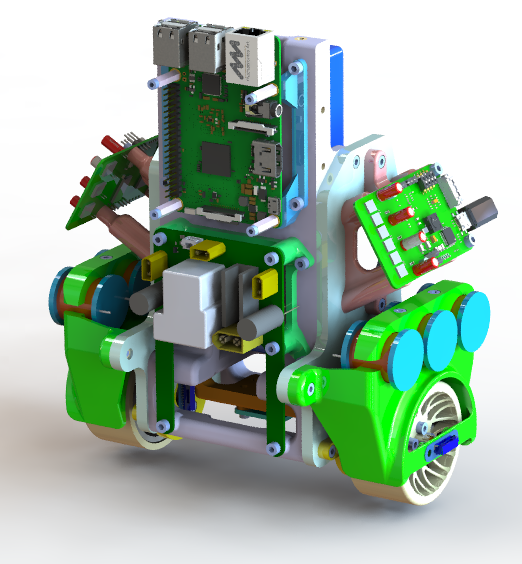

We've spent the past month getting two new chassis built, color coordinated this time. Getting the first robot built, tested, and controllable took quite a while. The BB2 robot was designed, built, assembled, and disassembled more times than a sane person would care to count. After getting the mechanical design nailed down, it was a simple task to 3D print a couple fresh chassis - not.

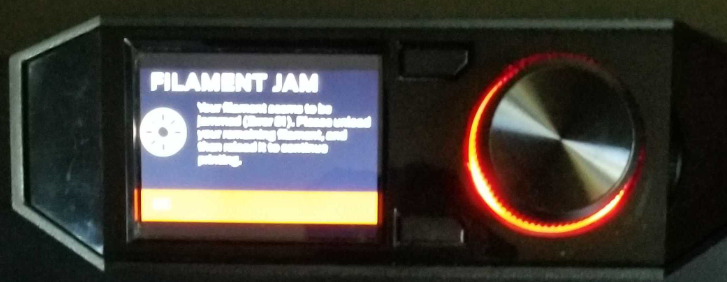

We've spent the past month getting two new chassis built, color coordinated this time. Getting the first robot built, tested, and controllable took quite a while. The BB2 robot was designed, built, assembled, and disassembled more times than a sane person would care to count. After getting the mechanical design nailed down, it was a simple task to 3D print a couple fresh chassis - not.3D Printing has become the method of choice for manufacturing custom components on the cheap. I'm sure many of you have some experience 3D printing and probably own your own machines. Anyone that owns an entry level 3D printer quickly learns their temperament. Hobby level 3D printing technology has changed the world, allowing an ambitious soul to quickly turn their ideas into reality. When the machine is working, the user is blessed with the ability to manufacture virtually any geometry their imagination desires. Maker-heaven forbid the machine is in a bad mood, a 12 hour print can take a week (ask me how I know).

JSook

JSook

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.