This update is going to be quite clumsy, but... It's a pretty important one!

Why clumsy and also important? Because during yesterday's midnight design troubleshooting (also chill out) I made everything simpler and better. I guess so, because discovered things are pretty neat.

//And a-also-o, showing them is a hard task, so I would try to describe it without pictures.

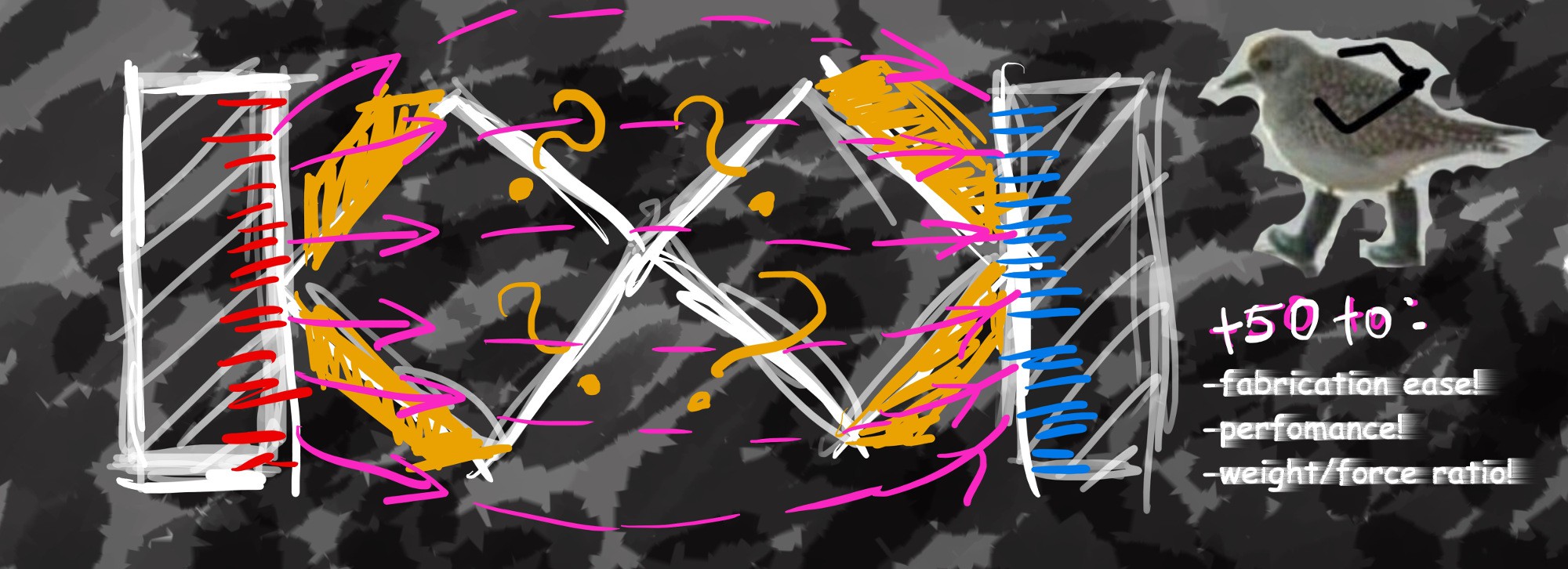

Let's start from some questionable stuff :D Bird here shows me yesterday, thinking about bending. Bending is quite important part of construction, as it is semi-soft and it's being squeezed along with bending of stripes...

Bird here shows me yesterday, thinking about bending. Bending is quite important part of construction, as it is semi-soft and it's being squeezed along with bending of stripes...

And yes - bending is a tough guy.

Why so? Fabrication process is amazing, but still had hardcore part - fighting with capillary effect. Epoxy loves to ruin stripes bending-abilities in all sort of places. We used oil to prevent that stuff and it works. However, it requires some skill.

Either way, even if you managed to fight back epoxy, you still have small gaps between stiff (containing magnets) sections, it also affects bending. On the other hand, to make small angles between elements possible, we also used a lot of epoxy on sides of magnet, and this is no good... So!

So there it is. After some too complicated solutions I've got an idea, what we can just leave central sections untouched. It showed as a question marks on that strange picture above.

And there fun things started!

- we use bigger magnets, one big instead of two medium-sized

- by that we reduce epoxy/magnets ratio, good

- magnetic field near magnets is pretty dense

- so we get greater pivoting torque and pulling force, as magnets are bigger and closer

- distribution of magnets mass is more reasonable now, that is very good

- yep, it's softer now and can withstand small twists, great

- also, doesn't require precise pouring of oil, because it wouldn't change much

- so, easier to fabricate overall, use of epoxy also lower

I see there only positive sides. As control circuit worked pretty well, structure with drawbacks annoyed me pretty much, and it makes me happy to know that they were solved at the end!

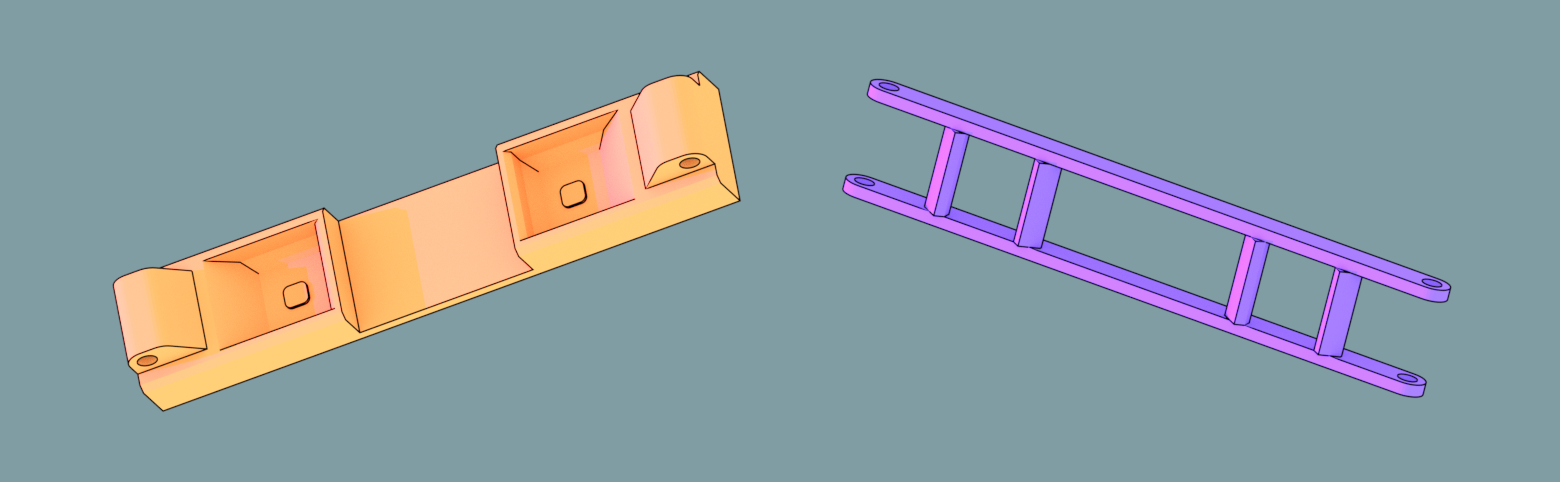

So there is new version of mold! I want to 3d-print it tomorrow:

Fun fact - it is also noticeably smaller, so even that requires less material to produce : )

Fun fact - it is also noticeably smaller, so even that requires less material to produce : )P.S. I found some electric steel today, also I bought wire. Now I can make electromagnets with desired shape, I think? Without induction heater this time, but hey! Enough novel things at once!, ahaha)

CapitanVeshdoki

CapitanVeshdoki

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.