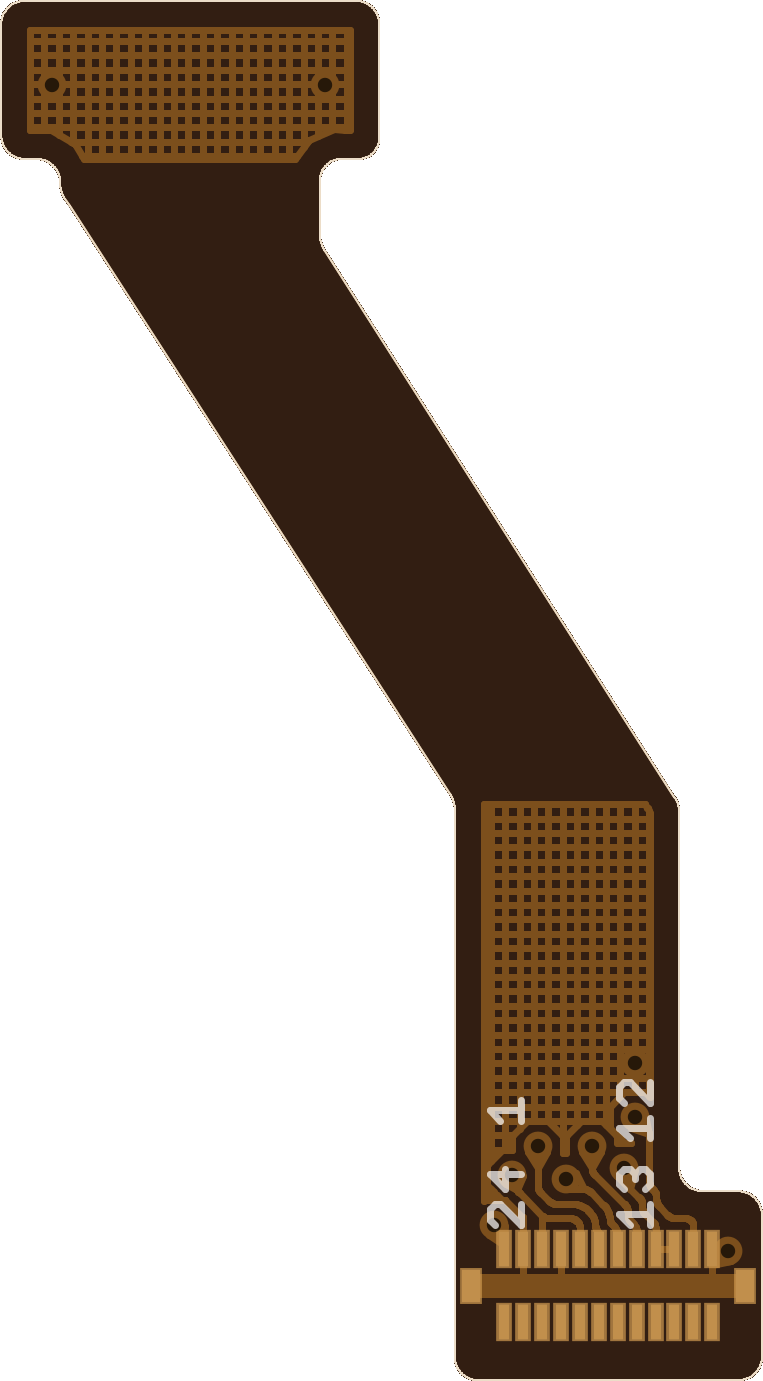

| Display | LCD IPS screen, 1.52”, 240x240 px |

| Audio | 10 mm mono speaker, 500mW |

| Battery | 420mAh Li-ion battery for hours of gameplay |

| Recharging and loading games | via Micro USB port |

What’s new?

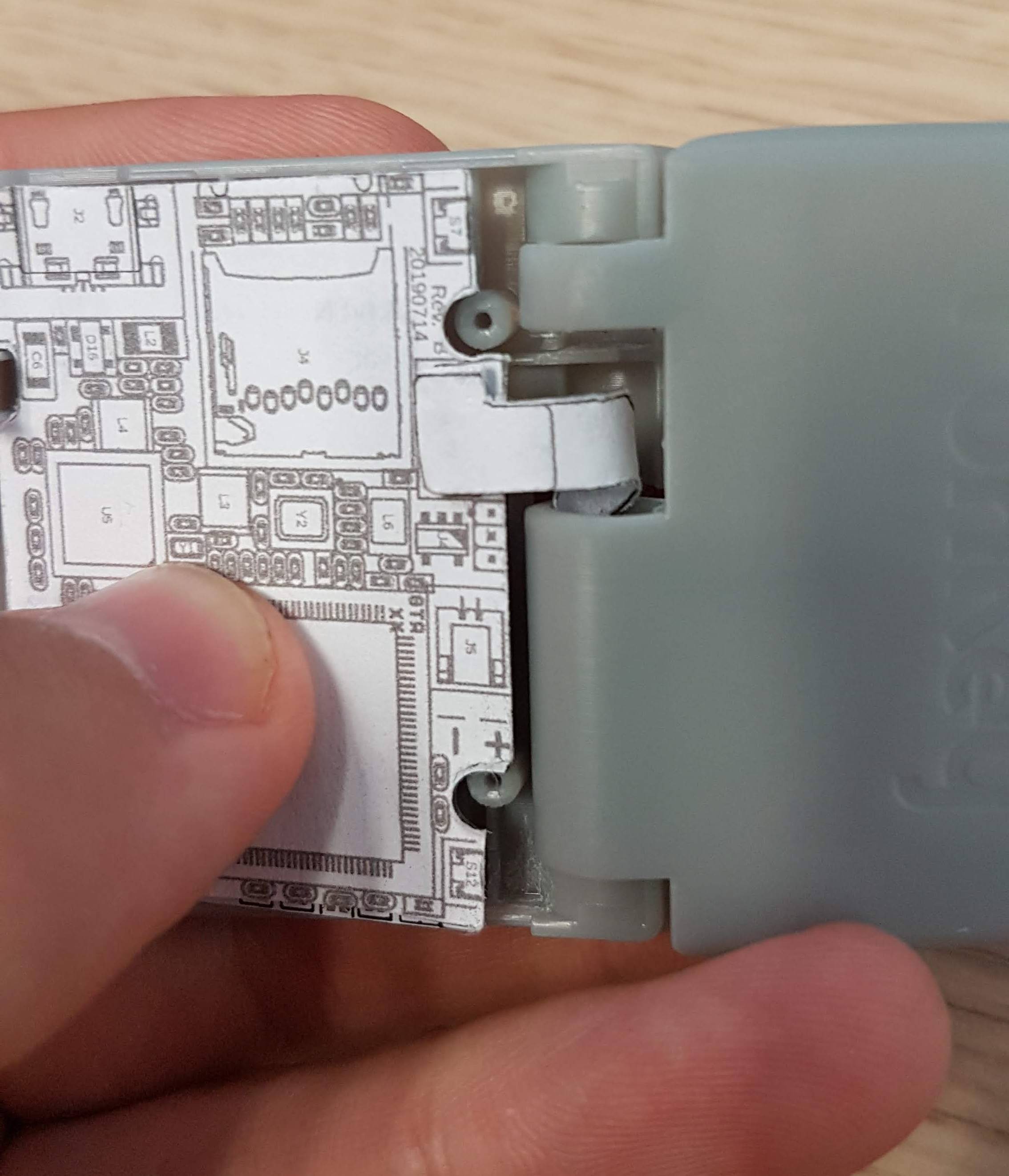

Mechanical design

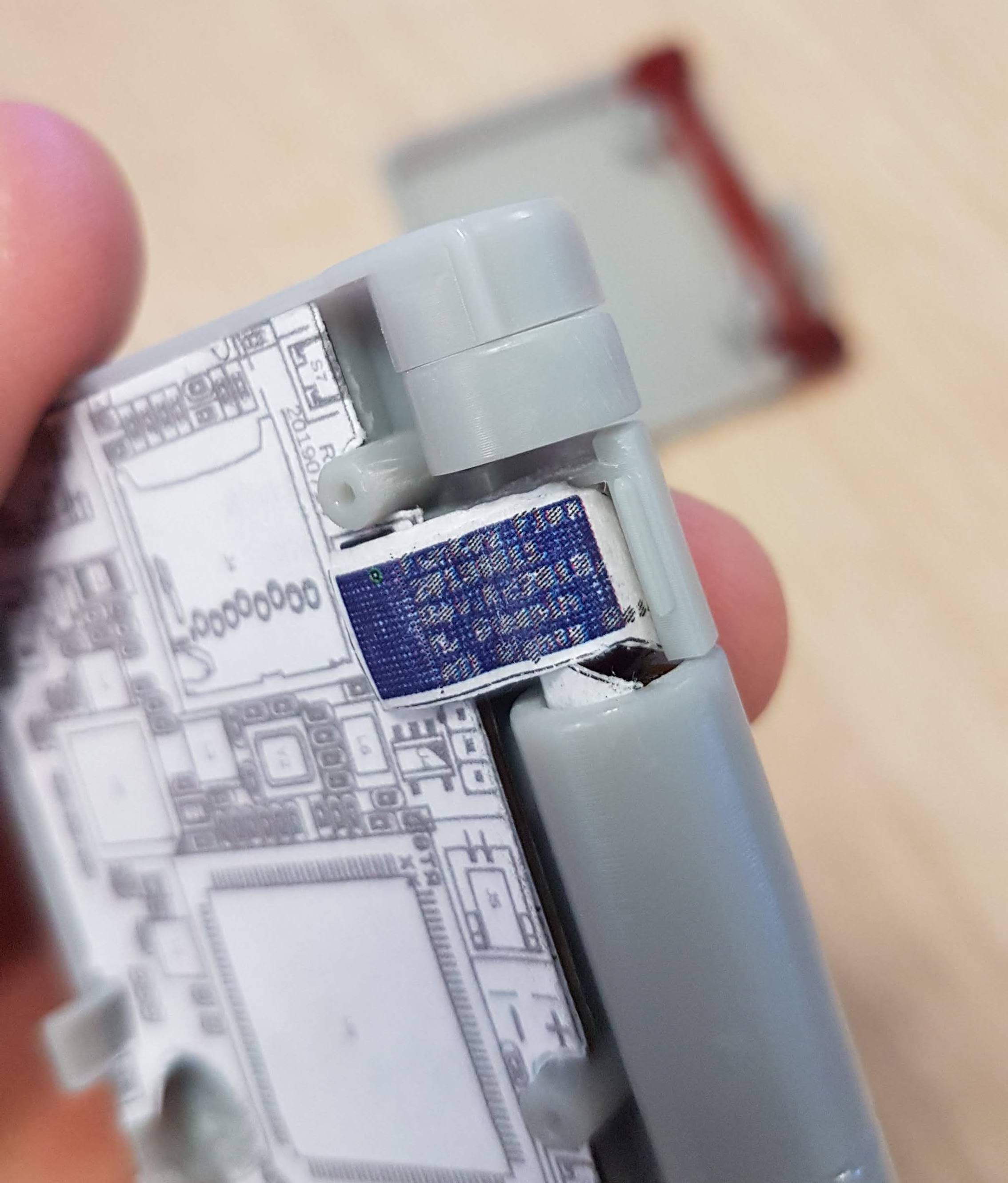

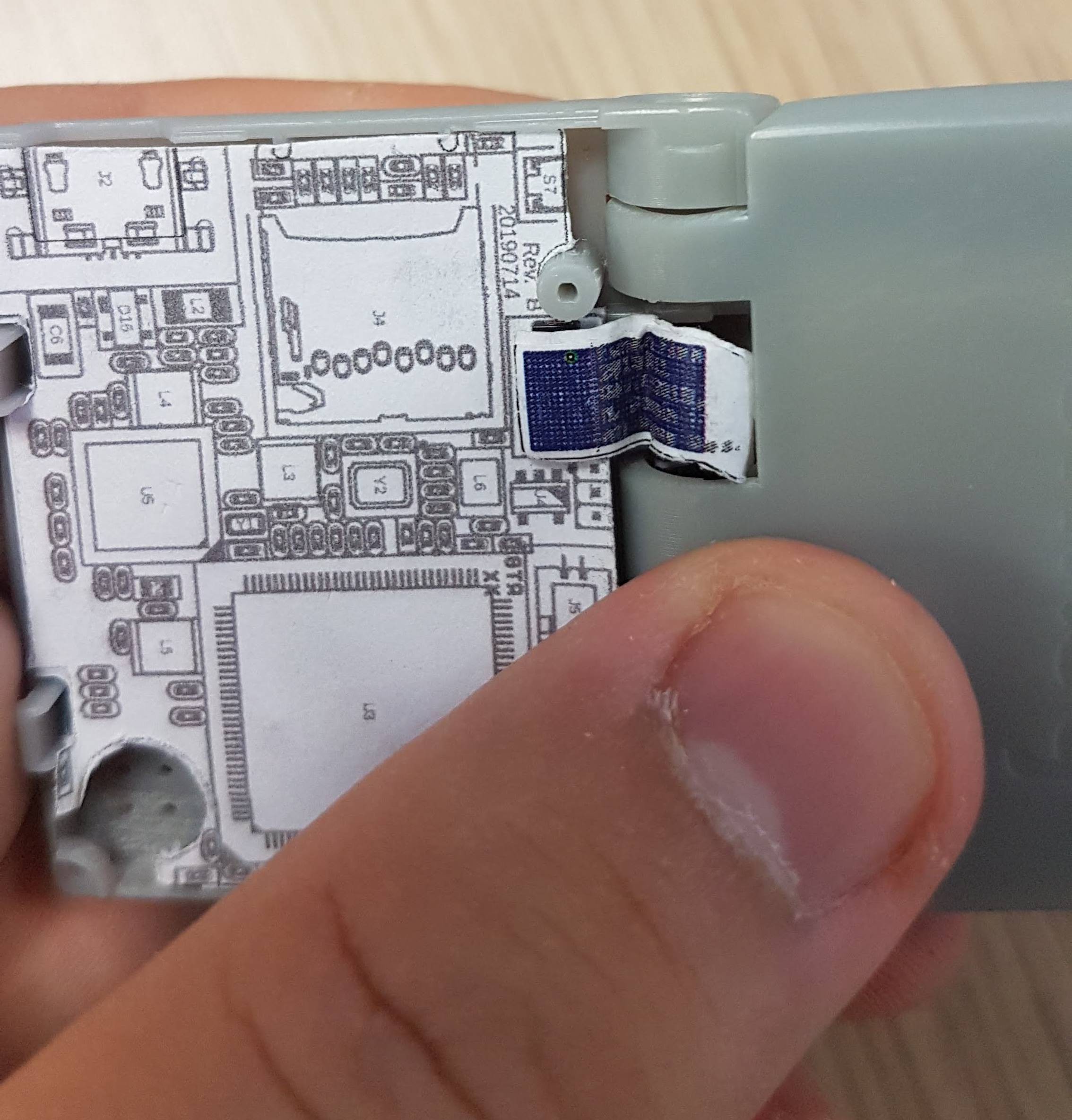

FunKey’s most discernable new features is the return of the foldable design but it's only the tip of the iceberg. Everything is new here, and of course the details will be presented more thoroughly in future logs but, to get a sense, here are the main new features:

- The casing

Completly rethought, it is now a slimmer package than Keymu and way smaller one than Funkey Zero: only 42.5x44.5x13.8 mm when closed.

It is also now sturdier thanks to a combination of snap/fit parts and two small screws on the back.

- The active...

c.Invent

c.Invent

alcor6502

alcor6502

greg

greg

Tony

Tony

Hi there ! Great Job , its very i want to use this on my website https://faceitfinder.com/